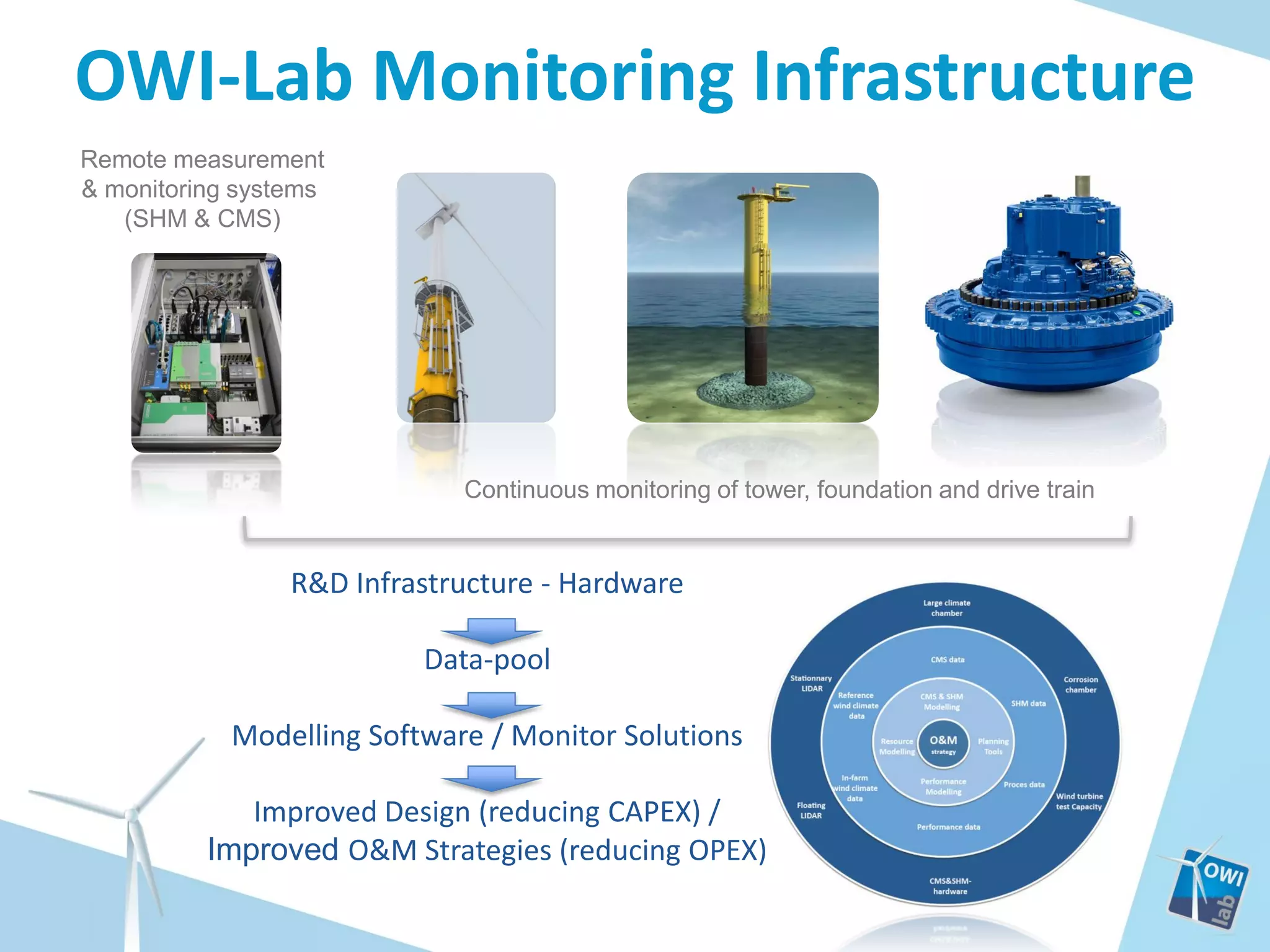

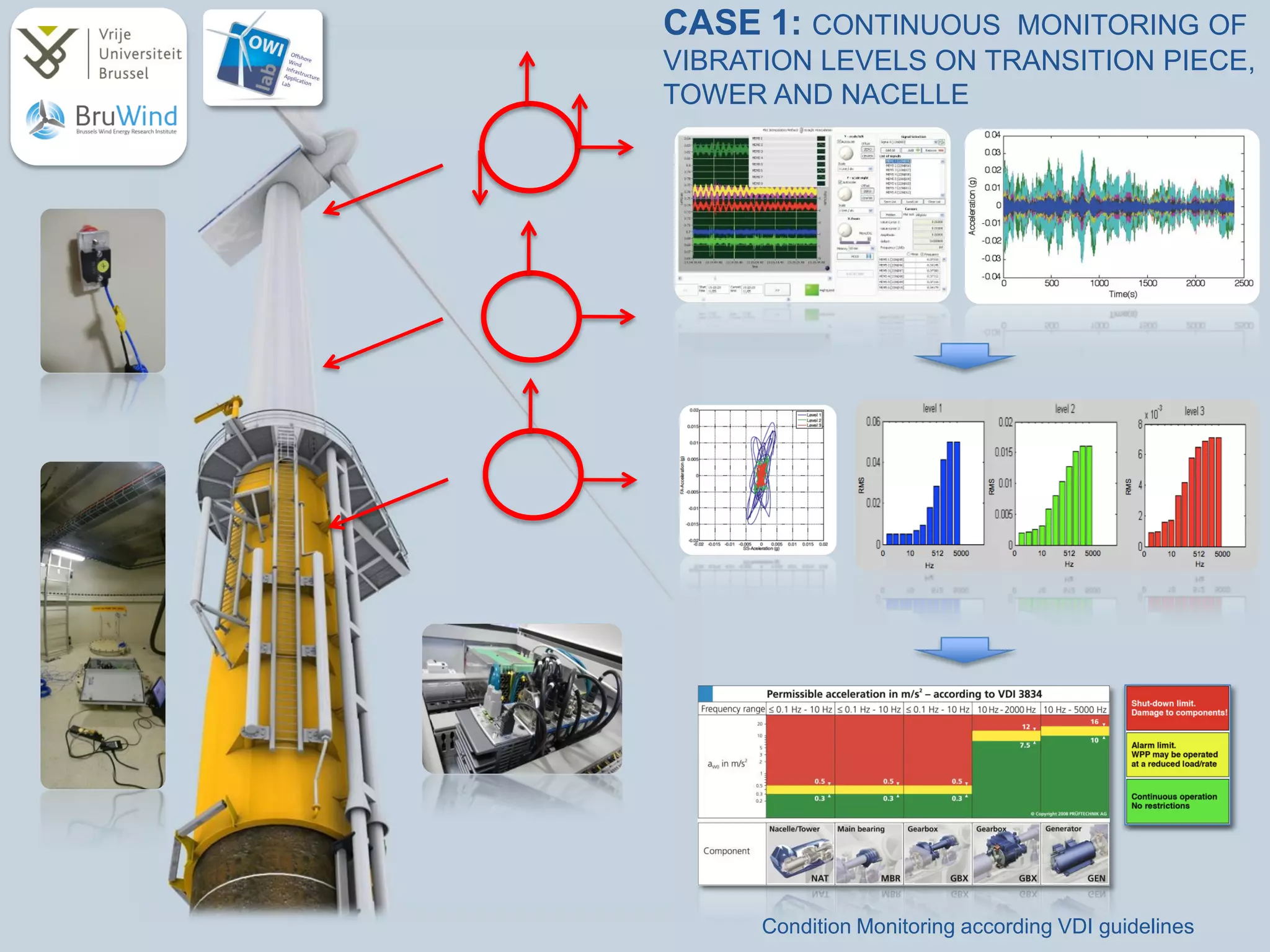

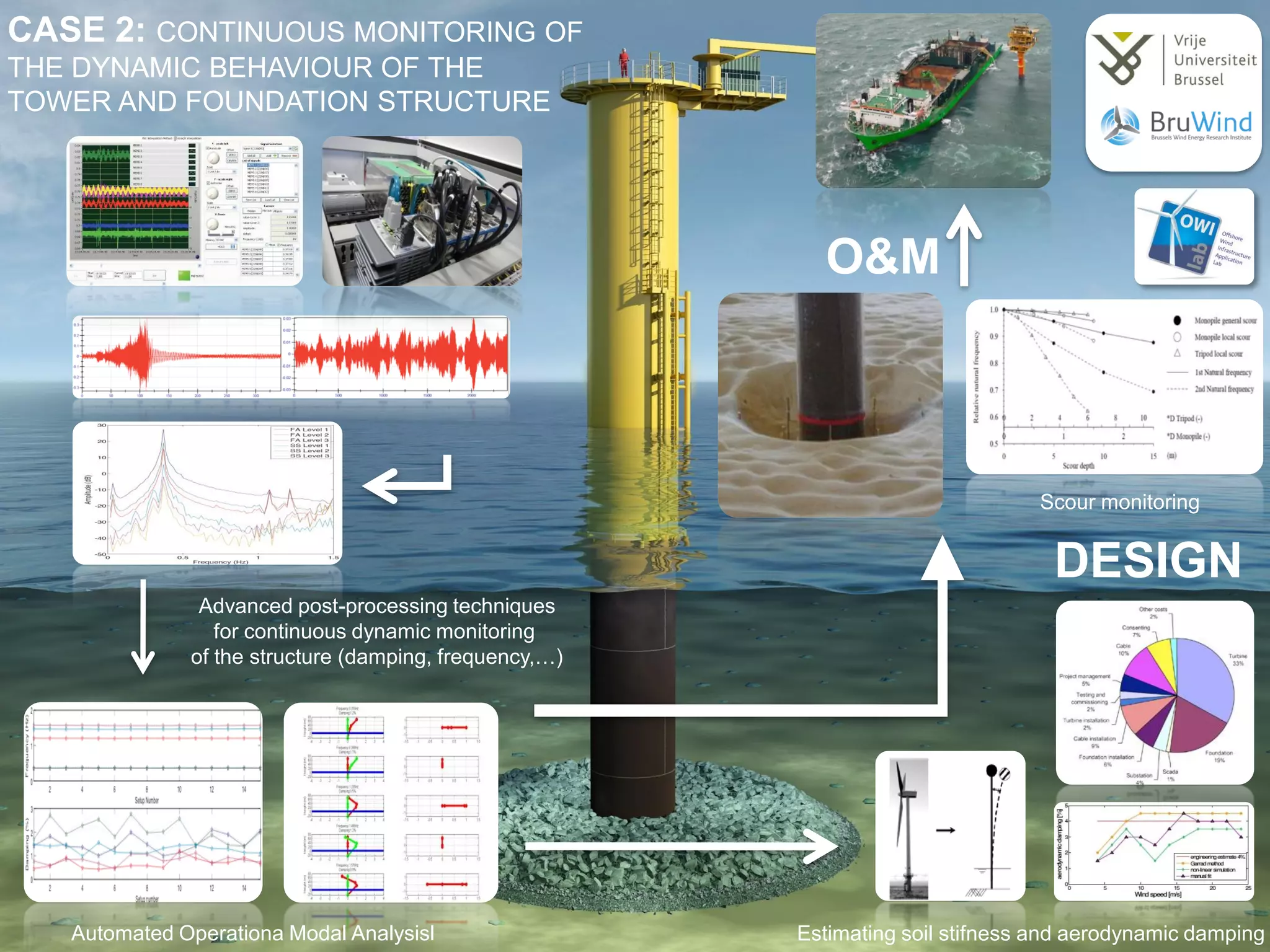

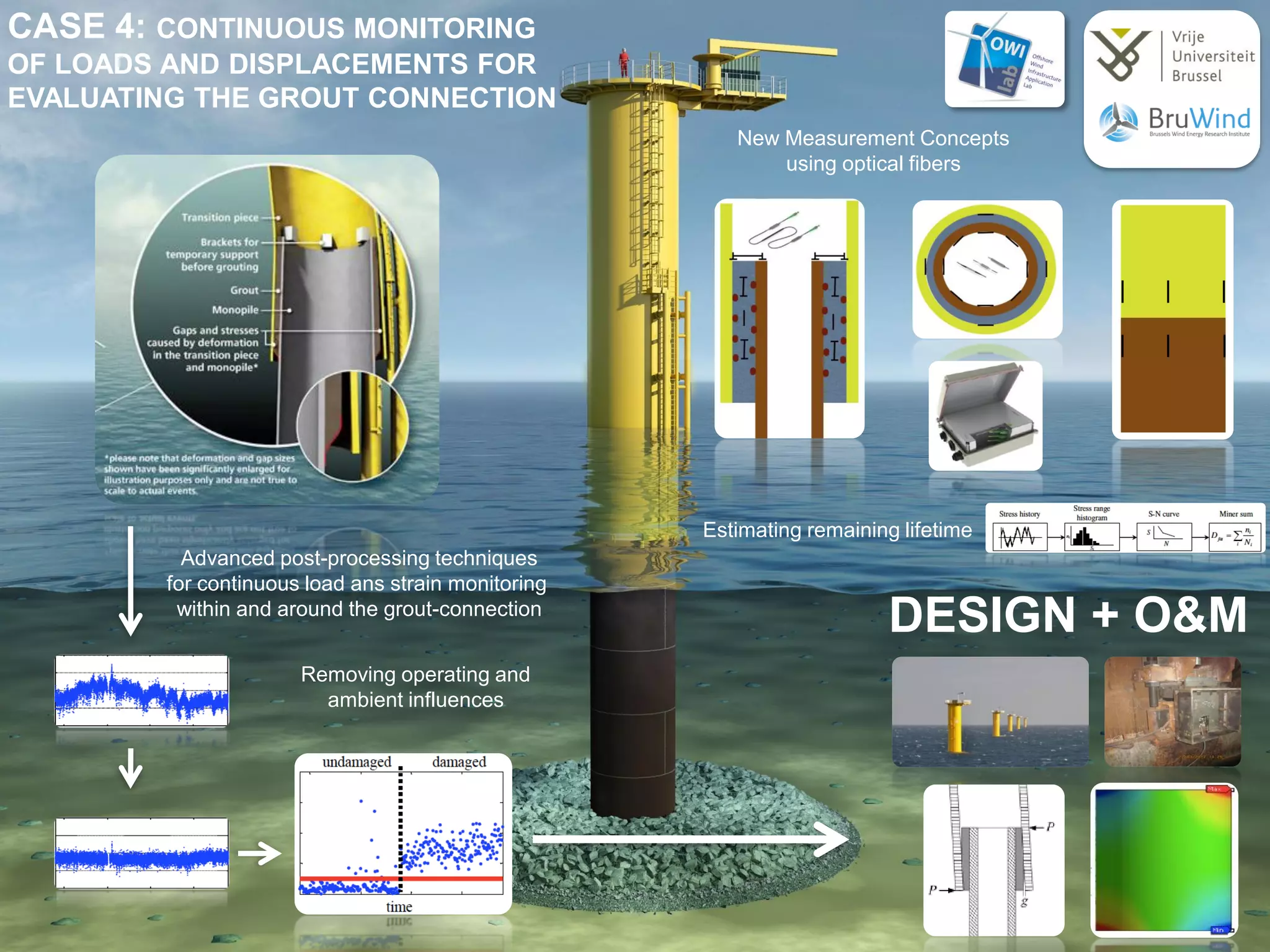

