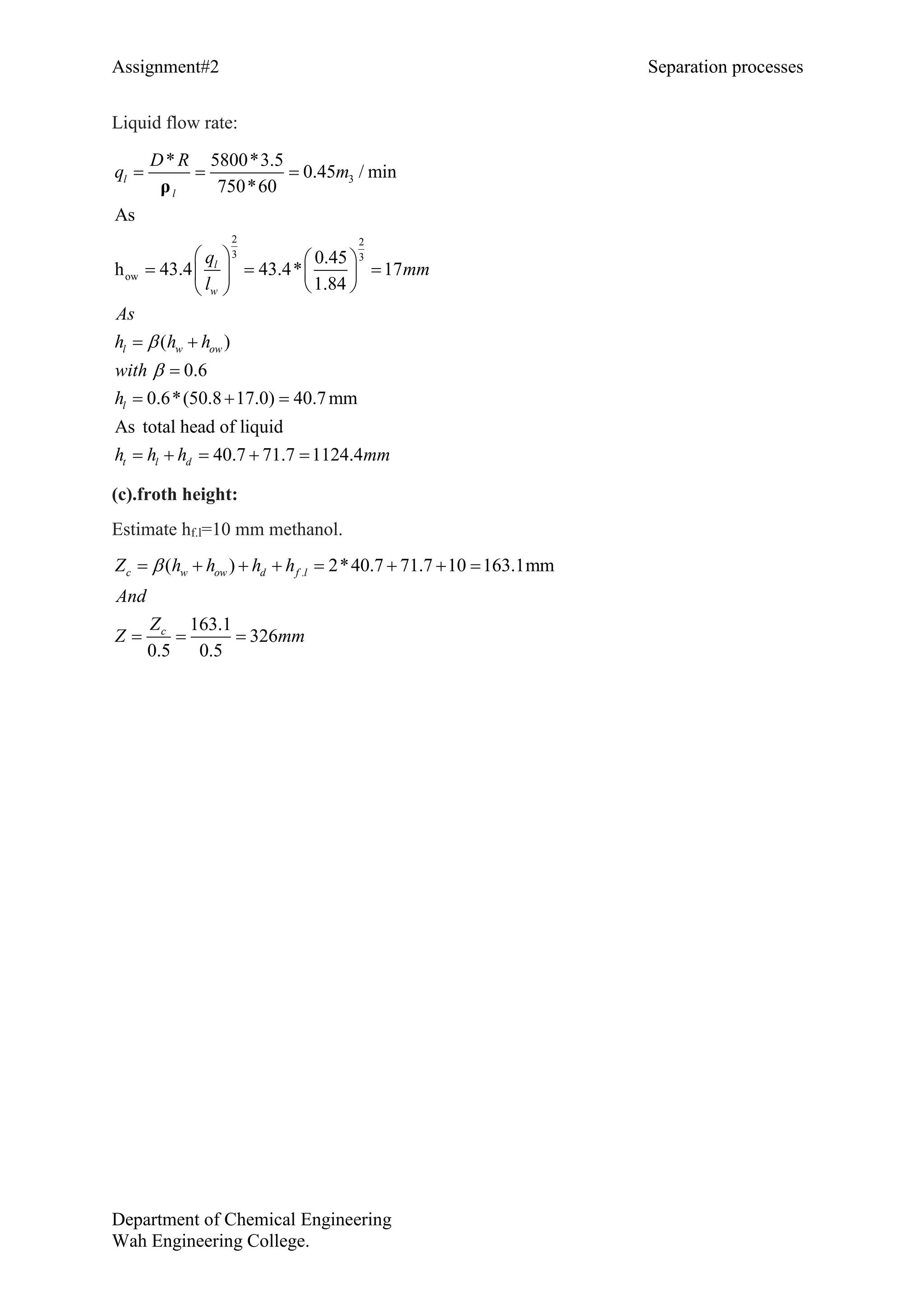

This document provides a multi-part assignment problem involving distillation column design and analysis. In part 1, the document summarizes the calculation of the number of theoretical plates and feed location for a binary distillation column separating benzene and toluene using the McCabe-Thiele method. The summary finds that the column requires 7 plates with the feed on plate 4. Part 2 involves using the Fenske equation to determine the minimum number of plates and minimum reflux ratio for a pentane-hexane separation. The summary states that the minimum number of plates is 4 and the minimum reflux ratio is 0.9024. Part 3 involves calculations to determine the allowable vapor velocity, column diameter, pressure drop per plate

