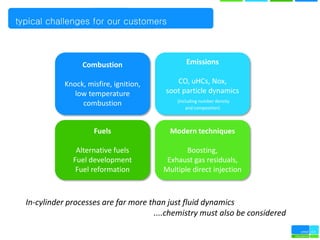

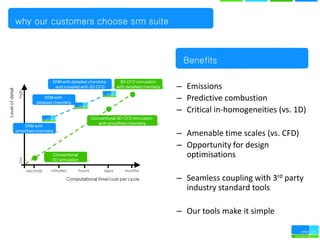

CMCL Innovations provides modeling software and consulting services focused on predictive combustion modeling. Their modeling philosophy uses integrated data, application, and optimization models. Their software suite, SRM, can model combustion, emissions, fuels and fuel reformation, injection systems, and in-cylinder processes through integrated fluid dynamics and chemistry models. Customers choose SRM for its ability to predict emissions and combustion trends, model critical in-homogeneities faster than CFD, seamlessly couple with third party tools, and help design optimizations. CMCL provides examples of SRM helping optimize diesel engine design for emissions and efficiency.