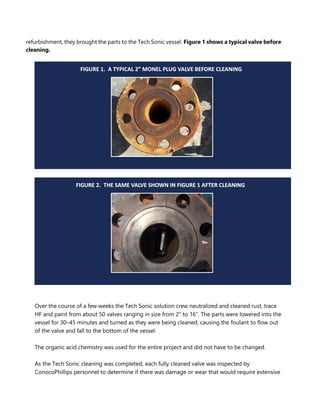

ConocoPhillips has implemented Tech Sonic's cleaning system to neutralize and clean hydrofluoric acid service valves more efficiently, reducing the cleaning time from 10-12 hours to 30-45 minutes. This ultrasonic process effectively removes scale without damaging the valves, enhancing safety and turnaround times. The successful use of this technology during a 2011 turnaround resulted in significant time savings and improved inspections, leading to a decision to utilize the method again in the future.