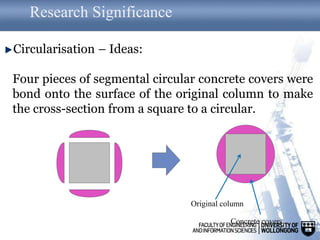

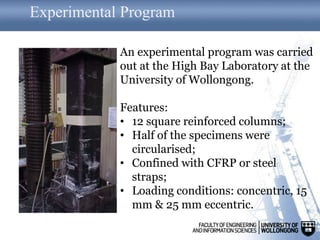

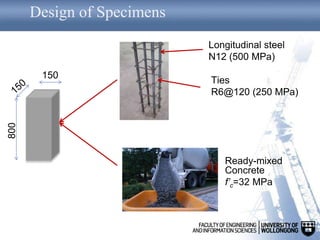

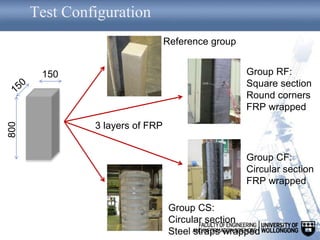

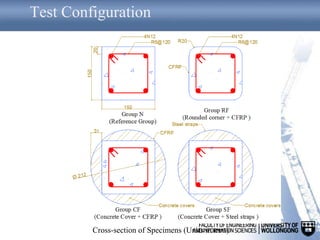

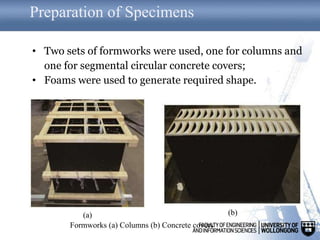

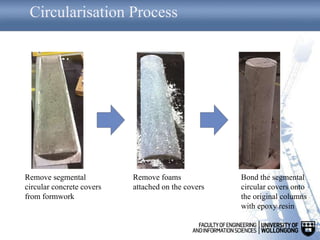

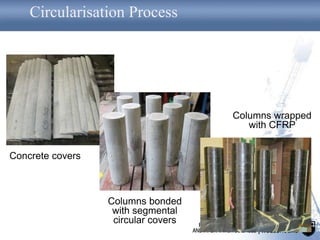

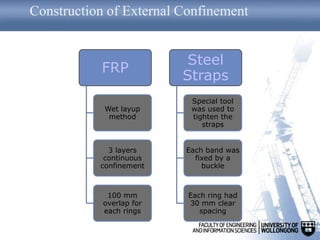

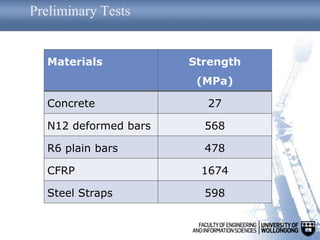

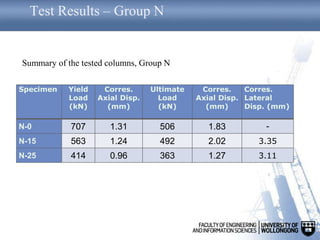

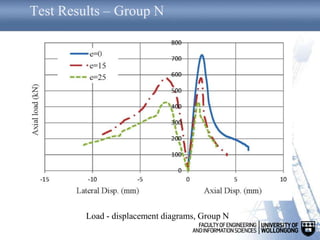

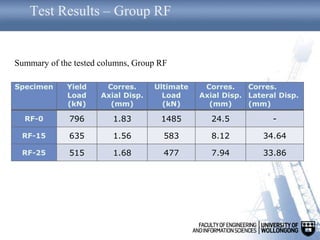

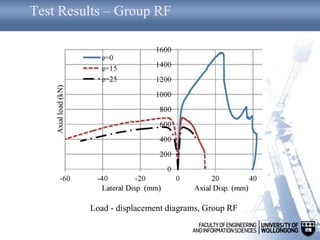

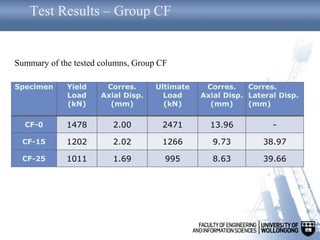

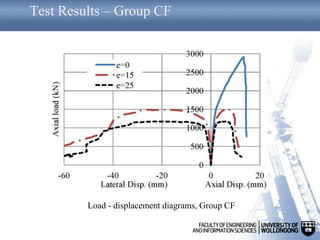

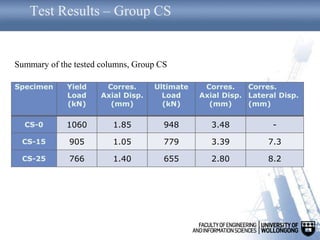

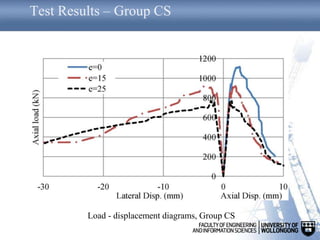

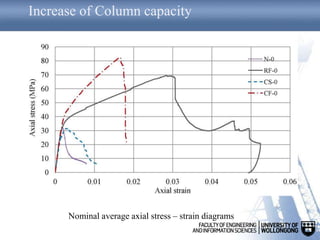

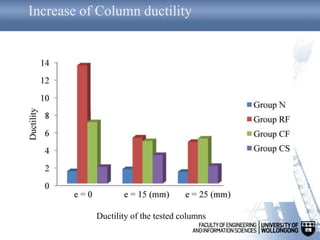

This document summarizes a study on a new method of retrofitting reinforced concrete columns called "circularisation". The study involved wrapping originally square concrete columns with circular concrete covers to change their cross-section to circular. Twelve square columns were tested under concentric and eccentric axial loads, with half undergoing circularisation first. Test results showed that circularisation dramatically increased the efficiency of FRP confinement, maximizing its strengthening effects. While eccentric loading reduced column capacity for all specimens, circularisation proved an effective technique for strengthening square reinforced concrete columns.