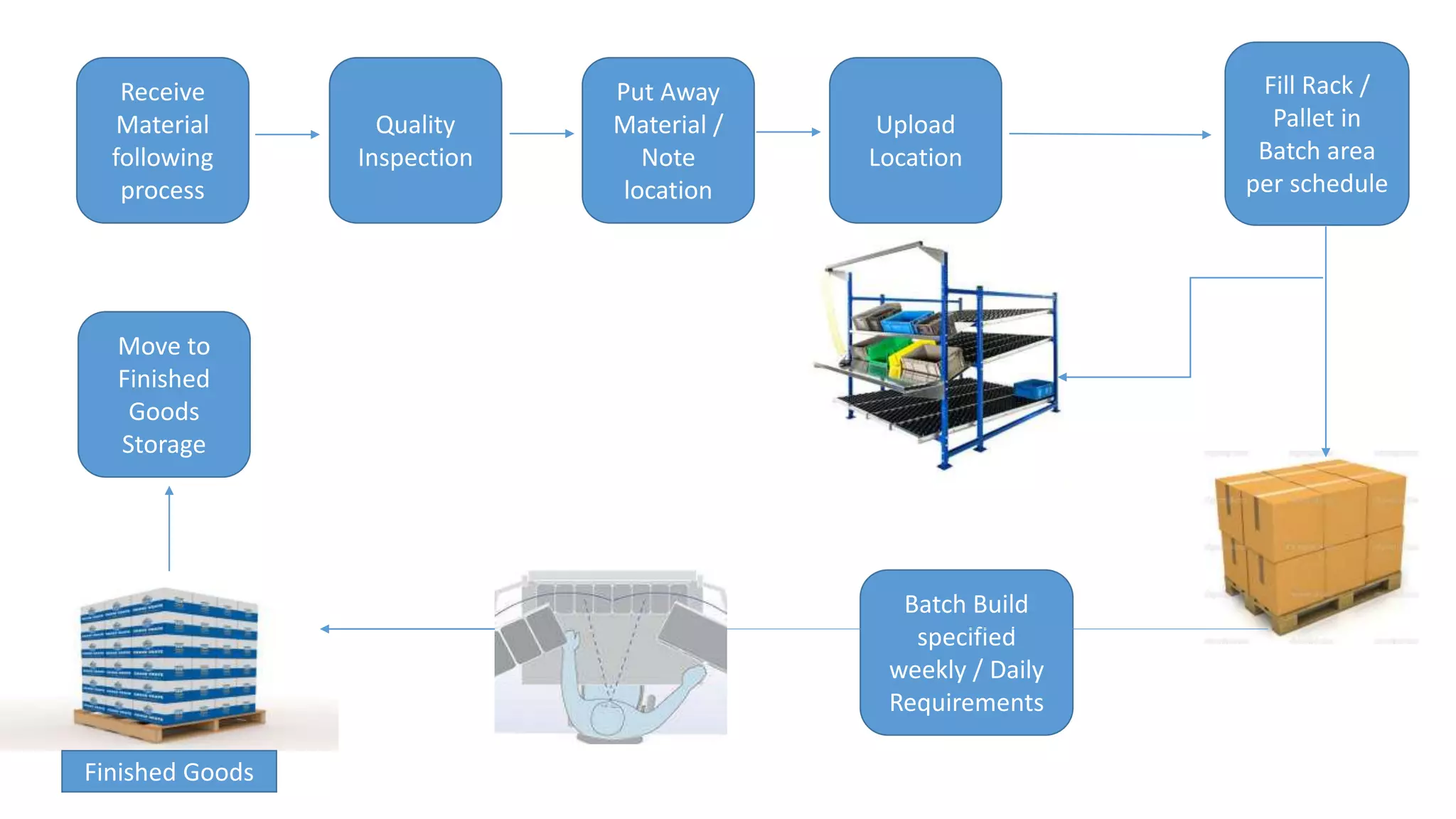

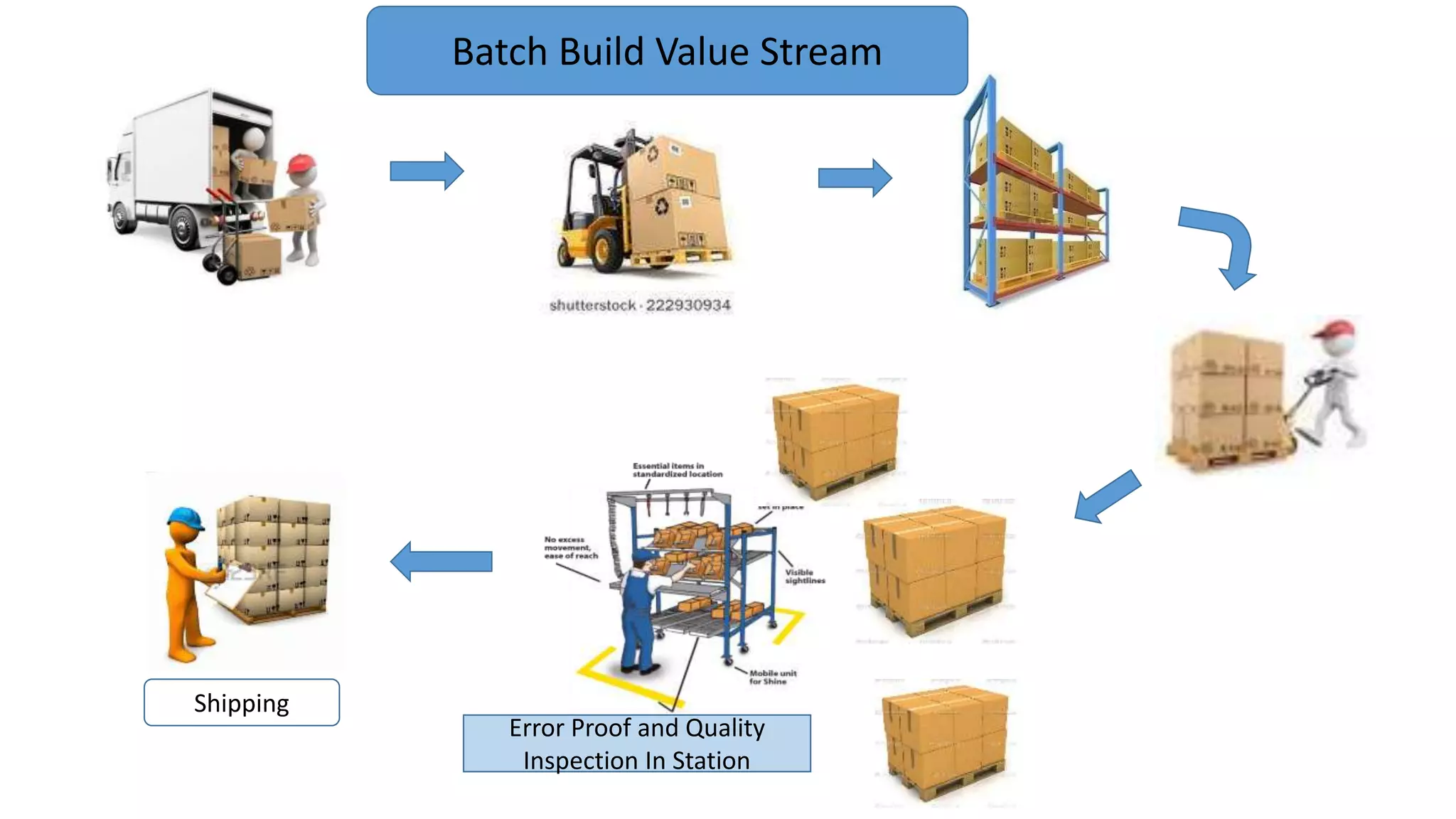

The document discusses implementing a batch build process for the 304 Family of Cameras to improve productivity and reduce costs. Batch building this high-volume product family would eliminate waste from the traditional pull-pick method. A work station would be created in production to build and test large quantities of cameras in batches due to the family requiring few components. Batch building would meet demand and offer the greatest cost savings compared to the current process. A proposed value stream map outlines the batch build process from receiving materials to finished goods storage.