STERILISATION AND DISINFECTION WITH SAFETY AND HAZARDS (1)-1.pptx

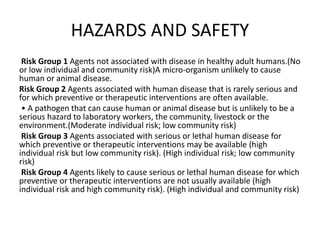

- 1. HAZARDS AND SAFETY Risk Group 1 Agents not associated with disease in healthy adult humans.(No or low individual and community risk)A micro-organism unlikely to cause human or animal disease. Risk Group 2 Agents associated with human disease that is rarely serious and for which preventive or therapeutic interventions are often available. • A pathogen that can cause human or animal disease but is unlikely to be a serious hazard to laboratory workers, the community, livestock or the environment.(Moderate individual risk; low community risk) Risk Group 3 Agents associated with serious or lethal human disease for which preventive or therapeutic interventions may be available (high individual risk but low community risk). (High individual risk; low community risk) Risk Group 4 Agents likely to cause serious or lethal human disease for which preventive or therapeutic interventions are not usually available (high individual risk and high community risk). (High individual and community risk)

- 2. ● Generally, work with known agents should be conducted at the biosafety level recommended ● All procedures involving the manipulation of infectious materials must be conducted within BSCs (biosafety cabinets) or other physical containment devices ● The recommended biosafety level(s) for the organisms represent those conditions under which the agent ordinarily can be safely handled ● Their are Four BSLs which consist of combinations of laboratory practices and techniques, safety equipment, and laboratory facilities. ● Each combination is specifically appropriate for the operations performed, the documented or suspected routes of transmission of the infectious agents, and the laboratory function or activity

- 3. ● Biosafety Level -1 represents a basic level of containment that relies on standard microbiological practices with no special primary or secondary barriers recommended, other than a sink for hand washing ● Biosafety Level 2 practices, equipment, and facility design and construction are applicable to clinical, diagnostic, teaching, and other laboratories in which work is done with the broad spectrum of indigenous moderate-risk agents that are present in the community and associated with human disease of varying severity. Examples: Hepatitis B virus, HIV, Salmonella, and Toxoplasma are representative of microorganisms assigned to this containment level. ● Biosafety Level 3 work is done with indigenous or exotic agents with a potential for respiratory transmission, and which may cause serious and potentially lethal infection. Examples : Mycobacterium tuberculosis, St. Louis encephalitis virus, and Coxiella burnetii . ● Biosafety Level 4 dangerous and exotic agents that pose a high individual risk of life-threatening disease, which may be transmitted via the aerosol route and for which there is no available vaccine or therapy. Agents with a close or identical antigenic relationship to BSL-4 agents also should be handled at this level. . Example: Viruses such as Marburg or CongoCrimean Hemorrhagic fever

- 5. CONTROL OF MICROBIAL ACTIVITY

- 6. TERMS USED . “biocide” is a general term describing a chemical agent, usually broad spectrum, that inactivates microorganisms. ● Biocides range in antimicrobial activity, suffix static,” refer to agents which inhibit growth (e.g., bacteriostatic, fungistatic, and sporistatic) and “-cidal,” referring to agents which kill the target organism (e.g., sporicidal, virucidal, and bactericidal). ● Antiseptics are biocides or products that destroy or inhibit the growth of microorganisms in or on living tissue (e.g. handwashes and surgical scrubs); ● Disinfectants are similar to antiseptics but generally are products or biocides that are used on inanimate objects or surfaces. Disinfectants can be sporostatic but are not necessarily sporicidal. ● Sterilization refers to a physical or chemical process that completely destroys or removes all microbial life, including spores. ● Preservation is the prevention of multiplication of microorganisms in formulated products, including pharmaceuticals and foods.

