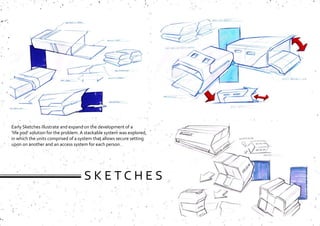

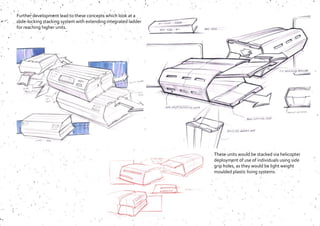

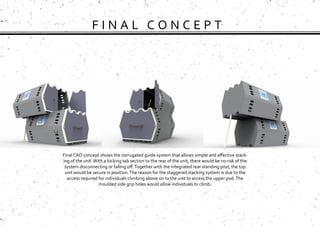

The document describes the design of a modular "life pod" system intended to address housing needs in refugee camps and disaster relief situations. The stackable pods are designed for efficient transportation and construction of temporary housing communities. Sketches show a locking stacking system with integrated ladder. The final CAD concept features a corrugated guide system allowing simple stacking. The lightweight plastic pods would provide living quarters and supplies for occupants. This collaborative design solution aims to better utilize space and resources for temporary housing worldwide.