Embed presentation

Download to read offline

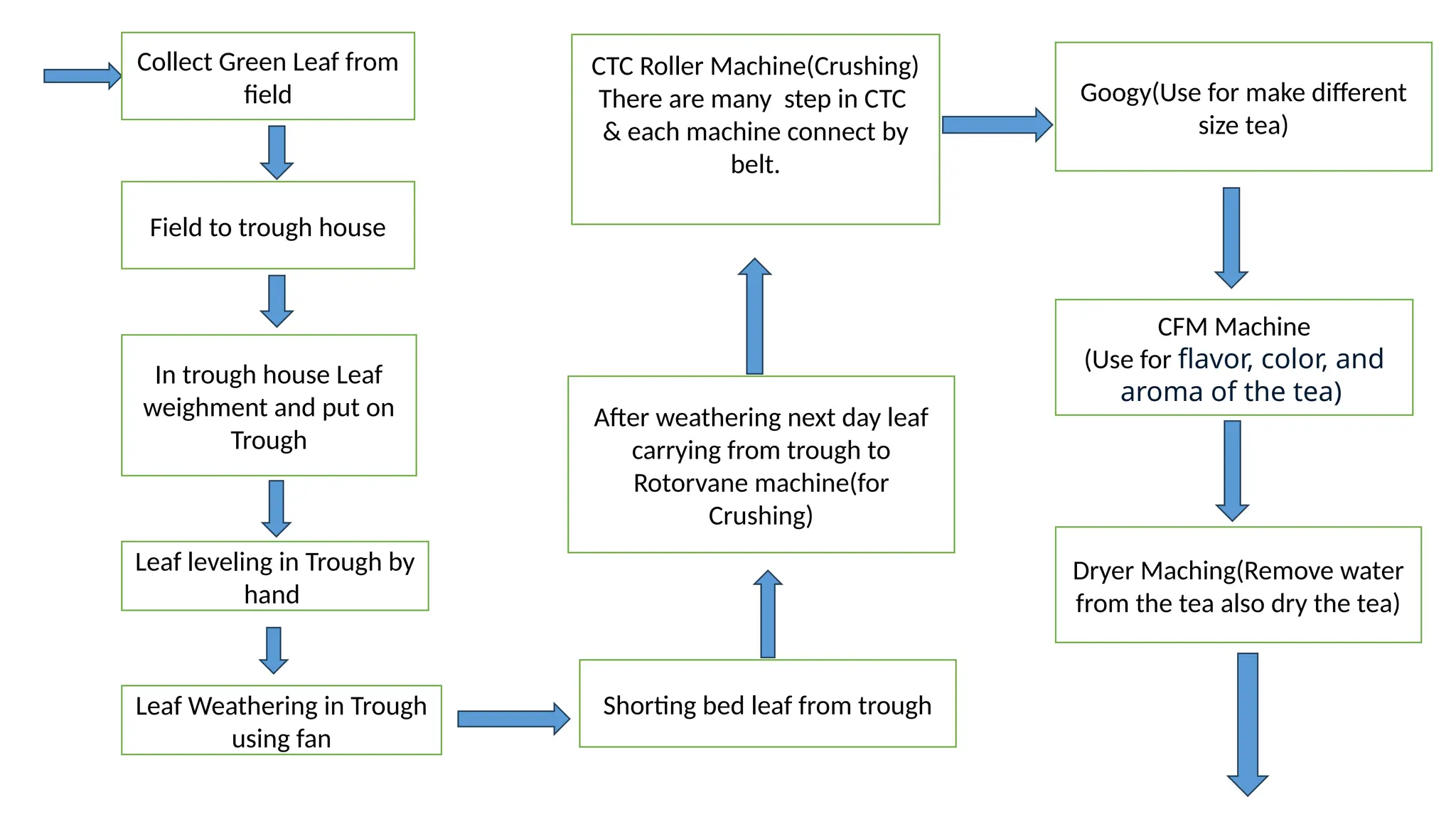

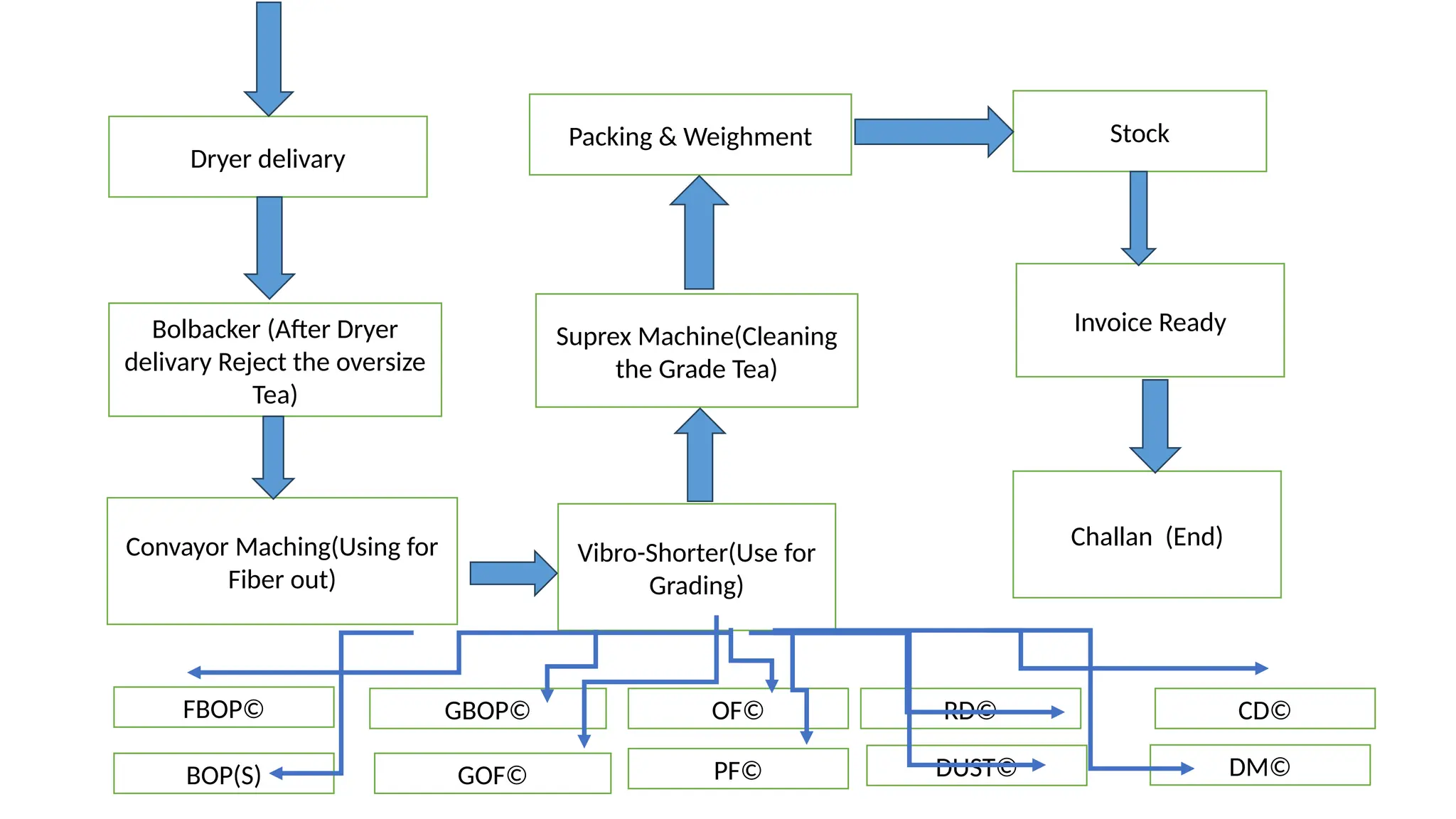

