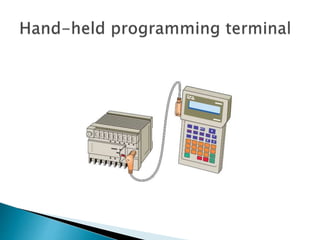

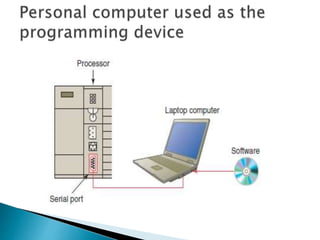

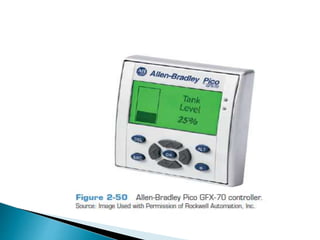

The document discusses various programming devices for programmable logic controllers (PLCs), highlighting handheld programming terminals and personal computers as common tools for entering and troubleshooting PLC programs. It explains the capabilities of programming software, including online editing and program documentation, and emphasizes the importance of human-machine interfaces (HMIs) in facilitating operator interaction with PLCs. Additionally, it outlines features of the Allen-Bradley Pico GFX-70 controller, which integrates HMI capabilities for real-time feedback and operation.