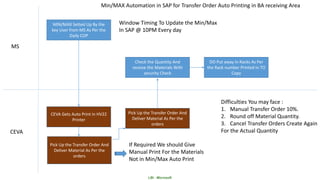

The document discusses automating material transfer orders in SAP based on daily minimum and maximum levels set by key users at Microsoft. It describes how CEVA receives automated printouts of transfer orders for materials within the min-max ranges to deliver to the BA receiving area. It notes some potential difficulties like manual transfer orders, round-off quantities, and canceling/recreating orders. It also states that min-max levels are updated in SAP each night at 10PM.