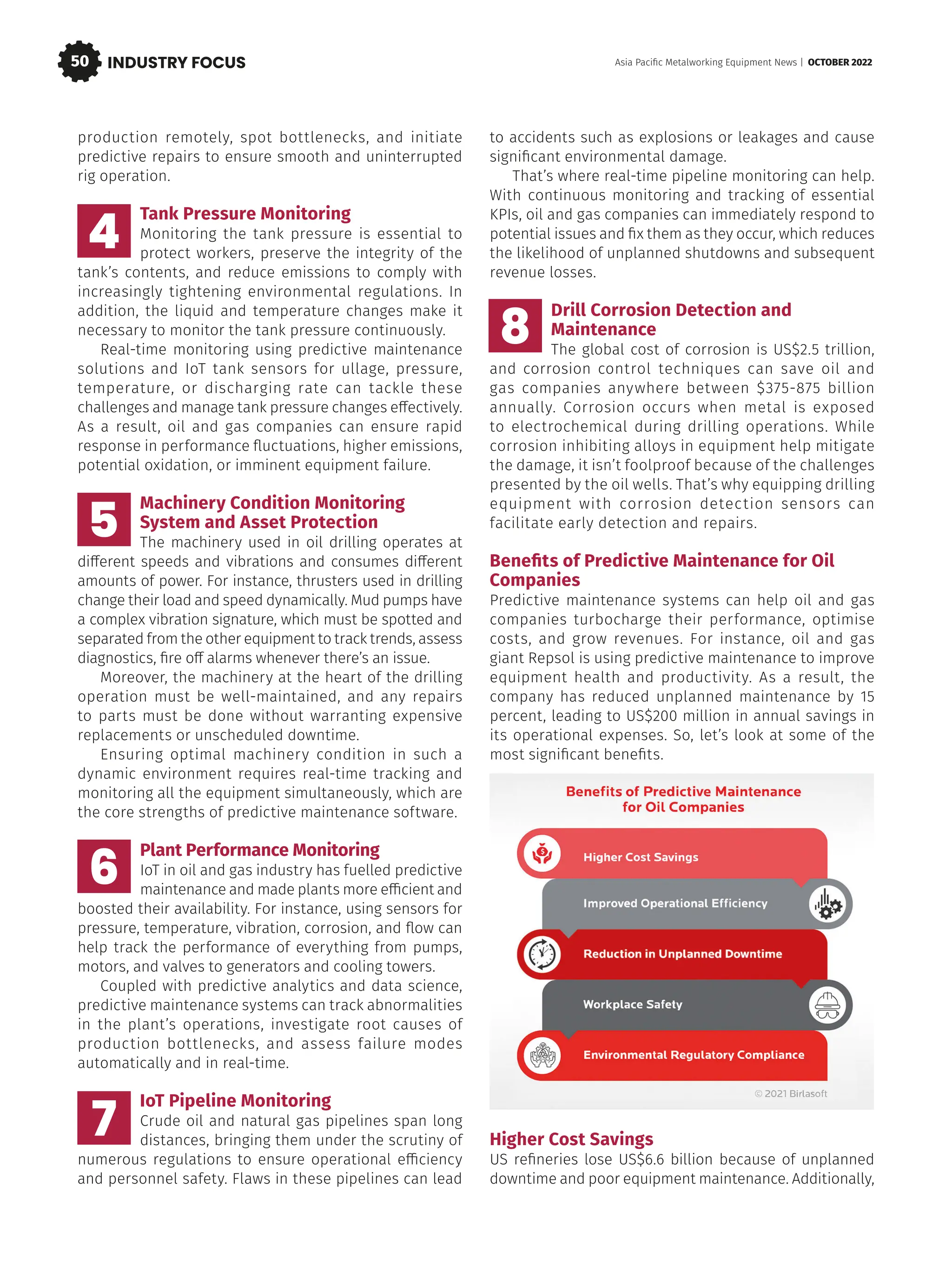

The document discusses the importance of predictive maintenance in the oil and gas industry, highlighting how it utilizes IIoT and AI technologies to minimize unplanned downtime and enhance operational efficiency, which can lead to substantial cost savings. Predictive maintenance systems analyze real-time data from various sensors to predict equipment failures, thus preventing costly breakdowns and maintaining safety standards. It also emphasizes the necessity for organizations to establish robust data management frameworks and analytics infrastructures to support successful predictive maintenance strategies.