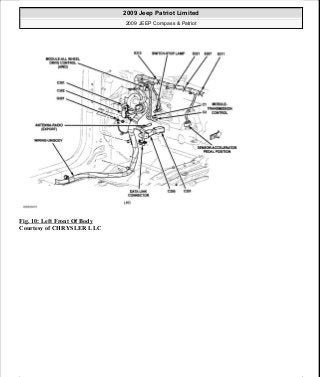

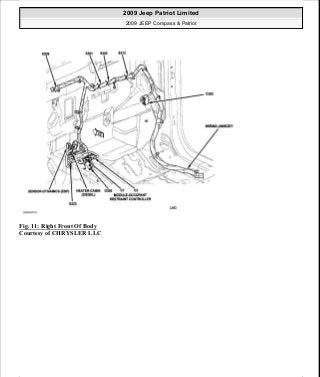

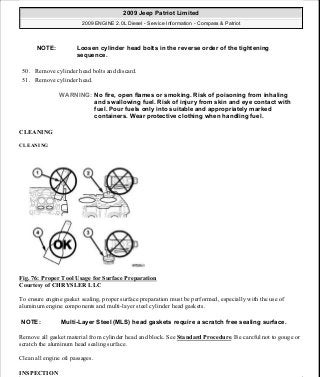

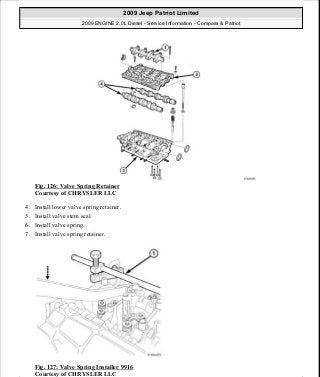

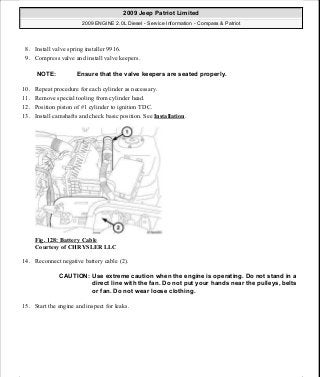

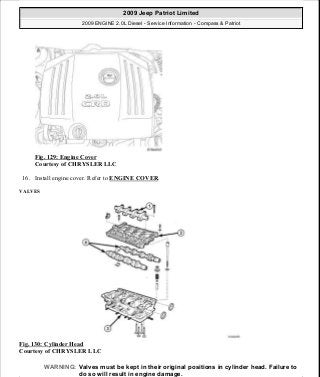

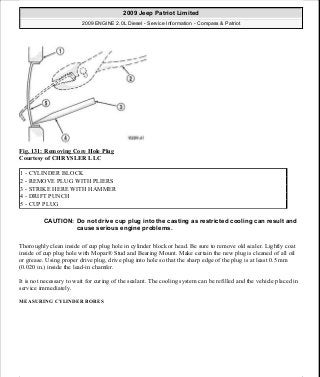

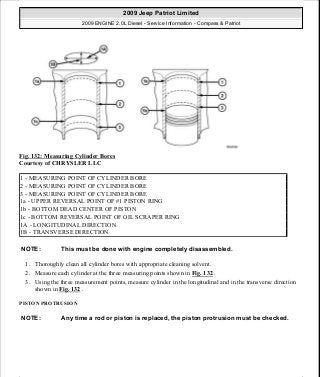

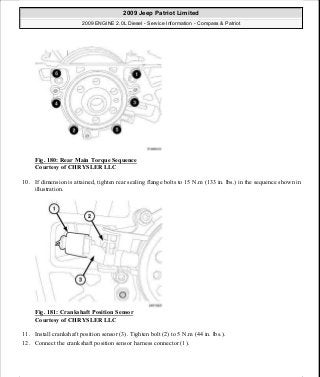

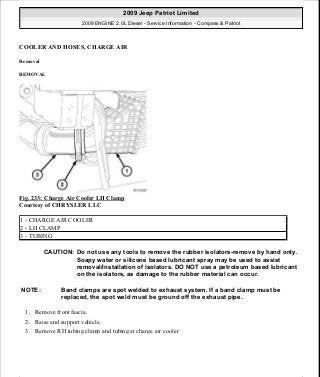

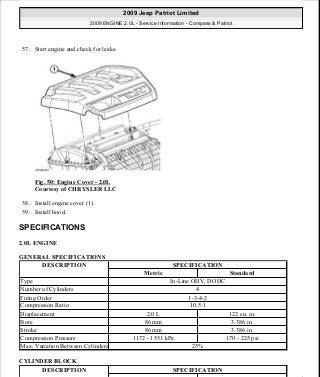

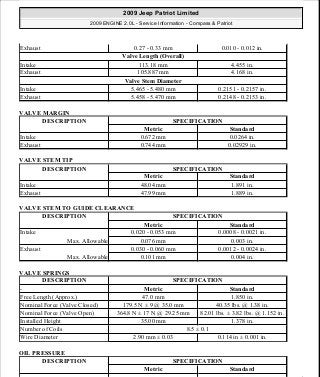

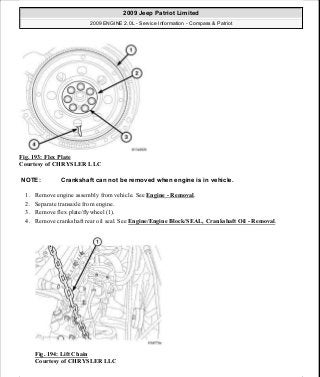

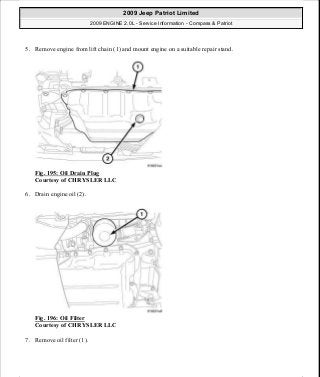

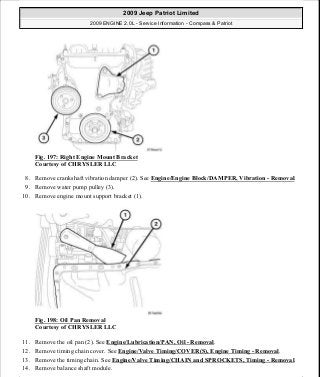

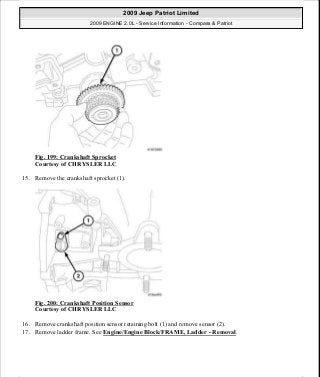

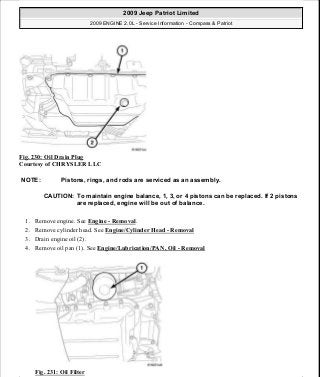

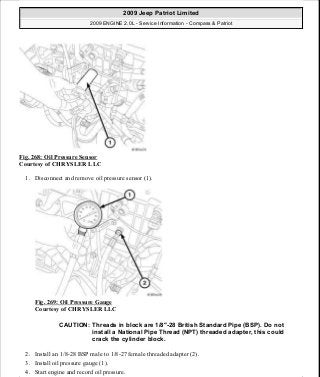

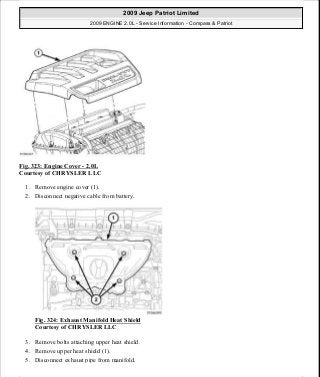

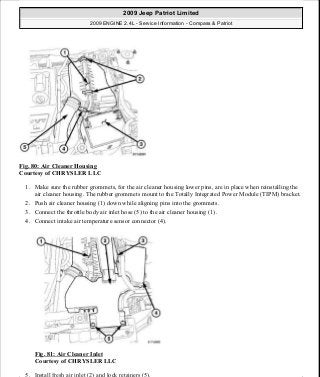

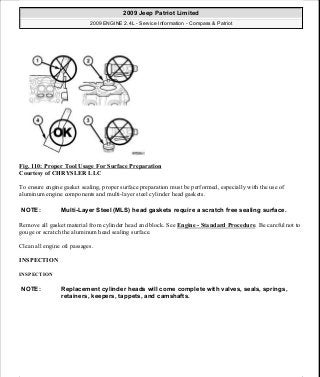

The document provides detailed service information for the 2009 Jeep Patriot with a 2.0L diesel engine, including procedures for compression testing and leak down testing, as well as guidelines for proper engine gasket surface preparation. It specifies the necessary cleaning tools, steps for engine disassembly and assembly, and necessary safety precautions to follow during maintenance. Additionally, it outlines the engine’s compression specifications and testing procedures to ensure optimal performance.