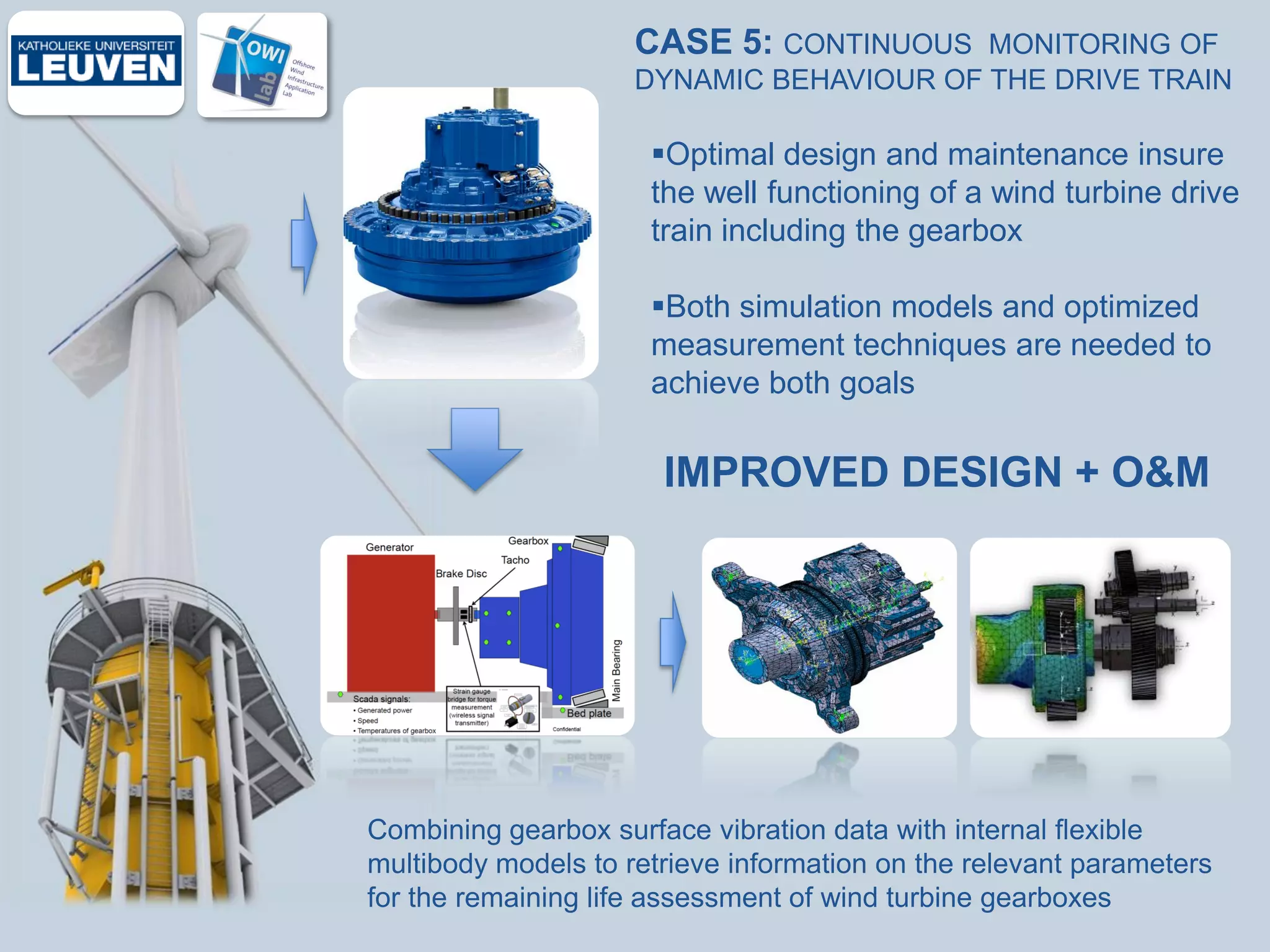

The document discusses an OWI-Lab monitoring infrastructure that focuses on continuous monitoring of offshore wind turbines. It describes 5 cases of monitoring key components: 1) vibration of the transition piece, tower, and nacelle, 2) dynamic behavior of the tower and foundation, 3) corrosion of the foundation structure, 4) loads and displacements of grout connections, and 5) dynamic behavior of the drive train. The goal is to use monitoring data and advanced modeling to improve both design, by reducing costs, and operations and maintenance strategies, by reducing expenses.