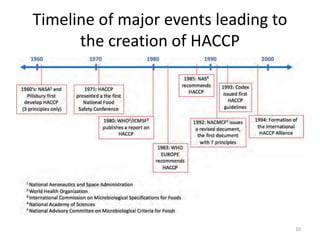

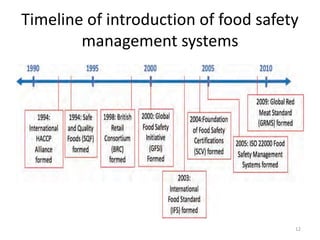

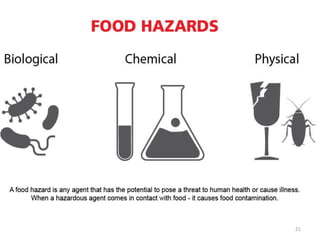

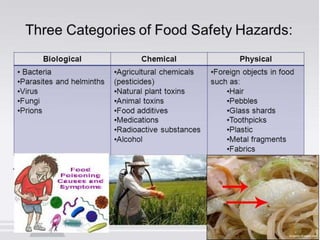

This document provides an overview of food safety history and concepts. It discusses how food safety emerged as a scientific discipline after outbreaks in the 1990s. The Hazard Analysis and Critical Control Point (HACCP) system was developed in the 1960s and implemented more widely in the 1970s in response to these outbreaks. The document also defines key food safety terms like contamination and introduces the major types of foodborne hazards. It outlines the scope of food safety across the production chain and concludes by discussing how further implementation of standards could continue decreasing foodborne illness worldwide.