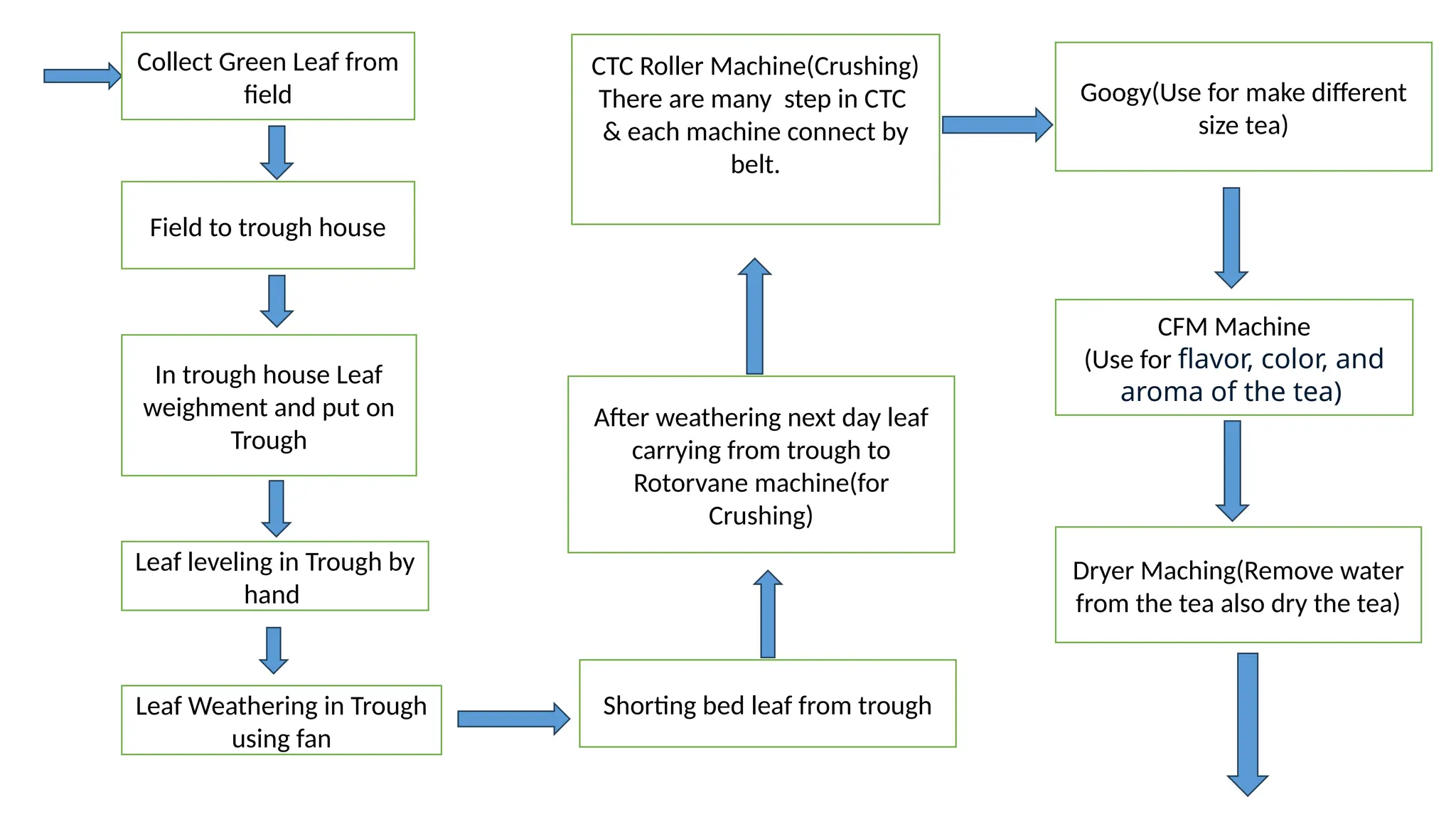

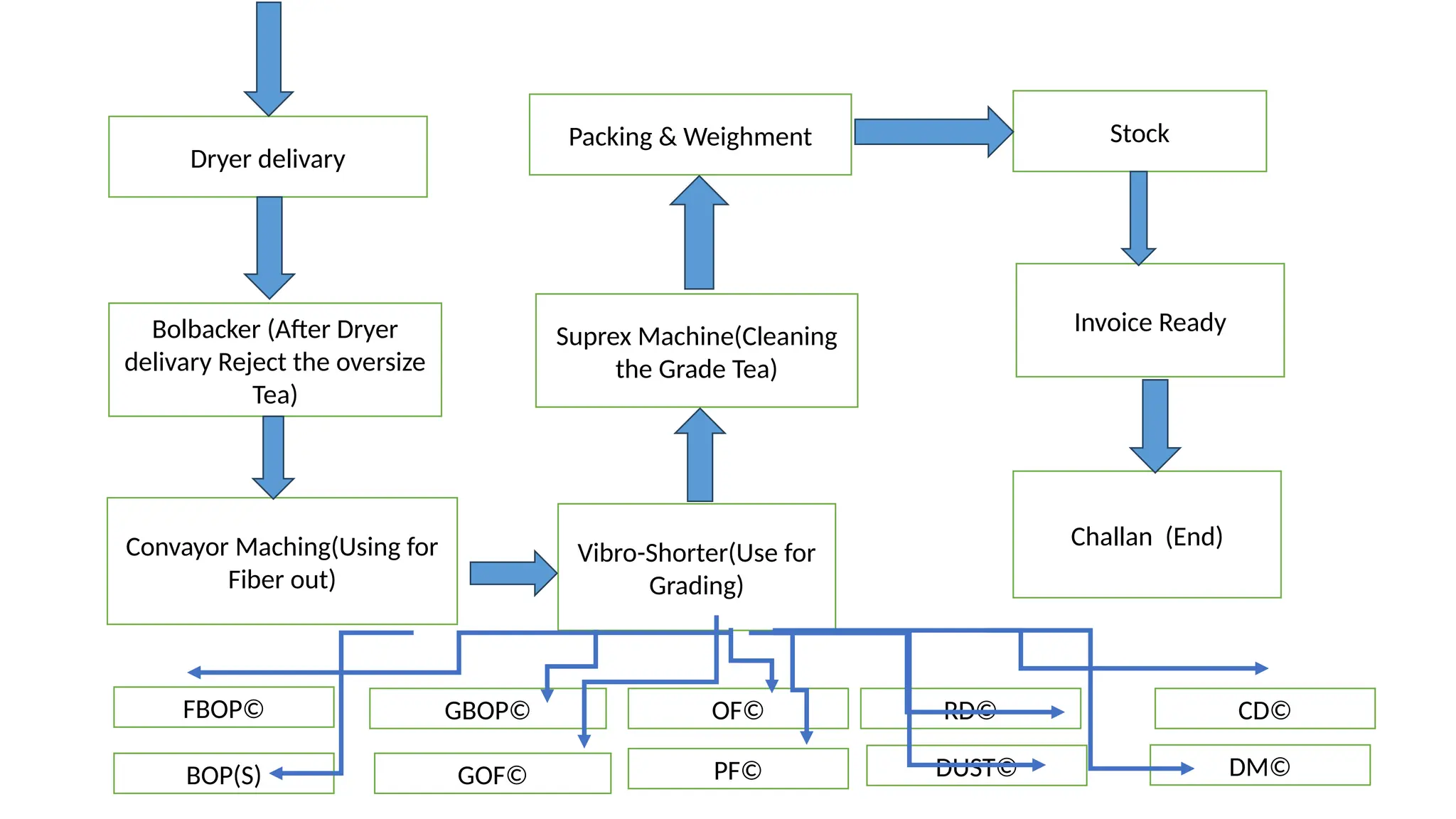

The document outlines the process of tea production, detailing steps from collecting green leaves to the final packaging of different tea grades. It includes methods such as weathering, weighing, drying, and grading using various machinery. The process emphasizes the importance of each step and the connections between machines.