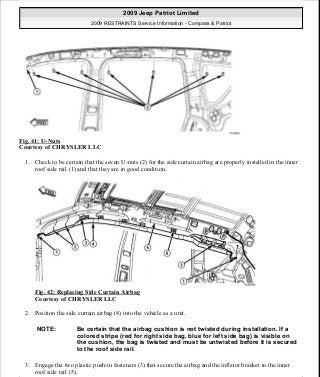

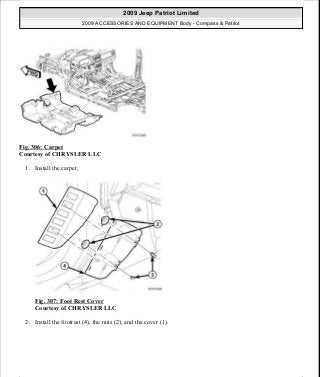

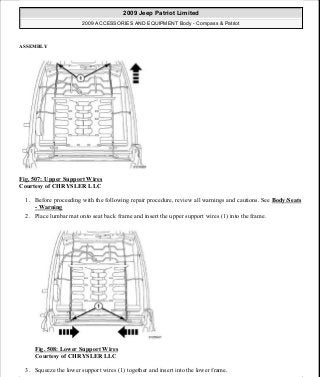

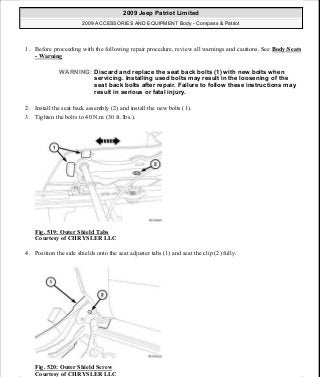

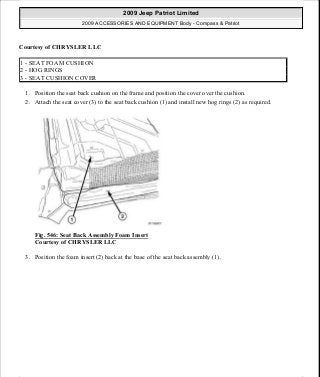

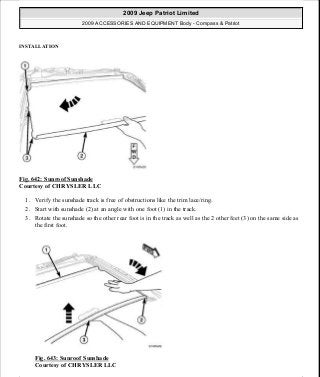

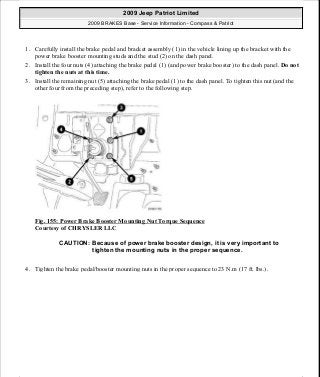

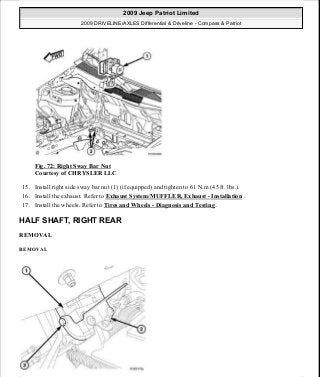

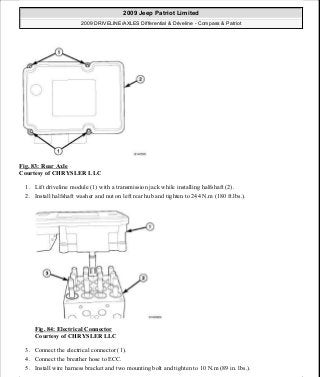

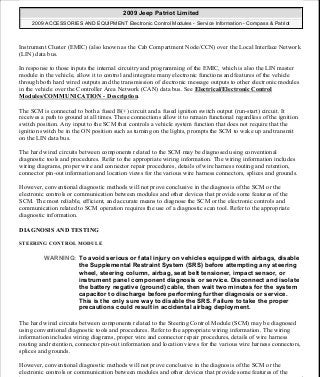

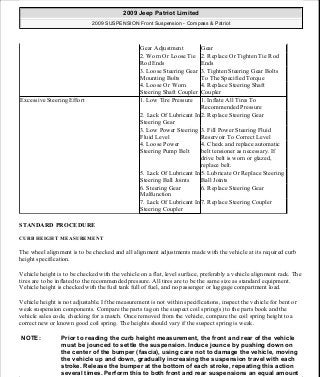

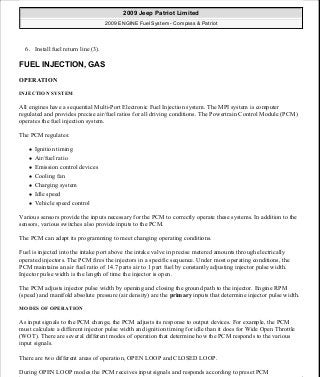

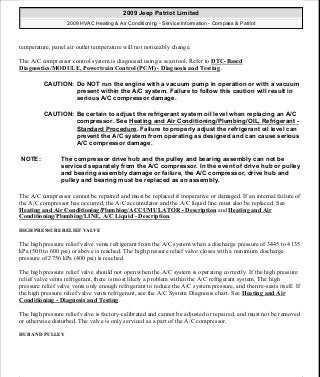

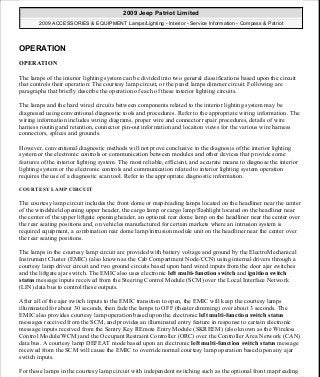

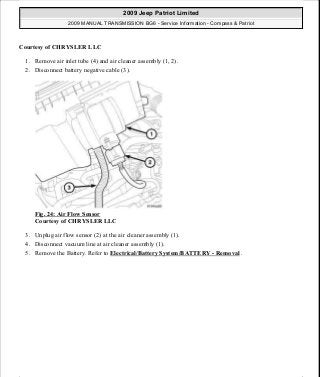

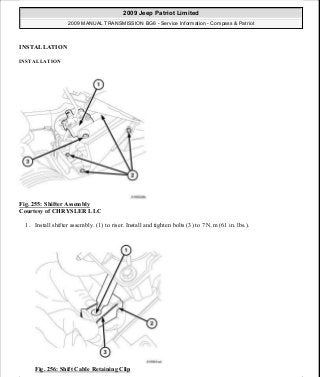

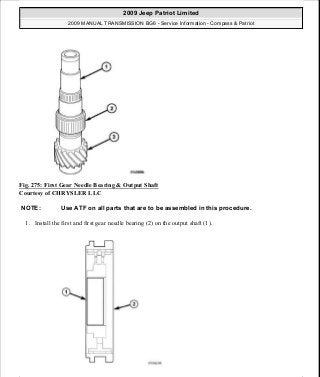

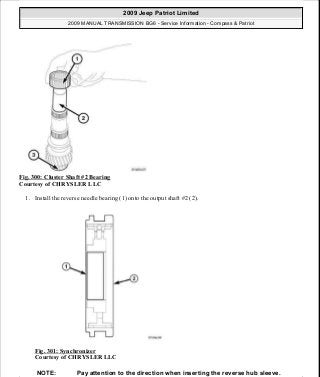

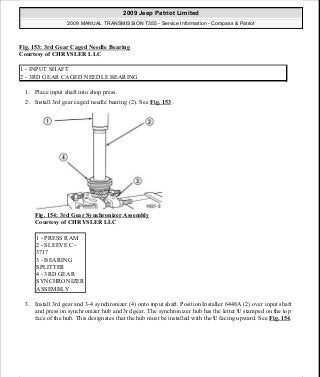

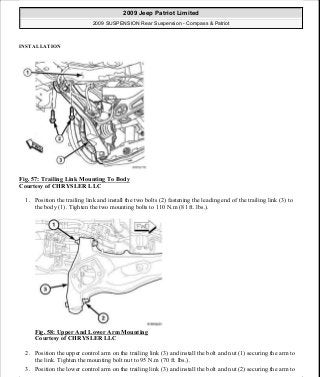

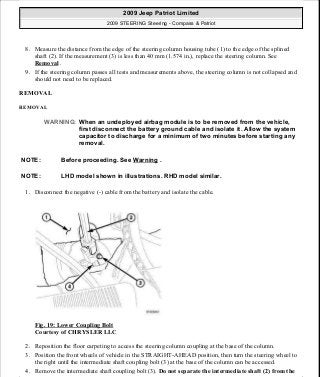

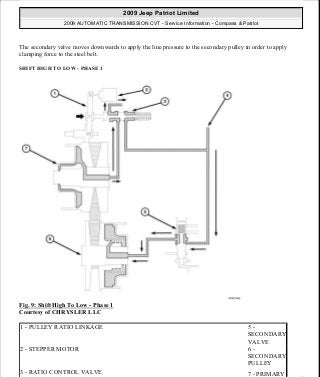

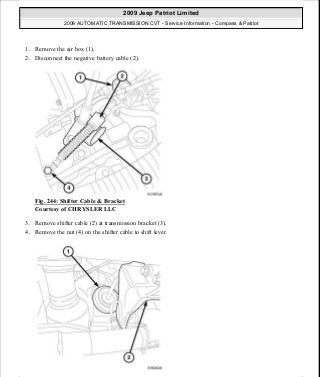

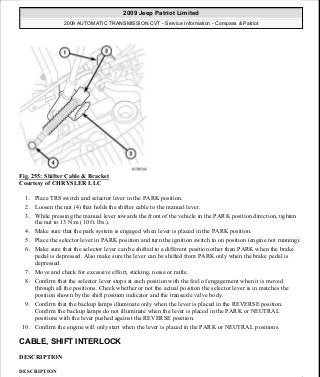

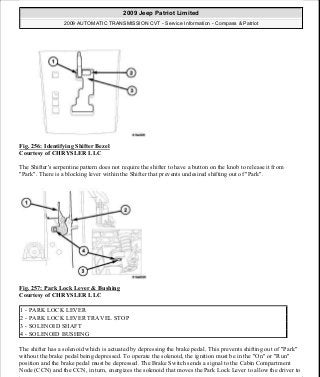

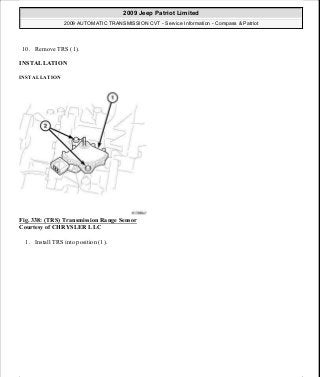

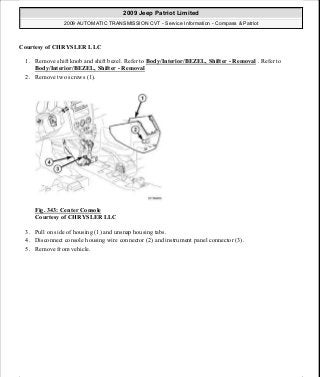

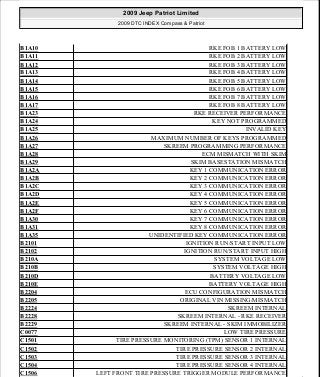

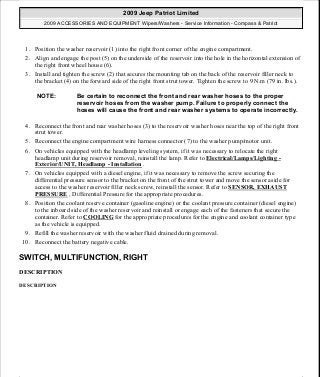

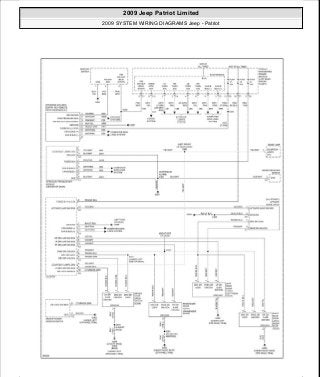

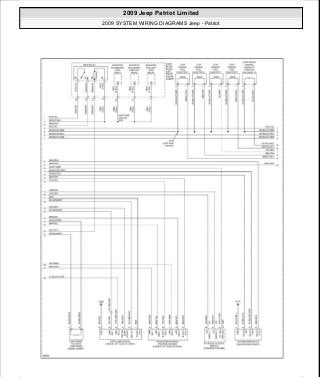

