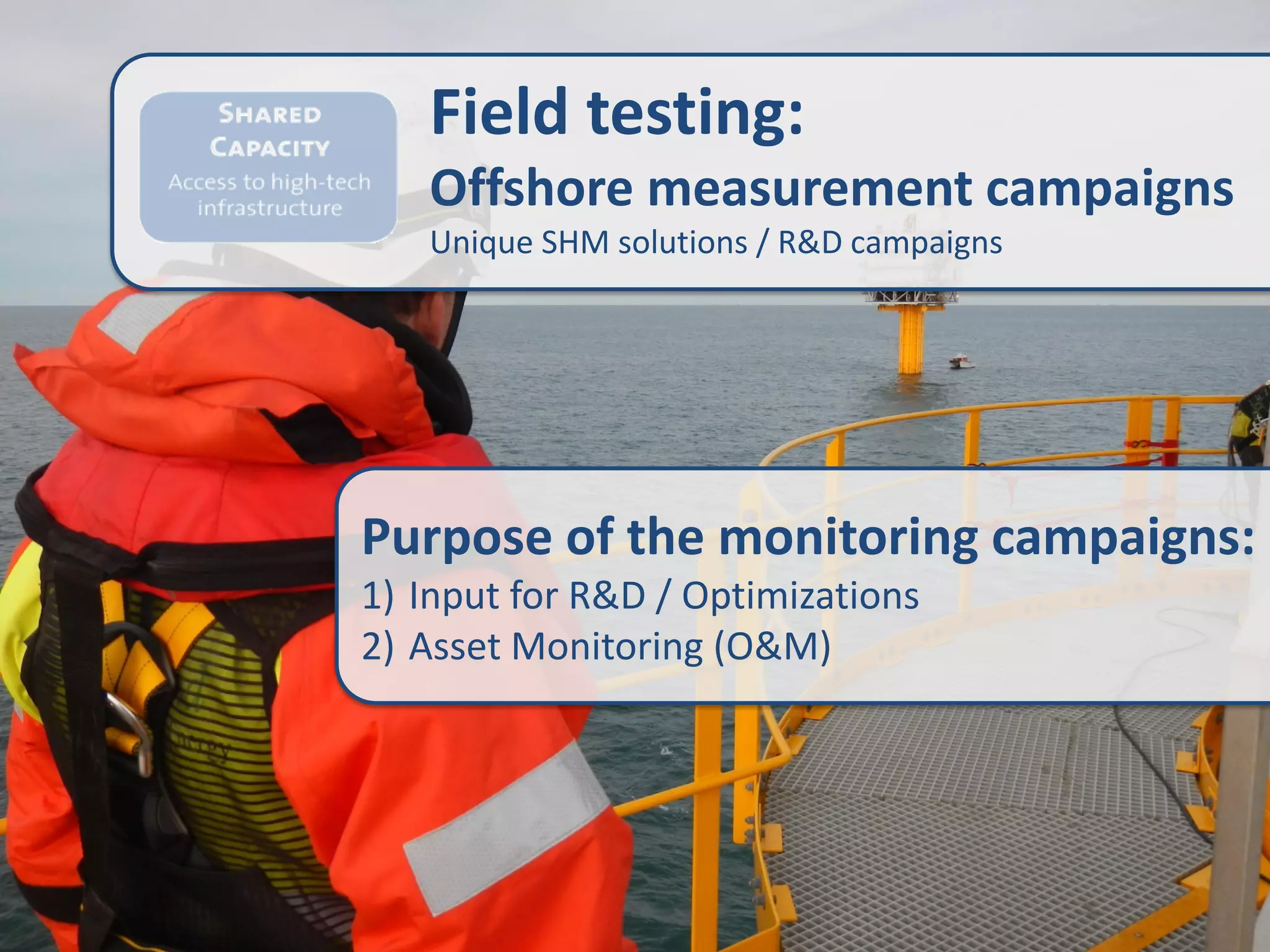

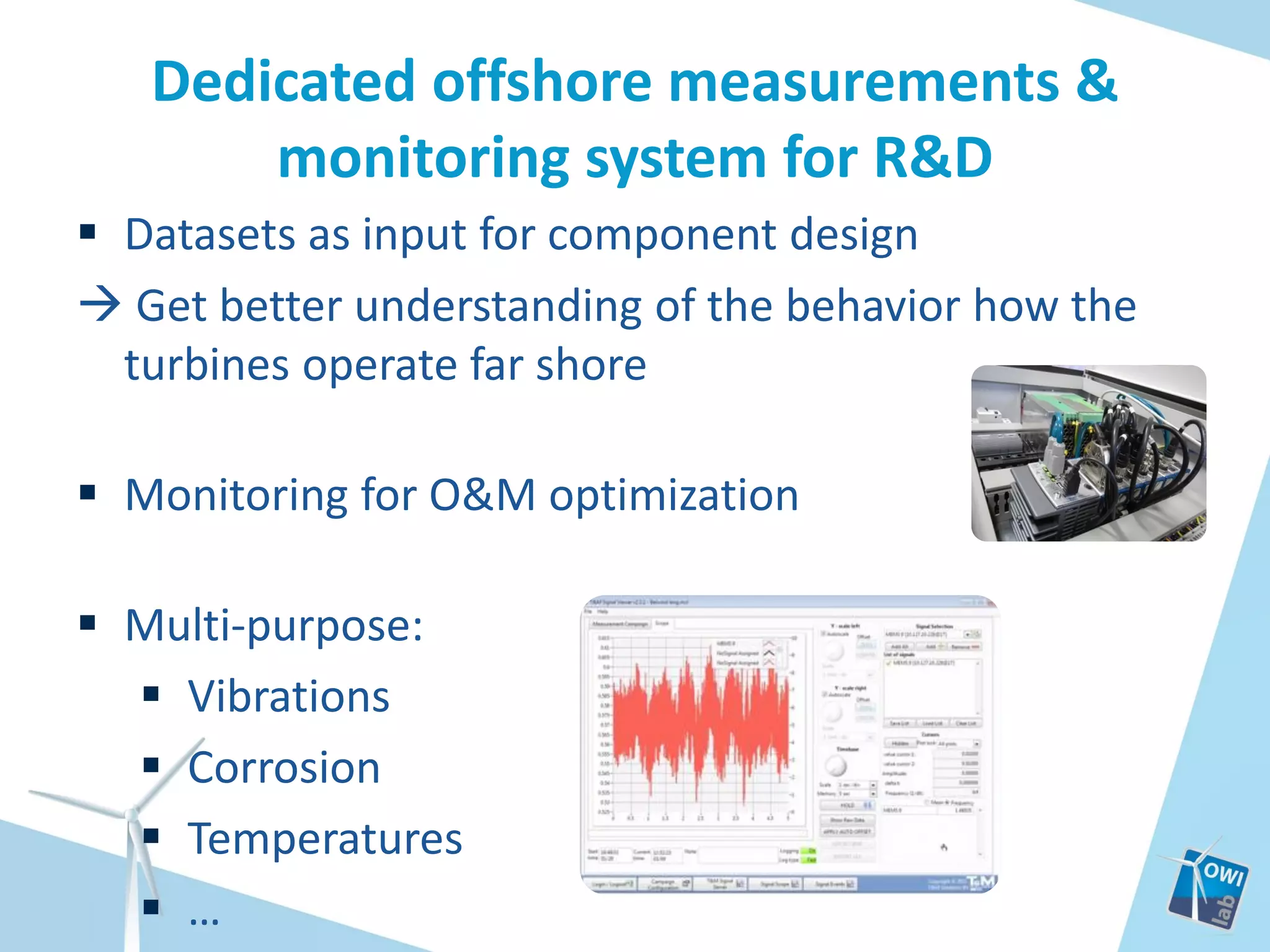

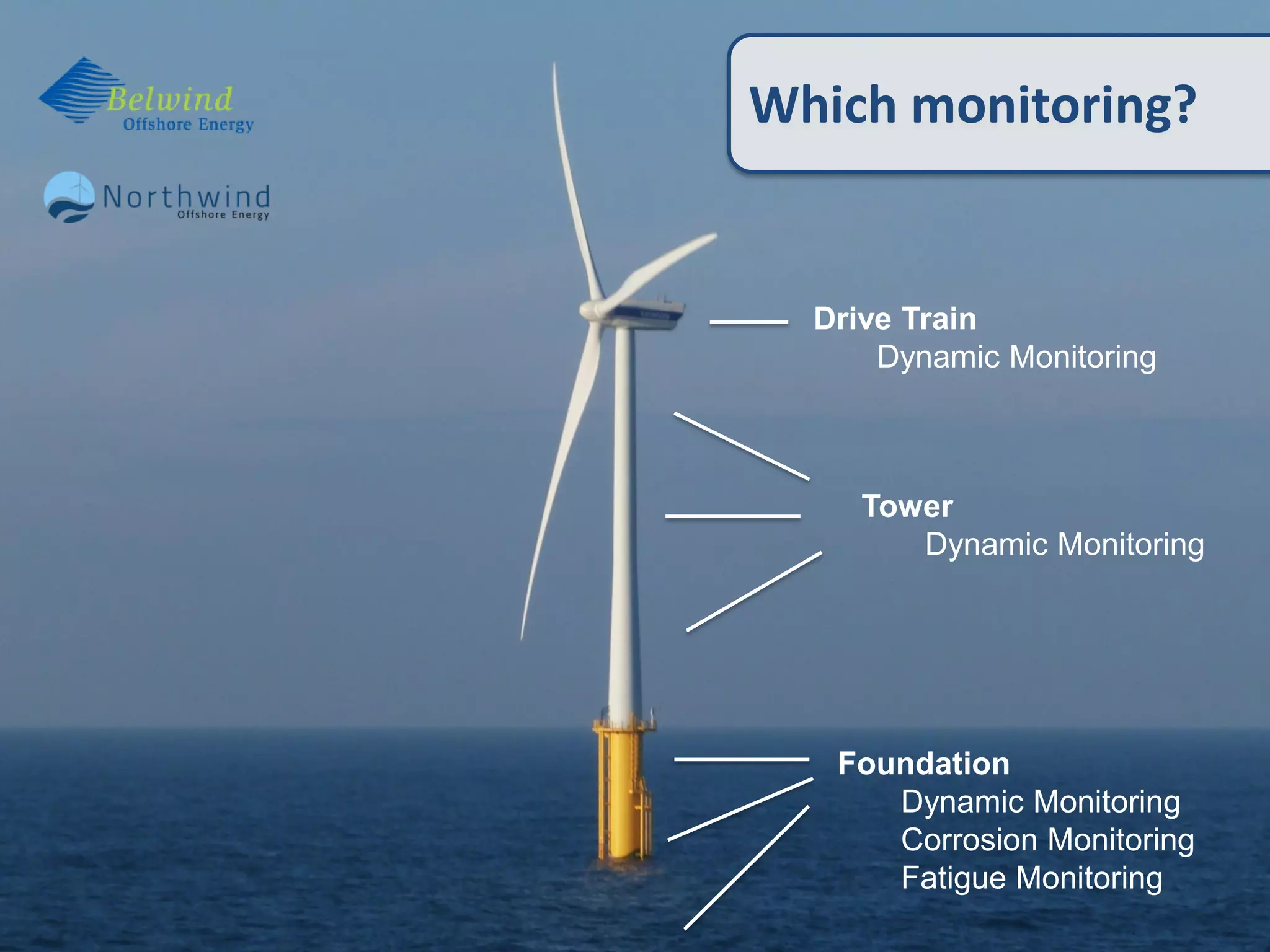

