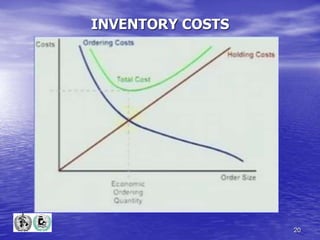

Materials management involves planning and controlling the flow of materials from identification of need through usage and accounting. Its objectives include efficiently supporting operations and organizational goals. Responsibilities include cost reduction, quality assurance, and coordinating inter-departmental efforts. Key areas are procurement, inventory control, and materials requirement planning and control. Inventory exists to hedge against uncertainties and avoid issues like machine downtime. It has costs like carrying, ordering, and shortages that systems aim to balance.