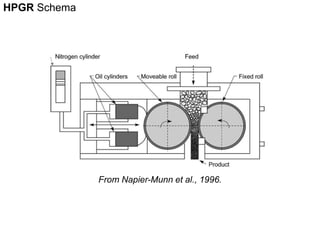

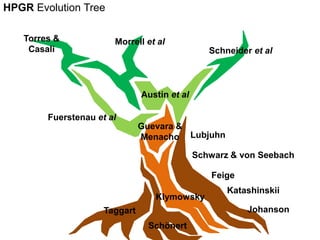

1. The document traces the evolution of models for high-pressure grinding rolls (HPGR) from early conceptual models in the 1980s to recent sophisticated models.

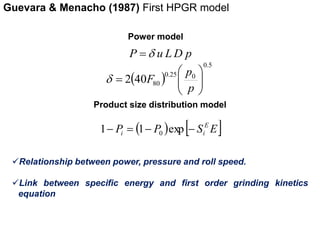

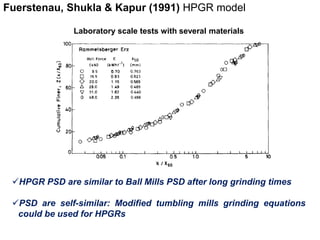

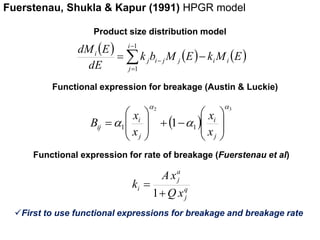

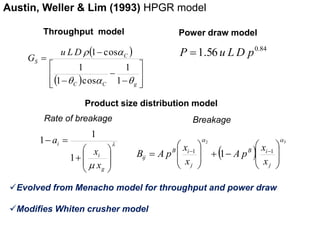

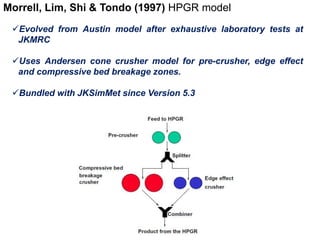

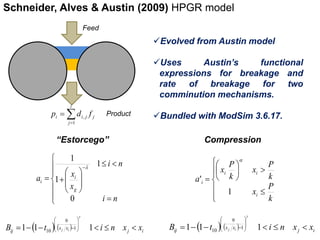

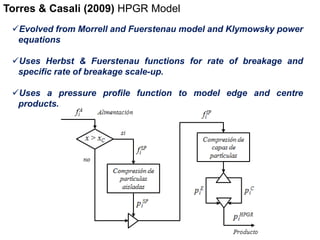

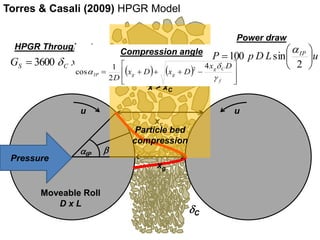

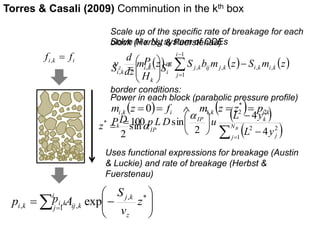

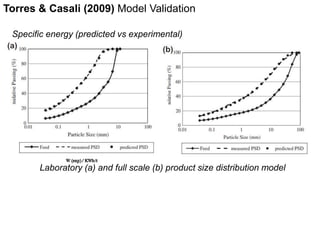

2. Early models focused on relating power draw, pressure, and roll speed, while later models incorporated functional expressions for breakage rates and product size distributions.

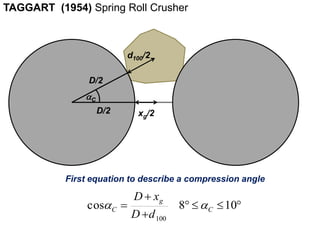

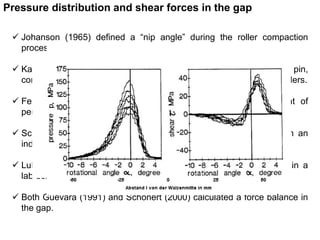

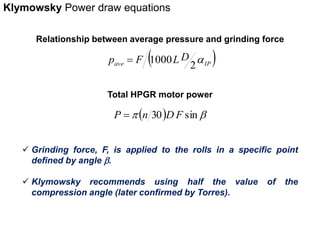

3. Breakthrough studies in the 1960s-1990s improved understanding of pressure distributions and forces in the HPGR gap, leading to more accurate power draw models.

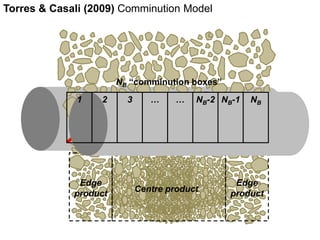

4. Recent models build on prior work, using advanced functions for breakage rates and accounting for edge and center product zones with pressure profiles.