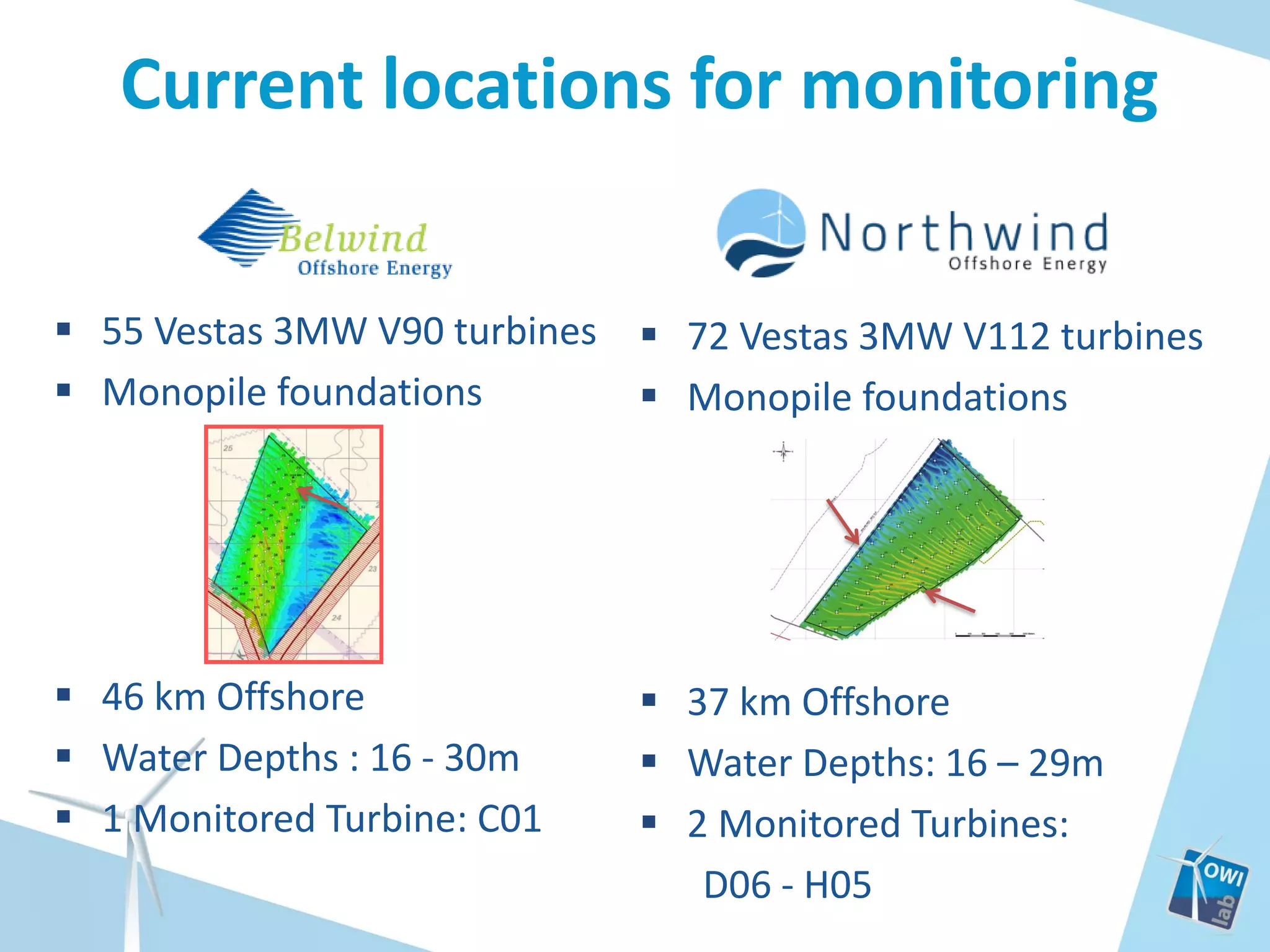

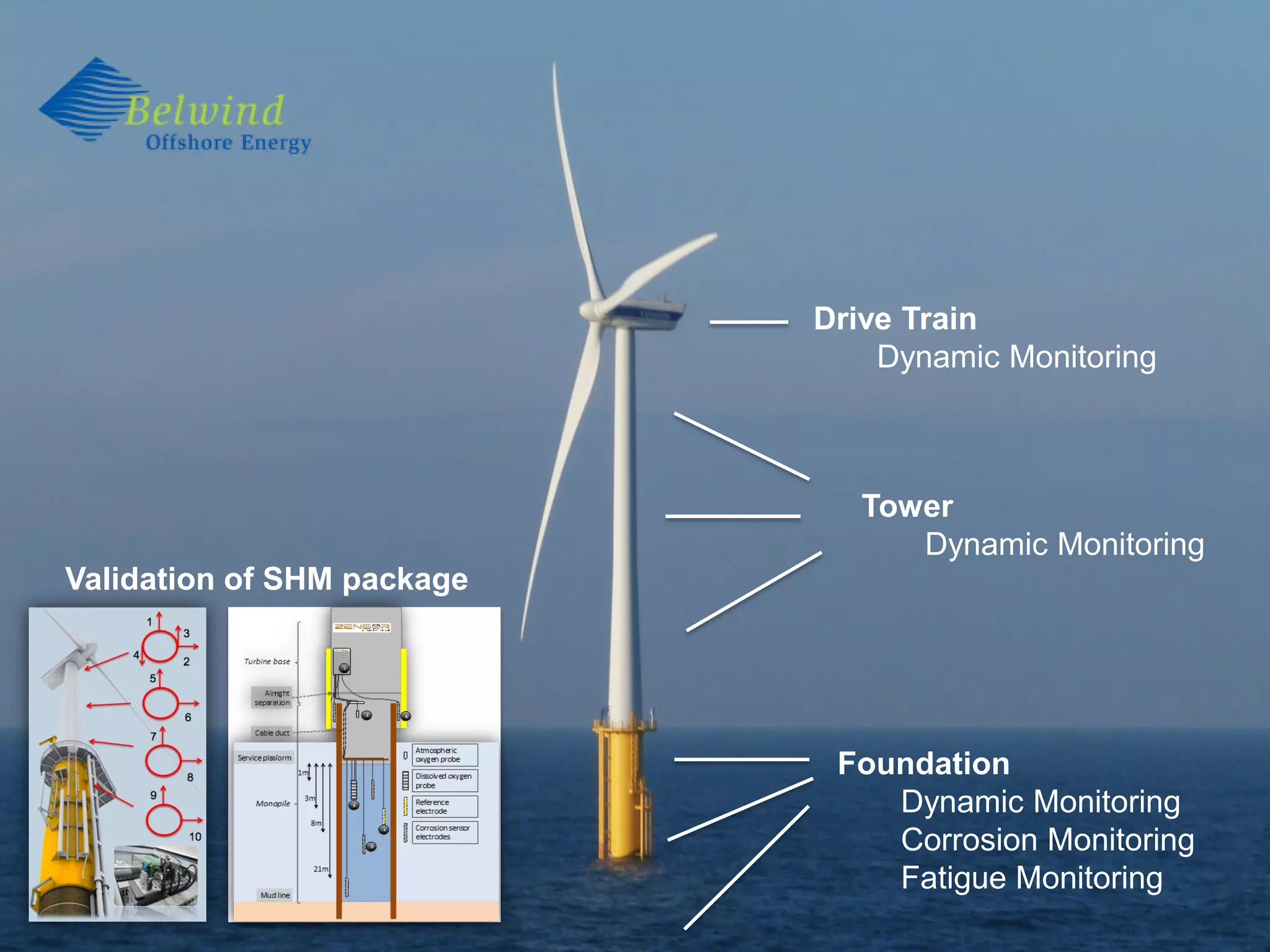

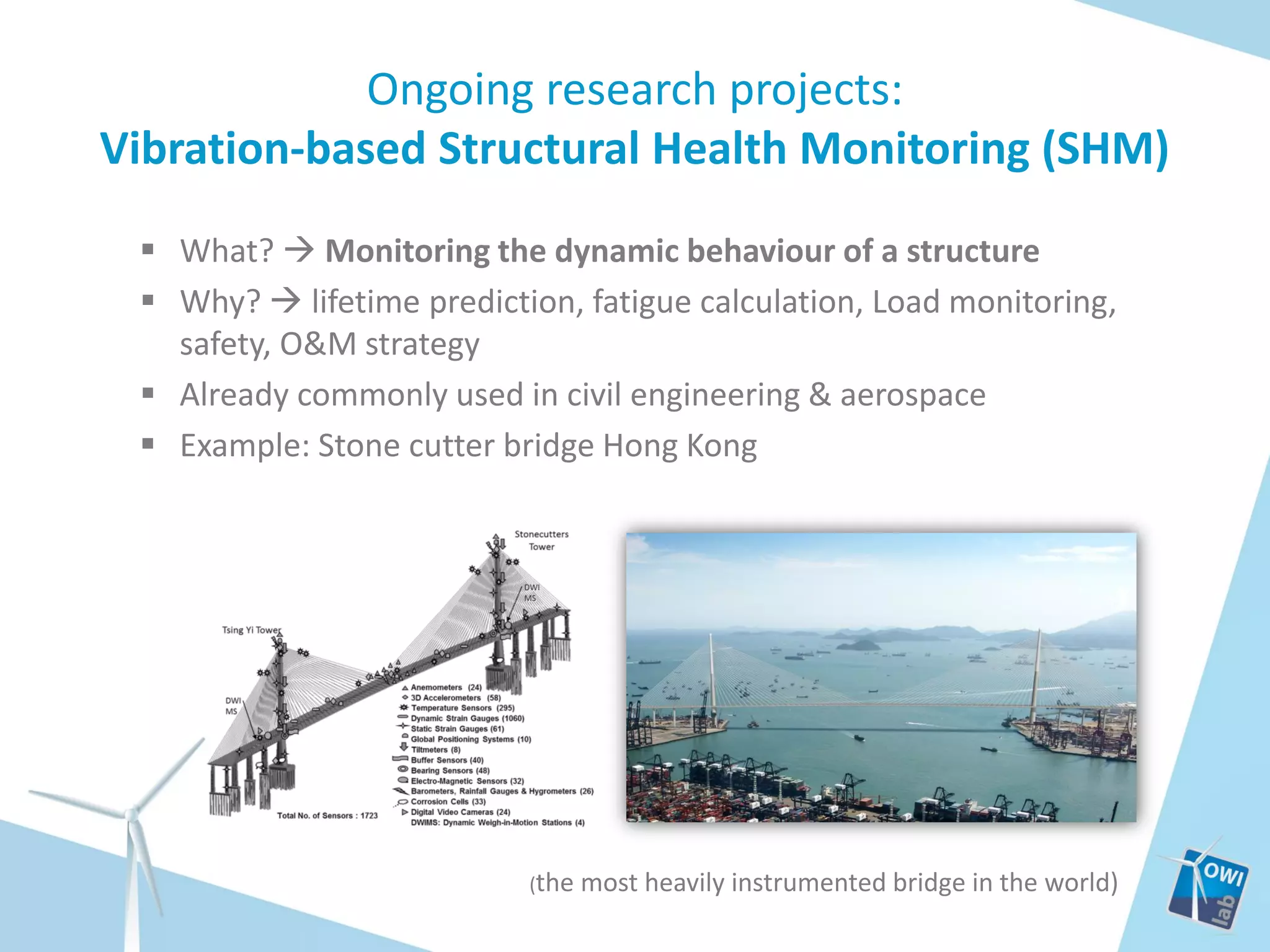

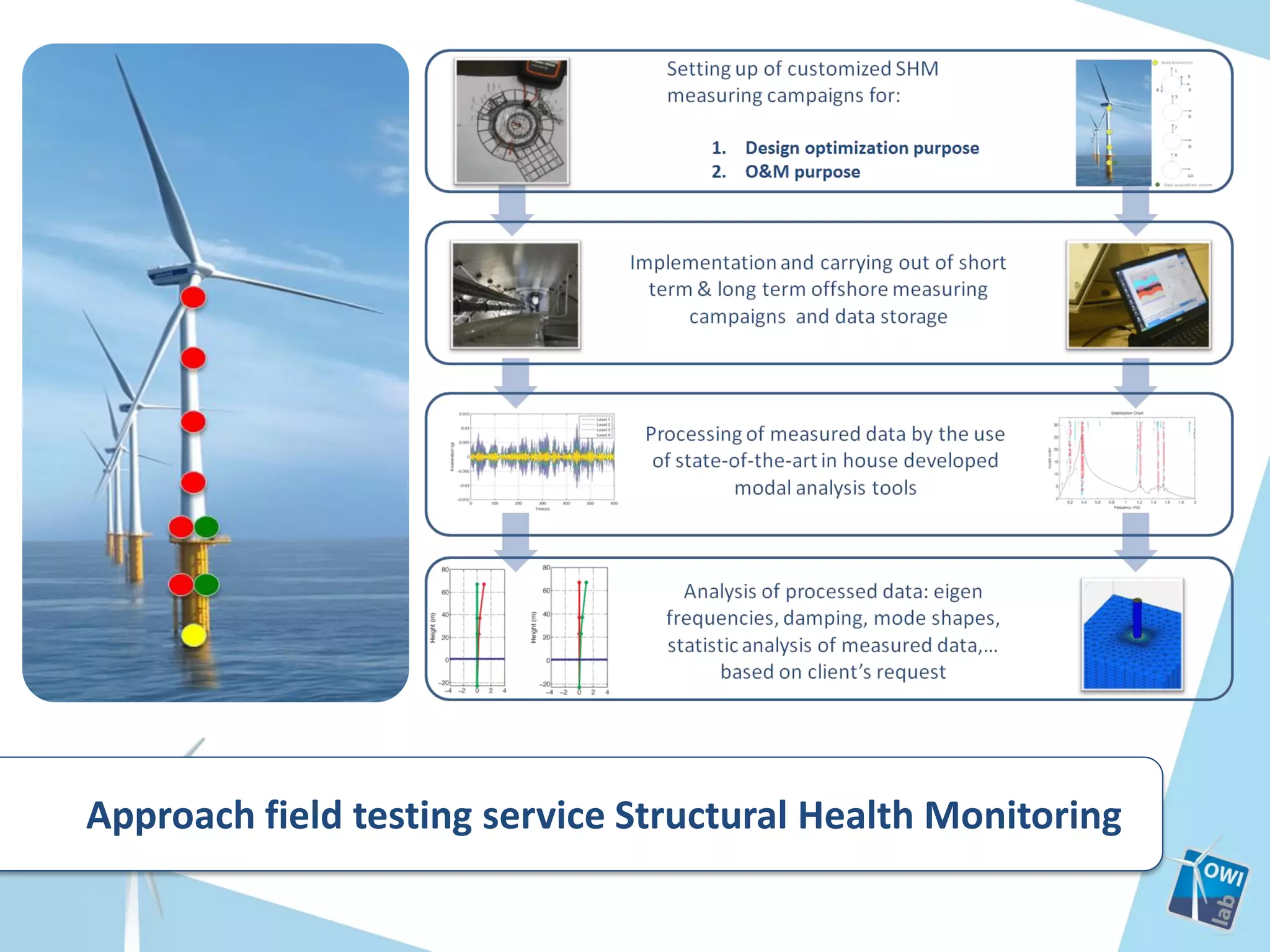