- 7. Cleaning ● The physical removal of foreign material, e.g., dust, soil, organic material such as blood, secretions, excretions and microorganisms ● Cleaning generally removes rather than kills microorganisms. ● It is accomplished with water, detergents and mechanical action. ● Cleaning reduces or eliminates the reservoirs of potential pathogenic organisms. ● The terms “decontamination” and “sanitation” may be used for this process in certain settings ● A number of biocides are also used for cleaning purposes;cleaning in these cases refers to the physical removal of foreign material from a surface. Sanitation: ● a process that reduces microorganisms on an inanimate object to a level below that of being an infectious hazard (e.g., dishes and eating utensils are sanitized).

- 8. Non-critical items ● Item that either come in contact with only intact skin but not mucous membranes or do not directly contact the patient ● Reprocessing of non-critical items involves cleaning and/or low level disinfection. Semi-critical items: ● devices that come in contact with non-intact skin or mucous membranes but ordinarily do not penetrate them. ● Reprocessing semi critical items involves meticulous cleaning followed preferably by high-level disinfection Critical items: ● Instruments and devices that enter sterile tissues,including the vascular system . ● Critical items present a high risk of infection if the item is contaminated with any microorganisms. ● Reprocessing critical items involves meticulous cleaning followed by sterilization

- 9. • Sterilization is the process by which all living cells, spores and acellular entities (e.g.) viruses, viroids and prions are either destroyed or removed from an object or habitat. It can also be defined as the killing or removing of all viable organisms within a growth medium. A sterile object is totally free of viable microorganisms, spores and other infectious agents.

- 10. Methods of sterilization • 1. Physical Method • ● Thermal (Heat) methods • ● Radiation method • ● Filtration method • 2. Chemical Method • . Gaseous method • Liquid method

- 13. • Heat Sterilization Heat is a mostly used method of sterilization. Moreover, it is a highly effective and most reliable process. • There are two major methods of using heat in sterilization which are dry heat and moist heat. • The principle behind both of these methods is similar. Dry heat induces the denaturation of protein, oxidative damage and toxic effect due to the high level of electrolytes. Moreover, the dry heat can also damage the DNA of the microorganism. As a result, the microorganism got killed. • Moist Heat kills the microorganisms by denaturation and coagulation of proteins.

- 14. There are several factors that can influence the heat killing procedure. A)Such as Temperature and Duration: The duration and temperature are inversely connected to each other. Therefore, in the case of the long duration of heat provided for sterilization, the temperature will be reduced while in case of high temperature the duration will be reduced. b)Characteristic of the Microorganism: Microorganisms can be present in both vegetative and spore form. Spore forms are generally heat resistant. Therefore, the sterilization process will vary on the basis of the characteristic of the microorganism. C)Type of Material: Organic substances often provide protection to the vegetative and spore form of microorganisms which reduces the lethal property of heat. Apart from that, the materials containing the substances are also needed to be heat stable for proper sterilization.

- 15. DRY HEAT a)Red Heat Inoculation loops, wires, forceps tips, needles are needed to be sterilized to inhibit microbial contamination. These instruments are held in the flame of a Bunsen burner until they become red hot. b)Flaming Glass slides, scalpels, and mouths of culture tubes or conical flasks are passed through Bunsen flame without allowing them to become red hot. •

- 16. C)Incineration • This procedure is used to reduce the infective material into ashes by burning. The incinerator is used for the process. Soiled dressings, animal carcasses, bedding, and pathological materials are dealt with this method. d)Hot Air Oven • It is a widely used method of sterilization by dry heat. The heat inside the oven is maintained by electricity and a fan fitted inside it provides the adequate distribution of hot air inside the chamber. A thermostat is also connected which maintains the temperature inside the chamber. 1600C for two hours is required for sterilization. There are also some alternative temperatures and holding time which include 1700C for 1 hour and 1800C for 30 minutes. Uses: Sterilization of • Glasswares like glass syringes, Petri dishes, flasks, pipettes, and test tubes. • Surgical instruments like scalpels, scissors, forceps, etc. • Chemicals such as liquid, paraffin, fats, sulphonamides powders etc.