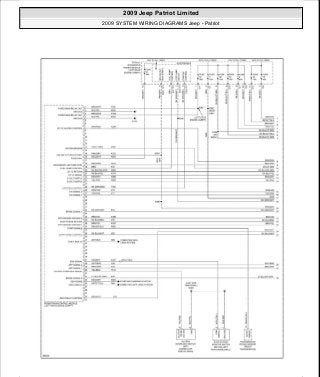

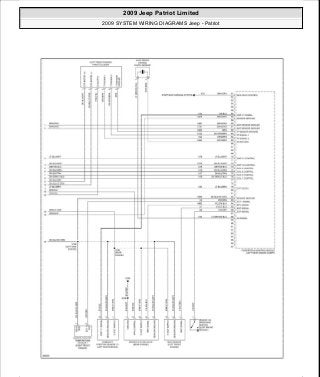

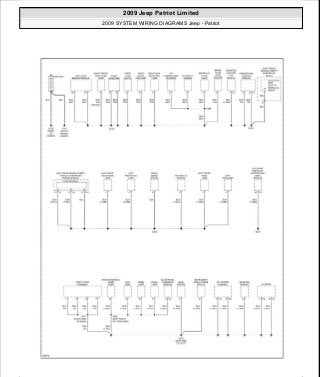

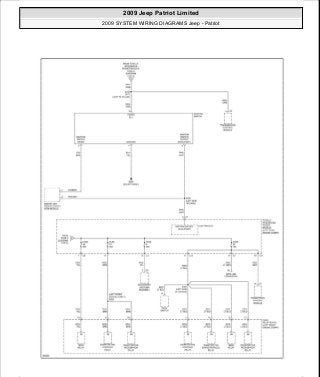

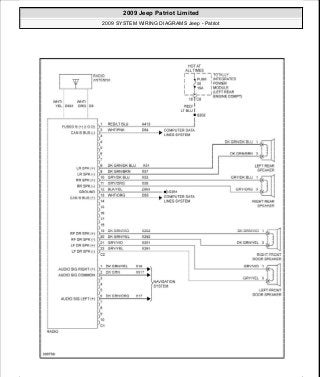

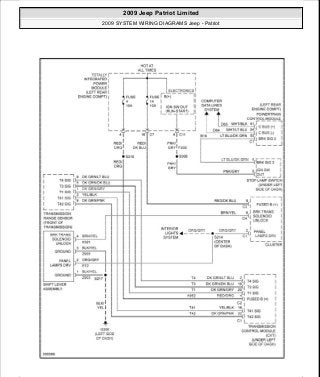

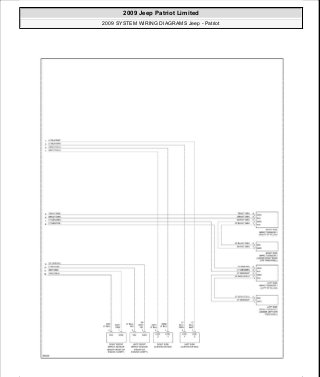

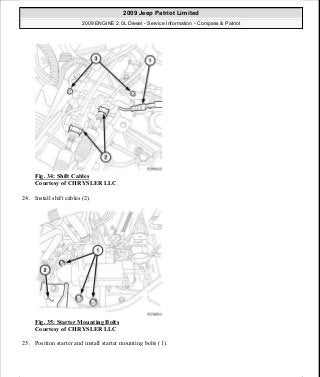

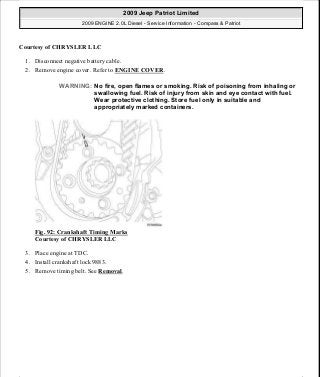

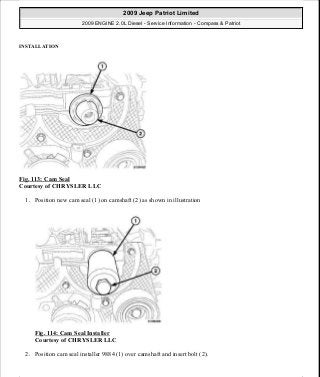

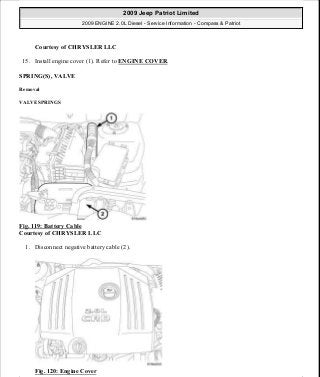

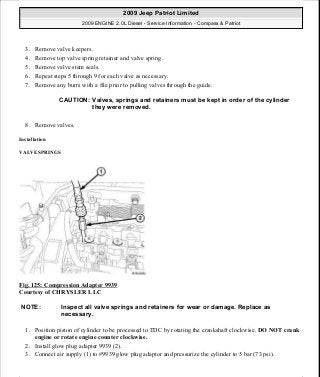

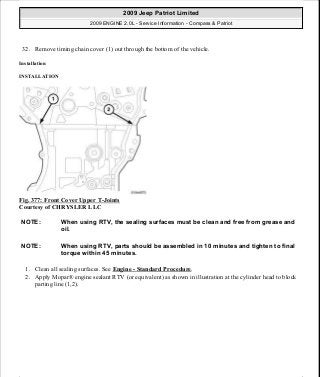

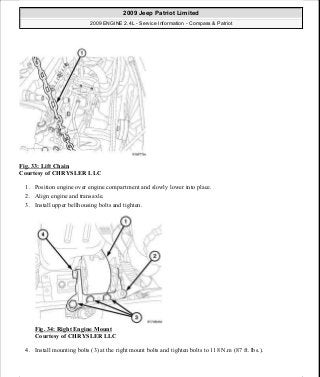

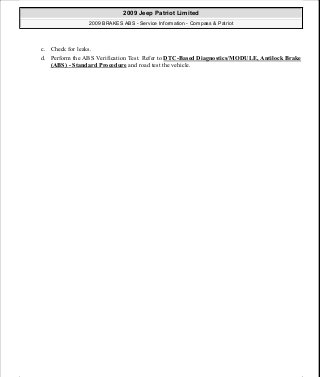

![9-8 JEEP

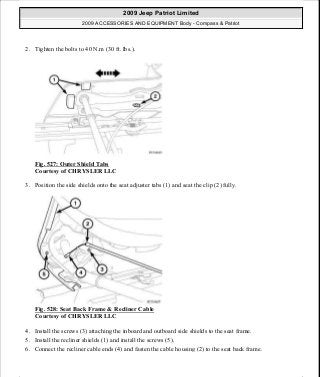

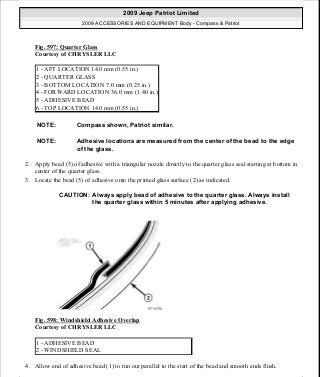

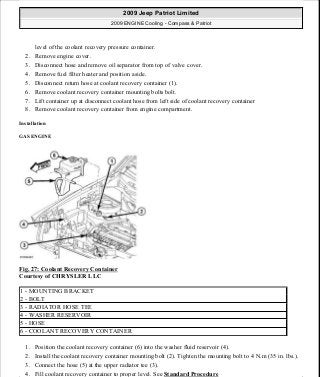

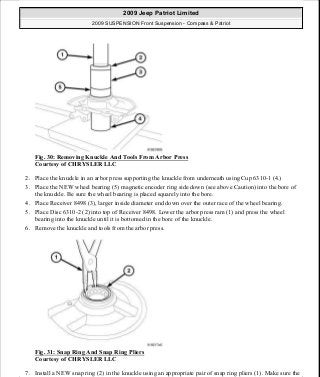

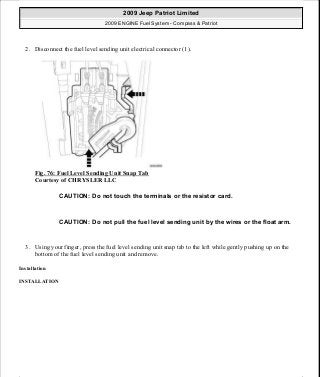

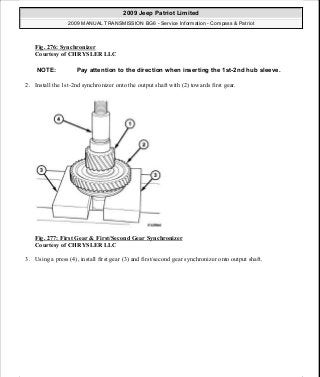

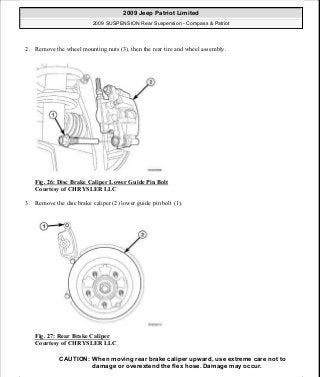

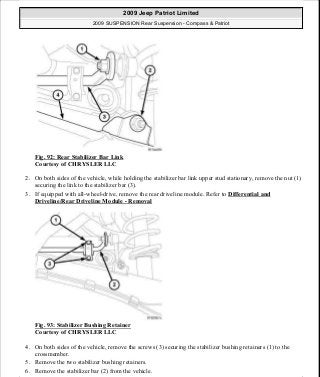

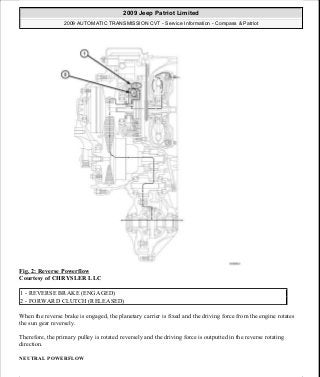

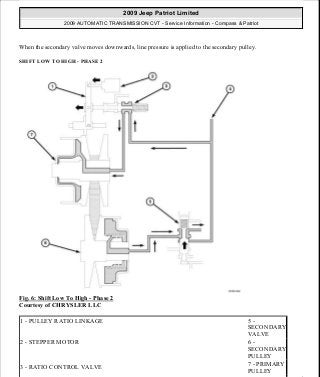

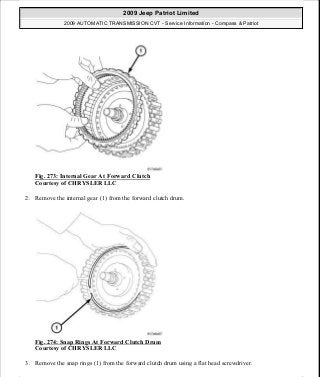

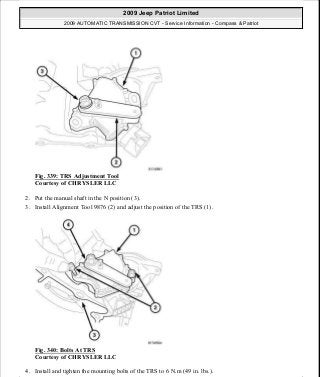

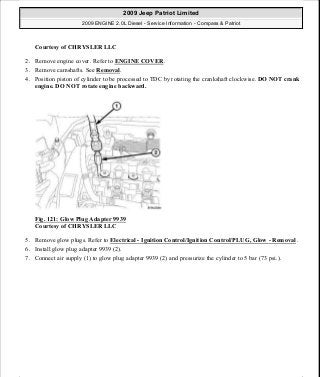

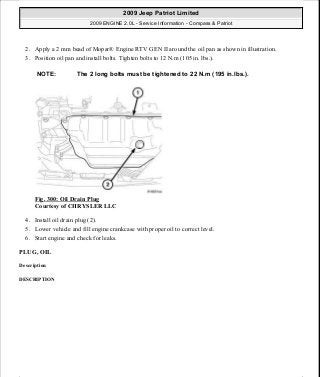

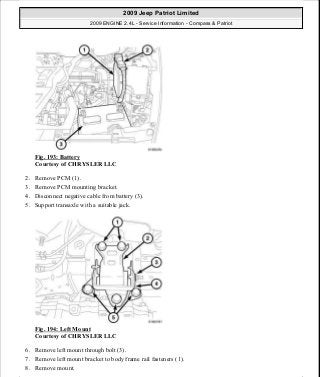

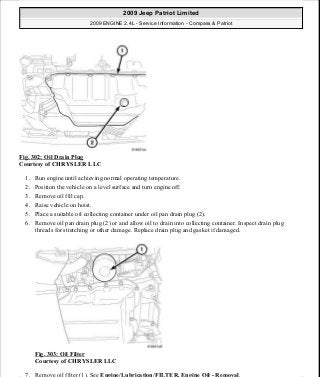

