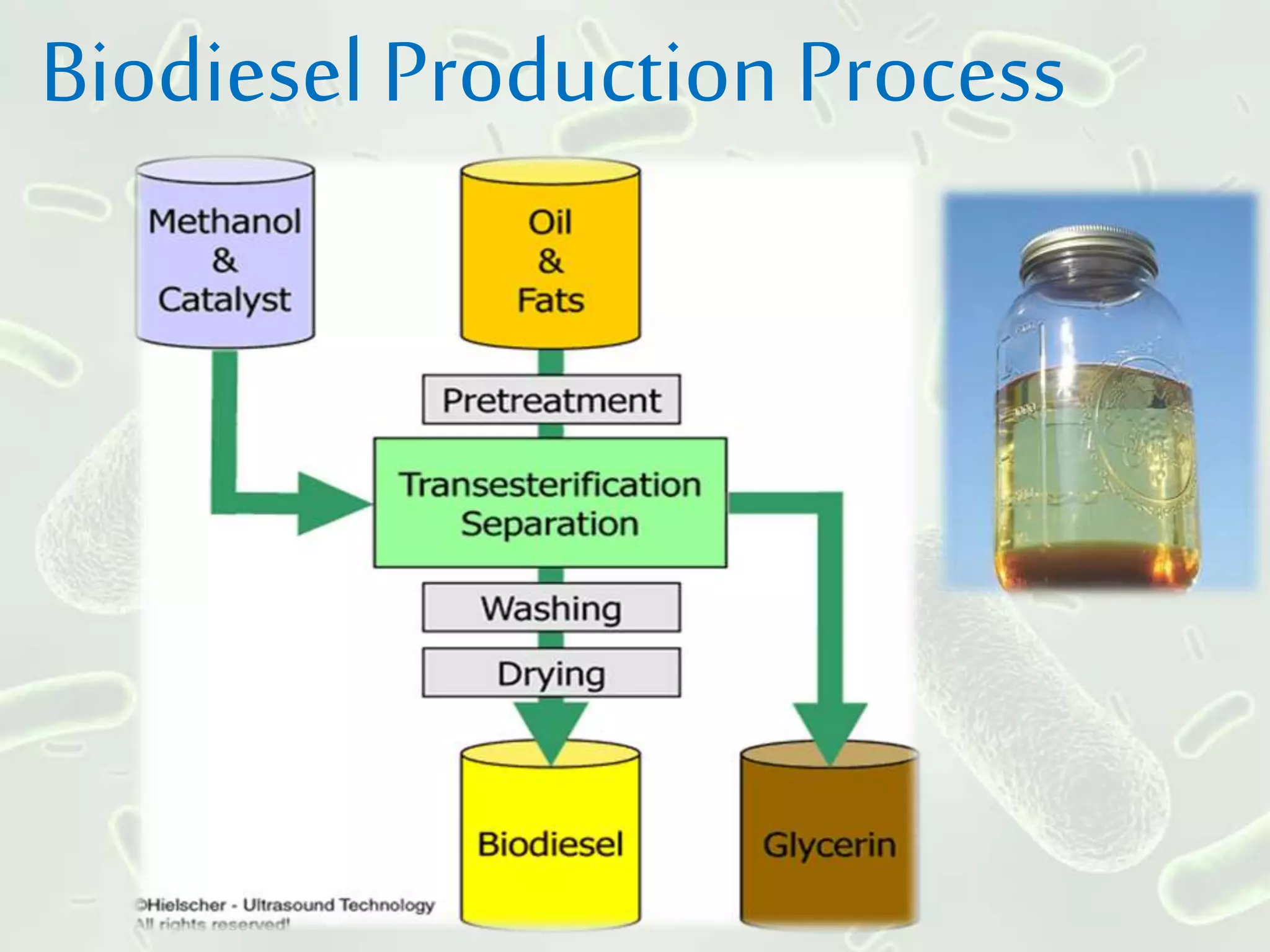

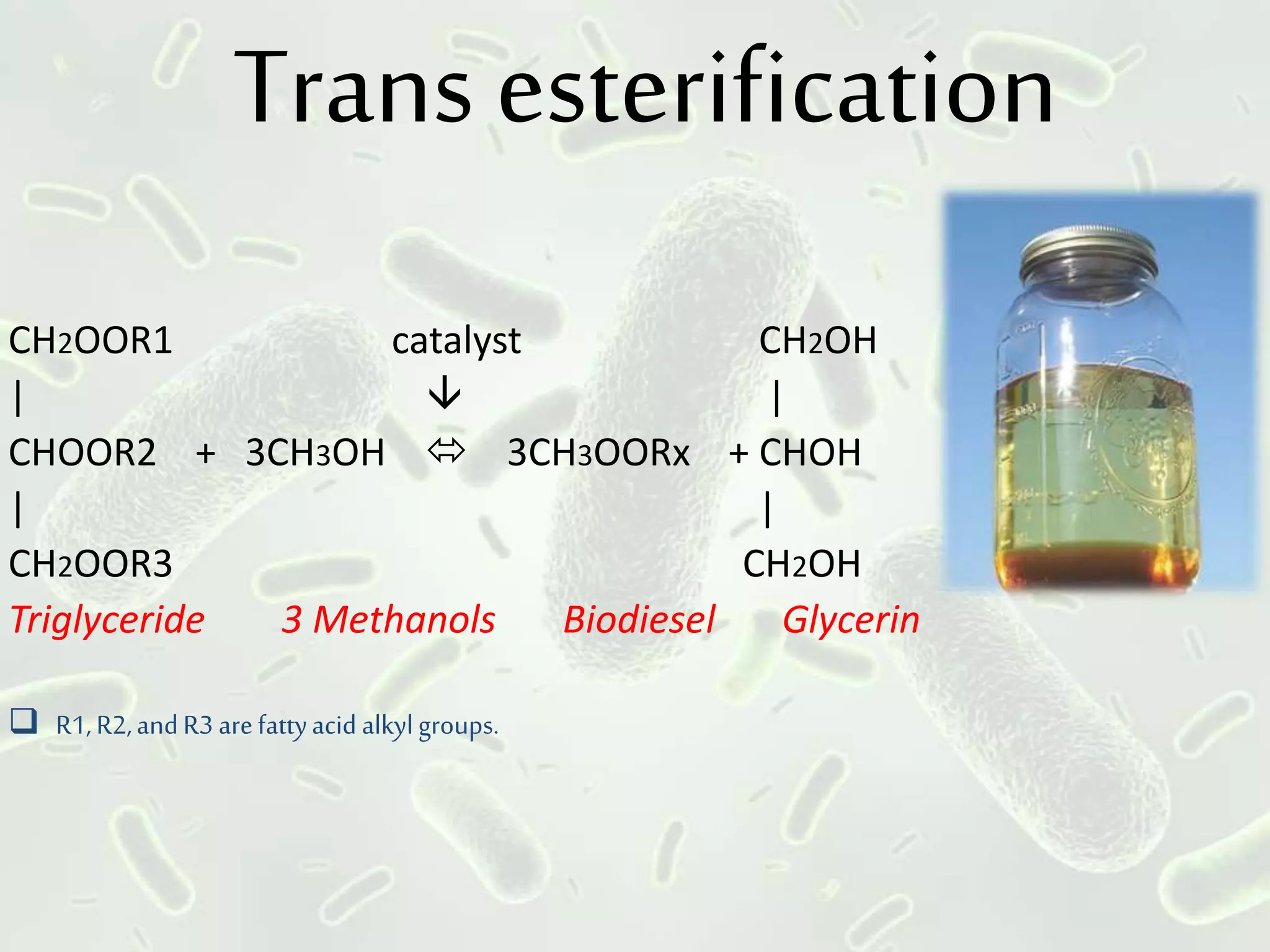

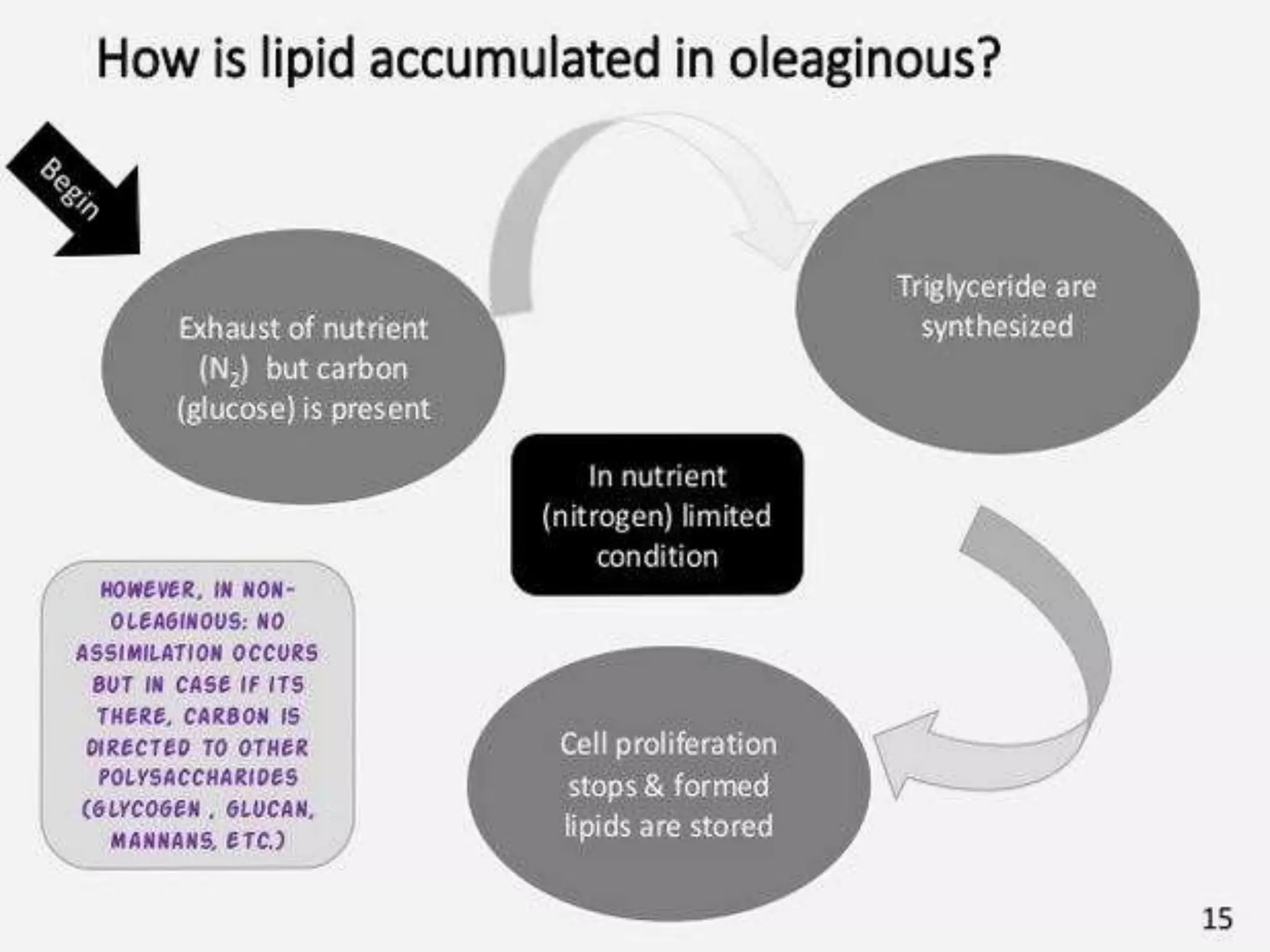

