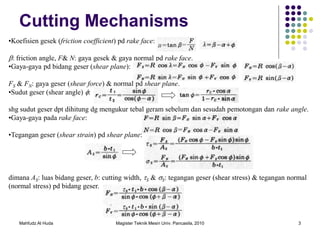

This document discusses the mechanics of cutting metal. It defines key terms like rake angle, shear angle, chip thickness, cutting ratio, and cutting forces. It also outlines assumptions made in analyzing the cutting process, such as orthogonal cutting and plastic deformation through shear on the shear plane. Equations are provided for chip velocity, shear strain rate, cutting forces, friction coefficient, and stresses on the shear plane.