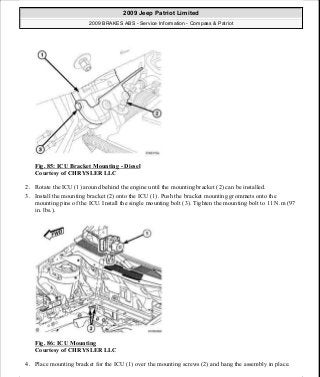

COMPASS • PATRIOT

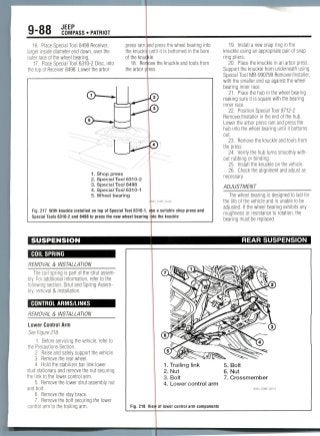

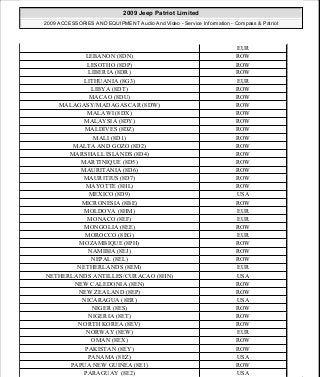

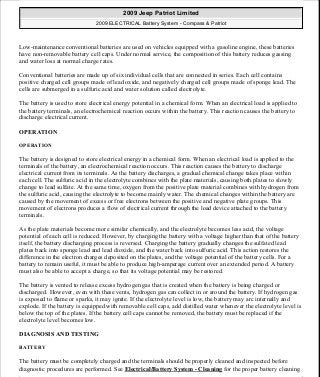

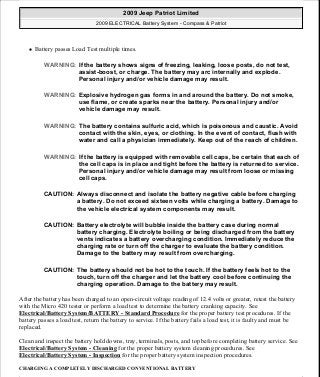

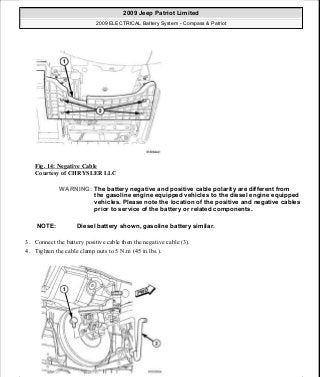

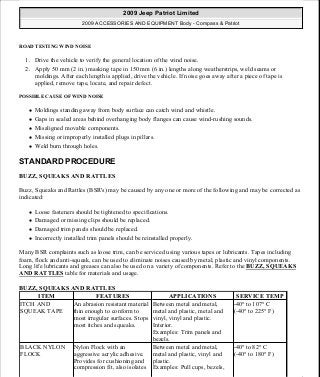

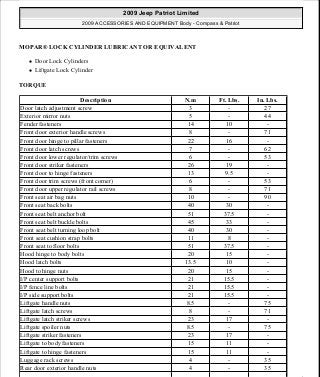

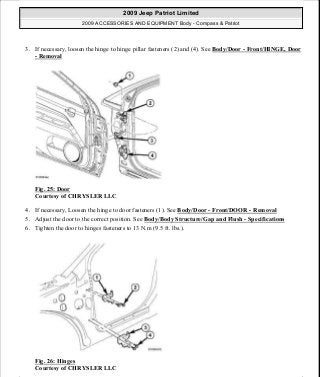

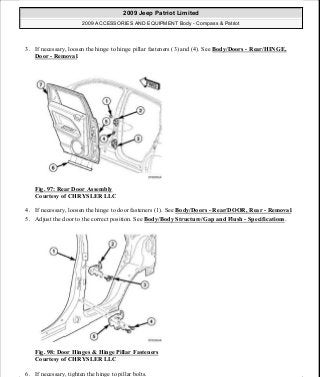

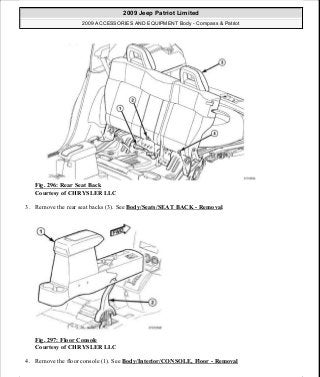

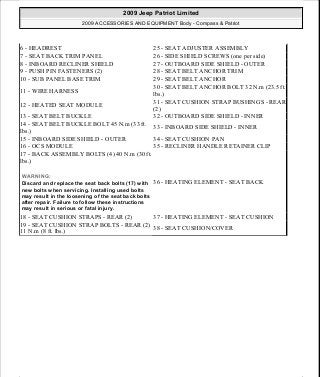

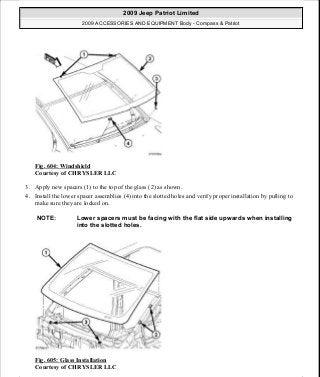

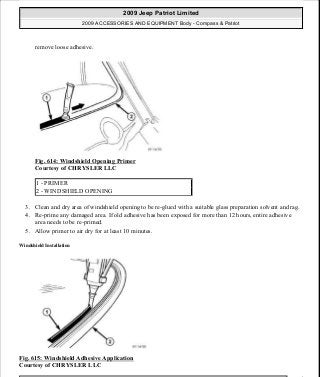

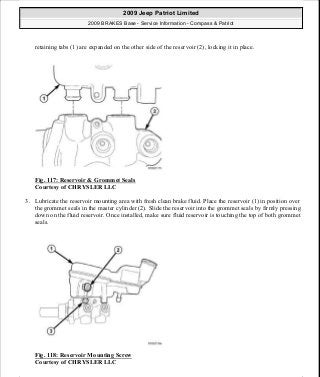

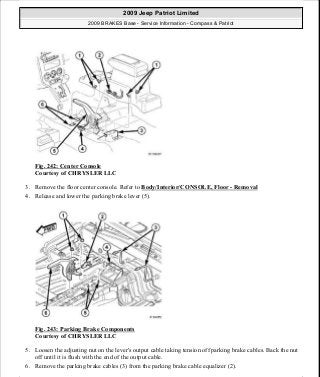

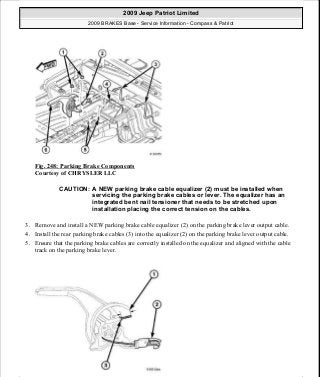

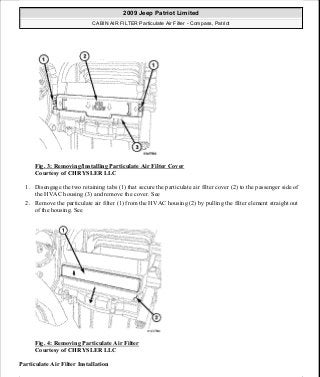

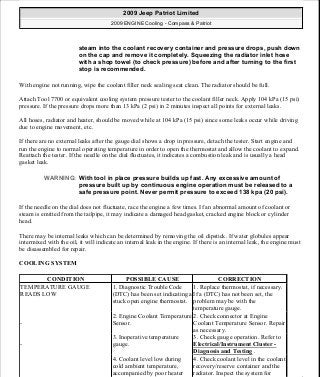

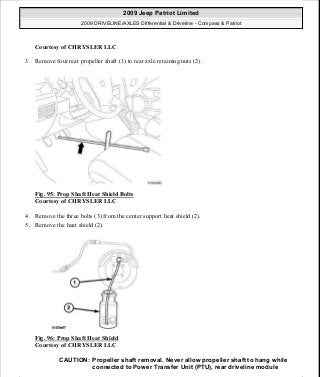

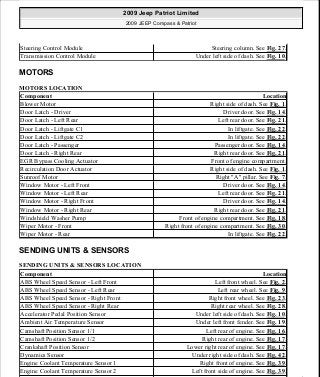

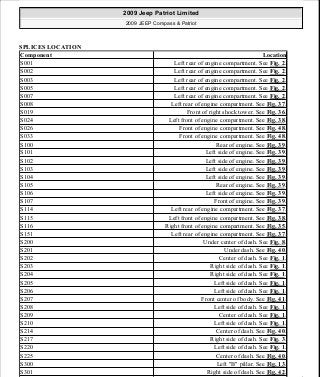

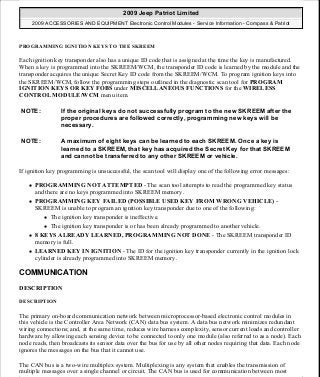

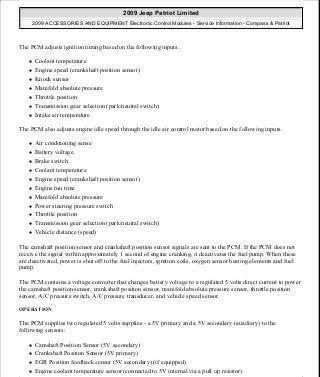

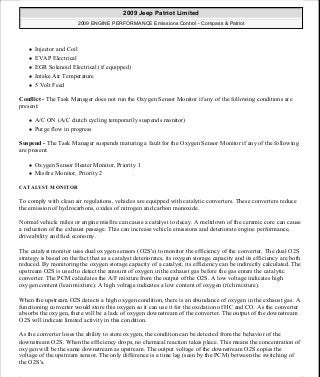

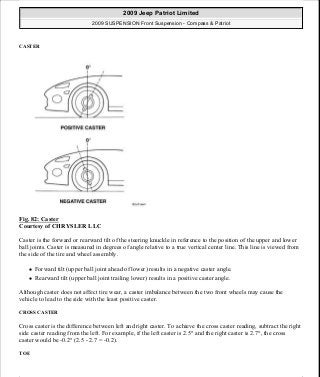

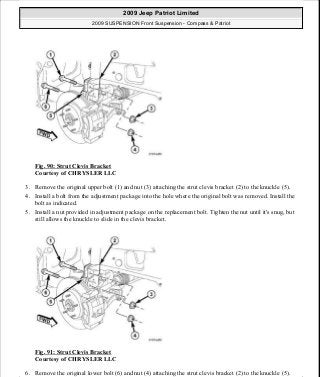

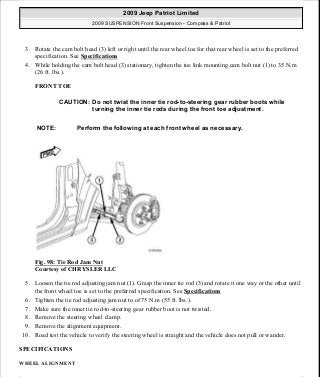

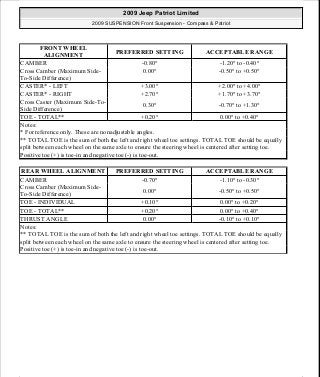

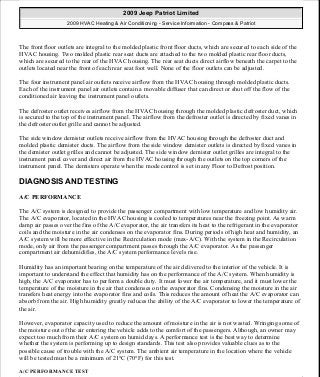

