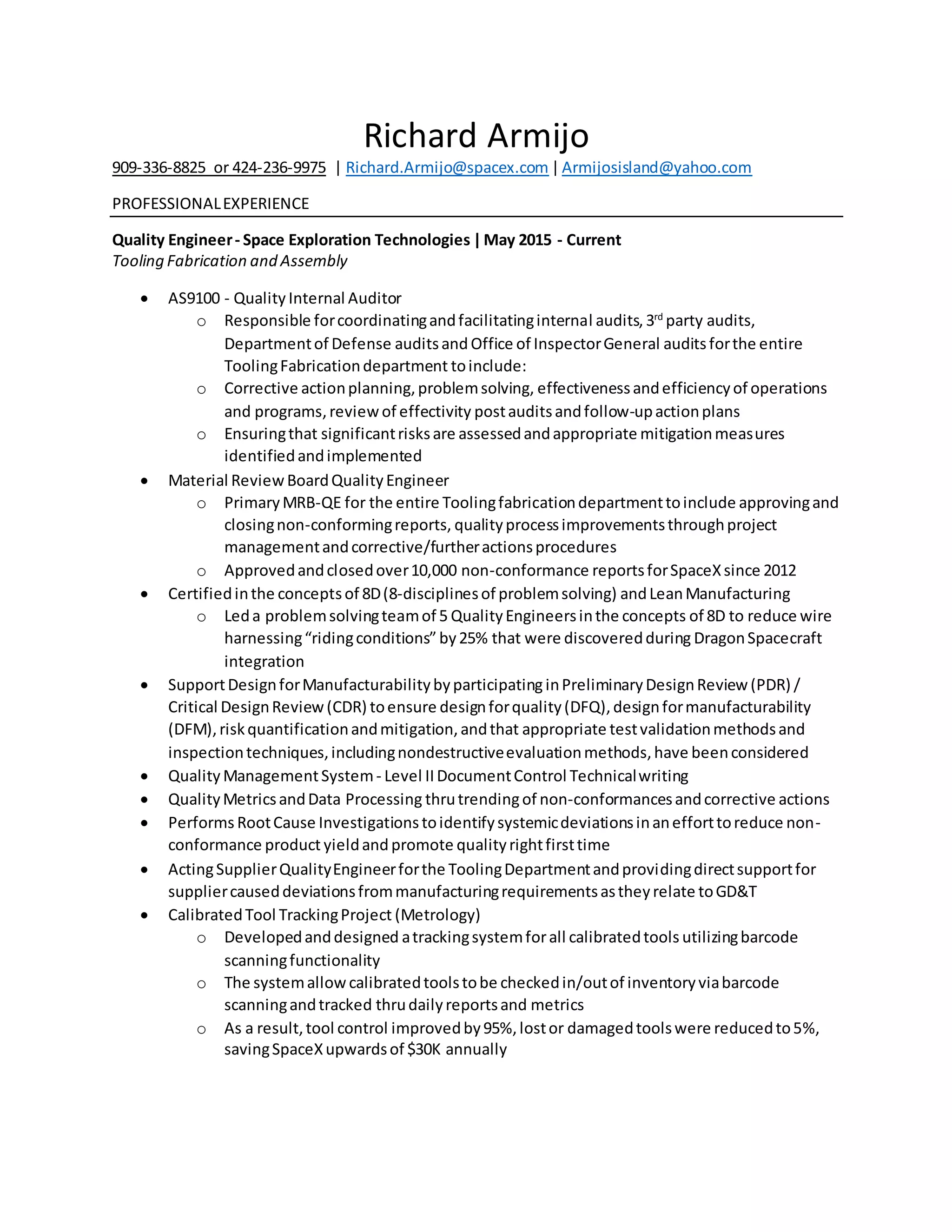

Richard Armijo has over 10 years of experience in quality assurance roles at SpaceX, including currently serving as a Quality Engineer in the Tooling Fabrication department. He is responsible for internal audits, corrective actions, and quality process improvements. Previously he worked as a Quality Engineer and Quality Inspector on the Dragon Spacecraft program where he developed non-conforming hardware tracking systems to reduce costs and risks. He also has 4 years of experience maintaining military aircraft as an Aviation Structural Mechanic in the Navy.