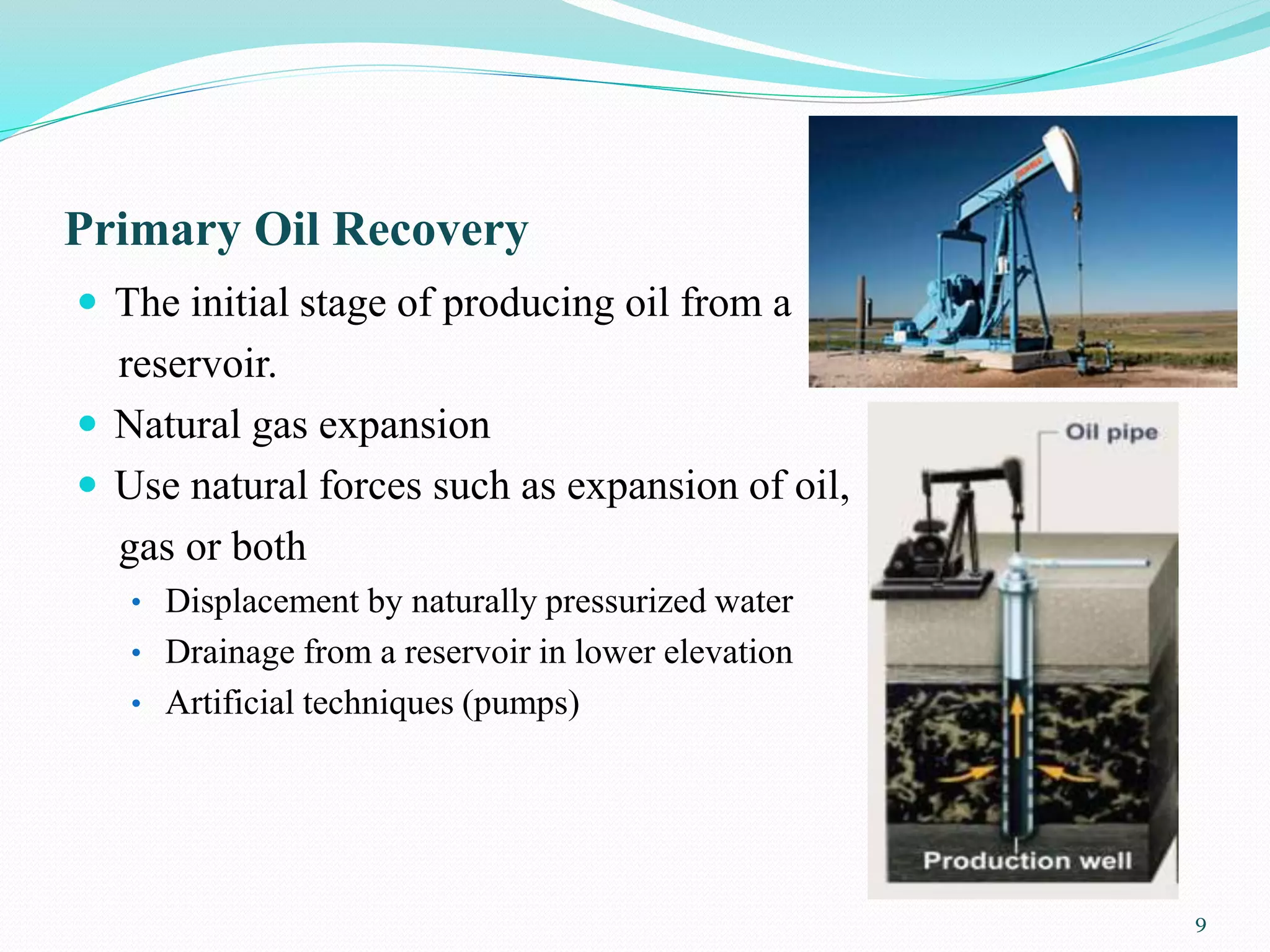

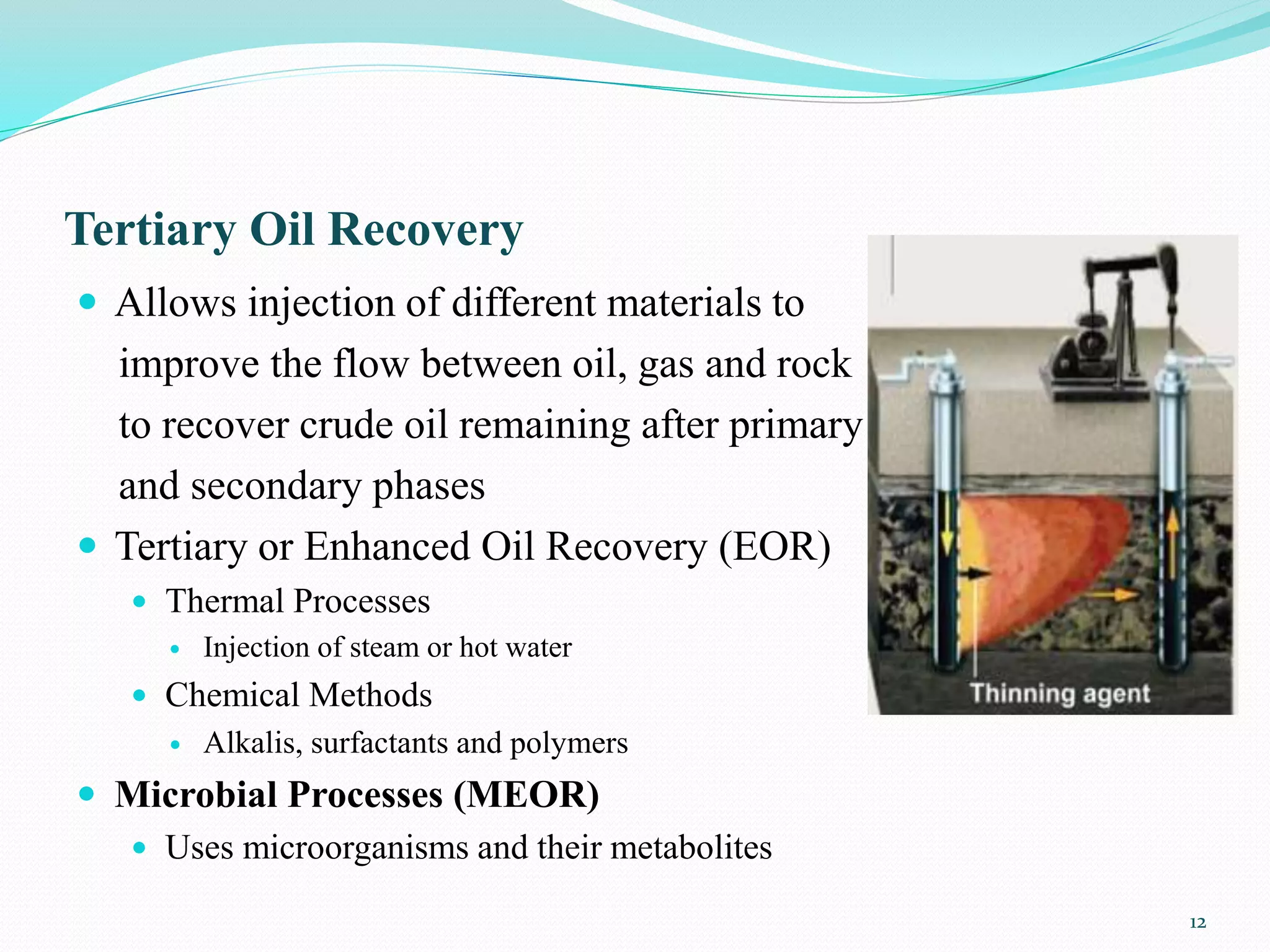

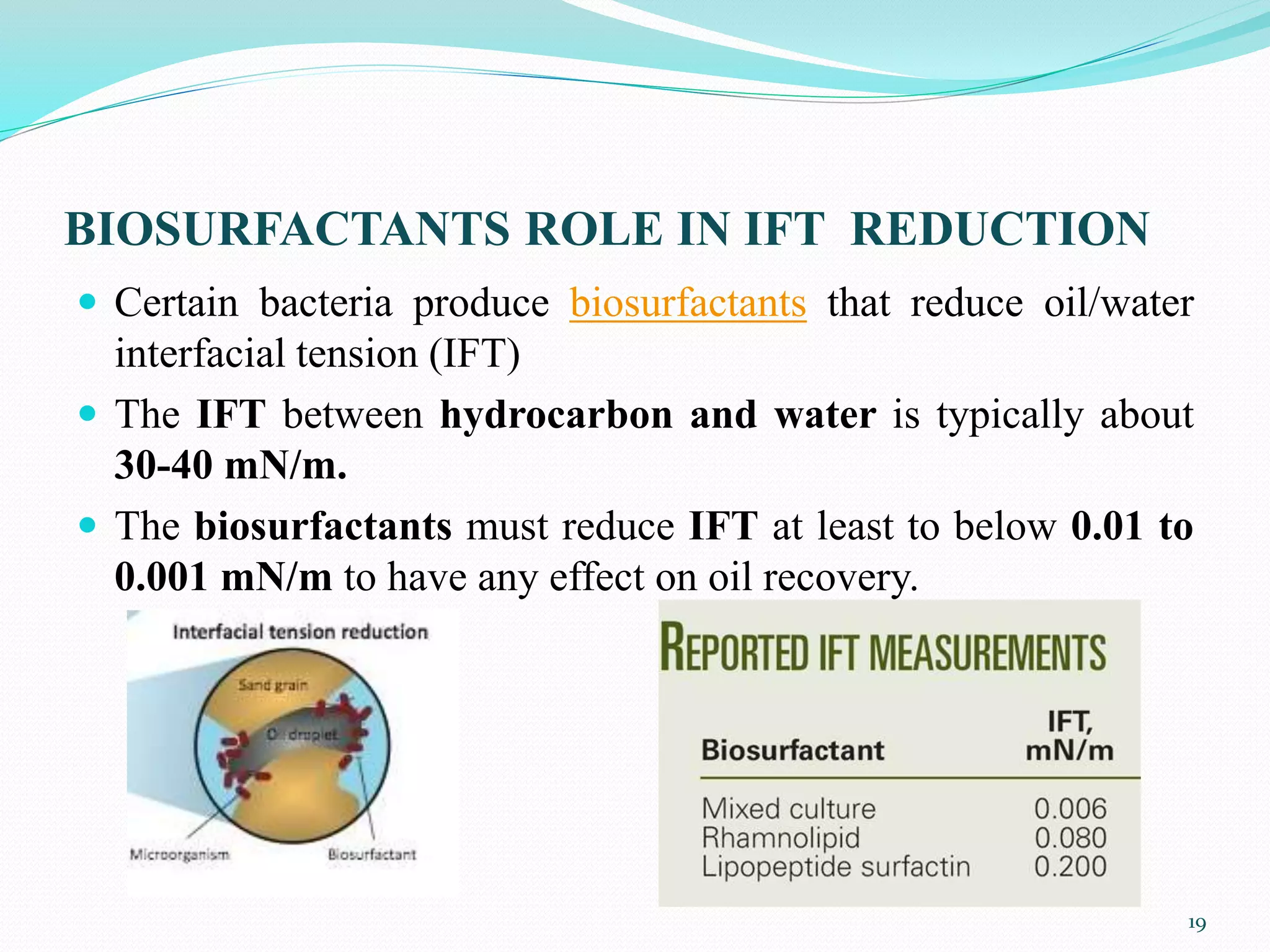

