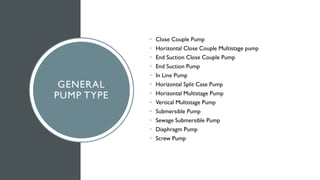

This document provides information on sales training for various industries and services. It discusses pump repairs and refurbishment for commercial and residential buildings. It also covers general pump types, mechanical seals, heat exchangers, and boiler and chiller process flow layout plans. The document aims to educate on rotating equipment services, pump systems, and heat exchanger types and applications.