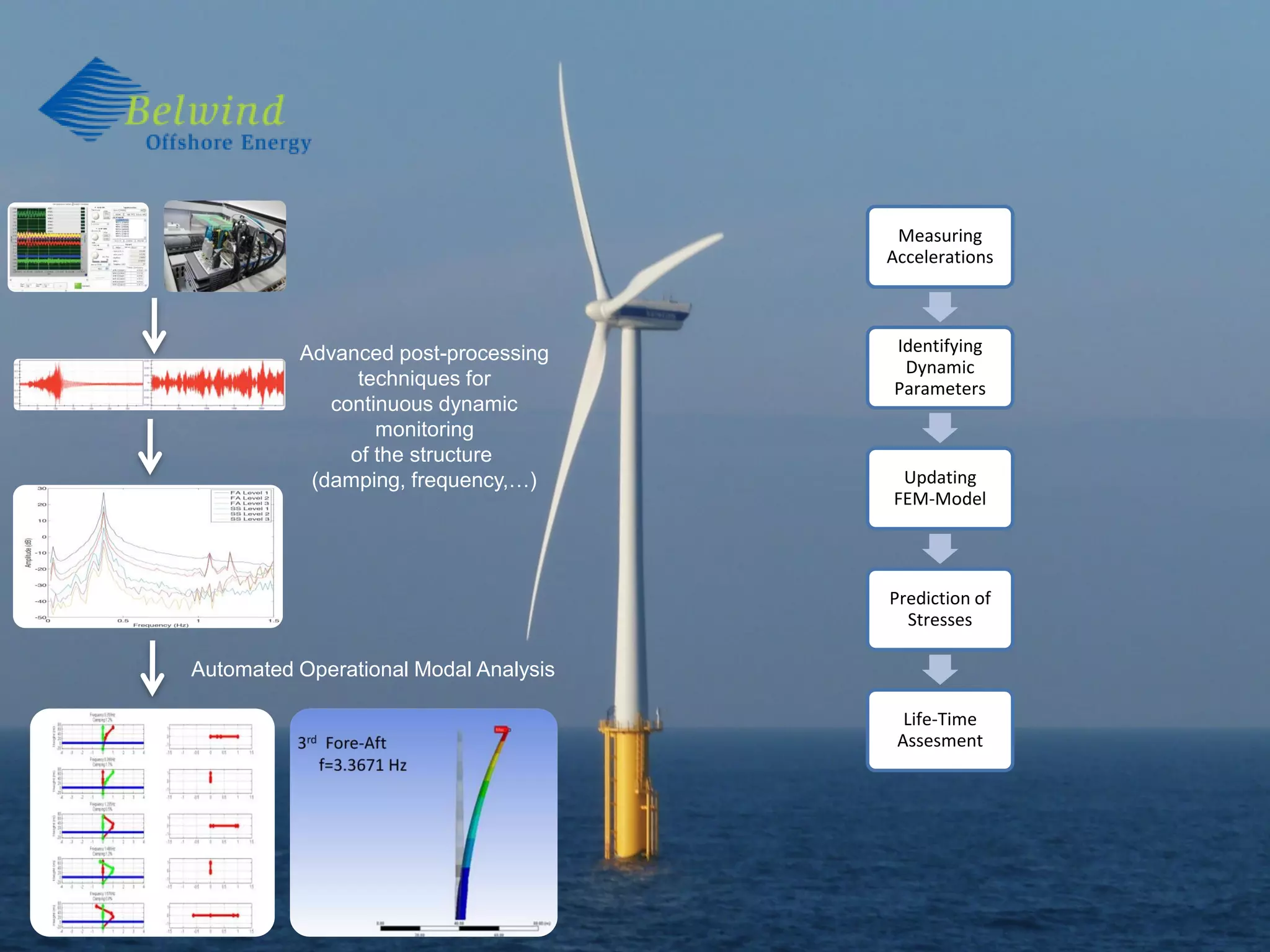

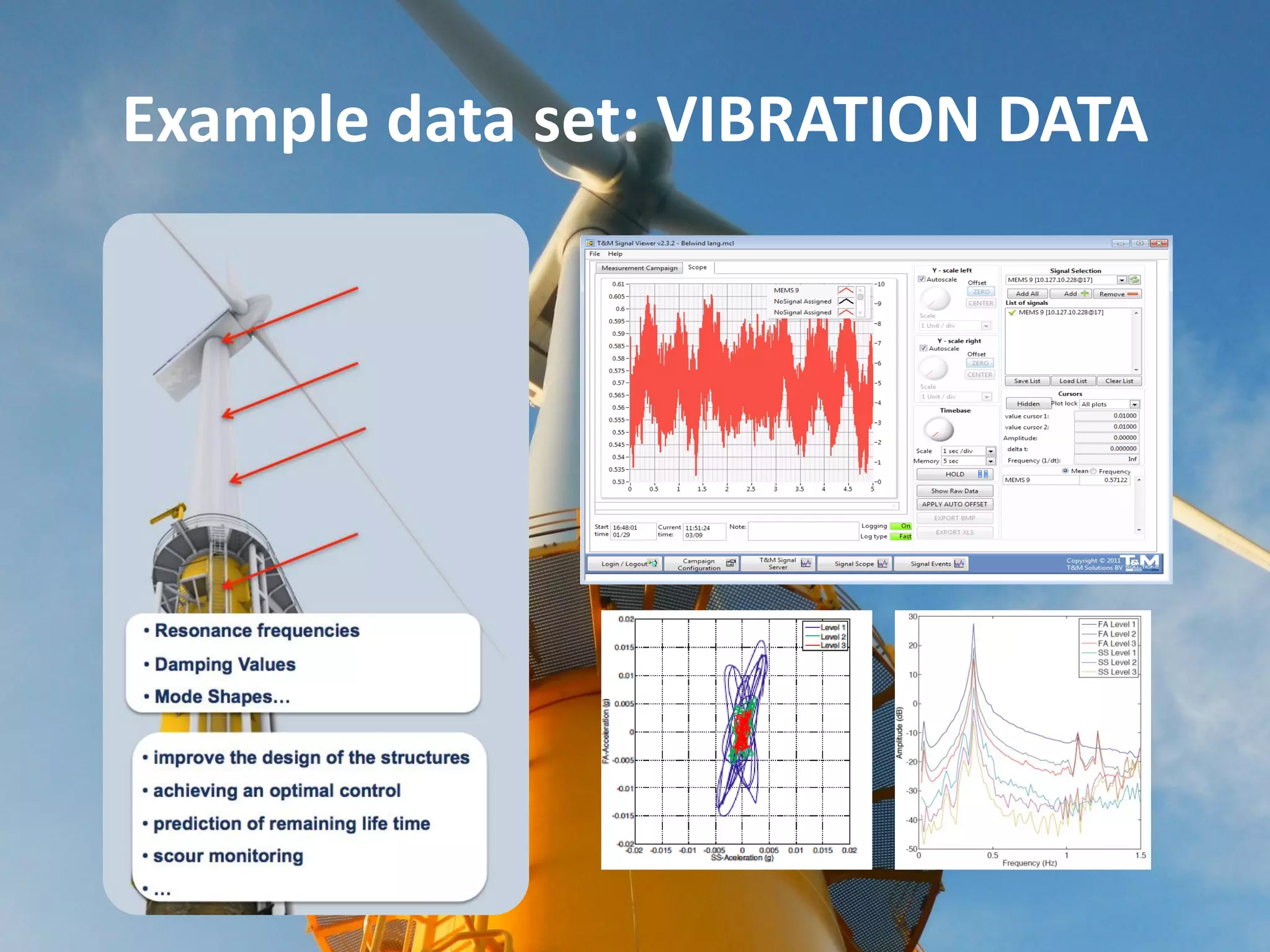

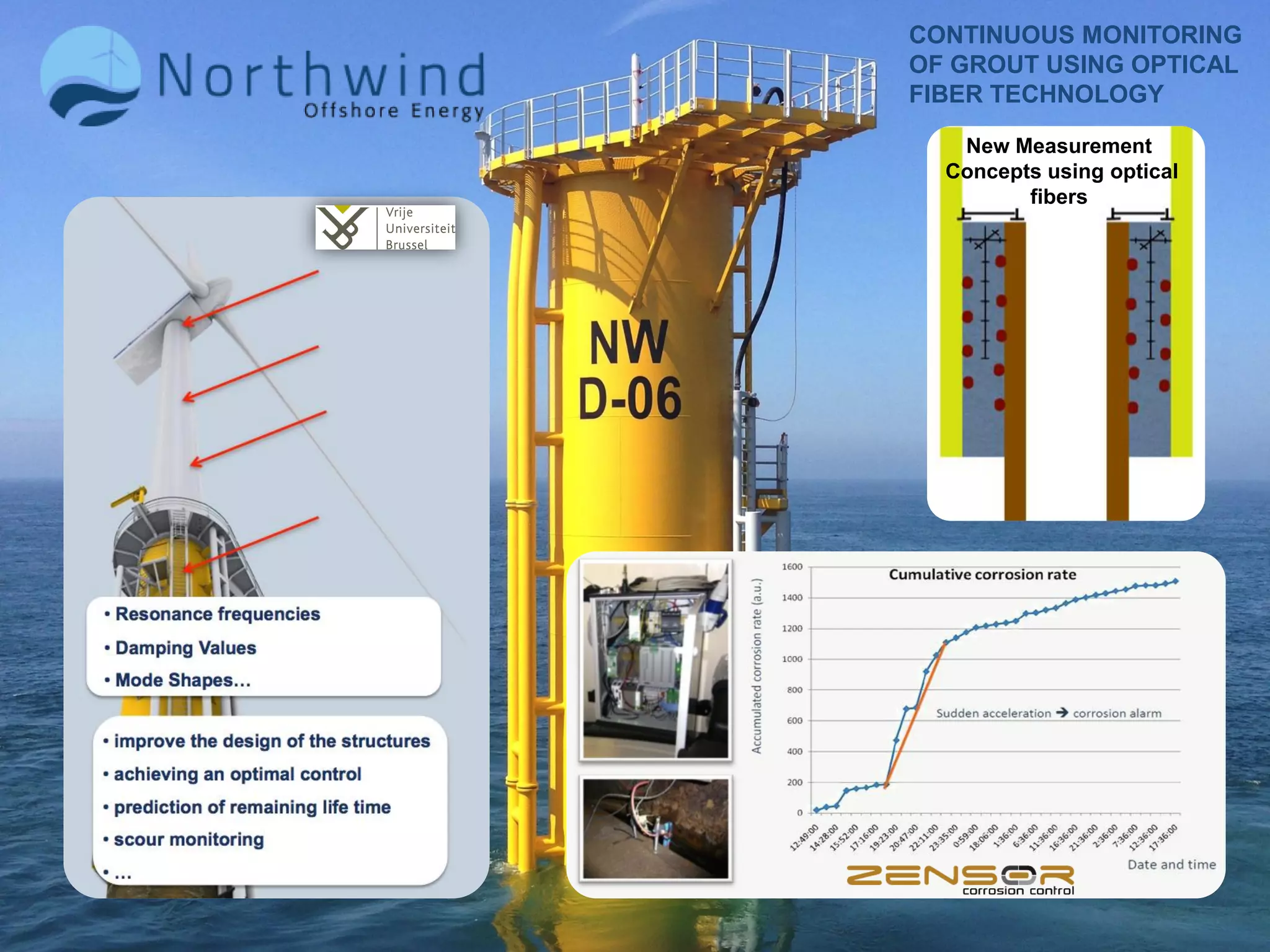

The Offshore Wind Infrastructure Application Lab (OWI-Lab) is a Flemish-funded R&D initiative that aims to increase the reliability and efficiency of offshore wind farms. It invests over 5.5 million euros in test and monitoring infrastructure to support research and development across the offshore wind industry value chain. OWI-Lab provides laboratory and field testing services, including unique offshore measurement campaigns to support both R&D projects and asset monitoring for operations and maintenance optimization. Current monitoring focuses on drive train dynamics, tower dynamics, foundation dynamics and corrosion, and data is collected from two offshore wind farms to support research projects.