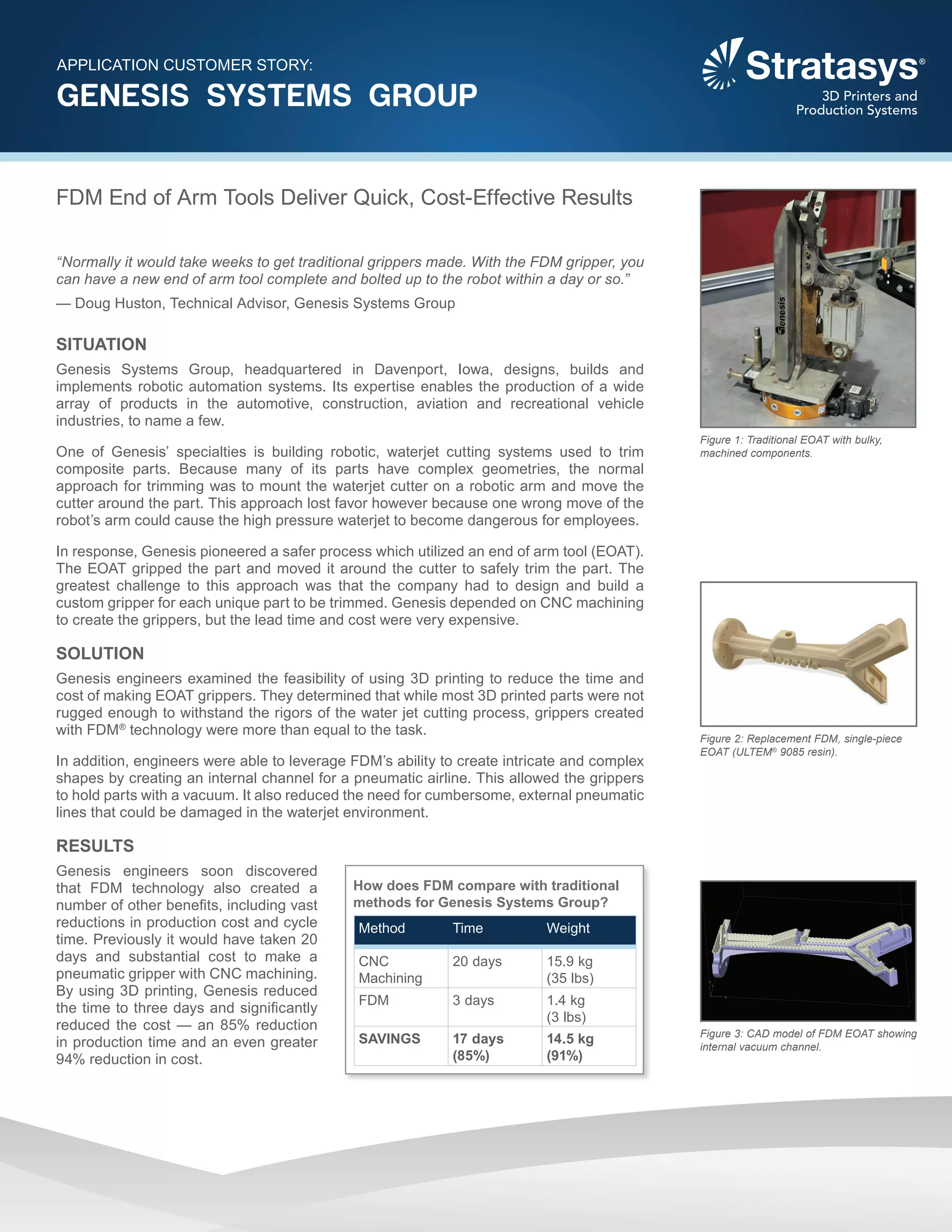

Genesis Systems Group designs and implements robotic automation systems. They pioneered a process using custom end of arm tools (EOATs) to grip parts for waterjet cutting, but creating each unique gripper with CNC machining was expensive and time-consuming. Genesis tested 3D printing and found FDM technology could produce grippers quickly, reducing production time by 85% and costs by over 90%, allowing replacement grippers to be installed within a day if needed. The redesigned lightweight FDM grippers also enabled the use of smaller, less expensive robots.