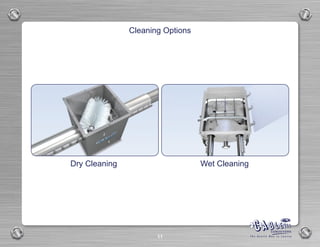

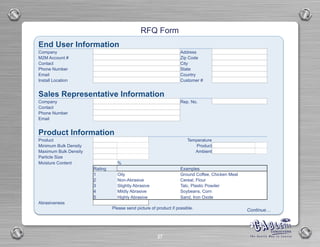

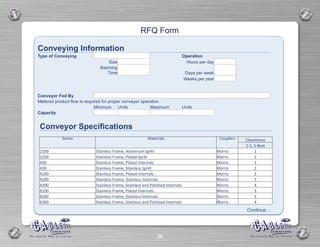

The document provides information about conveyor systems for transporting bulk materials. It describes the different conveyor sizes and their capacities, as well as options for gentle material handling, cleaning, and system layouts. Return on investment calculations are also presented to demonstrate potential savings from reducing product breakage during transport.