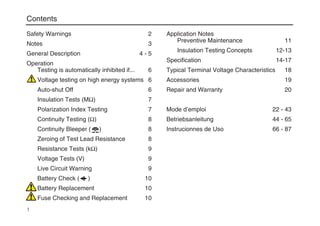

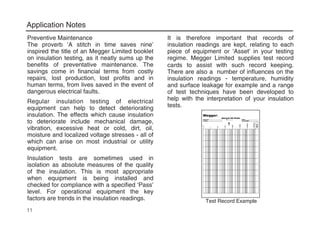

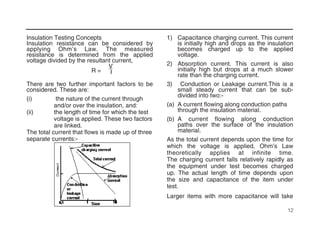

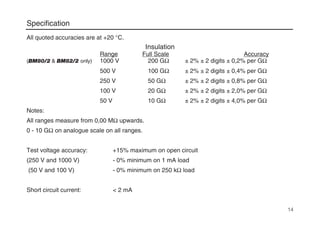

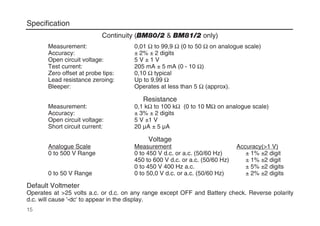

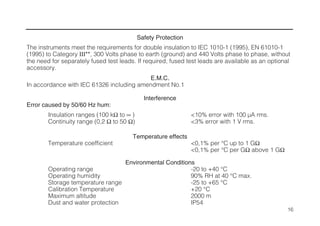

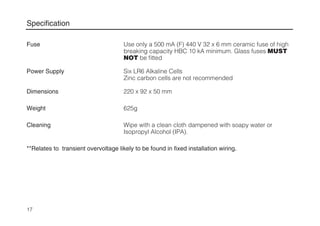

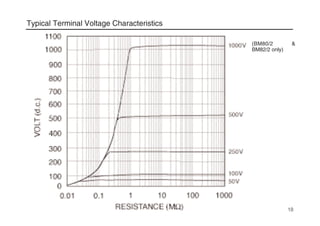

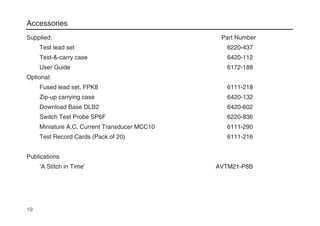

This document is a user guide for the BM80/2 Series Multi-Voltage Insulation and Continuity Tester. It provides safety warnings and describes the instrument's features for insulation testing, continuity testing, resistance testing, and voltage testing. It also covers instrument operation, battery replacement, fuse checking, and application notes for preventative maintenance and insulation testing concepts.