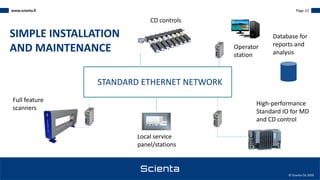

Scienta develops sensors and online measuring systems for the pulp, paper, impregnation and non-woven industries. It has over 64 years of experience in sensor production and has developed a wide range of sensors and scanning technologies. Scienta provides flexible and reliable measurement solutions that integrate easily with customer processes and automation systems.