- 17. 2 Moist Heat Sterilization Moist heat readily kills viruses, bacteria and fungi. It kills by degrading nucleus acids and by denaturing enzymes and other essential proteins. Exposure of microorganisms to boiling water will destroy vegetable cells and eukaryotic spores. However this temperature will not kill bacterial endospores. In order to destroy bacterial endospores moist heat sterilization above 100degrees using saturated steam under pressure is done. Steam sterilization is carried out with an autoclave

- 18. Temperature below 1000C(moist heat) a)Pasteurization • There are two different types of pasteurization methods that are used for sterilization of milk, Holder method (63oC for 30 minutes) and flash method (720C for 20 seconds followed by cooling quickly to 130C). • This method is effective against all non-sporing pathogens such as mycobacteria, Salmonella, etc. except Coxiella burnetii which survives the holder method due to heat resistant characteristics. b)Inspissation • Media like Lowenstein- Jensen’s and Loeffler’s serum are required to sterile at 80-850C for 30 minutes daily on three consecutive days. This process is known as inspissation and the instrument used iscalled inspissator. C)Vaccine bath • It is used for sterilization of bacterial vaccines at 600C for one hour. Serum or other body fluids can be sterilized by heating in a water bath at 560C for several successive days. d)Low-temperature steam formaldehyde sterilization (LTSF) • This method is applicable for materials that cannot withstand 1000C temperature. In this method, steam at subatmospheric pressure at 750C with formaldehyde vapor is used. Bacillus stearothermophilus plays an important role as a biological control to test the efficacy of the test.

- 19. • At a temperature of 1000C(Moist heat) a)Boiling • It is an effective method that can kill vegetative cells. Boiling for 10-30 minutes can kill most of the vegetative cells; however, many spores can withstand this temperature. Boiling can be employed when adequate methods are not available to sterilize glass syringes, rubber stopper, etc. b)Tyndallisation • In this case, steam at 1000C for successive 3 days is used. It is also known as intermittent sterilization. In this case, the first exposure kills the vegetative forms, and in the intervals between the heating and remaining spores germinates into vegetative forms which are killed on subsequent heating. This process is applied for sterilization of egg, serum or sugar-containing media which can be damaged due to exposure in high temperature for a longer period. C)Steam sterilizer • Koch’s and Arnold’s steam sterilization is usually used for media which can easily decompose due to the high temperature in the autoclave. Those media are kept on a perforated tray and steam at 1000C and at atmospheric pressure passes through the media for 90 minutes. It is an effective method to kill vegetative cells

- 20. • Temperature above 1000C (under pressure) a)Autoclave • Steam above 1000C or saturated steam has a better killing capacity than dry heat. Bacterial proteins coagulate rapidly at moist heat. Saturate steam has the ability to penetrate any porous material. When steam comes into contact with the cooler surface it condenses into water and releases its latent heat to the surface. The large reduction in volume sucks in more steam to the same site and the process continues until the temperature of the substance raised to that of steam. The condensed water produced moist conditions for killing the microbes present

- 21. • The autoclave is a modified pressure cooker which contains a vertical or horizontal cylinder. The cylinder is made up of stainless still. A lid on the cylinder is placed and fastened by screw clams to make it airtight. The lid contains a steam discharge unit, a pressure gauge, and a safety valve. Moreover, a thermostat is present to monitor the temperature. Heat is produced by electricity. At the time of sterilization, the cylinder is filled with an adequate amount of water and it is kept for some time for preheating. After that, the materials which are needed to be sterilized are inserted into the cylinder and the lid is then closed tightly. The temperature will increase eventually along with the pressure. When the temperature reaches 121.10C and the pressure at 15 psi the sterilization is performed for 15 minutes.

- 22. • Uses of an autoclave • Sterilization of • Culture media, rubber material, dressing gloves. • Materials that are unable to withstand dry heat in a hot air oven.