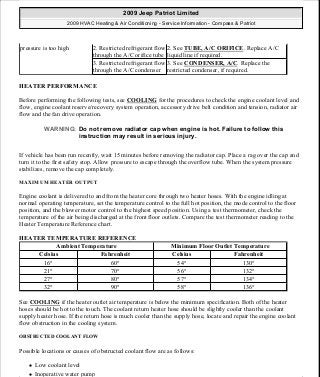

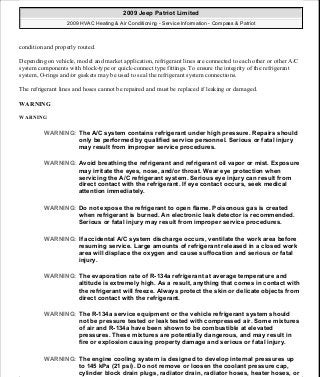

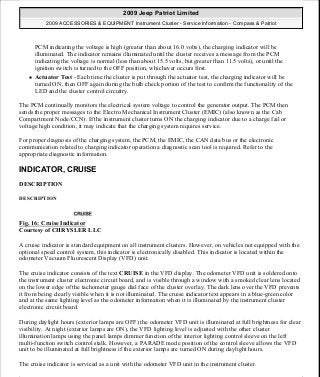

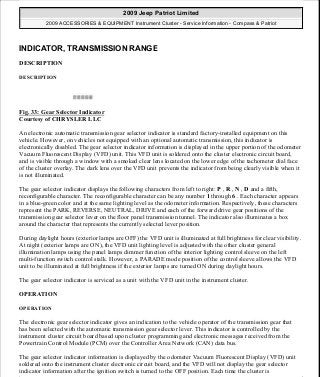

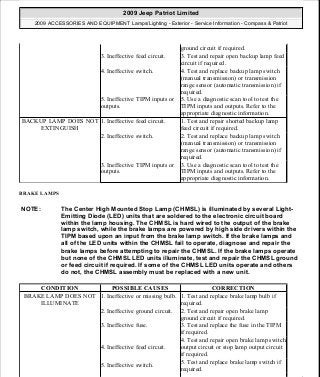

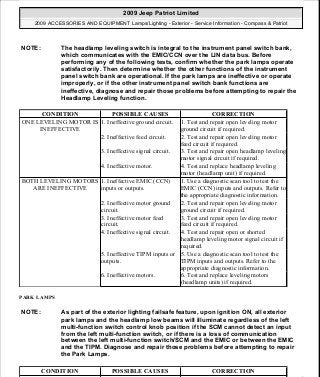

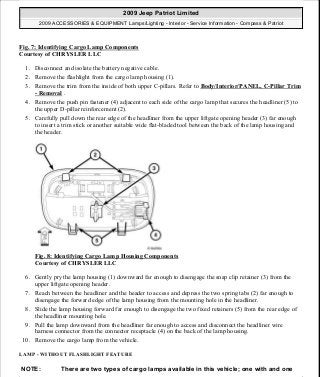

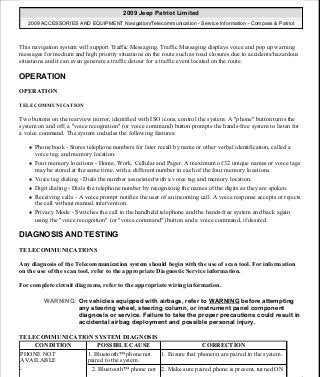

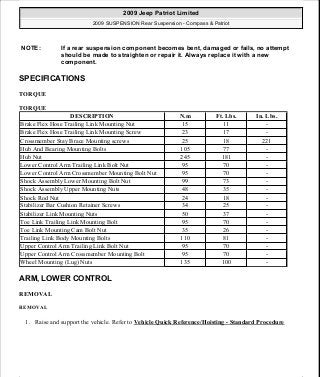

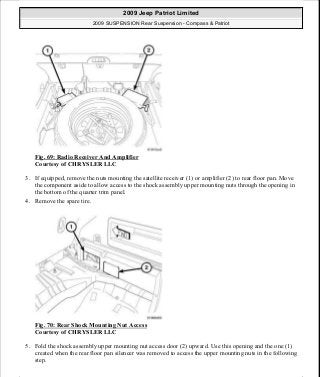

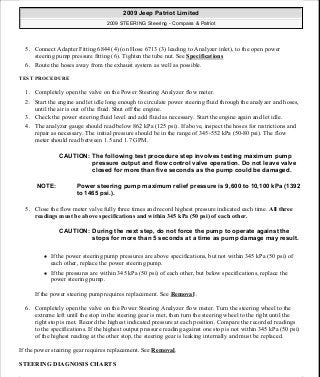

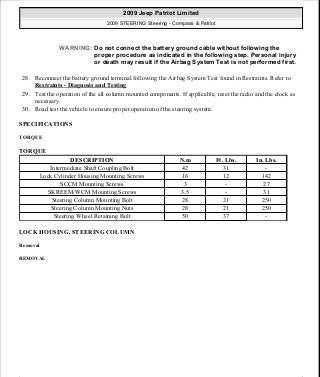

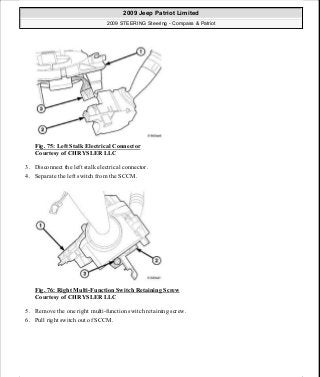

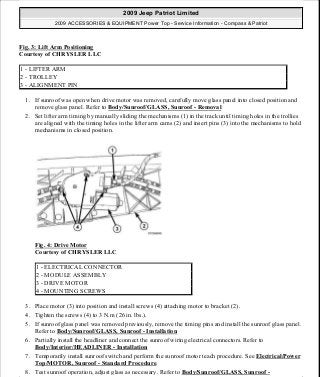

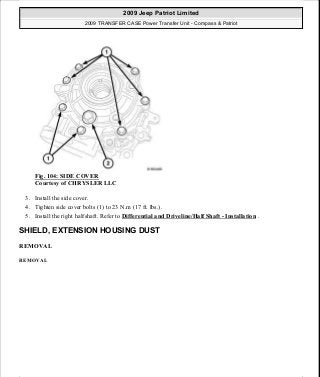

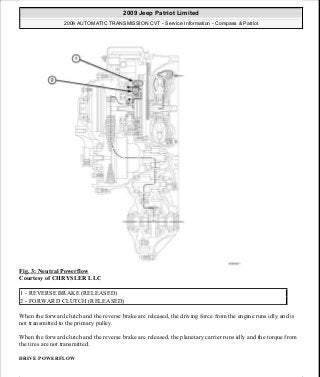

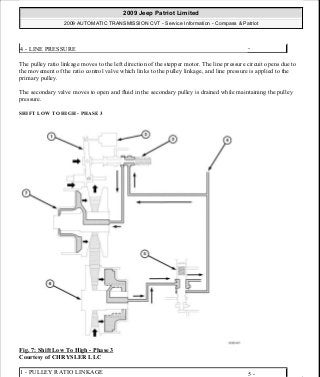

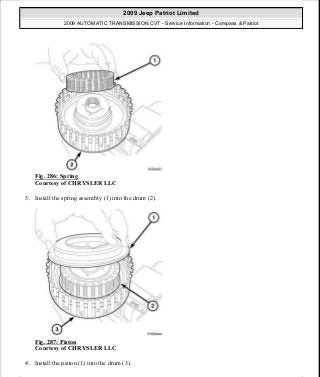

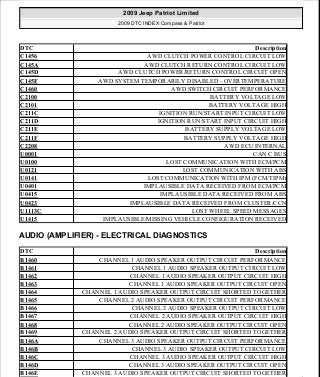

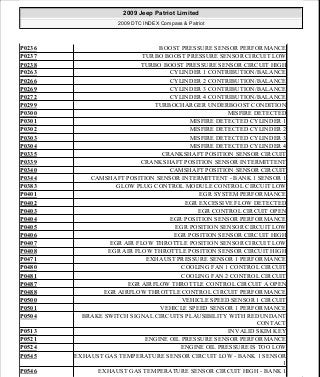

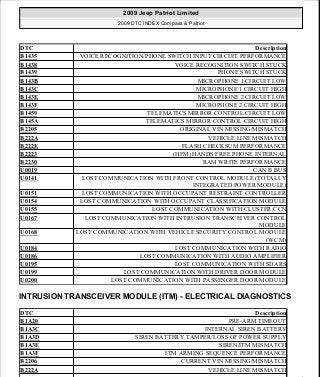

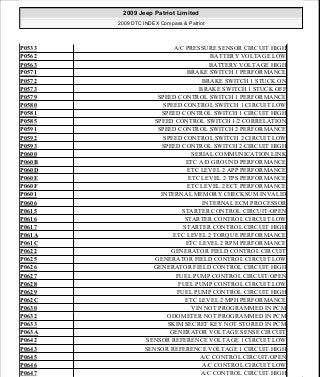

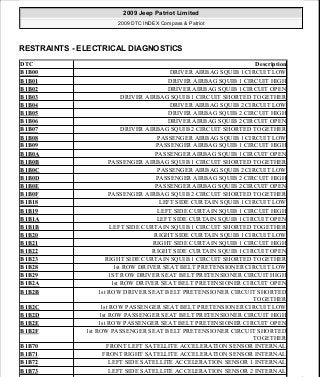

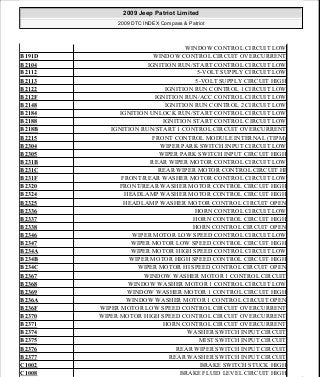

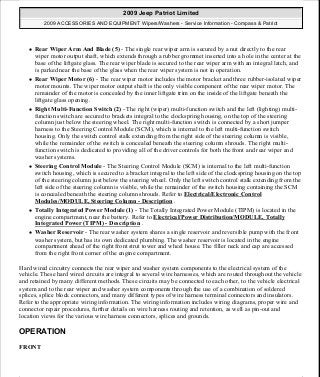

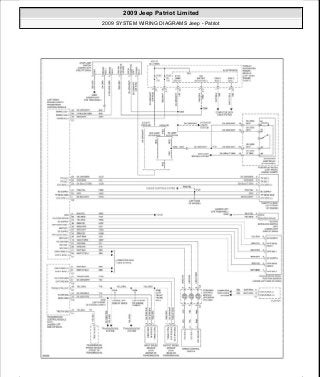

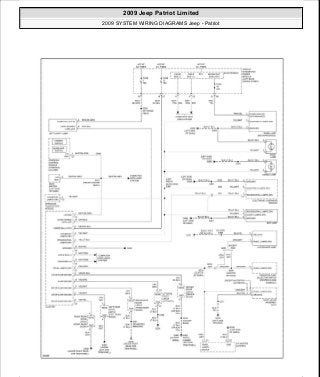

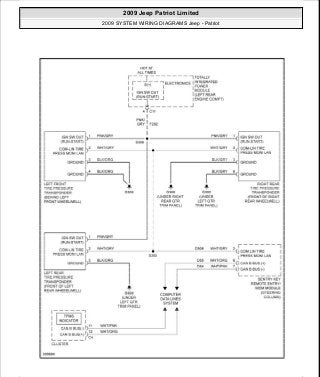

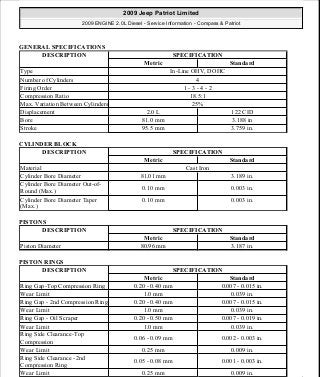

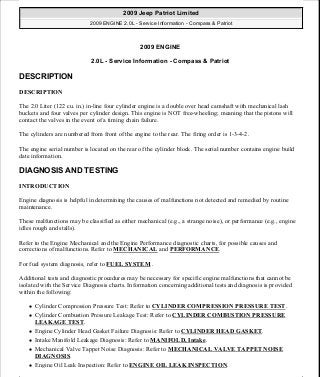

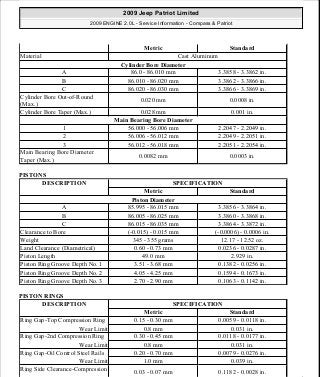

