1. Food Safety Basics

Importance of food safety: Prevent foodborne illness, protect customers, and maintain reputation.

Cost of foodborne illness: Legal fees, loss of sales, negative publicity, etc.

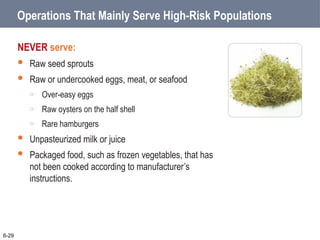

High-risk populations: Elderly, children, pregnant women, and immunocompromised individuals.

2. Forms of Contamination

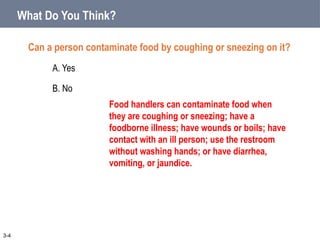

Biological: Bacteria, viruses, parasites, fungi (e.g., Salmonella, Norovirus).

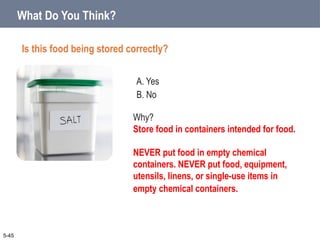

Chemical: Cleaners, sanitizers, pesticides.

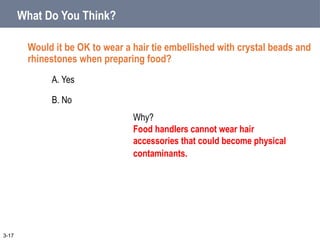

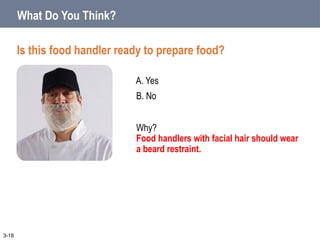

Physical: Hair, glass, metal shavings.

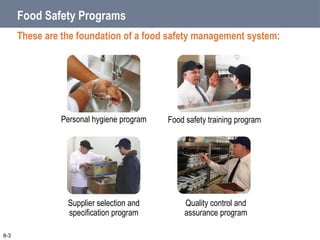

3. Personal Hygiene

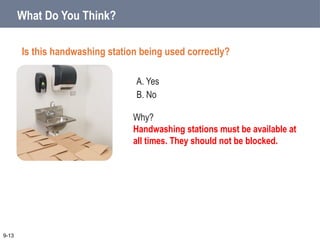

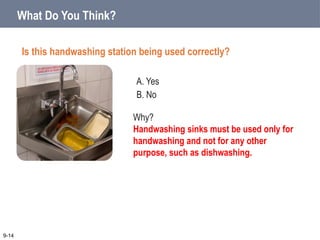

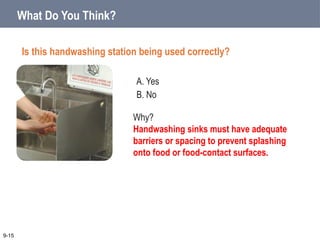

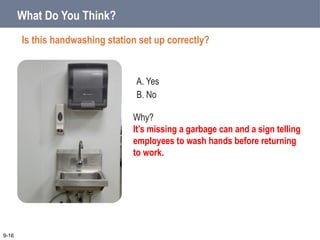

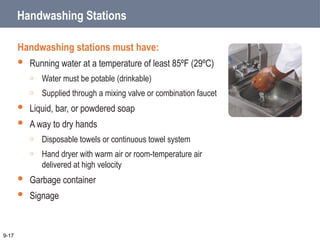

Handwashing: At least 20 seconds, especially after restroom use.

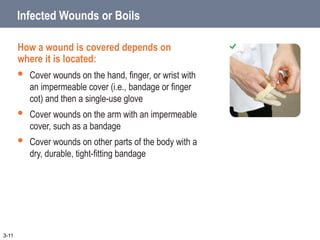

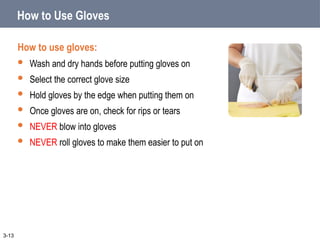

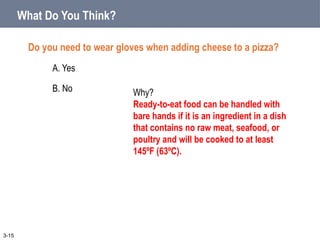

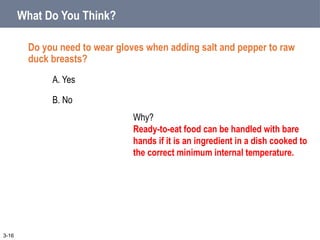

Proper glove use and personal cleanliness.