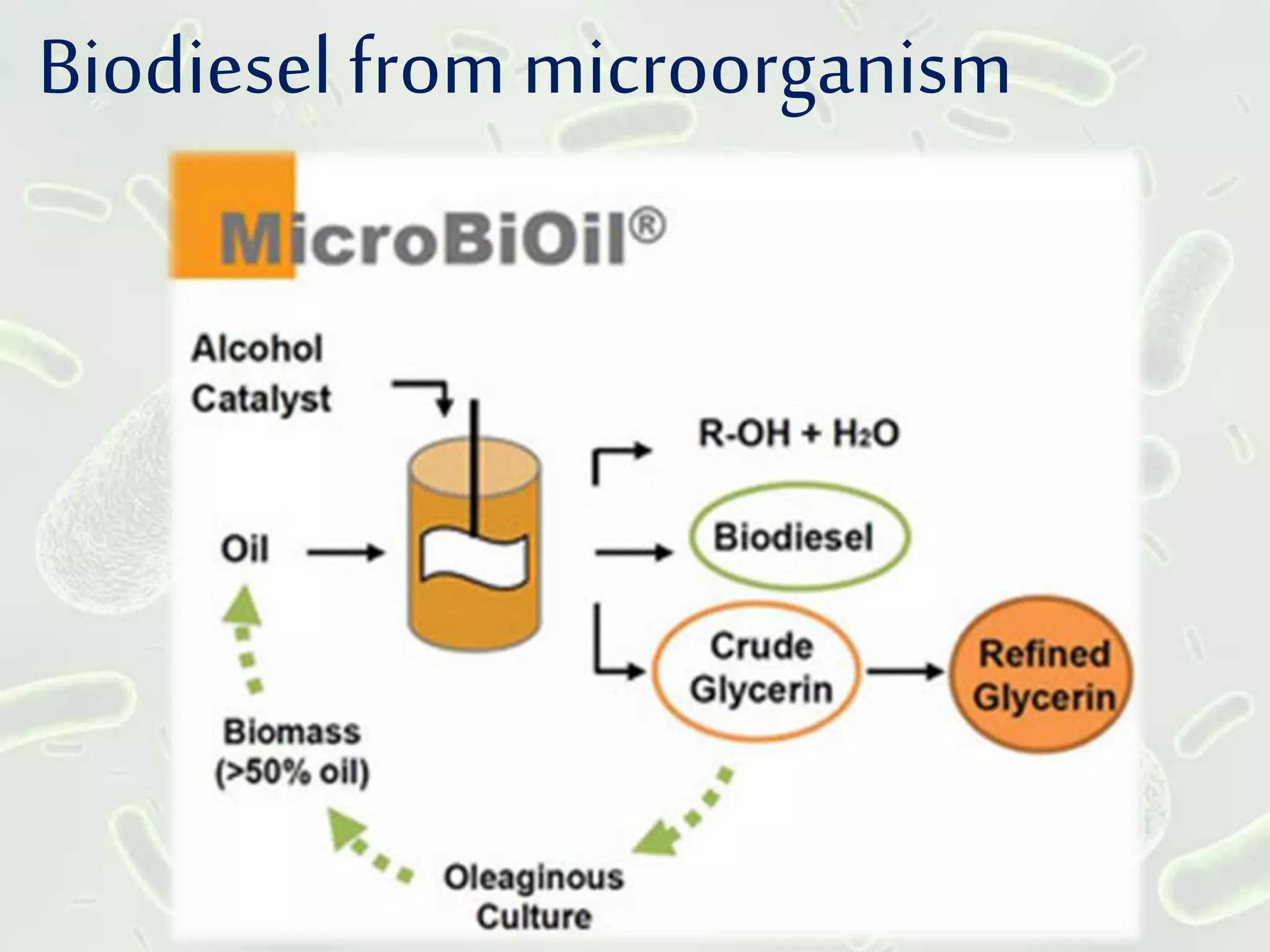

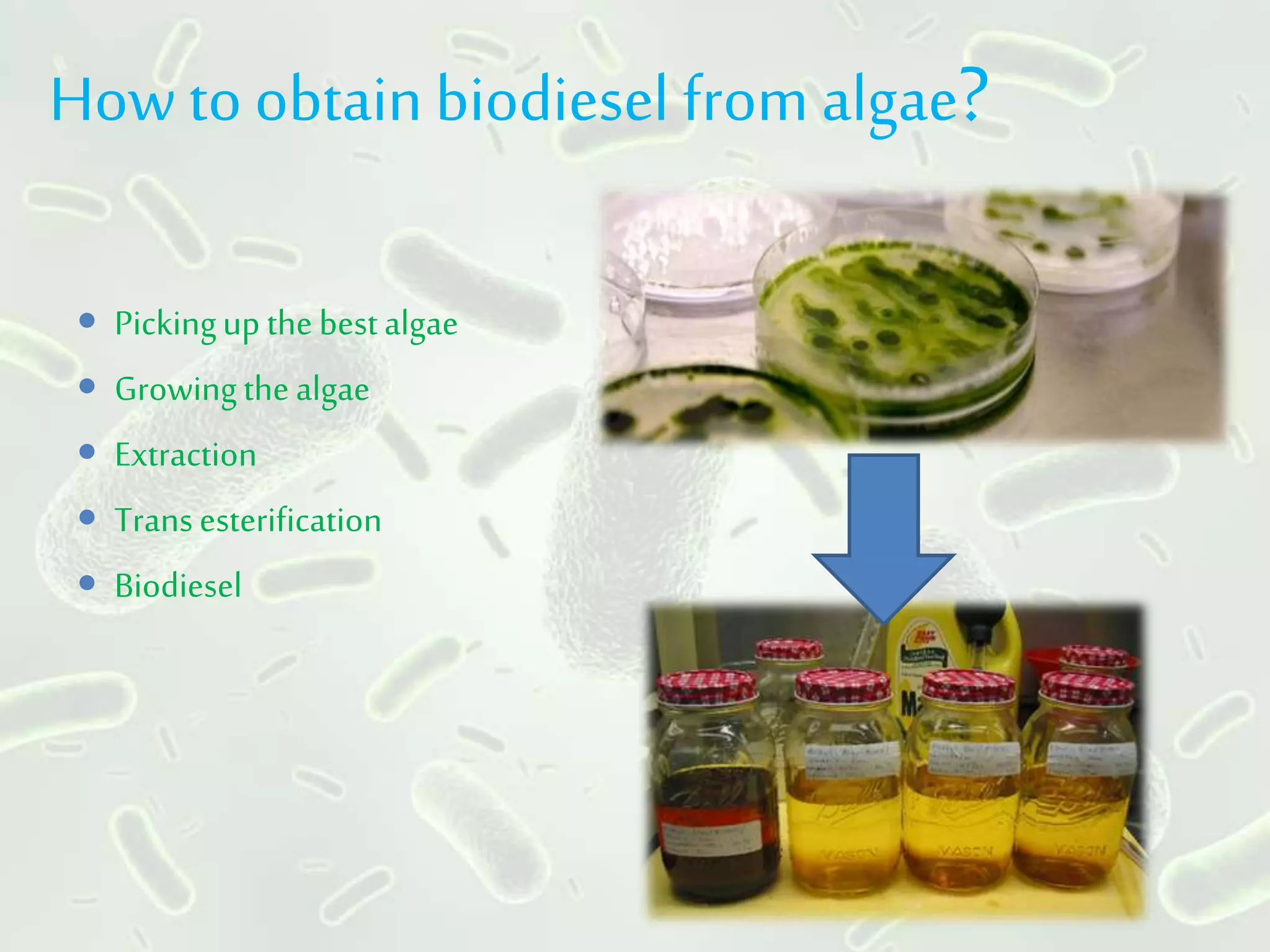

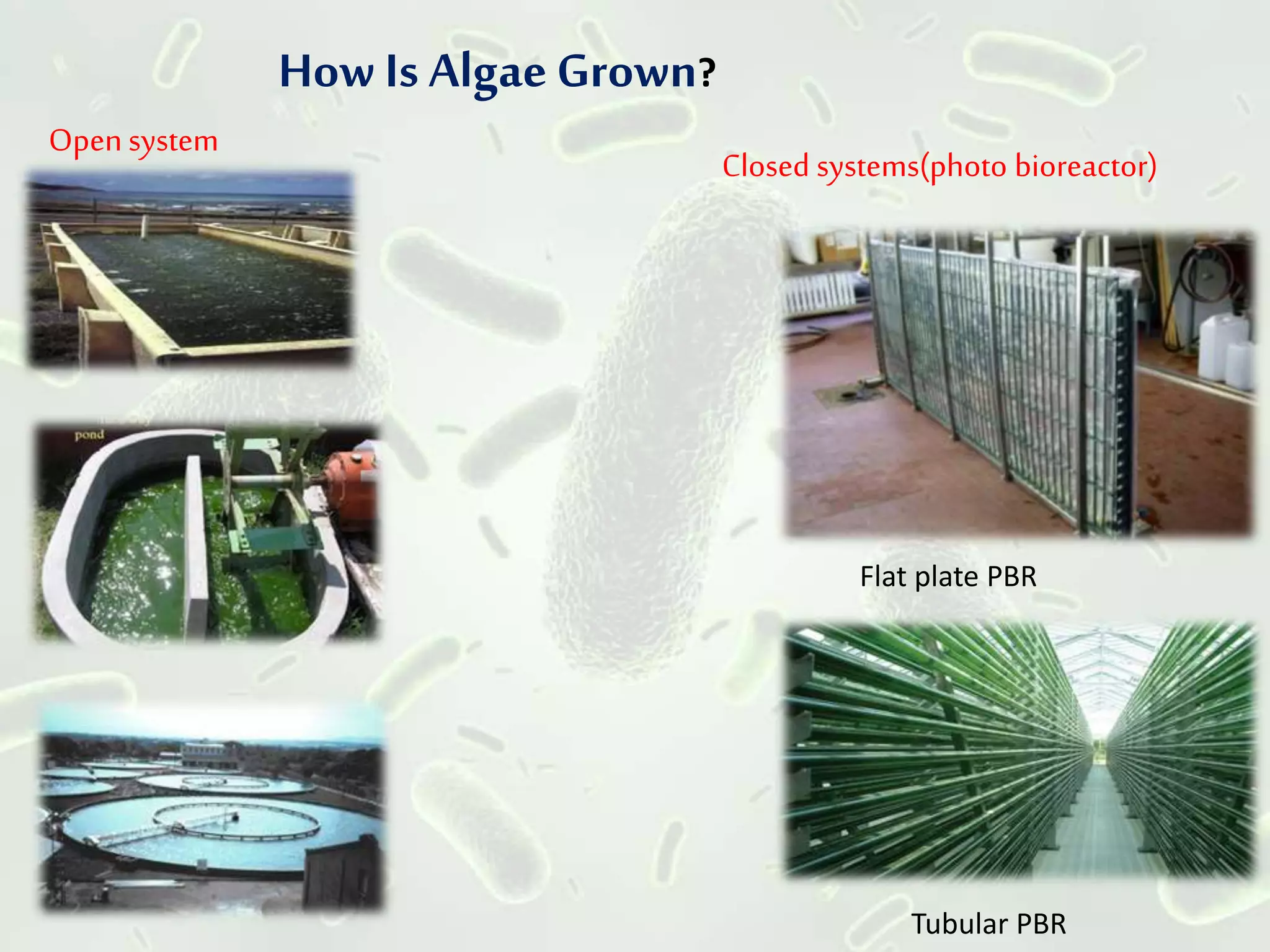

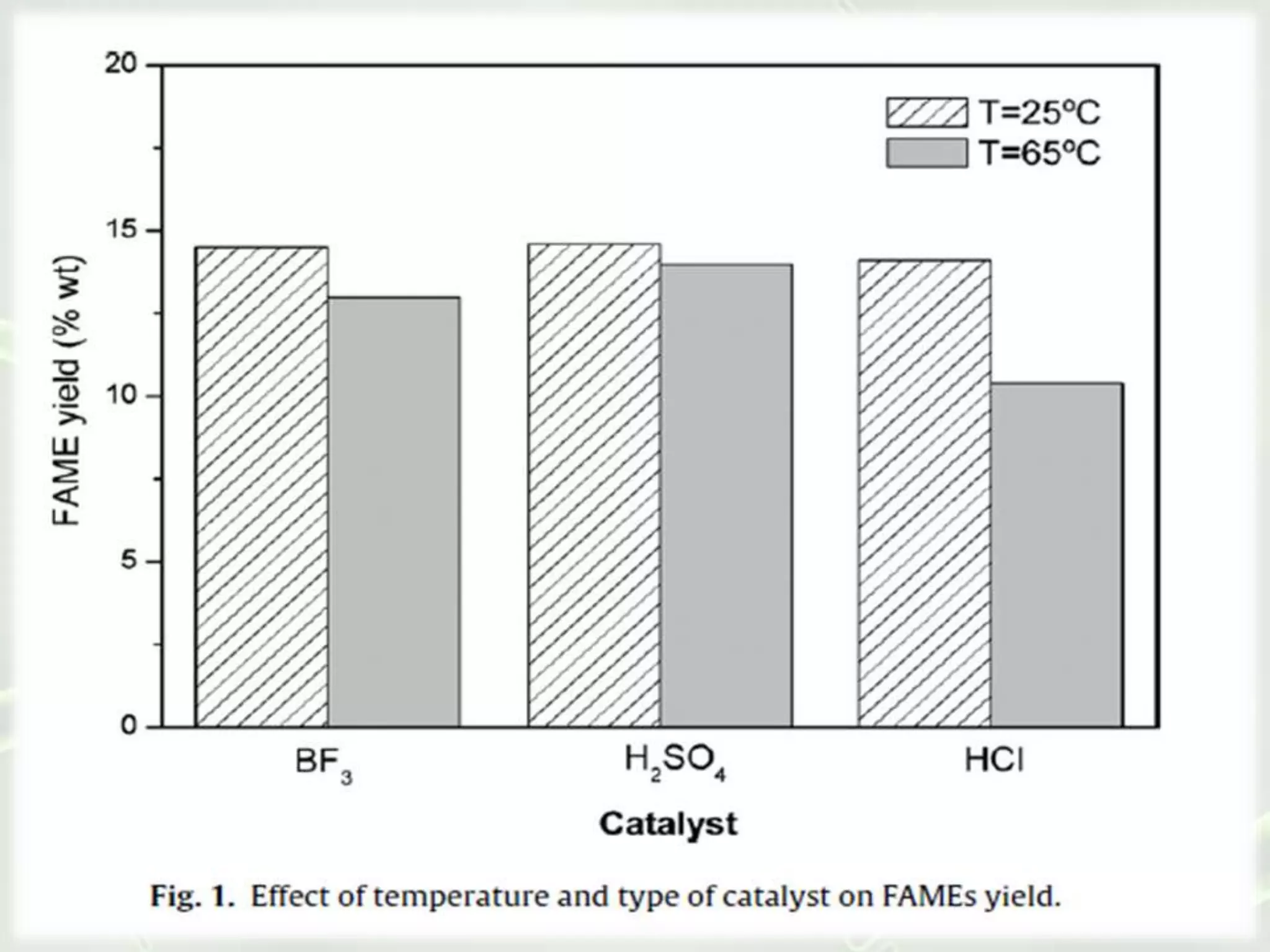

