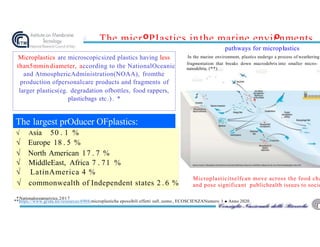

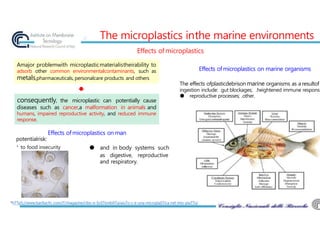

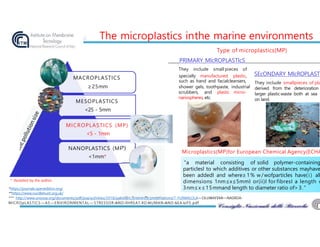

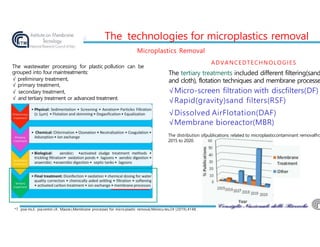

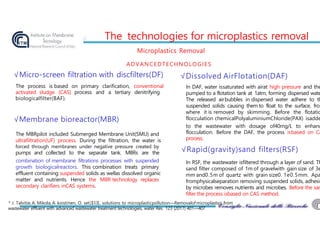

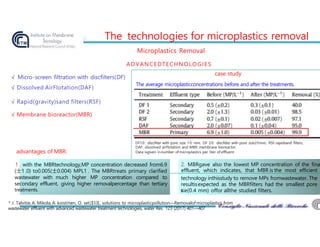

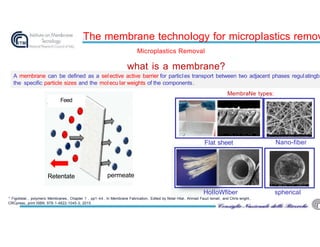

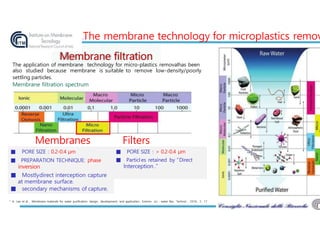

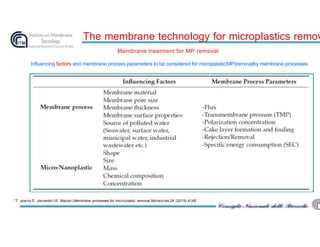

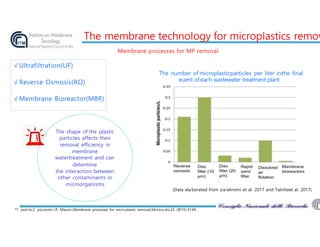

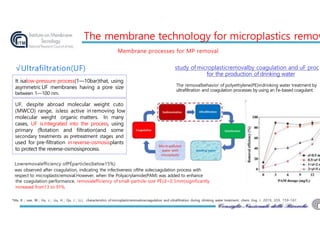

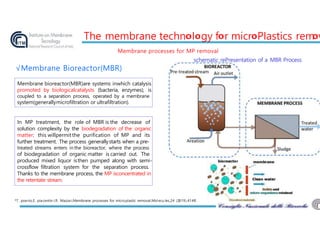

The document discusses the environmental impact of microplastics, highlighting their origins, occurrence, and effects on marine and human health. It details various methods of microplastic removal from wastewater, notably advanced technologies like membrane bioreactors, which demonstrate high efficacy in reducing microplastic concentrations. The report emphasizes the importance of innovative solutions for mitigating the dangers posed by microplastics in the marine environment and public health.