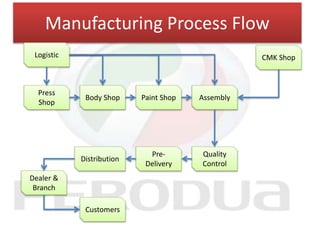

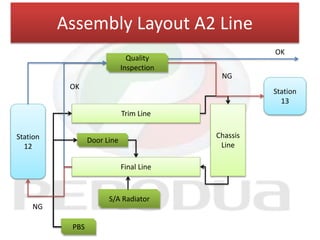

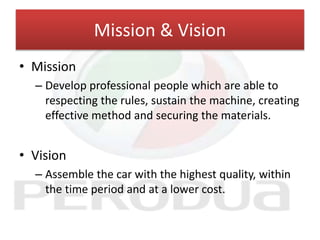

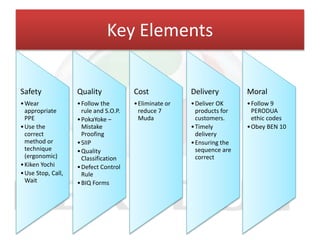

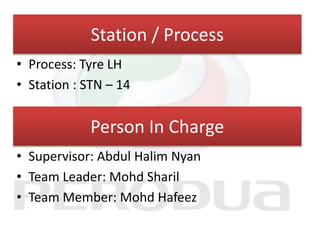

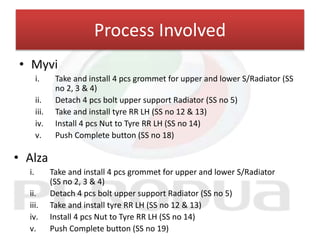

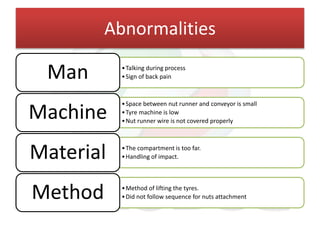

The document summarizes a shop attachment program at an assembly shop from December 5-12, 2016. It includes the manufacturing process flow, assembly layout, mission and vision statements focusing on developing professional skills and assembling high quality cars on time and at low cost. Key elements of safety, quality, cost, delivery and moral standards are outlined. The specific process, personnel in charge, abnormalities found, and countermeasures proposed for a tire installation station are then detailed.