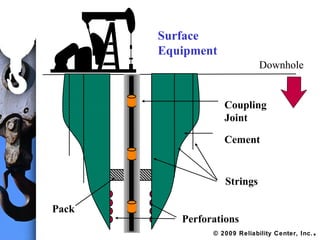

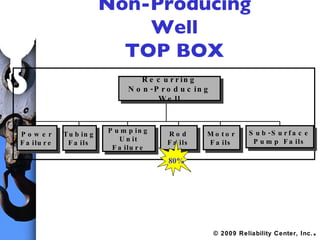

The document presents a root cause analysis of non-producing oil wells, detailing various failures and their associated costs. Key issues identified include equipment failures and operational challenges that lead to production interruptions. The analysis emphasizes the need for understanding mechanical and operational causes to improve reliability and reduce costs.