- 23. • Filtration method 1. Filtration is a method that accomplishes decontamination and even sterilization. 2. Heat-sensitive liquids and gasses are sterilized by the use of filtration method. 3. The liquid or gas is passed through a filter, a device with pores too small for the passage of microorganisms, but large enough to allow the passage of the liquid or gas. The selection of filters for sterilization must account for the size range of the contaminants to be excluded. 4. Some microbial cells are greater than 10 μ m in diameter, and the smallest bacteria are less than 0.3 μ m in diameter rather than directly destroyed the contaminating microorganism the filters simply removes them. 5. There are two types of filters (a) Depth Filters (b) Membrane Filters

- 24. • Depth Filters * This is made up of fibrous or granular materials that have been bonded into a thick layer filled with twisting channels of small diameters. * They can also be made of diatomaceous earth, unglazed porcelain, asbestos, bromosilicates and other similar materials. * The solution containing microorganisms is sucked through the thick layer of the fibrous material under vacuum and microbial cells are removed by physical screening or entrapment and by adsorption to the surface of the filter material. They are used for the filter sterilization of air in industrial processes. In the home, the filter is used in forced air heating and cooling systems .it is a simple depth filter, designed to trap particulate matter such as dust, spores, and allergens.

- 25. • Depth filters are important for bio-safety applications. For example, manipulation of cell cultures, microbial cultures, and growth media require that contamination of both the operator and the experimental materials are minimal. These operations can be efficiently performed in a biological safety cabinet with airflow, both in and out of the cabinet, directed through a depth filter called a HEPA filter or high-efficiency particulate air filter. A typical HEPA-Filter is a single sheet of borosilicate (glass) fibers that has been treated with a water-repellant binder. It removes 0.3 μ M test particles with an efficiency of at least 99.97%; they thus effectively remove both small and large particles, including most microorganisms, from the airstreams.

- 26. Membrane filteration • Membrane filters have a known uniform porosity of predetermined size (generally 0.45 µm ) sufficiently small to trap microorganisms. Using the membrane filter technique, sample is passed through the membrane using a filter funnel and vacuum system. Any organisms in the sample are concentrated on the surface of the membrane. • The membrane, with its trapped bacteria, is then placed in a special plate containing a pad saturated with the appropriate medium. The passage of nutrients through the filter during incubation facilitates the growth of organisms in the form of colonies, on the upper surface of the membrane. Discrete colonies thus formed can be easily transferred to confirmation media. • Membrane filter technique is an effective, accepted technique for testing fluid samples for microbiological contamination. It involves less preparation than many traditional methods and is one of a few methods that will allow the isolation and enumeration of microorganisms. Membrane filters are used extensively in the laboratory and in the industry to sterilize fluid materials. • The membrane filter technique is of different types based on the size of the material to be separated.

- 27. Step-by-step Procedures • Firstly, collect the sample and make any necessary dilutions • Then, select the appropriate nutrient or culture medium. Dispense the broth into a sterile Petri dish, evenly saturating the absorbent pad. • After that, flame the forceps, and remove the membrane from the sterile package. • Then, place the membrane filter into the funnel assembly. • Now, flame the pouring lip of the sample container and pour the sample into the funnel. • Then, turn on the vacuum and allow the sample to draw completely through the filter. • After that, rinse funnel with sterile buffered water. Turn on the vacuum and allow the liquid to draw completely through the filter. • Again, flame the forceps and remove the membrane filter from the funnel. • Then, place the membrane filter into the prepared Petri dish. • After that, incubate at the proper temperature and for the appropriate time period. • Finally, count and confirm the colonies and report the results

- 28. Advantage of Membrane Filter Technique • Permits testing of large sample volumes. Theoretically, almost any volume of non-turbid water could be filtered through the disk, the organisms from any given volume being deposited in the disk. • The membrane can be transferred from one medium to another for purposes of selection or differentiation of organisms thus allowing isolation and enumeration of discrete colonies of bacteria. • Results can be obtained more rapidly than by the conventional MPN standard methods. It provides presence or absence information within 24 hours. Uses of Membrane Filters • Membrane filters are used extensively in the laboratory and in the industry to sterilize materials likely to be damaged by heat sterilization. These materials include nutritional supplements of culture media, and pharmaceutical products such as drugs, hormones, sera, and vitamins. Effective and acceptable technique to monitor drinking water, air quality, etc. • Useful for bacterial monitoring in the pharmaceutical, cosmetics, electronics, and food and beverage industries. • Allows for removal of bacteriostatic or bactericidal agents that would not be removed in pour plate, spread plate, or MPN techniques. • Can be used to allow selective passage of the organism of interest by selecting a membrane filter of appropriate porosity. Such practices are done in the pharmaceutical industry to allow the passage of a particular virus strain while preparing vaccines.

