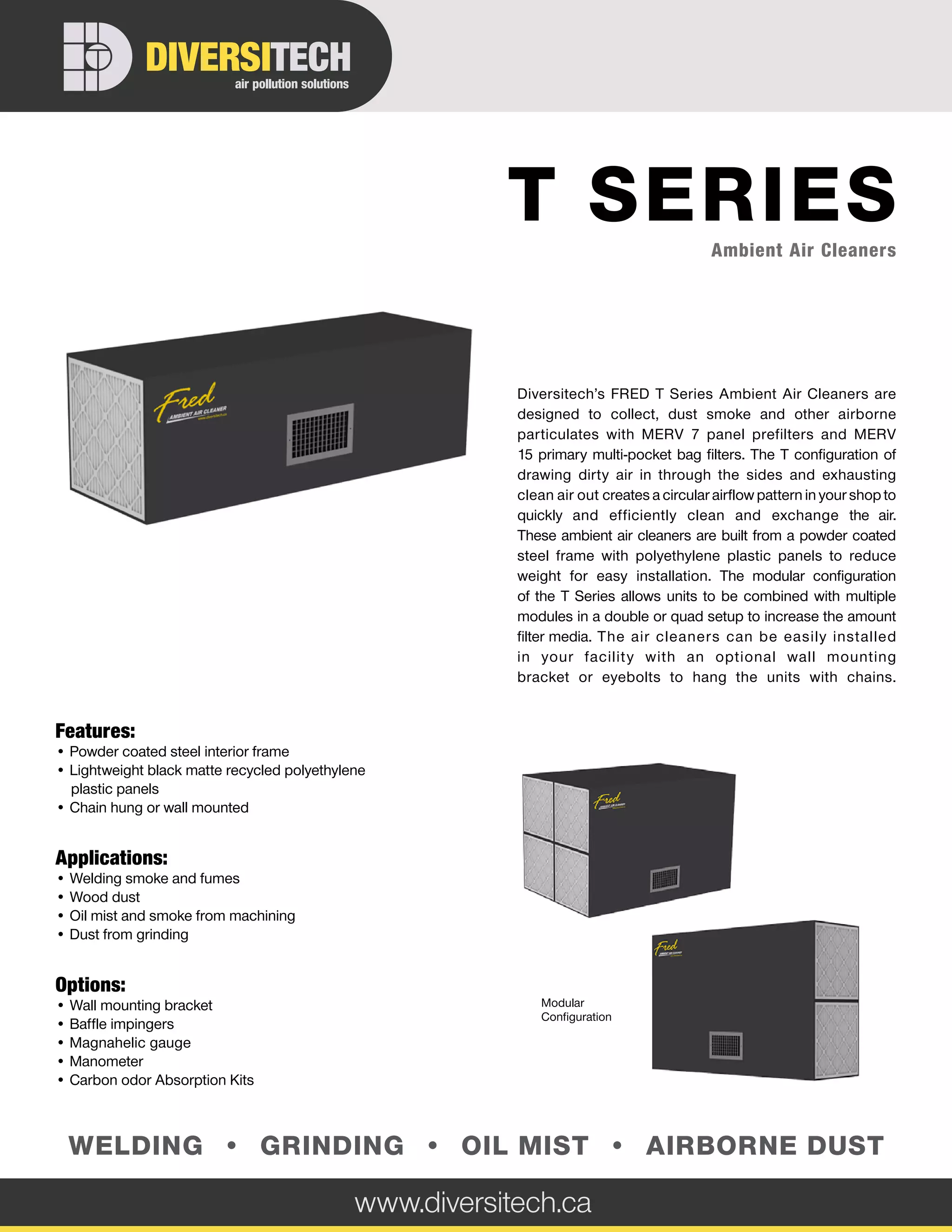

The T Series ambient air cleaners are modular units made of powder coated steel and plastic that can be wall mounted or chain hung. They use MERV 7 and MERV 15 filters to collect dust, smoke, and other particles from welding fumes, wood dust, oil mist, and grinding. The staggered, circular airflow pattern pulls dirty air in through the sides and exhausts clean air out the front.