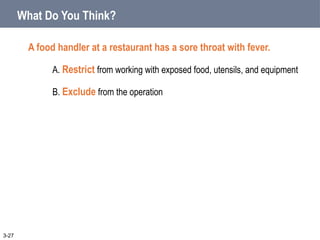

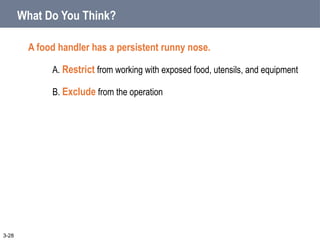

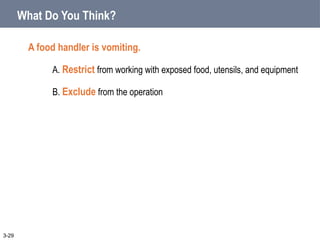

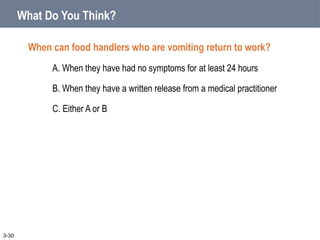

Exclude or restrict sick employees.

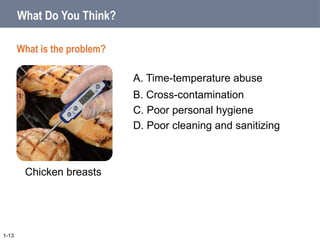

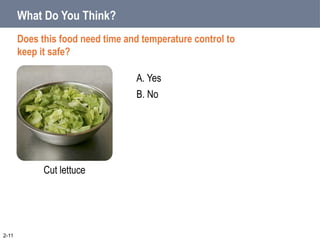

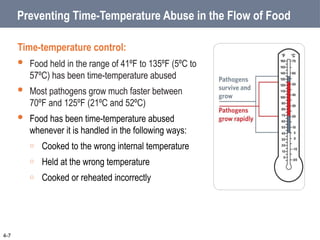

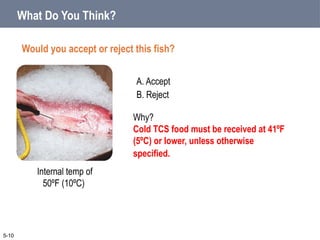

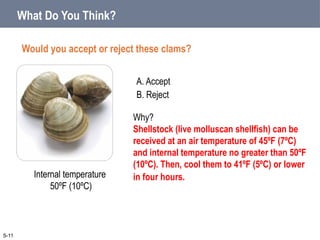

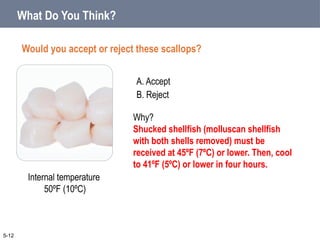

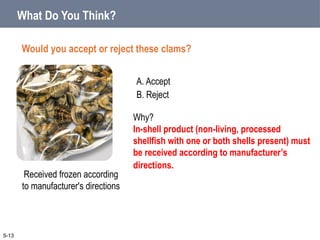

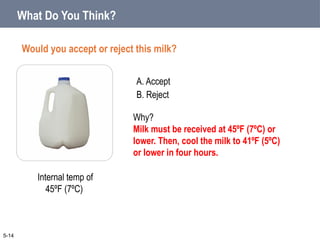

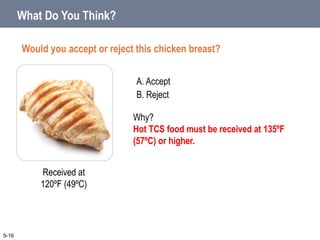

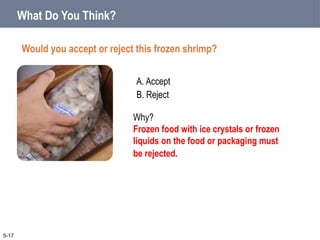

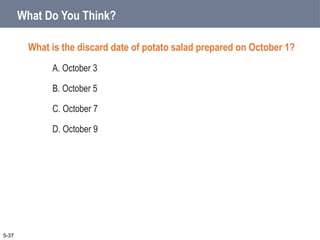

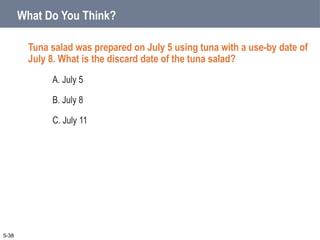