![Assignment#2 Separation processes

Department of Chemical Engineering

Wah Engineering College.

Number of theoretical plates = 7

Feed plate = 4

Question#2:

A distillation column receives a feed that is 40 mole % n-pentane and 60 mole % n-hexane.

Feed is saturated liquid with a flow rate of 2,500 lbmol/hr. The column is at 1 atm. A

distillate of 90 mole % n-pentane is desired. A total condenser is used. Reflux is a saturated

liquid. A bottom from the reboiler is 98 mole % n-hexane. Determine the minimum number of

equilibrium trays and the minimum reflux ratio.

Data: Vapor pressure, Psat, data: ln Psat = A - B/ (T + C), where Psat is in kPa and T is in K.

Compound A B C

n-pentane (1) 13.9778 2554.6 - 36.2529

n-hexane (2) 14.0568 2825.42 - 42.7089

Heat of evaporation for n-pentane, = 11,369 Btu/lbmol, CpL,C5 = 39.7 Btu/lbmol×o

F

Heat of evaporation for n-hexane, = 13,572 Btu/lbmol, CpL,C6 = 51.7 Btu/lbmol×o

F

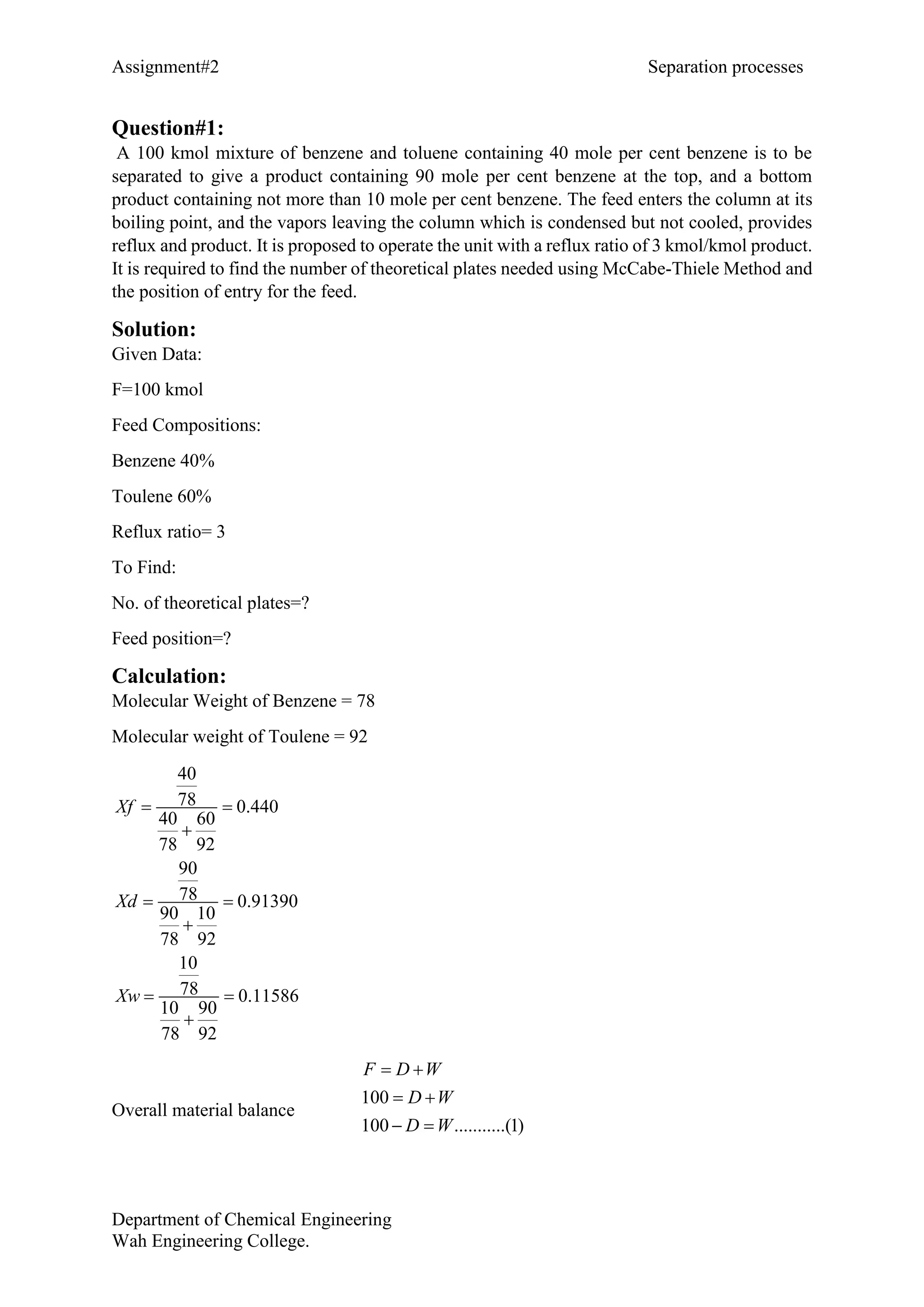

𝛼 𝐷 = 3.1102

𝛼 𝐵 = 2.7955

Solution:

As total condenser is used so minimum number of trays can be find by Fenske equation

1

log[ * ]

1

log( )

D B

D B

m

ave

X X

X X

N

a

0

0.2

0.4

0.6

0.8

1

0 0.2 0.4 0.6 0.8 1](https://image.slidesharecdn.com/assignment2-160405212353/75/pressure-drop-calculation-in-sieve-plate-distillation-column-4-2048.jpg)

![Assignment#2 Separation processes

