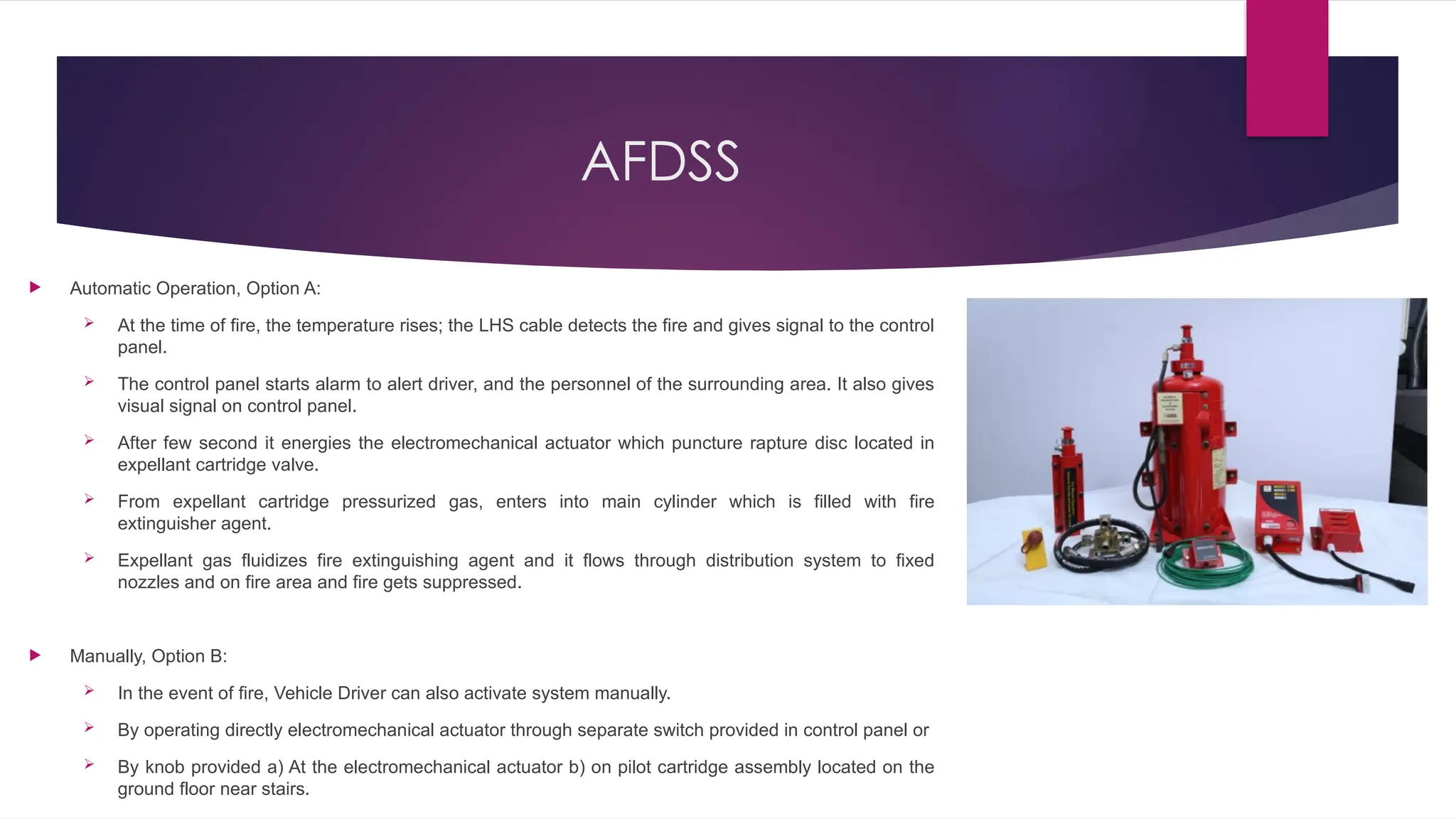

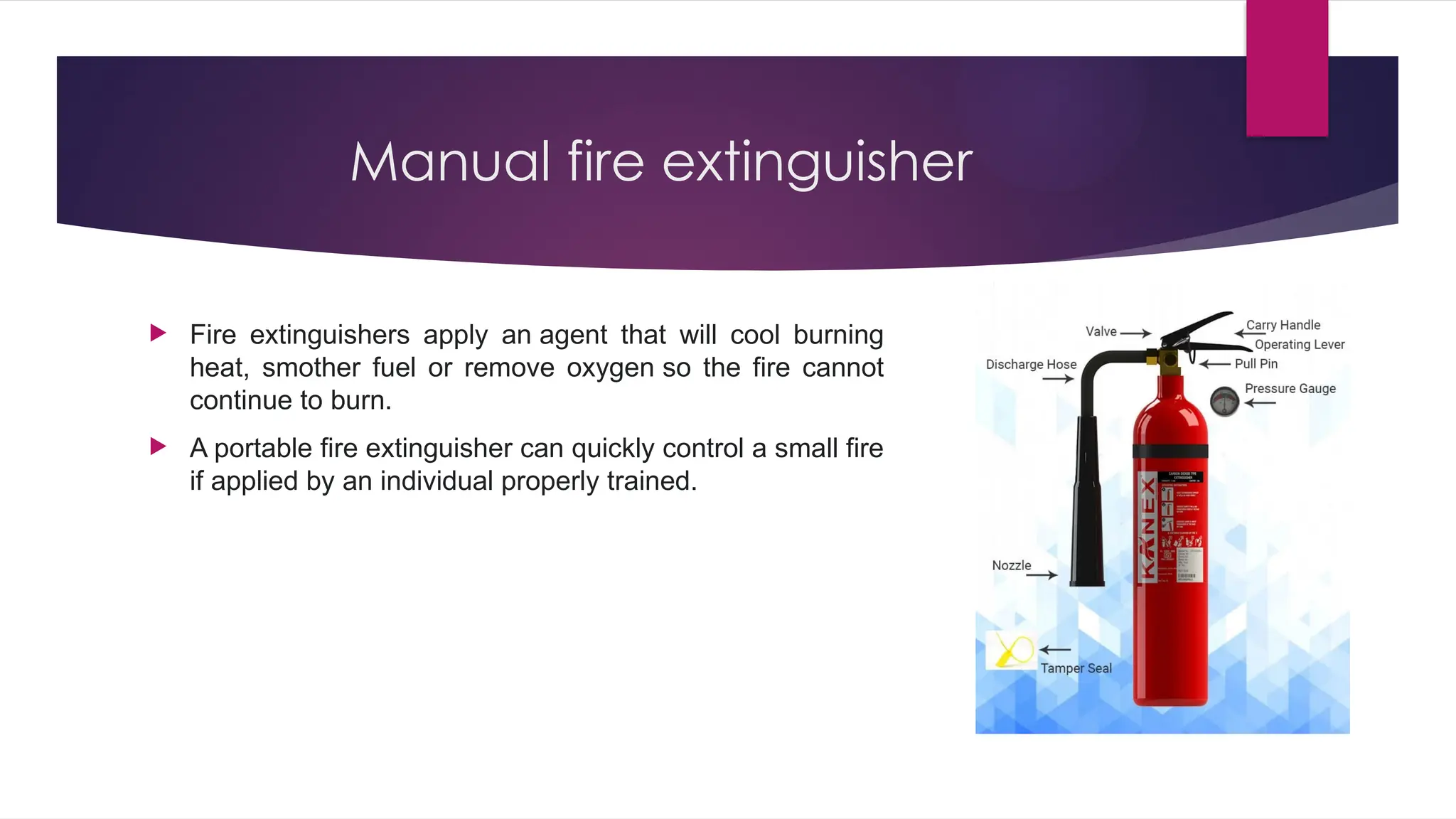

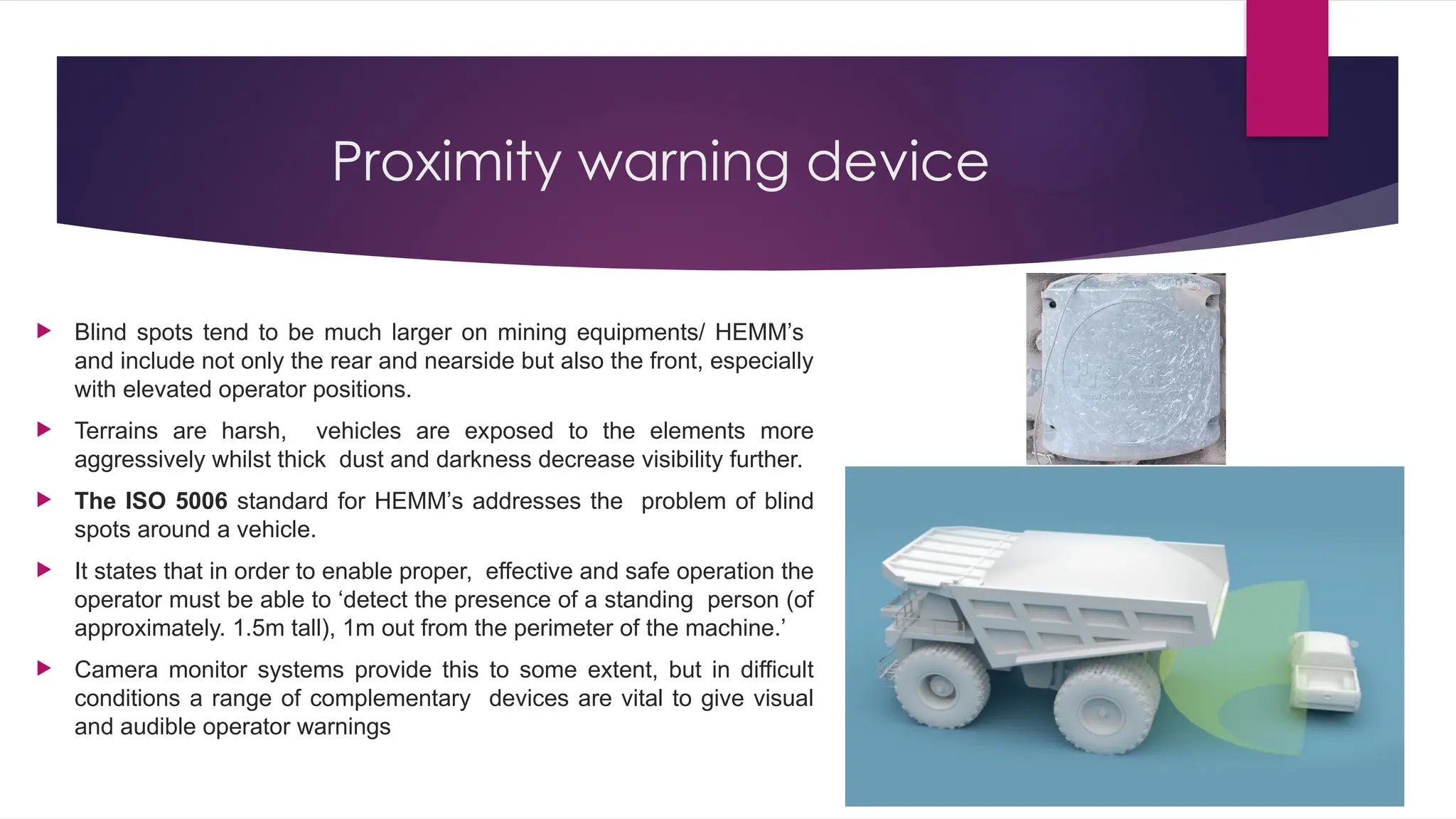

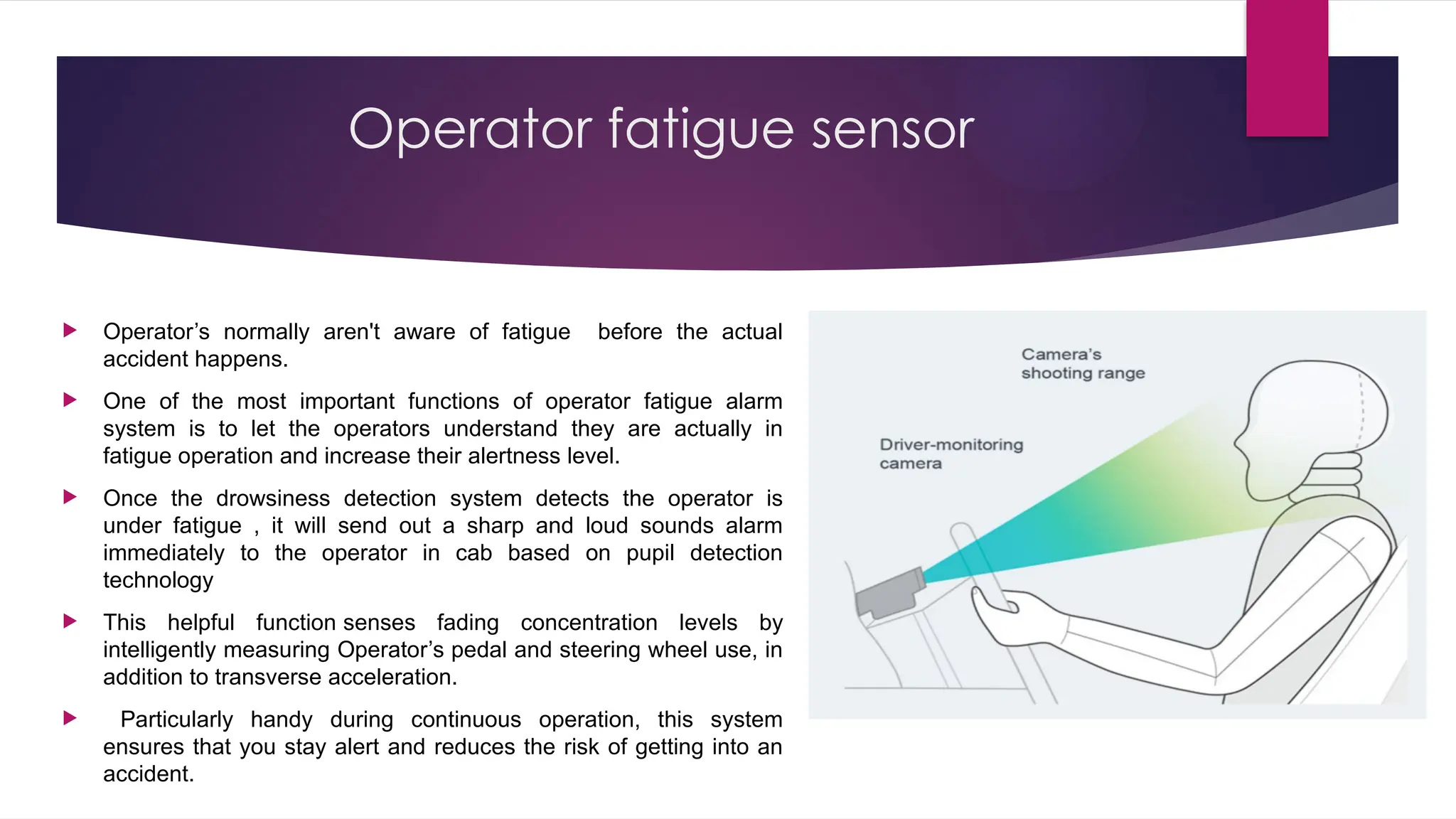

The document outlines safety and operational features of heavy mining machinery, including advanced braking systems, fire suppression measures, and protective structures such as ROPS and FOPS. It details emergency response systems, operator alerts for fatigue, and various visibility aids like cameras and mirrors. Additionally, it specifies compliance with safety standards and the importance of payload monitoring systems.