- 29. Disadvantages of Membrane Filter Technique • Many membrane filters allow viruses and some mycoplasmas to pass through. • They may absorb relatively large amounts of the filtrate and may introduce metallic ions into the filtrate.

- 30. • * It differs from the depth filter because it functions more like a sieve and trapping particles on the filter surface. About 80-85% of the membrane surface area consists of open pores. The porosity provides for a relatively high fluid flow rate. * The solution to be sterilized is forced through the filter with a vacuum or with pressure from a syringe, peristaltic pump and collected in previously sterilized container. * They are used to sterilize pharmaceutical ophthalmic solutions, culture media, oils ,antibiotics and other heat sensitive solutions.

- 31. • * Air can also be sterilized by filtration. Examples are surgical masks and cotton lugs on culture vessels that let air in but keep microorganism out.

- 33. • Radiation Many forms of electromagnetic radiation are very harmful to microorganisms. Microwares, ultraviolet (UV) radiation, X- rays,gamma rays (Y-rays) and electrons can effectively reduce microbial growth if applied in the proper close.

- 34. • Ionizing Radiation Ionizing radiation is a form of radiation which has very short wave length and high energy, which can cause atoms to lose electrons (ionize). Two major forms of ionizing radiation are: (i) X-rays (short waves length of 10-3 to 102 nanometer) which are artificially produced. (ii) Gamma rays (short wave length of 10-3 to 10-1 nanometer) which are emitted during radioisotope decay.

- 35. • Low Levels or Doses of Radiation will produce mutation in the microorganisms which may indirectly lead to the death of microorganisms. In cases where large doses or high levels of these radiation are used the microorganisms are directly and instantly killed. Ionizing radiation can be used to sterilize items

- 36. • Gamma and X-radiation have high penetrating power and are able to kill microorganisms by inducing or forming toxic free radicals (ions) viruses and other microorganism are inactivated by exposure to ionizing radiation. Ionizing radiations are used to pasteurize or sterilize products e.g. most commercially produced disposables and plastic petro dishes are sterilized by exposure to gamma rays

- 37. • Ultraviolet (UV) Radiation * These are radiation of short wave length (from 10 to 400μ M) and high energy. * The most lethal UV radiation has a wavelength of 260μ M, the wavelength mostly absorbed by DNA. * The primary mechanism of UV damage is the formation of thymine dimmers in DNA. * Two adjacent thymines in a DNA strand are covalently joined to inhibit DNA replication and function.

- 38. • Non-ionizing radiation • Infrared radiation and UV radiation comes under this of radiation. Infrared radiation is used for mass sterilization of syringes and catheters. UV radiation with a wavelength of 240nm to 280nm has bactericidal capacity. The UV radiation causes protein denaturation and interferes with DNA replication of bacteria. UV radiations are used for sterilization of close areas, surfaces, operation theaters, laminar airflow, etc.

- 39. Chemical methods • Several chemical agents are used as antiseptic and disinfectants. The properties of a chemical antiseptic or disinfectant are following • The chemical disinfectants need to have a broad spectrum of activity against all microorganisms such as bacteria, viruses, protozoa and fungi. • The chemical agents should act in the presence of organic matter. • High penetration power is an important property of the chemical agents • The chemical agent needs to be chemically stable under both acidic and basic environments. • The chemical substances should not have any corrosion activity in metals. • The disinfectants are needed to be non-toxic if absorbed into circulation. • Finally, the chemical agents are needed to be easily available and less expensive.

- 40. a)Alcohols • Ethyl alcohol and isopropyl alcohol are frequently used as chemical agents for disinfection. Both of the chemicals facilitate the protein denaturation of bacterial proteins. 70% ethyl alcohol is the standard concentration which is used for disinfection. These are used as skin antiseptics. Apart from this methyl alcohol has activity against fungal spores and used to disinfection of inoculation cabinets. b)Aldehydes • Formaldehyde • It is known for its bactericidal, sporicidal and virucidal activities. It can be used in both aqueous and gaseous form. A 10% formalin solution is a standard chemical disinfectant. It is used for • Prevention of tissues for histological examinations. • Sterilization of bacterial vaccines • Preparation of toxoids from toxins.