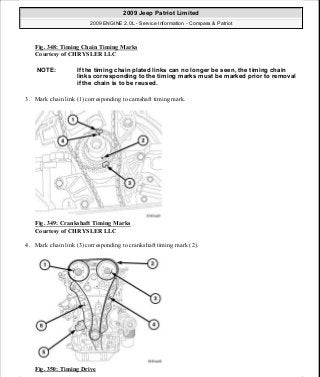

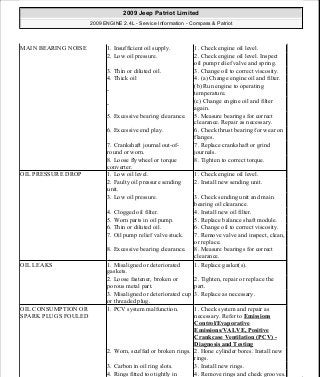

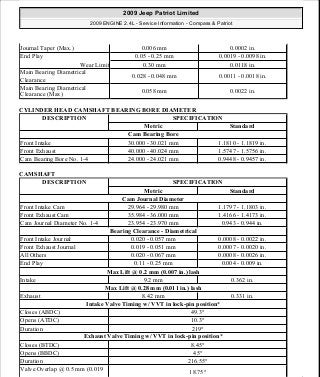

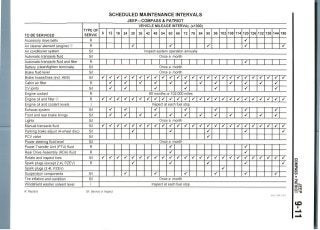

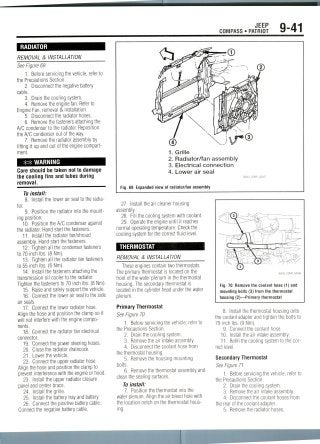

WHEEL ALIGNMENT

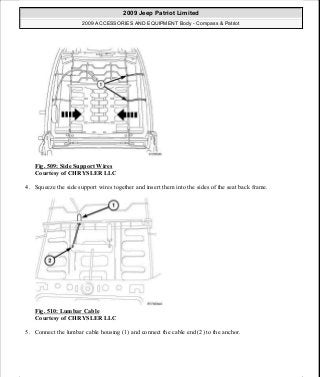

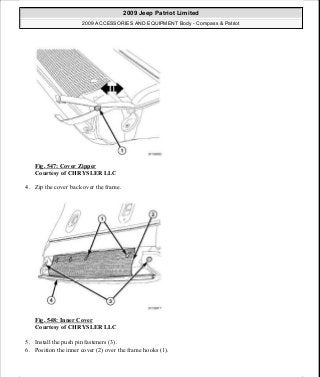

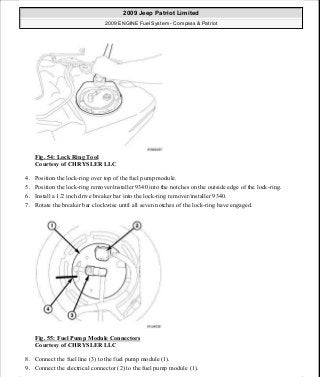

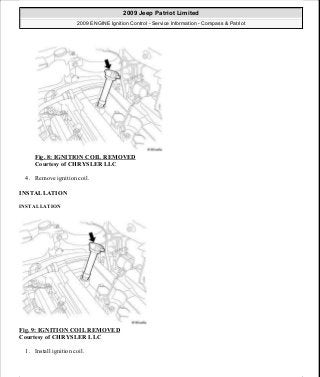

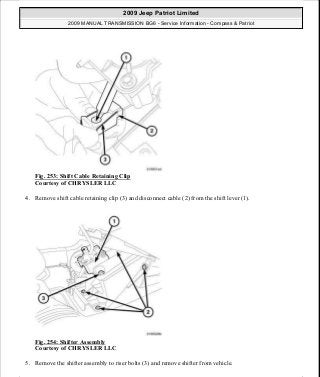

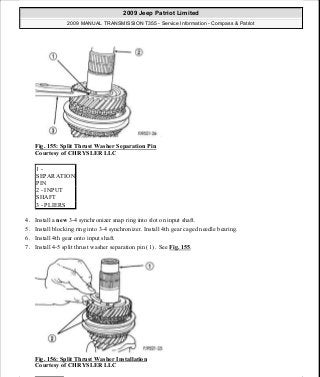

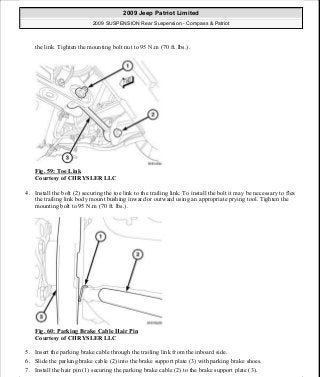

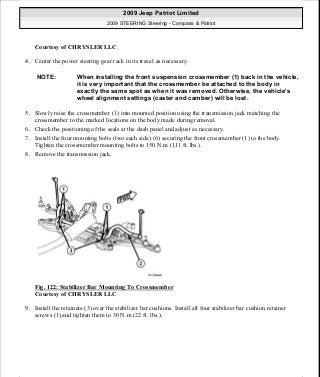

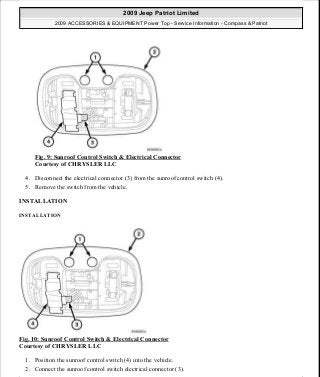

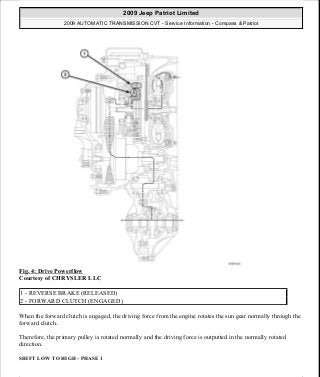

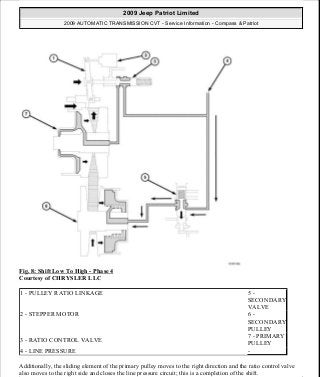

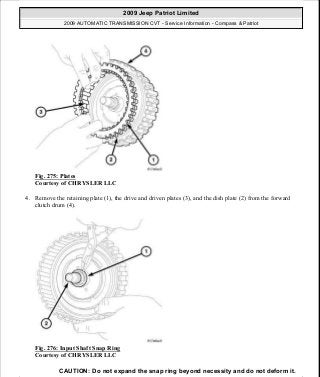

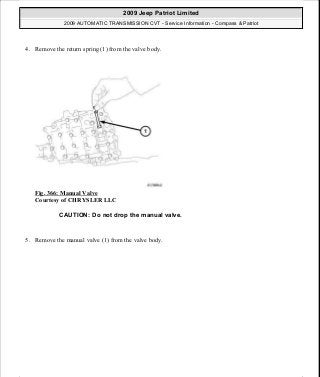

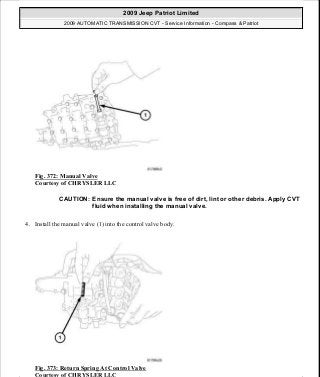

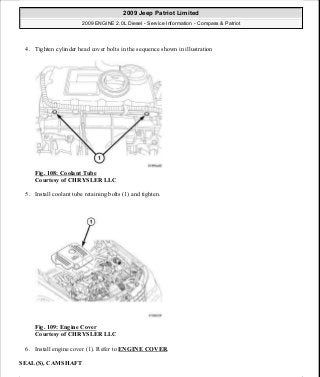

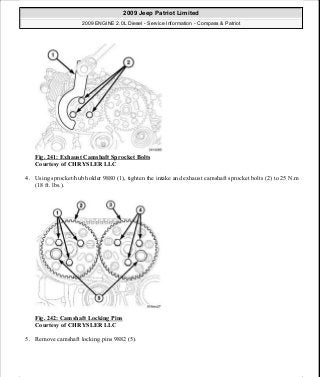

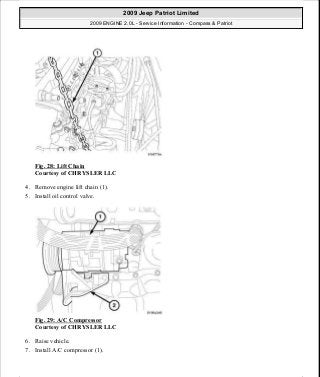

Caster Camber

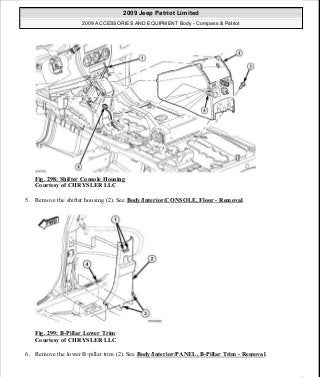

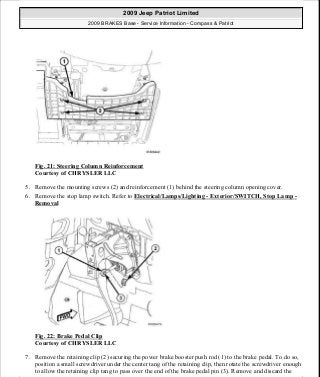

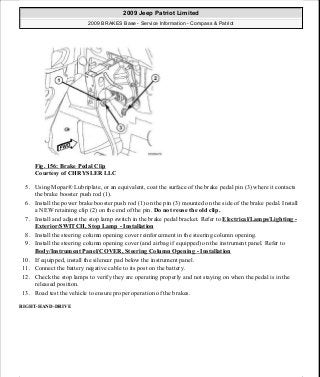

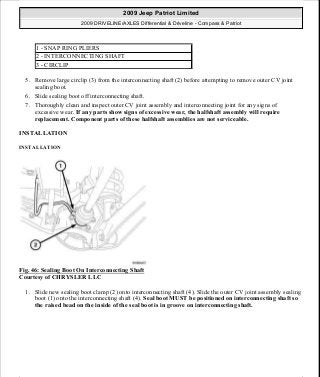

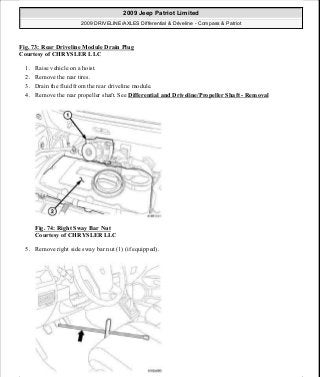

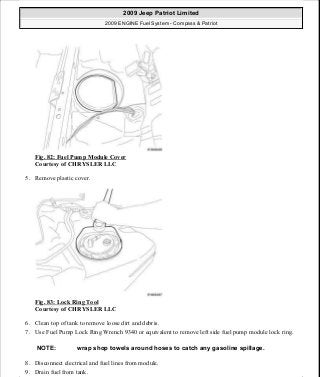

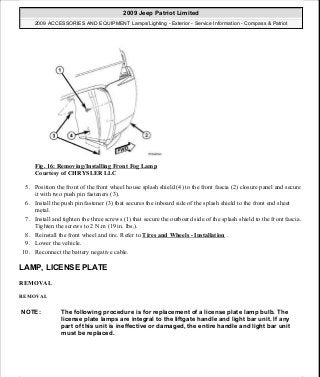

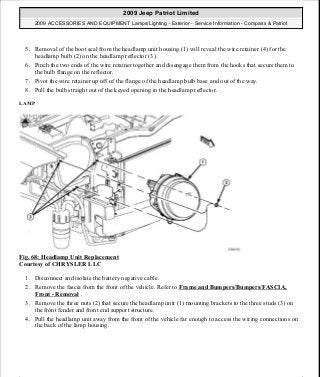

