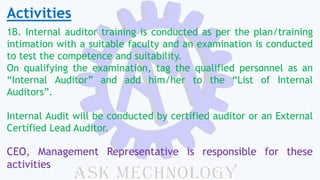

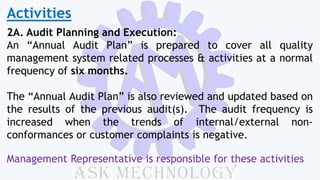

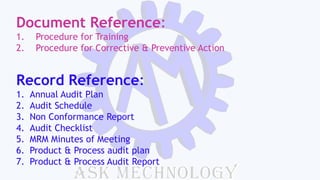

The document outlines the procedure for conducting internal audits to ensure adherence to IATF 16949 and ISO 9001 standards across all functions, excluding finance and accounts. It details the auditor qualification, training, audit planning, execution, and corrective actions for non-conformances while assigning responsibilities to management representatives. The document also includes references to related procedures and records to maintain compliance and track audit processes.