This document presents an undergraduate thesis analyzing the stress distribution in parabolic and ellipsoidal concrete domes. The student, Nazeer Slarmie, conducted a literature review on shell structures and shell theory. Slarmie then developed closed form solutions to determine the membrane stress equations for a parabolic dome of revolution and attempted to do the same for an ellipsoidal dome of revolution through a method of sections.

![2-9

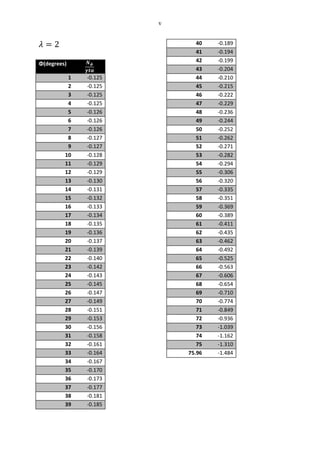

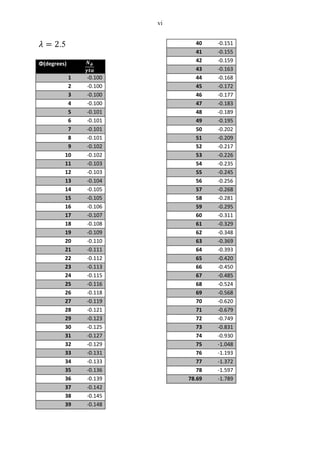

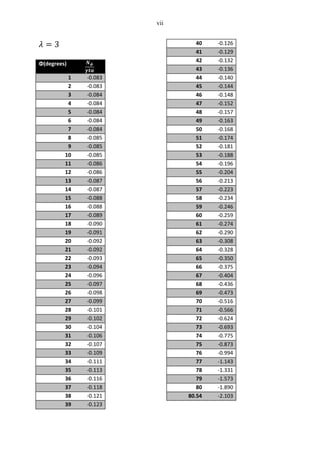

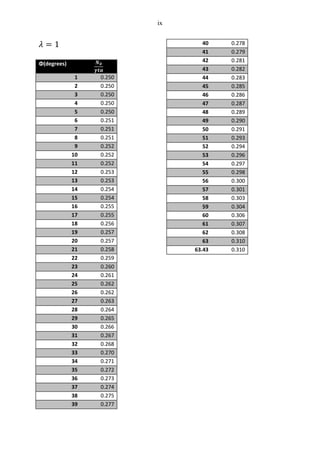

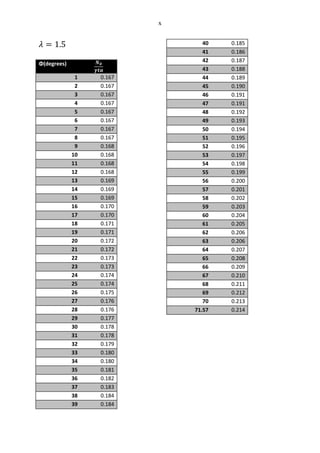

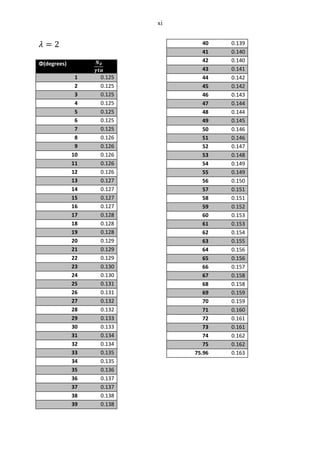

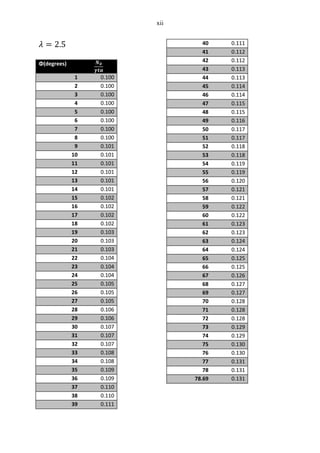

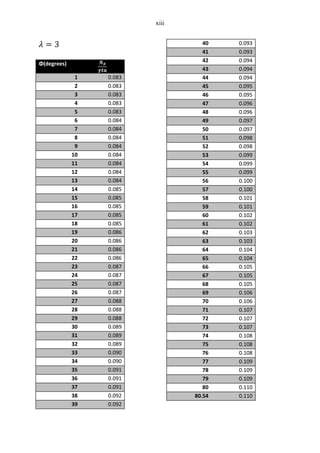

1 (2.1) General meridonal stress equation

N [∫ ( ) ]. (2.1)

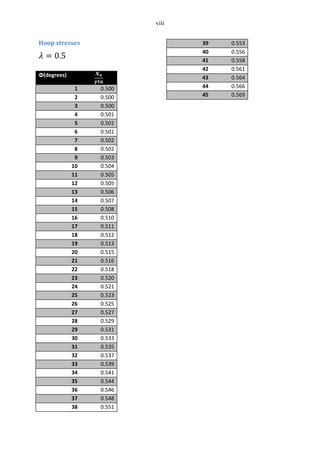

2 (2.1) General hoop stress equation

(2.1)

This equation shows that the hoop stress is a function of meridonal stress, geometric

properties as well as the loading.

2.3.3 Deformation of Shells

The equations for the displacement of a spherical dome under axisymmetric loading were

determined by using the hoop and meridonal stresses found above. These displacements were

initially in the hoop and meridonal direction, however that for the sake of practicality, the

equations were developed such that the horizontal shell displacement as well as the rotation

of the meridian (δ and V respectively) can be calculated.

(N N ) (2.3)

* N – N (N N ) + (2.4)

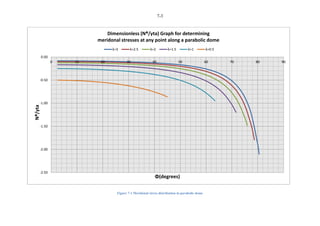

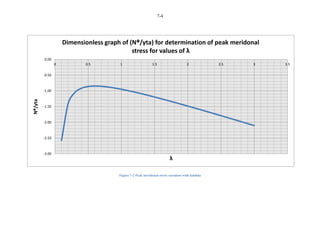

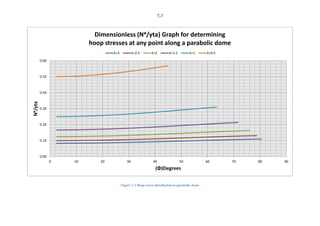

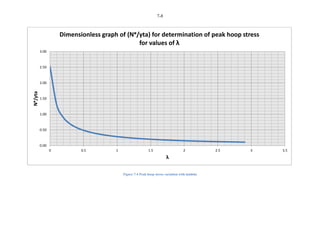

2.4 Membrane analysis of concrete domes of revolution

The membrane field of internal forces comprises of the meridonal, hoop and a membrane

shear force. However, under axisymmetric loading conditions, the membrane shear force is

zero throughout the shell and the internal force field comprises of meridonal and hoop forces

only. The directions of principal normal stresses coincide with meridonal and hoop curve and

the shear stress will be zero along these directions.](https://image.slidesharecdn.com/4d589dfb-0192-4406-b7cb-91f9657402c7-161027121742/85/Thesis-2012-23-320.jpg)