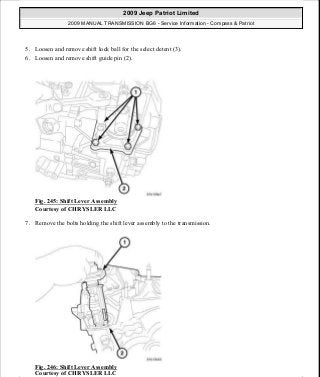

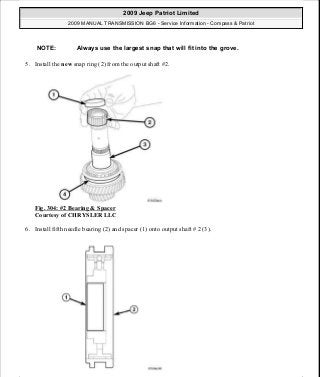

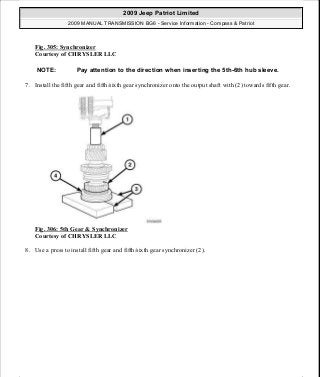

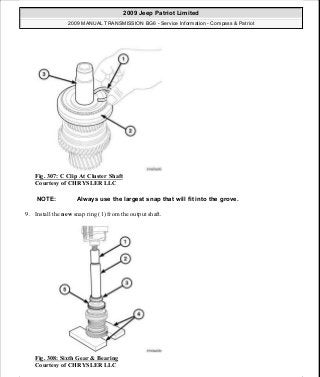

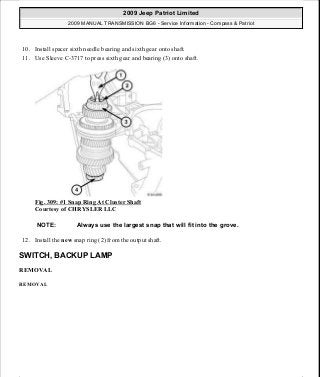

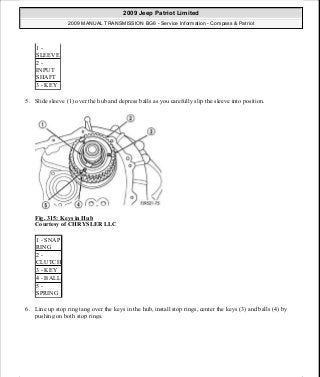

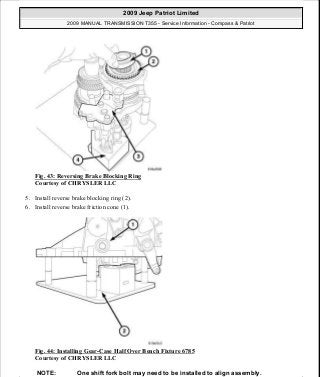

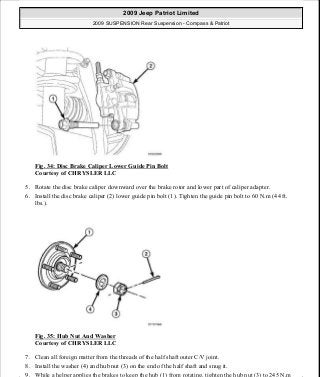

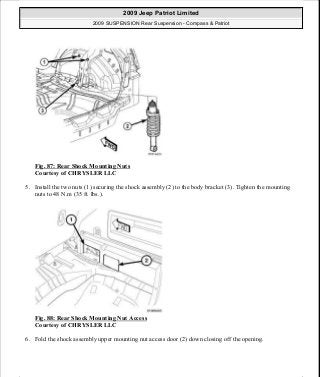

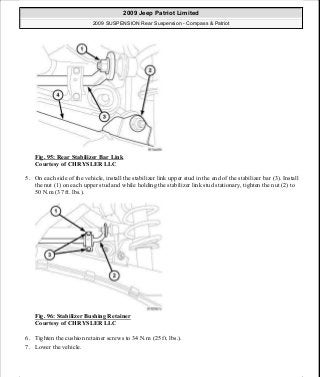

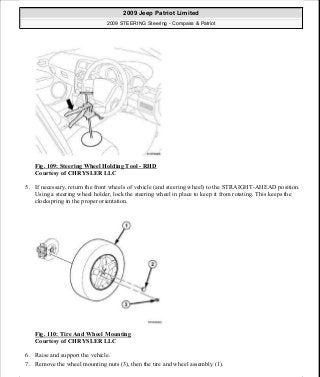

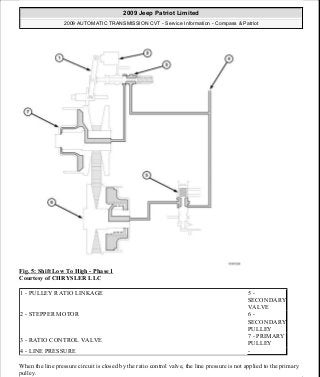

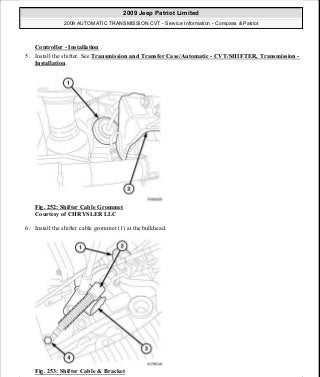

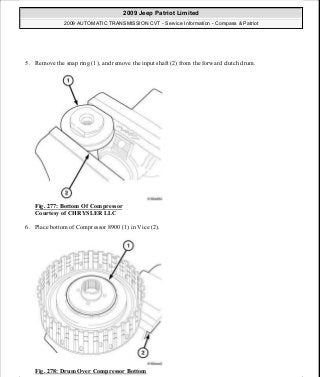

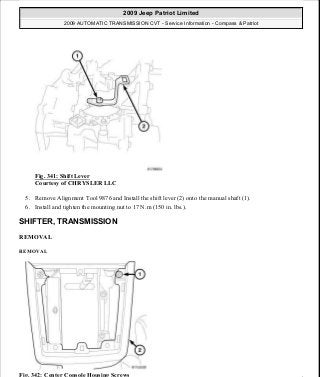

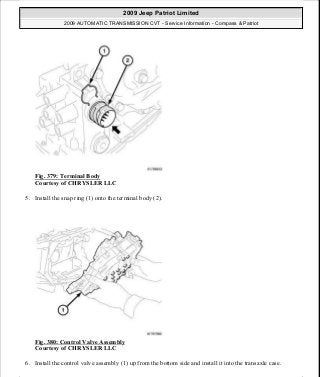

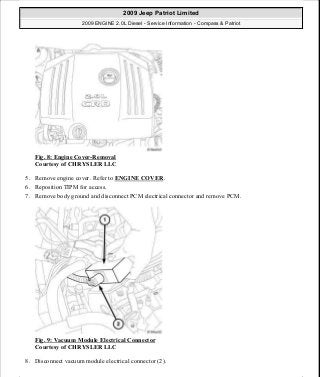

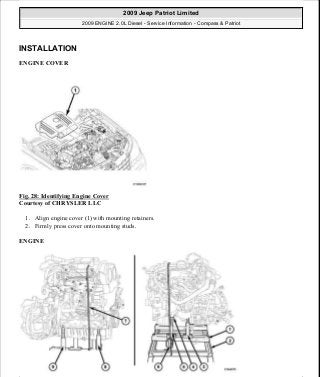

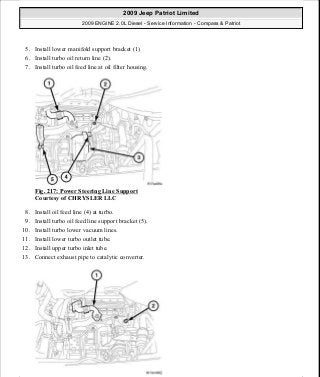

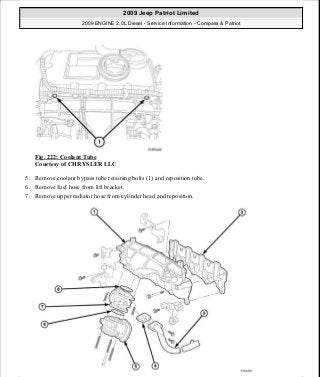

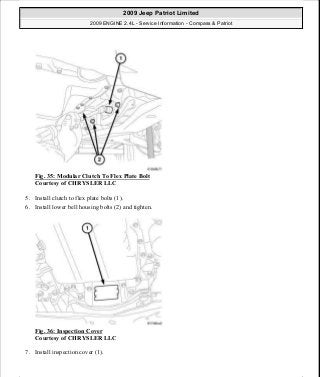

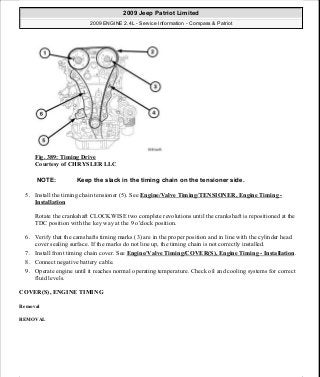

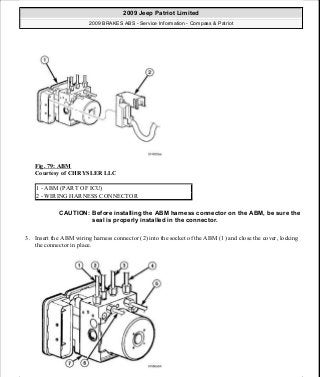

Year

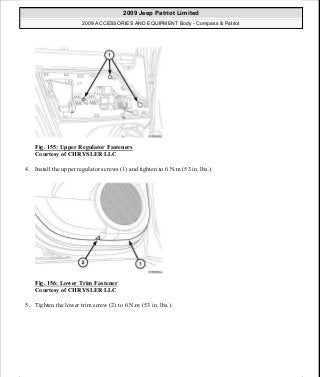

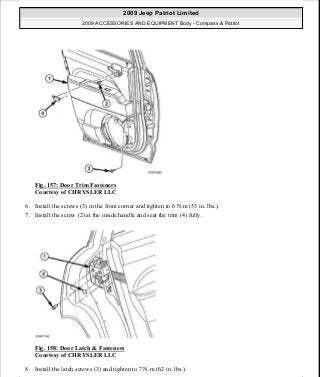

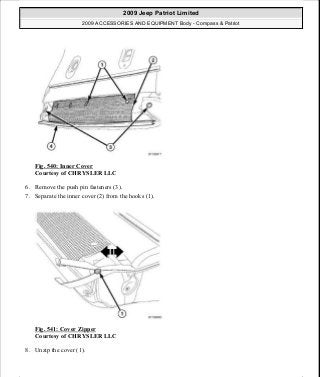

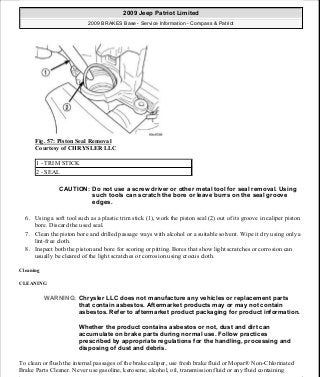

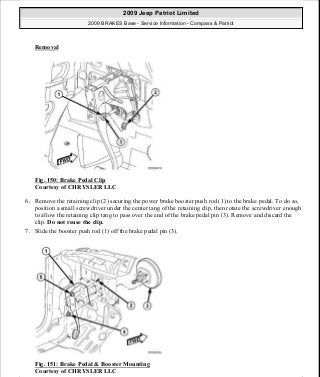

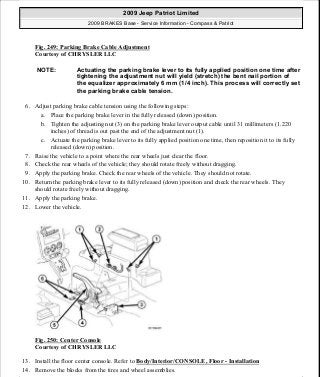

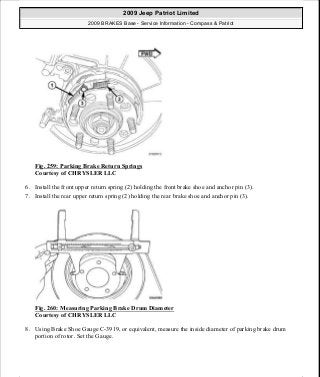

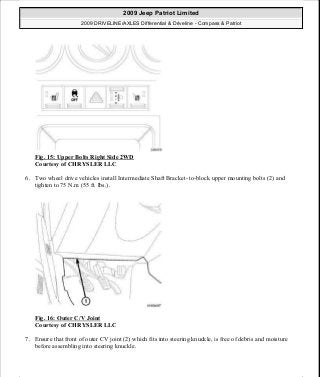