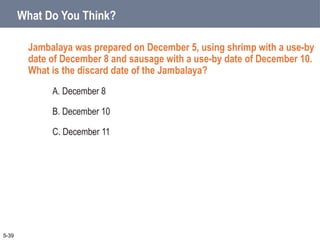

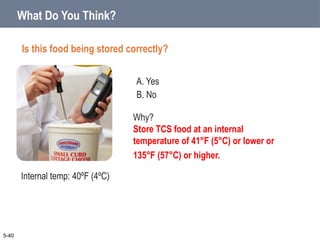

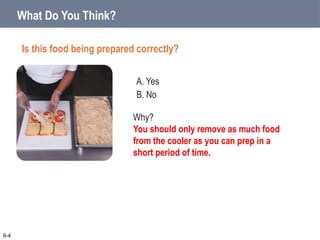

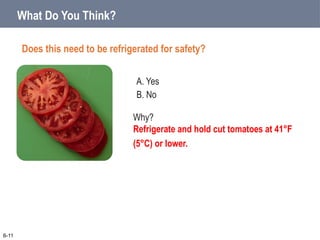

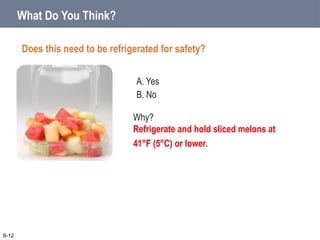

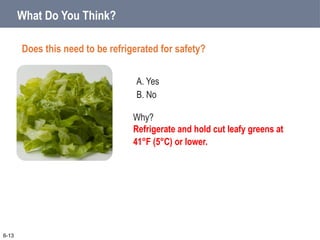

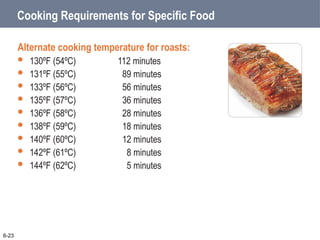

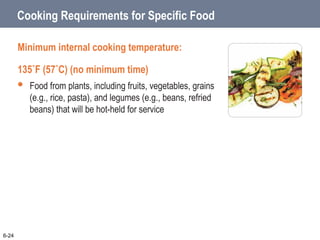

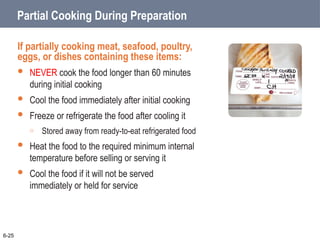

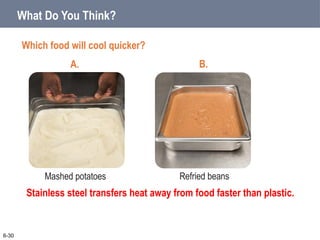

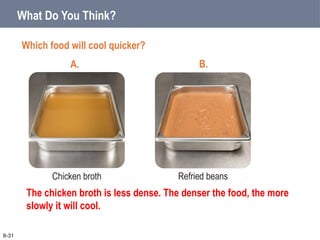

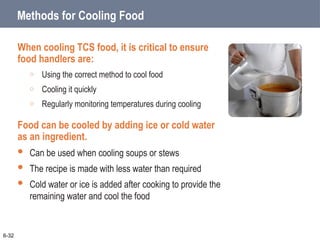

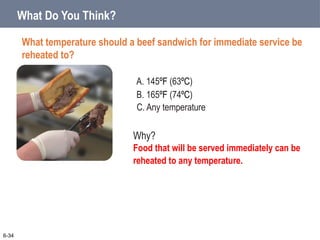

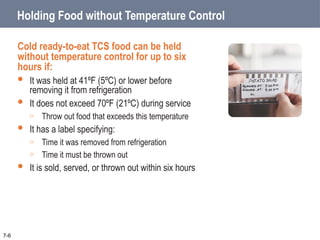

4. Time and Temperature Control (TCS)

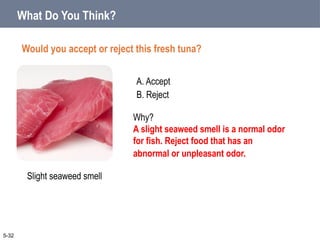

