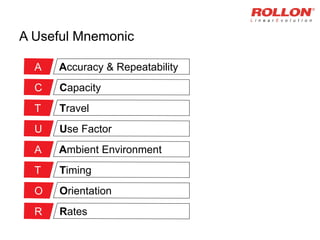

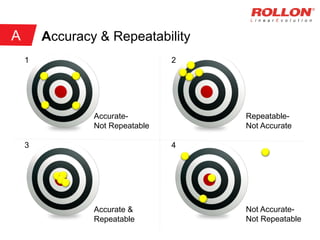

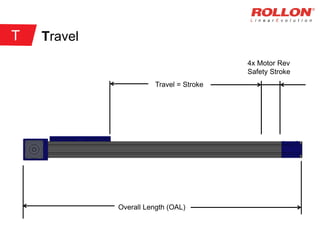

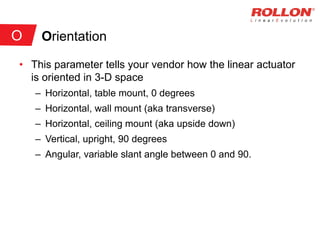

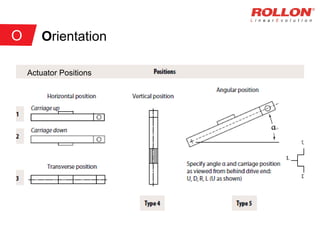

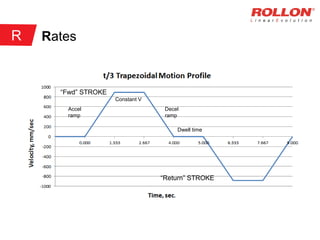

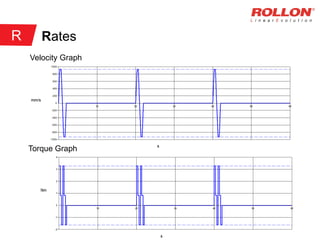

The document outlines essential considerations for specifying and sizing electromechanical linear actuators, emphasizing the importance of understanding seven technical and one commercial specification parameters. Key aspects include accuracy, capacity, travel, usage factor, ambient environment, timing, orientation, and rates of motion. The goal is to ensure error-free installation and operation by fully characterizing the actuator's requirements.