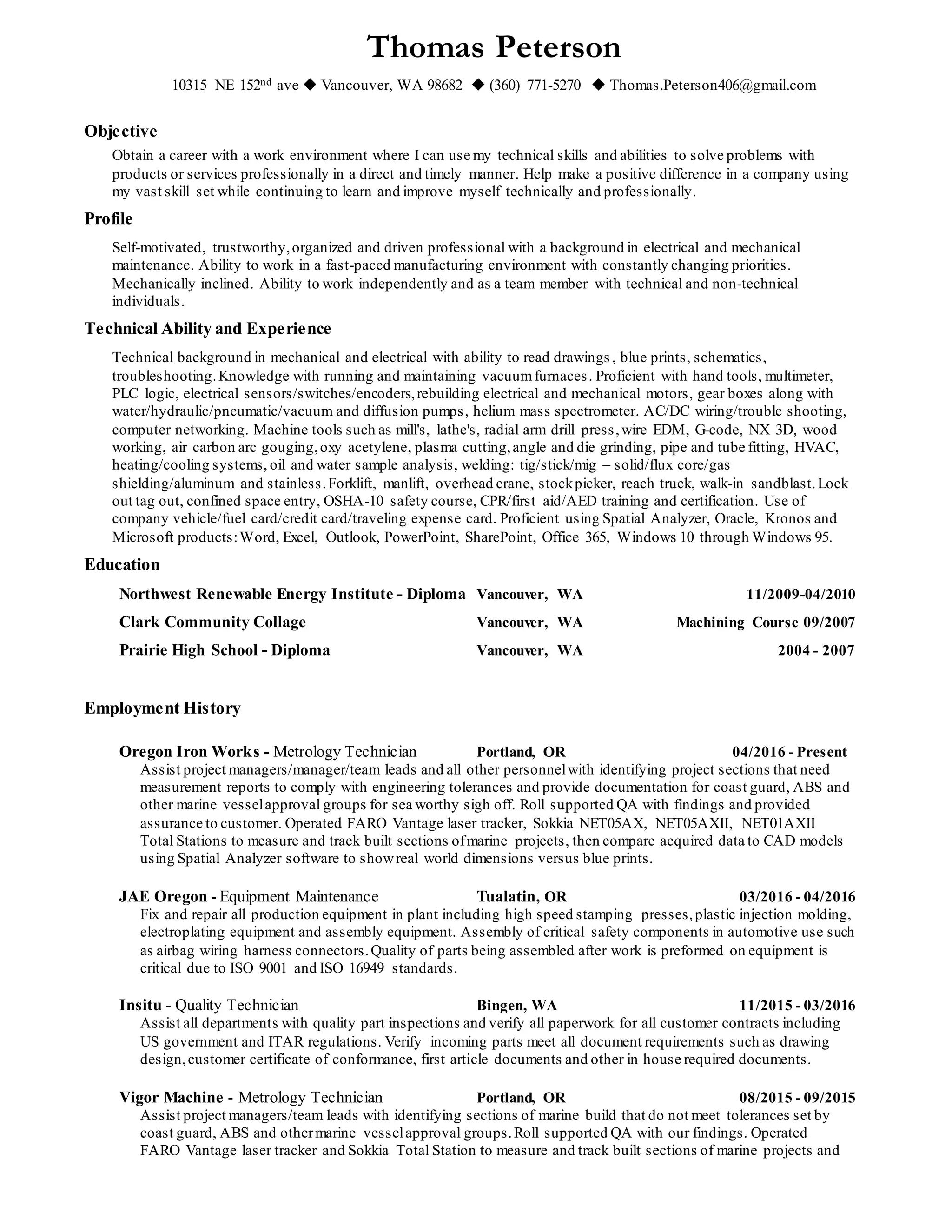

Thomas Peterson is seeking a career using his technical skills to solve problems professionally. He has a background in electrical and mechanical maintenance and experience working in manufacturing. He has skills in areas such as mechanical systems, electrical systems, vacuum furnaces, hand tools, PLC logic, sensors, motors, pumps, machining, welding, forklifts and more. His work history includes positions as a metrology technician, quality technician, engineer technician and more where he assisted with tasks like inspections, measurements, equipment maintenance and repairs.