1) Drying curves plot drying rate versus remaining water content and can describe the drying process in steps with changing drying rates.

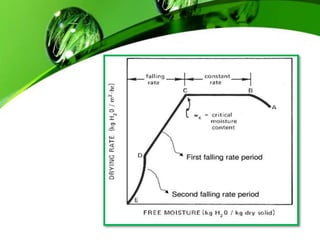

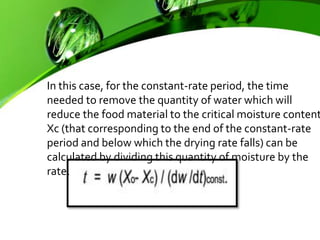

2) There is an initial constant rate period where unbound surface water is removed, followed by a falling rate period where the drying rate decreases as water moves internally through the material.

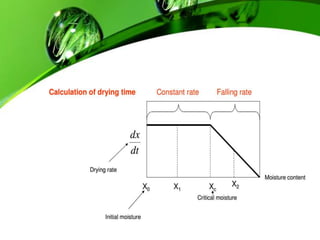

3) Drying rates determined experimentally can be used to calculate drying times to design drying equipment and operations. Simplified calculations can provide useful estimates by assuming constant temperature and humidity.