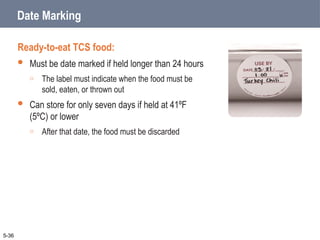

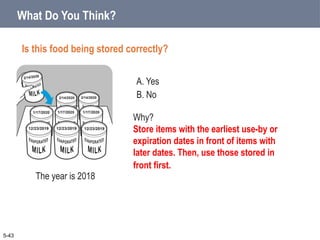

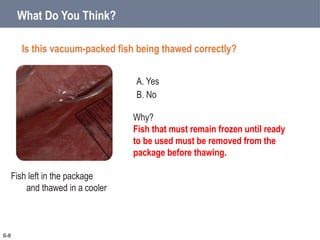

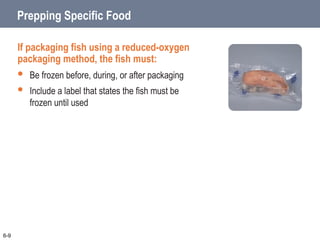

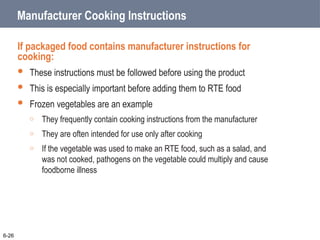

TCS foods: Milk, eggs, meat, poultry, fish, cooked rice/pasta, etc.

Danger Zone: 41°F–135°F (5°C–57°C).

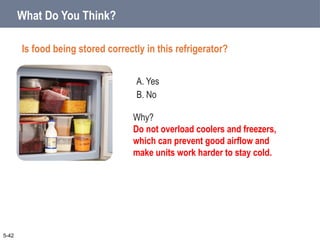

Keep hot foods above 135°F and cold foods below 41°F.

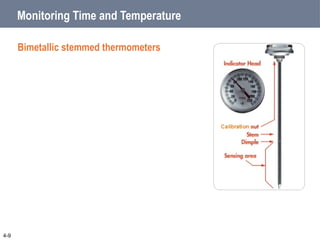

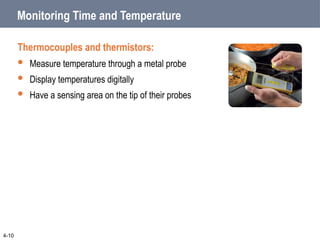

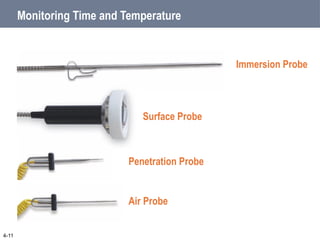

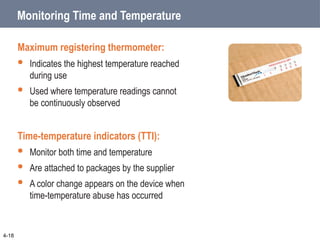

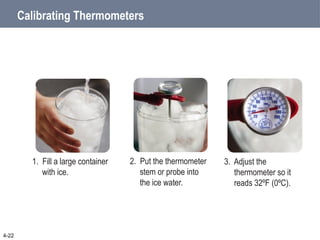

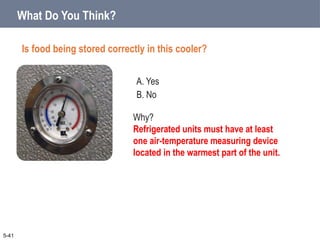

Use thermometers to monitor temperatures.