Department of Chemical Engineering

Wah Engineering College.

𝛼 𝐷 = 3.1102

𝛼 𝐵 = 2.7955

1

2

1

2

( * )

(3.1102*2.7955)

2.9486

ave D B

ave

ave

a a a

a

a

1 0.9 1 0.1log[ * ] log( * )

1 1 .9 0.1

log( ) log(2.9486)

log(81)

log(2.9486)

4.1

D B

D B

m

ave

m

m

X X

X X

N

a

N

N

Minimum reflux ratio

*(1 )1

[ ( )]

1 (1 )

1 0.9 2.9486*(1 0.9)

[ ( )]

2.9486 1 0.4 (1 0.4)

0.9024

ave DD

m

ave F F

m

m

a XX

R

a X X

R

R

Question#3:

A sieve-plate column operating at atmospheric pressure is to produce nearly pure methanol

from an aqueous feed containing 40 mole percent methanol. The distillate product rate is 5800

kg/hr. (a) for a reflux ratio of 3.5 and a plate spacing of 18in, calculate the allowable vapor

velocity and column diameter. (b) calculate the pressure drop per plate if each sieve tray is

1

8

-in. thick with

1

4

-in. holes on a

3

4

-in. triangular spacing and a weir height of 2 in. (c) what is

the froth height in the downcomer ?

Solution:

Given data

5800 /

3.5

40 mole % methanol.

D kg hr

R

Physical properties of Methanol:

M.w = 32, normal boiling point 650

C

Density of liquid Methanol =ρL= 750 kg/m3

(650

C), surface tension= 19 dyn/cm.](https://image.slidesharecdn.com/assignment2-160405212353/75/pressure-drop-calculation-in-sieve-plate-distillation-column-5-2048.jpg)