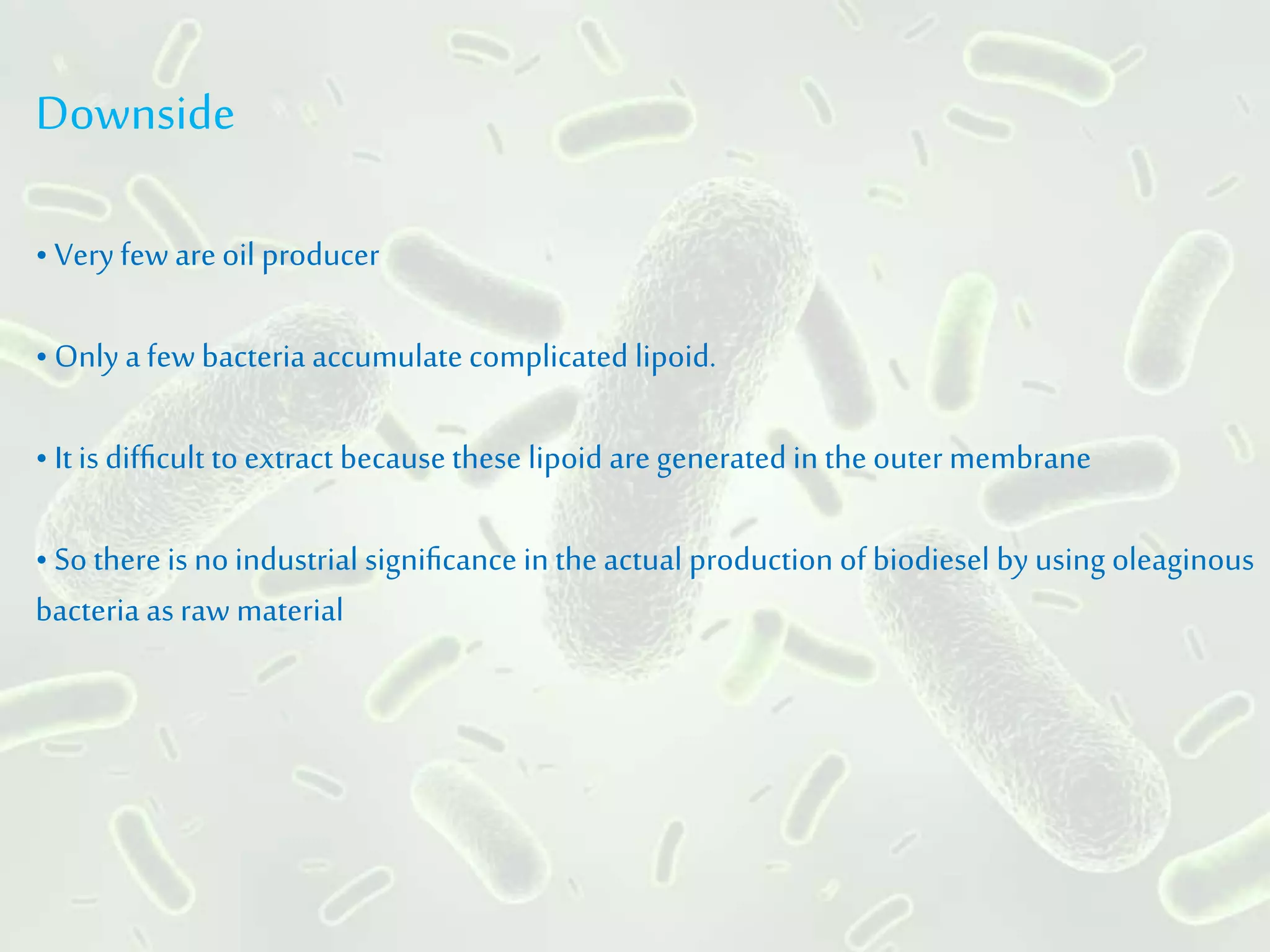

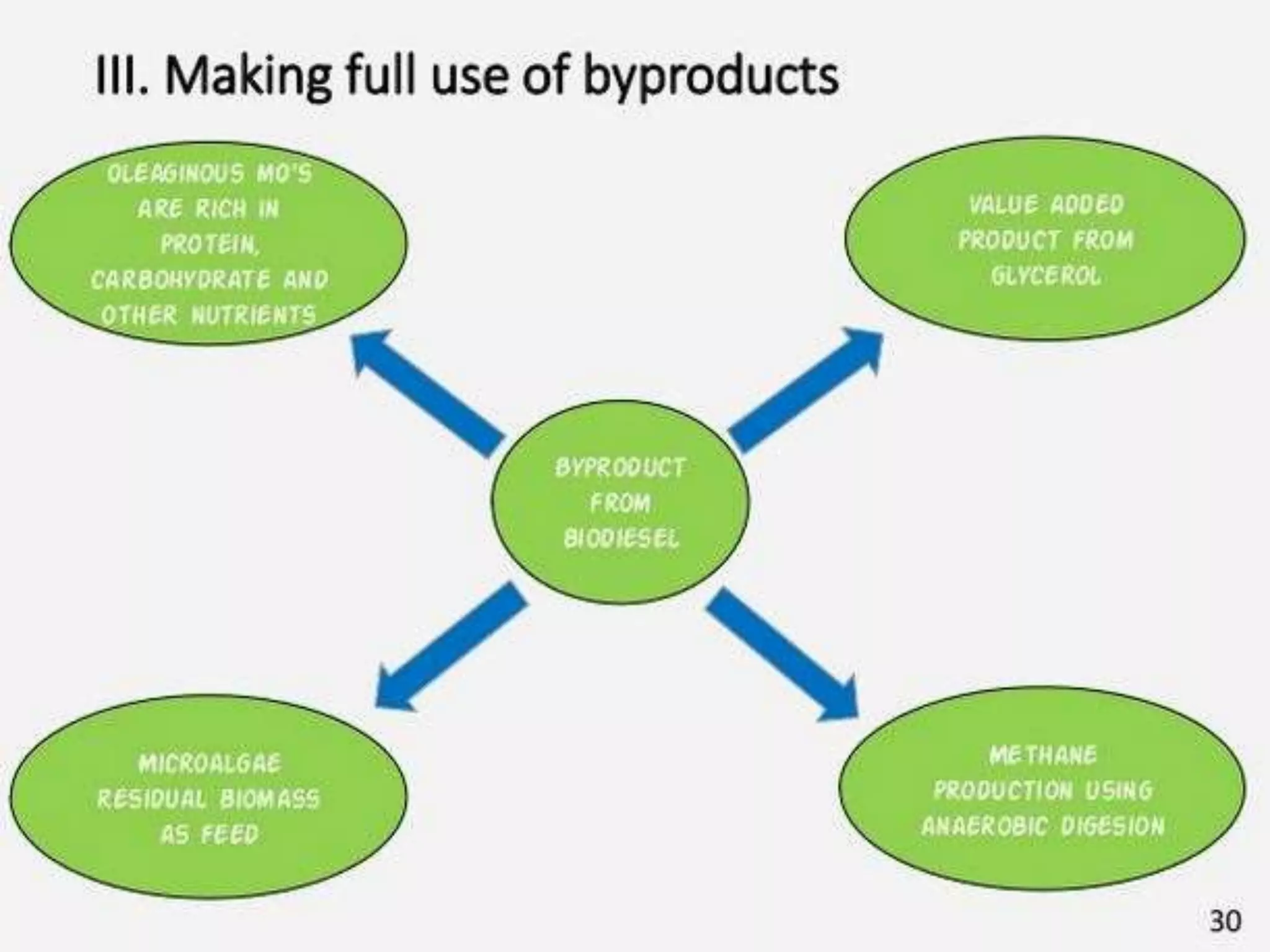

This document discusses microbial biodiesel production. It begins with an introduction to biodiesel and its history. It then discusses what biodiesel is and how it is made from vegetable oils, animal fats, or microbes. The rest of the document focuses on biodiesel production using microbes like microalgae, bacteria, fungi and yeast. It discusses the advantages of using microbes, such as their ability to grow rapidly and accumulate high amounts of lipids. It also provides details on the biodiesel production process when using different types of microbes, including lipid extraction and transesterification. In conclusion, while microbial biodiesel production is promising, further improvements are still needed to make it economically competitive with