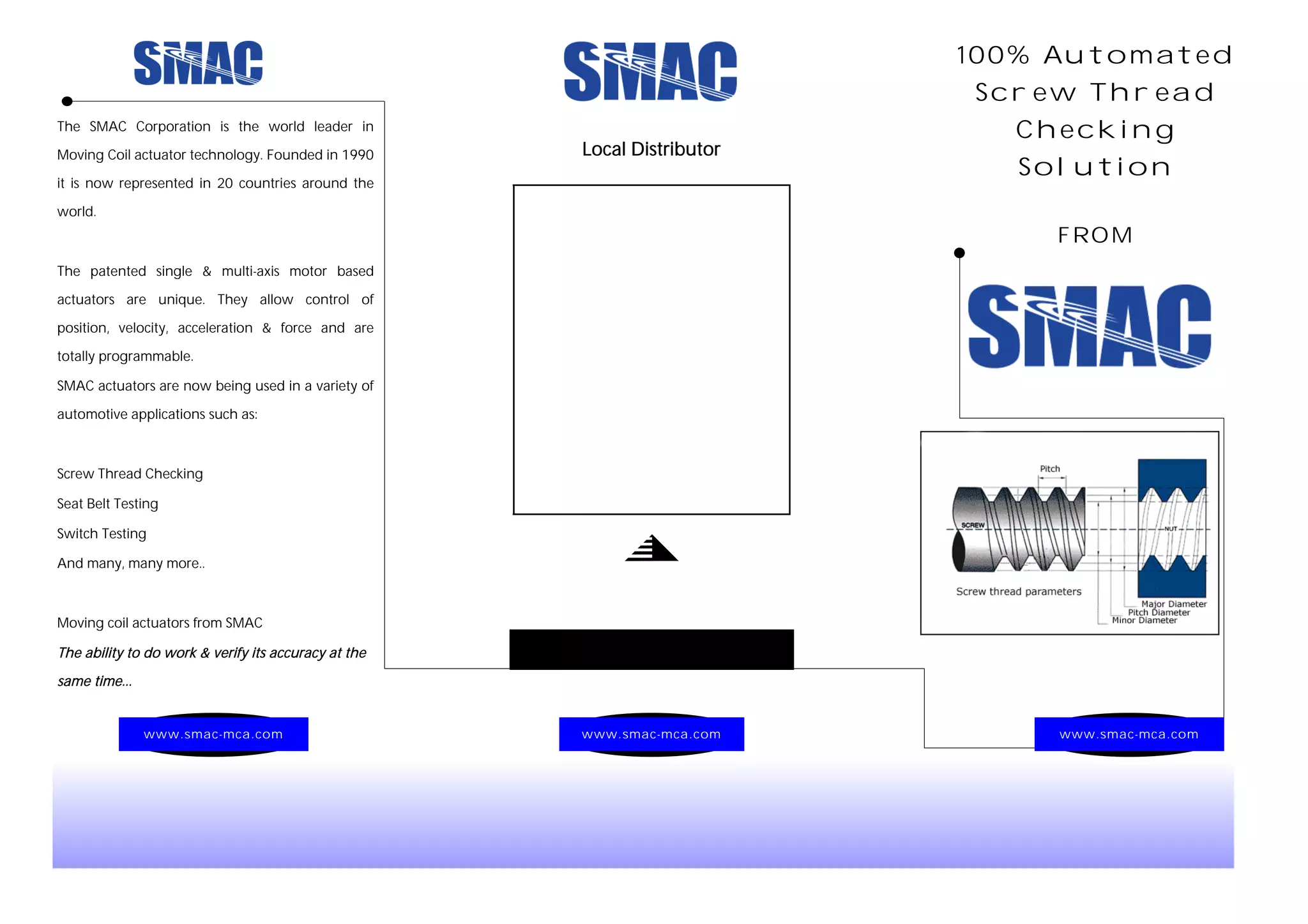

The document discusses SMAC Corporation, a leading provider of moving coil actuator technology. SMAC actuators can control position, velocity, acceleration, and force, and are being used in automotive applications like screw thread checking, seat belt testing, and switch testing. The document specifically focuses on SMAC's 100% automated screw thread checking solution, which can measure parameters like oversized/undersized threads, number of threads, cross threading, thread depth, and pitch. The SMAC system offers advantages like programmable force, torque, position and velocity controls to prevent component damage, on-the-fly part recognition, and data collection of measurements.