- 41. b)Glutaraldehyde • It has its activity against bacteria (Mycobacterium tuberculosis), fungi and viruses (including HIV, hepatitis B, etc). It can also kill spores and is known for its less toxic nature. It is used as a 2% buffered solution. Glutaraldehyde is used for • Sterilization of cystoscopes, endoscopes, and bronchoscopes • Sterilization of plastic endotracheal tubes, face masks, metal instruments, etc. C)Orthophathalaldehyde • Orthophathalaldehyde (OPA) is a high-level disinfectant and is known for its stability during storage. It has bactericidal effects against mycobacteria. 0.5% OPA is slowly sporicidal and OPA vapors irritate the respiratory tract and eyes, therefore, it must be handled with appropriate safety.

- 42. • C)Phenols • Lister (father of antiseptic surgery) used phenol for the first time in the sterilization of surgical instruments. Phenols work as a disinfectant and kill microorganisms by cell membrane damage. It is toxic for the skin. • Different derivatives of phenol are used as antiseptics which are following Cresols • An example of cresol is Lysol which is mostly used for sterilization of infected glasswares, floors, etc. Chlorhexidine • Savlon is an example of a chlorhexidine solution which is widely used in wounds, preoperative disinfection of the skin. It is bactericidal at high dilution. Moreover, it also has fungicidal activity. Chloroxylenol • Dettol is commercially available as a chloroxylenol solution. It is less toxic and less irritant. Hexachlorophene • It is bacteriostatic at very high dilution.

- 43. D)Halogens • Chlorine and iodine are commonly used disinfectants. Chlorine is used in water supplies, swimming pools, food, and dairy industries. Chlorine compounds in the form of bleaching powder, sodium hypochlorite, and chloramines. The disinfection action of all the chlorine compounds is due to the release of free chlorine which becomes a strong oxidative agent. • Iodine in alcoholic and aqueous solution is used as a skin disinfectant. It is active against M tuberculosis and slightly active against spores. Compounds with iodine with surface-active agents known as iodophors are claimed to be more active than aqueous or alcohol solution.

- 44. • Oxidizing agents • Hydrogen peroxide • It is effective against most organisms in the concentration of 3-6 %. However, it kills spores at higher concentrations (10-25%). The mode of action is by the liberation of free hydroxyl radical on the decomposition of hydrogen peroxide. These free radicals are active ingredients in the disinfection process. • Peracetic acid • It is an oxidizing agent and is a more potent germicidal agent than hydrogen peroxide. • Salts • Slats of heavy metals have a toxic effect on bacteria. The salts of copper, silver, and mercury are used as a disinfectant. They are protein coagulant ant act by combining with sulphydryl groups of bacterial proteins and other essential intracellular compounds. Merthiolate (sodium ethyl mercurithiosalicylate) is used in a dilution of 1:10000 for the preservation of sera.

- 45. • Dyes • Two groups of dyes, aniline and acridine dyes have been used as a skin and wound antiseptics. Both the dyes have bacteriostatic activity. Aniline dyes include crystal violet, brilliant green, and malachite green. Acridine dyes include acriflavine, cuflavin, proflavin, and aminacrine. • Vapor phase Disinfectants • Ethylene Oxide (ETO) • It is a colorless liquid with a boiling point of 10.70C. It is effective against all types of microorganisms including viruses and spores. It acts by alkylating the amnio carboxyl, hydroxyl and sulphydryl groups in protein molecules. In addition, it reacts with DNA and RNA. It is specially used for sterilizing plastic and rubber articles, respirators, heart-lung machines, dental equipment, etc. • Betapropilolactone (BPO) • This is a condensation product of ketane and formaldehyde. It has rapid action and used in0.2%. It is more efficient in fumigation than formaldehyde. BPO is used for the inactivation of vaccines.