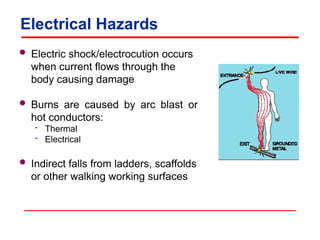

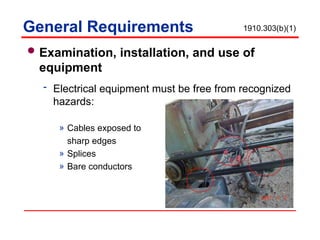

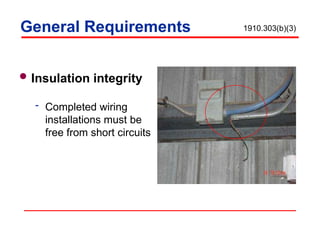

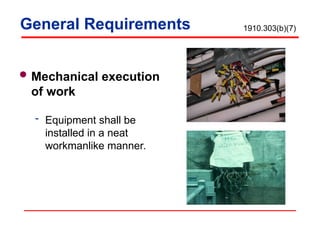

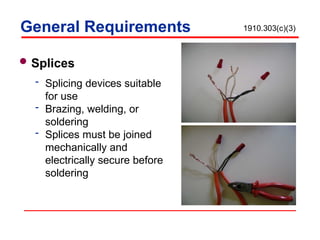

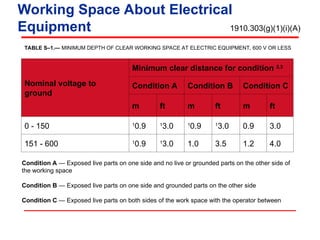

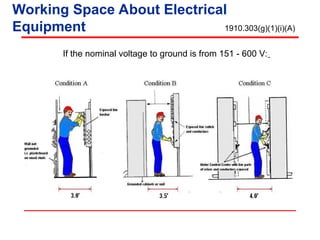

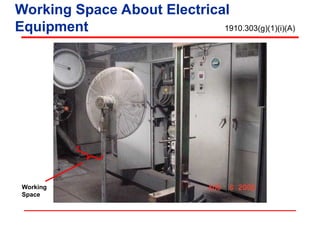

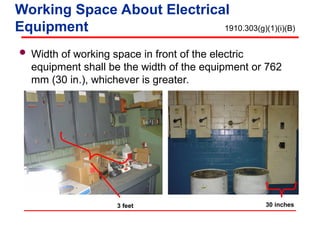

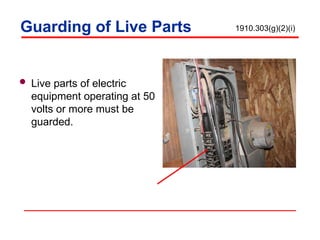

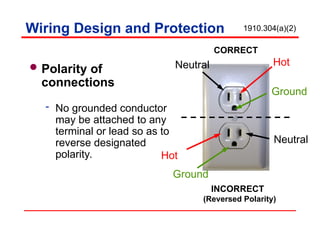

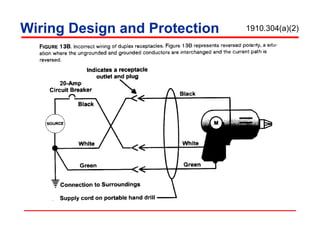

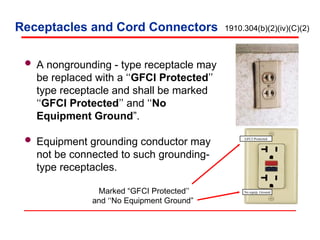

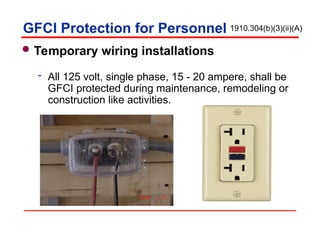

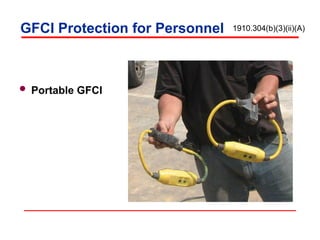

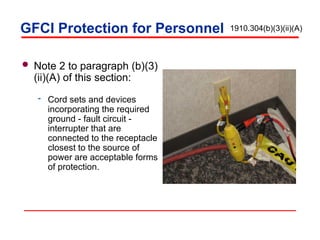

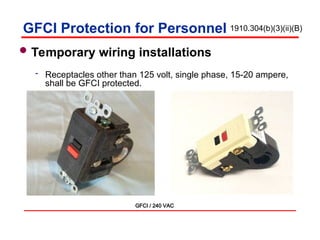

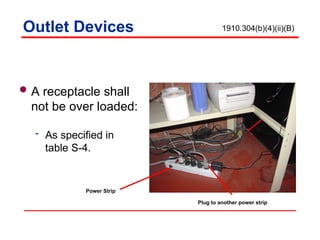

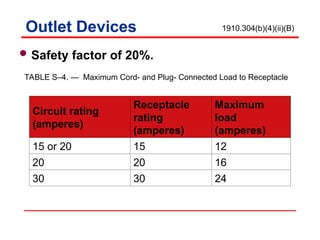

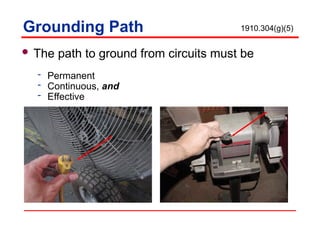

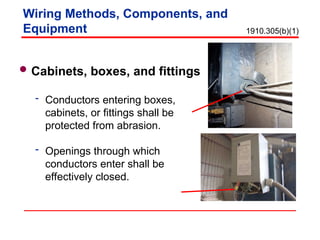

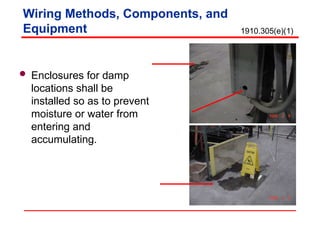

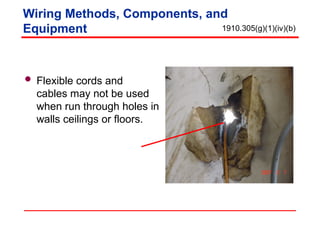

The document outlines electrical safety regulations under OSHA 29 CFR 1910 Subpart S, focusing on recent changes, common electrical hazards, and best practices for safe working conditions. It emphasizes the importance of compliance with established requirements for electrical installations, utilization systems, and equipment safety measures. Additionally, the document provides guidelines for safe access to electrical equipment, proper wiring practices, and the use of ground fault circuit interrupters to protect personnel.