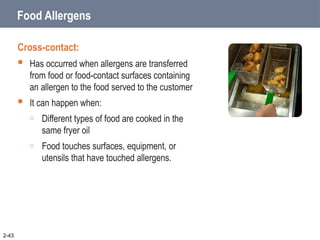

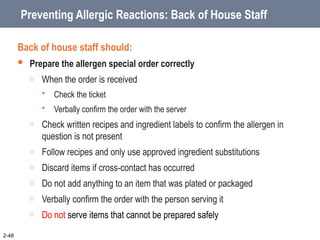

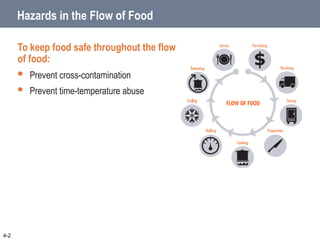

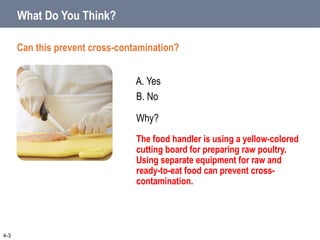

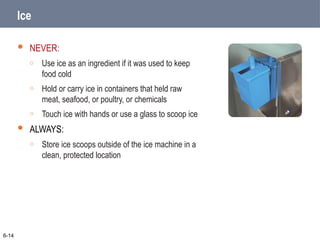

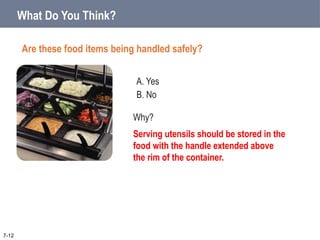

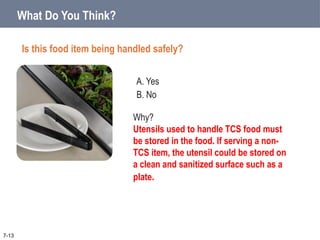

5. Cross-Contamination and Allergen Management

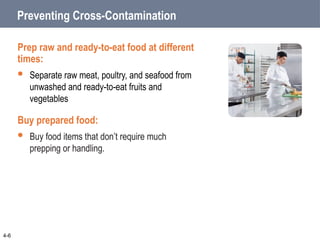

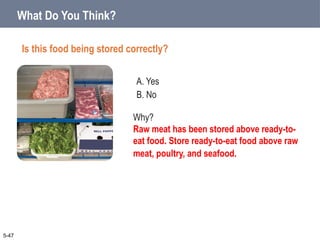

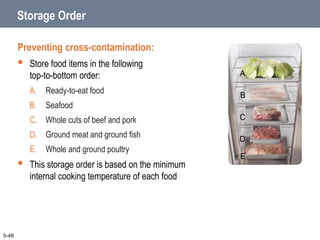

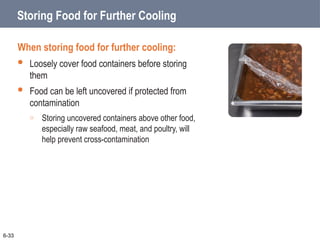

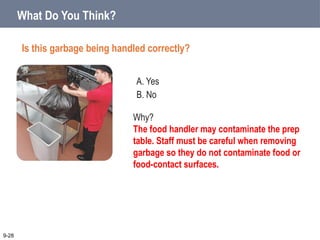

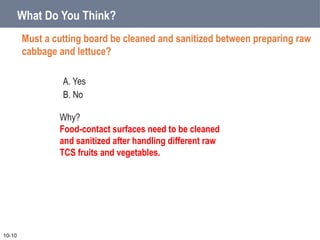

Prevent cross-contamination: Use separate equipment, clean surfaces.

Store raw foods below ready-to-eat foods.

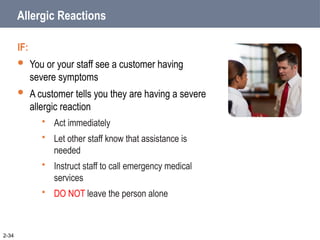

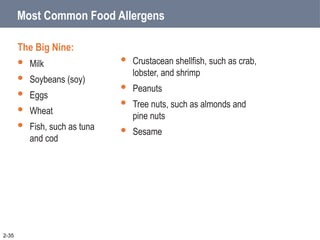

Allergen awareness: Major 9 allergens, prevent allergen cross-contact.

