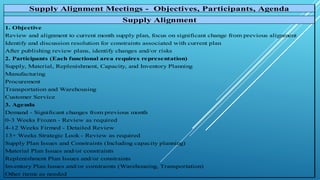

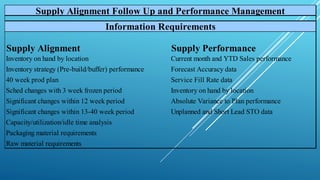

The document outlines the objectives and structure of supply alignment meetings, focusing on reviewing the current month's supply plan and addressing significant changes and constraints. Key participants from various functional areas are involved in discussing demand fluctuations, supply issues, and performance against key performance indicators. The agenda includes reviewing inventory, performance metrics, and potential opportunities for improvement related to replenishment and capacity planning.