Embed presentation

Download to read offline

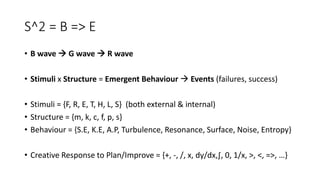

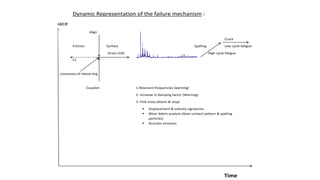

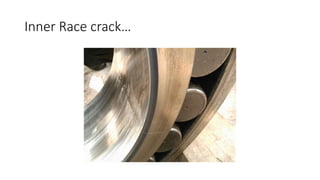

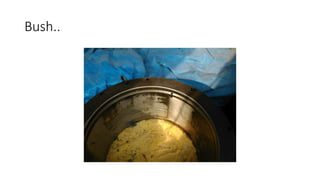

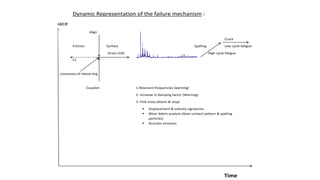

The document discusses solving complex engineering problems creatively. It talks about understanding failures by using a model that examines intention, behavior, and events. It then provides an example of analyzing the failure of a bearing, looking at the inner race crack, rollers, and bush using a dynamic representation over space and time. It concludes by discussing potential plans and improvements that could be made, such as changing the oil type and adding a breather or electrostatic cleaner.