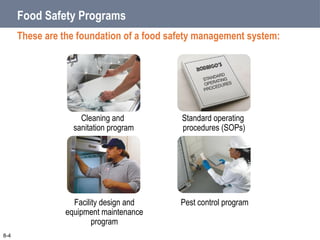

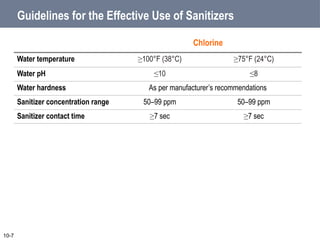

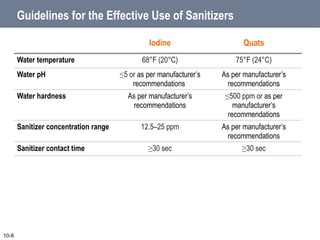

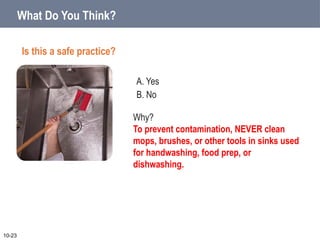

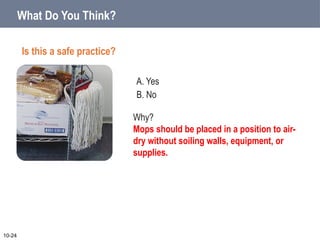

6. Cleaning and Sanitizing

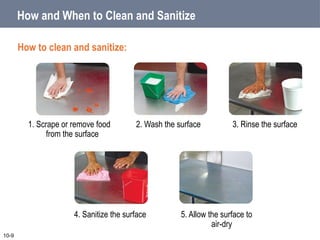

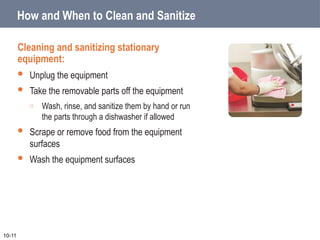

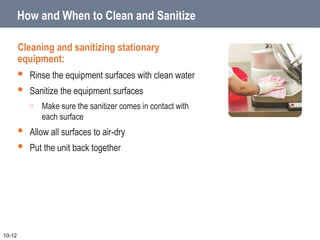

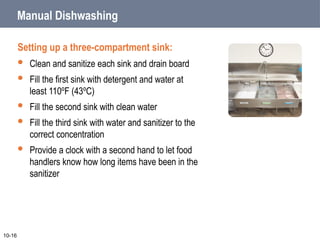

Clean (remove dirt) before sanitizing (kill germs).

Use proper sanitizing solutions and methods.

Clean surfaces between uses.

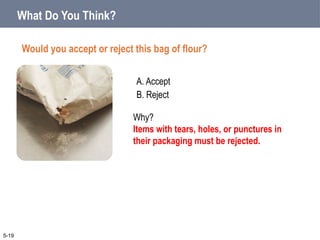

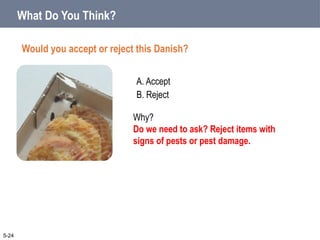

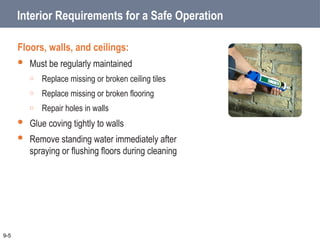

7. Facility Safety and Pest Control

Maintain the premises: Clean, dry, and in good repair.

Prevent pest access: Seal gaps, keep food covered, remove trash promptly.

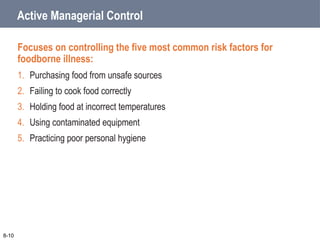

8. Food Safety Management Systems

Implement HACCP (Hazard Analysis and Critical Control Points).

Monitor CCPs (Critical Control Points), take corrective actions, and keep records.

9. Regulatory Agencies and Inspections

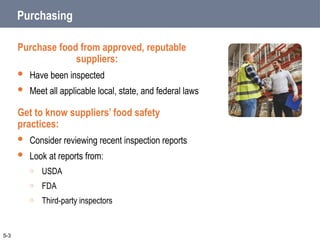

FDA, USDA, CDC, and local health departments set food safety regulations.

Prepare for inspections: Keep records, train staff, and maintain standards.