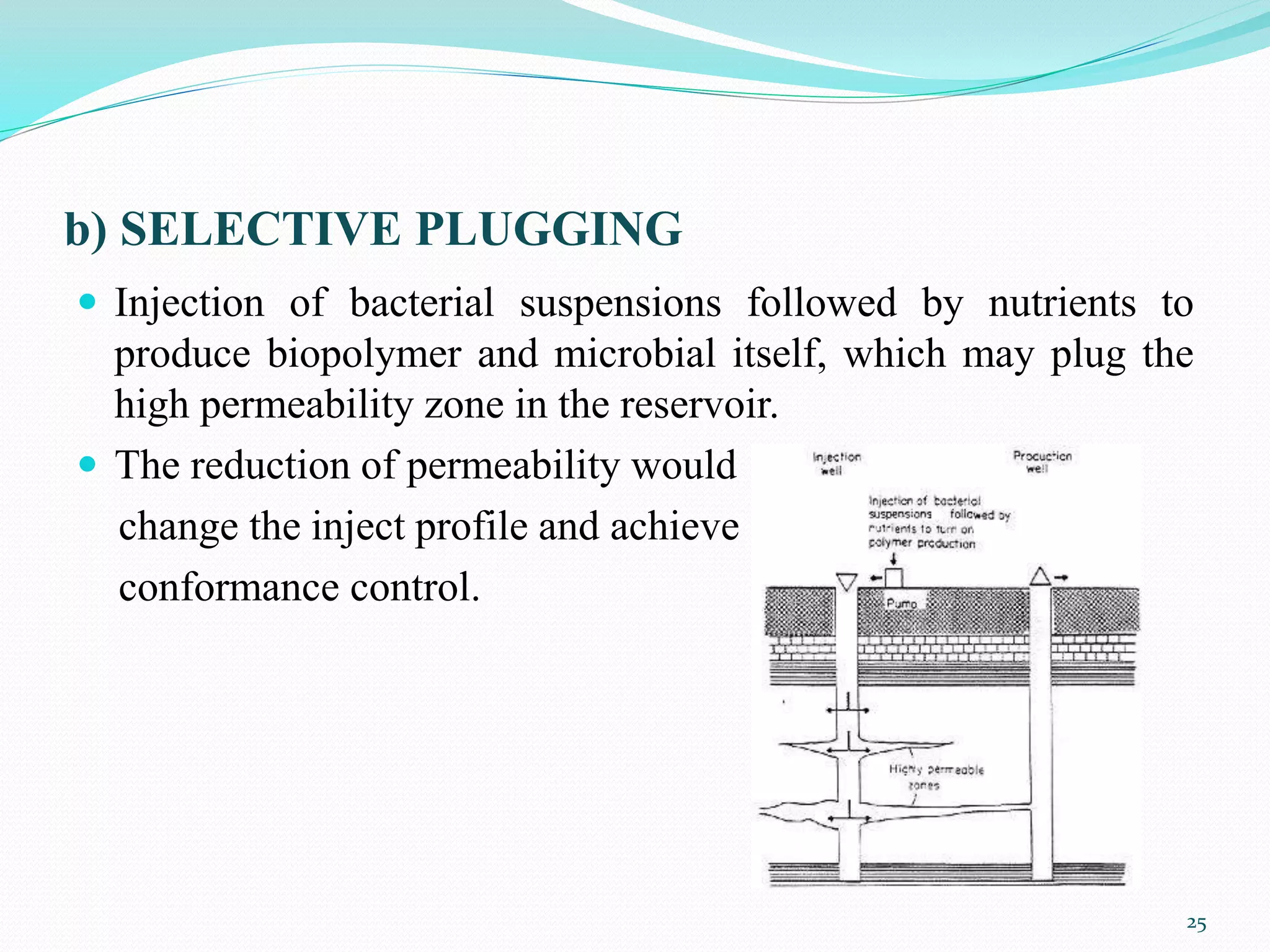

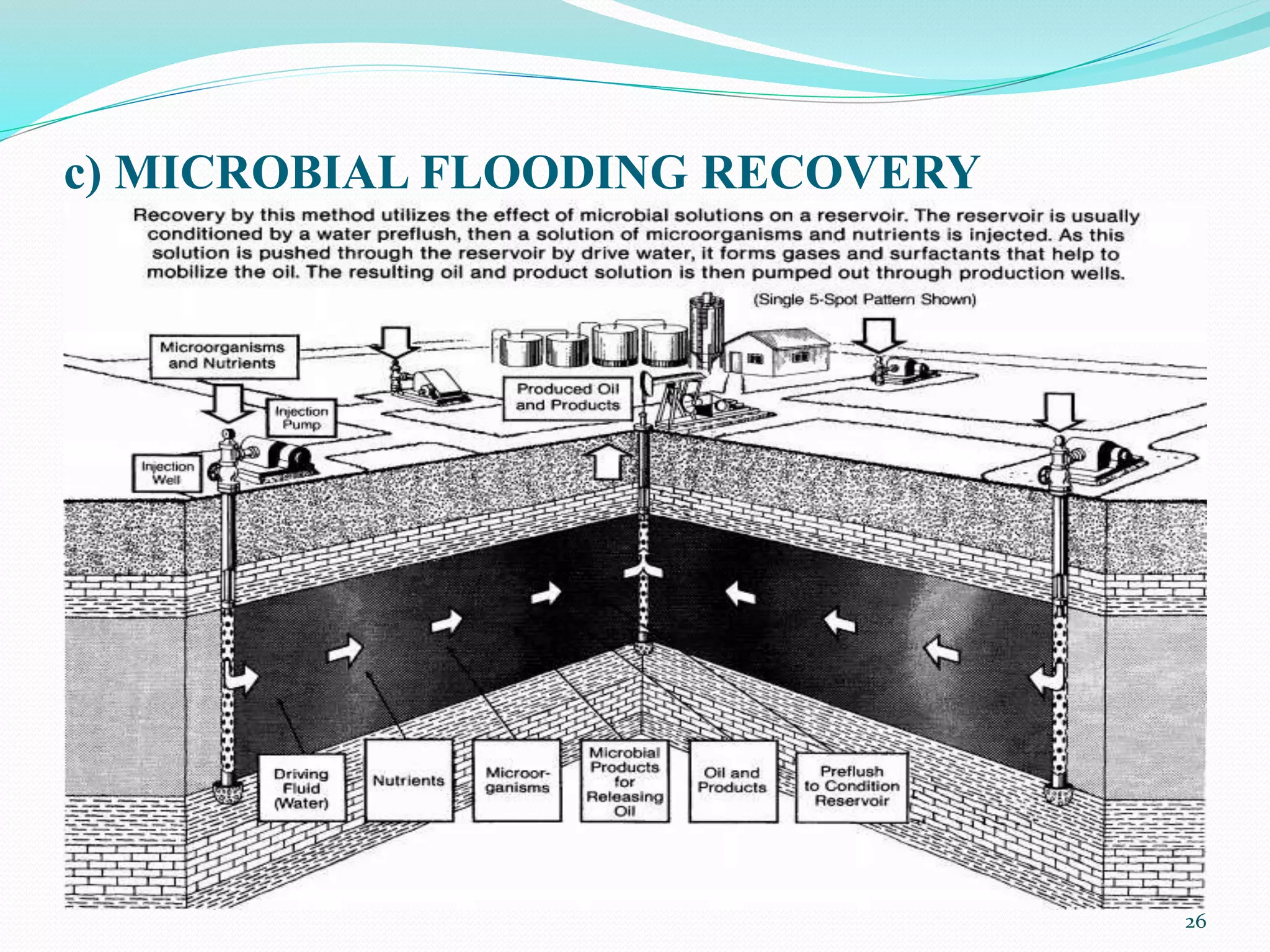

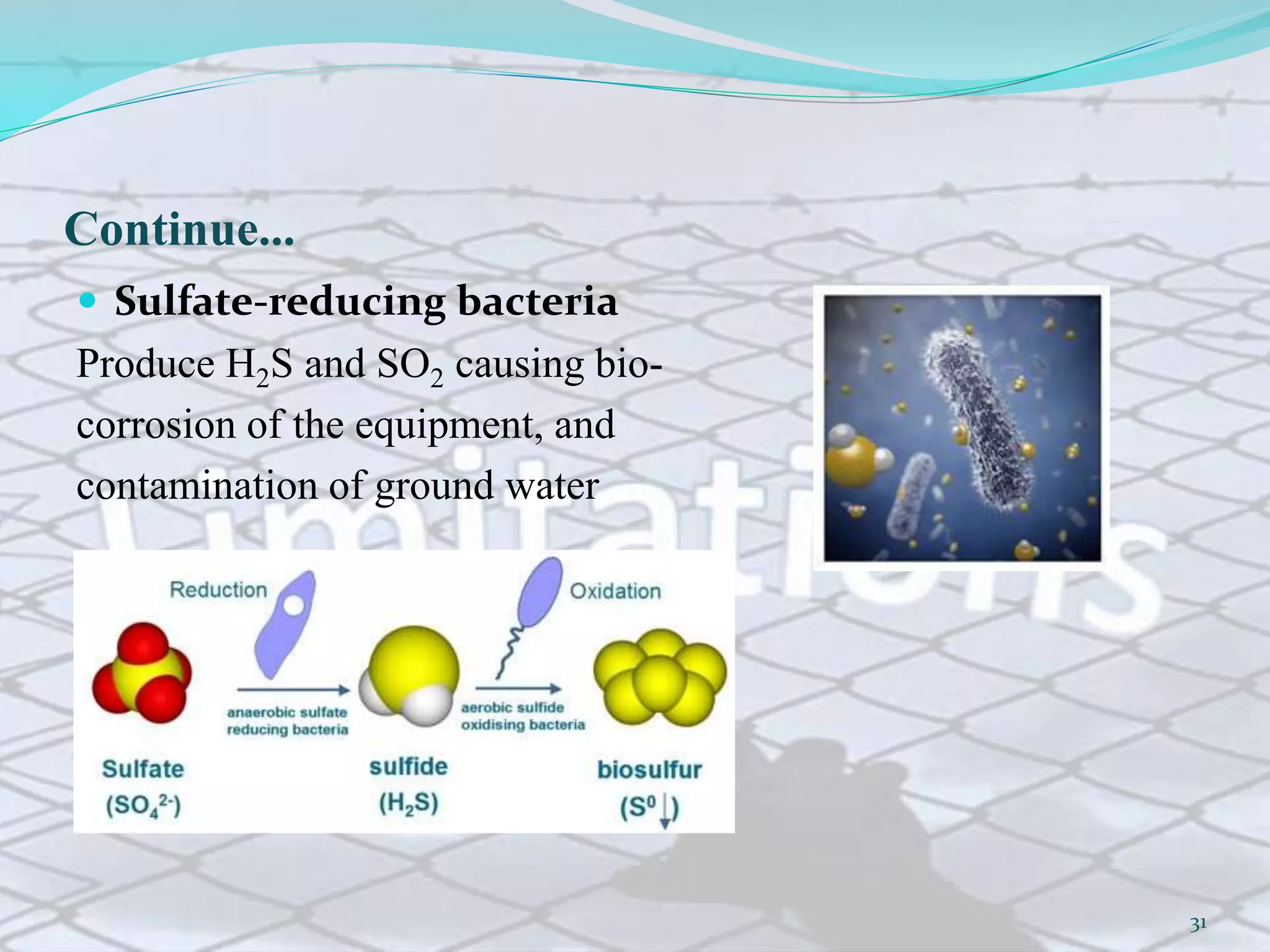

The document discusses microbial enhanced oil recovery (MEOR), a method that utilizes microorganisms and their metabolites to mobilize residual oil in reservoirs, aiming for a significant increase in oil recovery rates. It covers various oil recovery methods, the role of microorganisms, and the economic and ecological aspects of MEOR, highlighting its cost-effectiveness and environmental compatibility. It concludes that while MEOR has shown promise through research and pilot tests, further investment and research are needed to implement it widely in the industry.