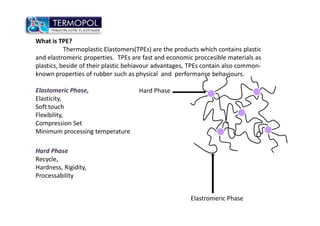

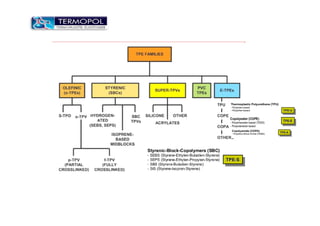

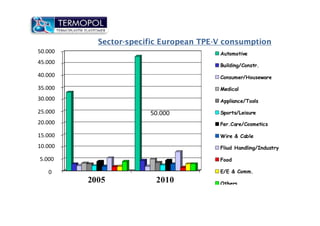

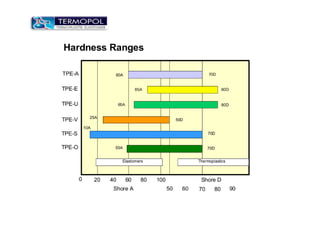

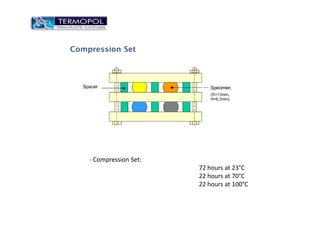

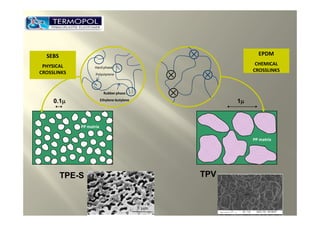

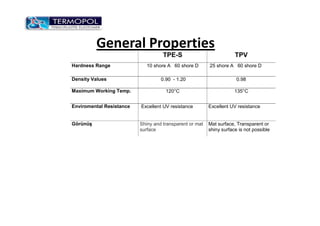

This document provides an introduction to thermoplastic elastomers (TPEs). TPEs have both plastic and rubber-like properties, allowing them to be processed like plastics while maintaining characteristics of rubber such as flexibility and softness. The document discusses various types of TPEs and their applications in industries like automotive, medical, and electronics. It also provides information on TPE properties like hardness, compression set, temperature resistance and guidelines for processing TPEs using different techniques like extrusion, injection molding, and blow molding.