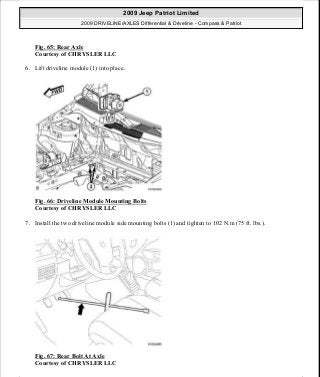

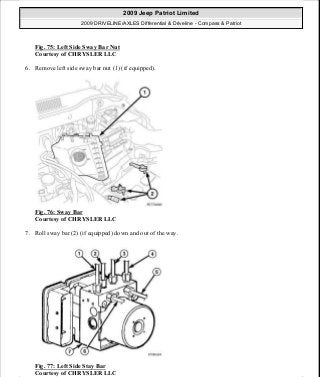

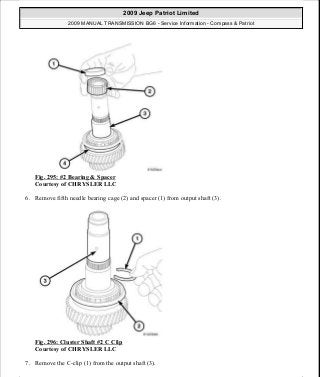

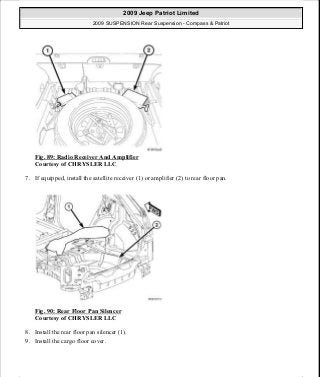

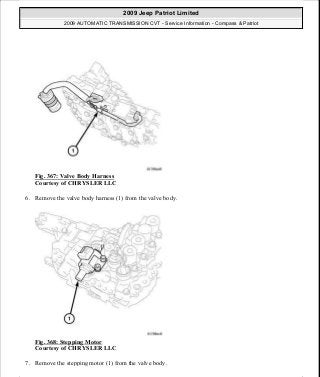

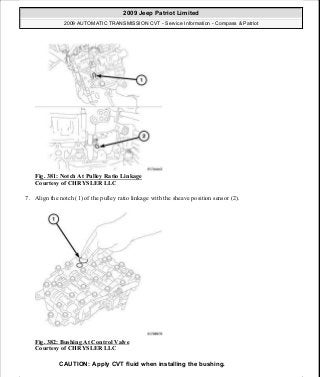

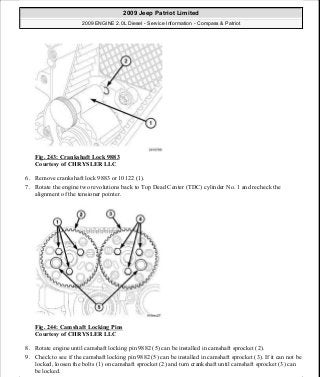

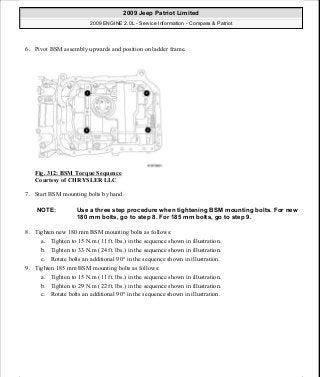

2007

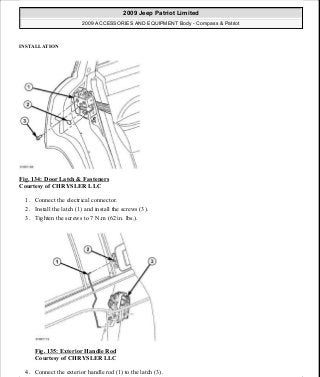

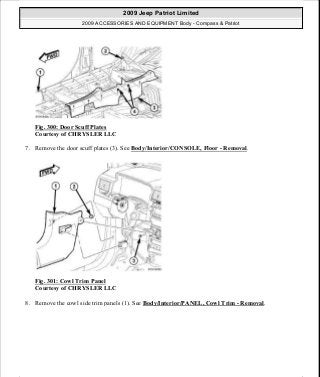

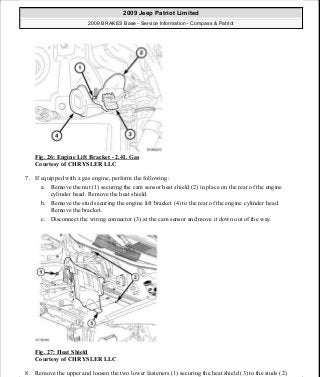

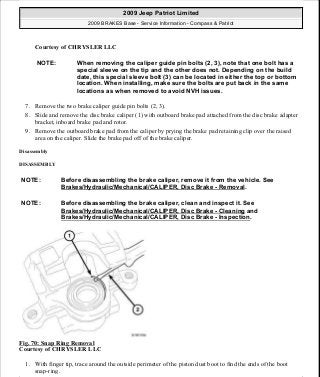

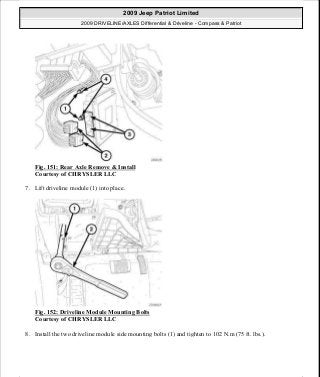

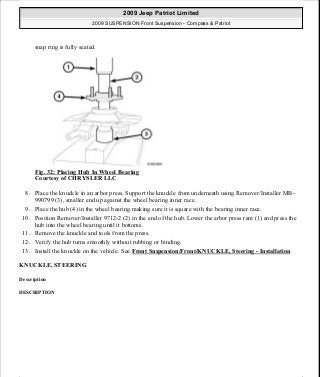

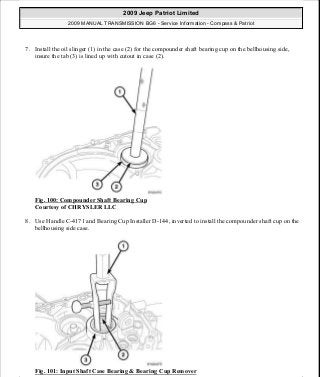

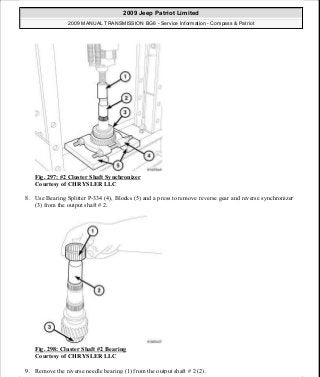

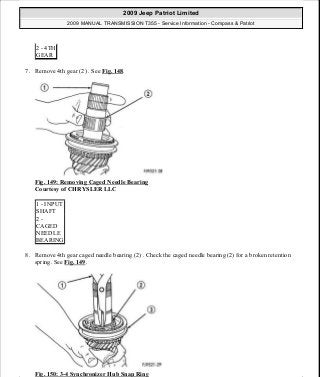

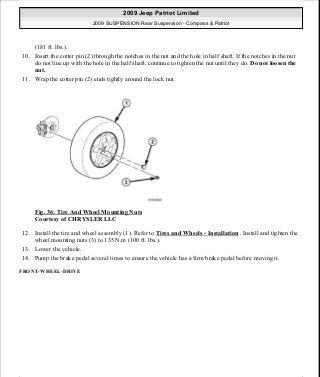

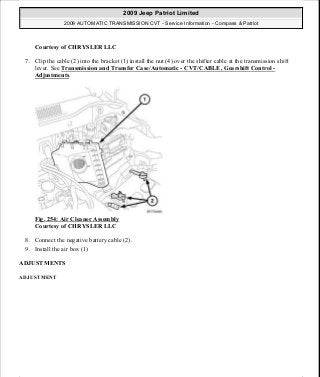

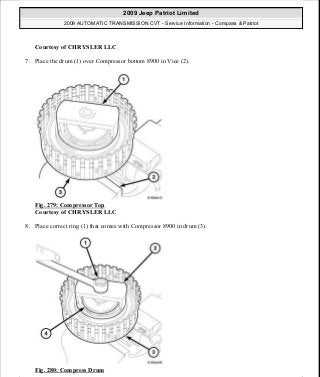

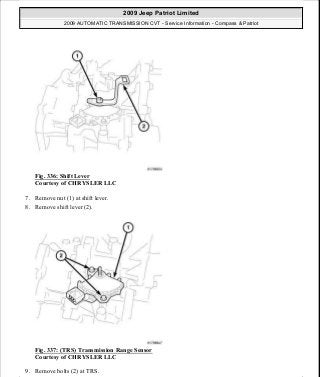

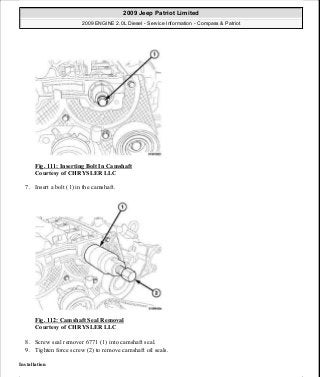

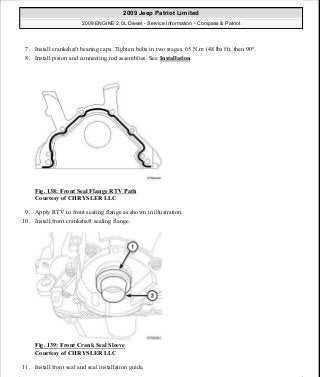

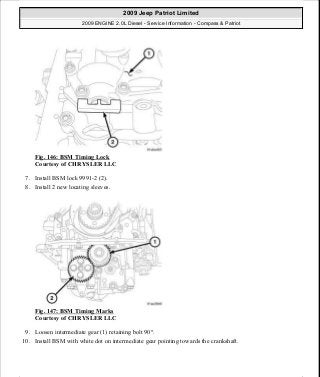

2008

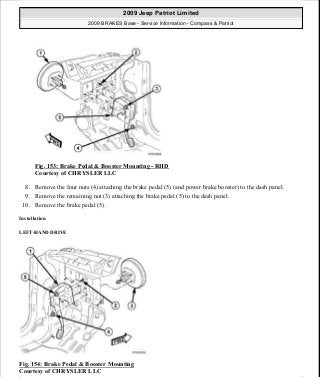

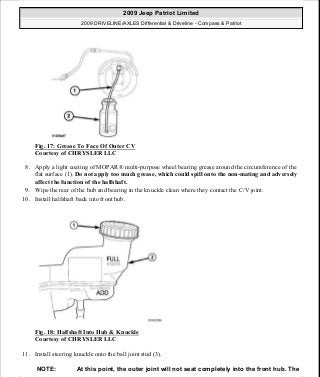

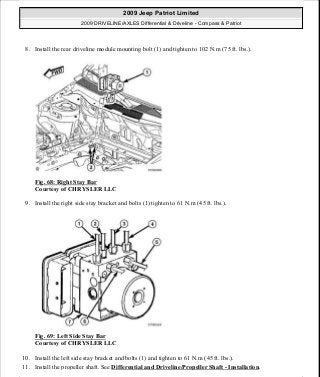

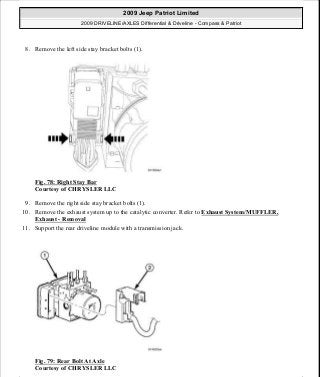

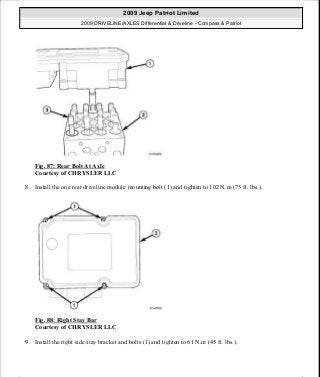

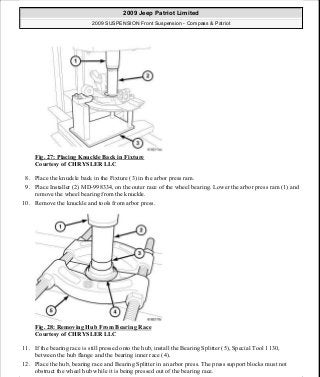

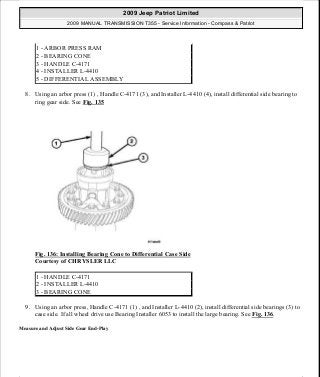

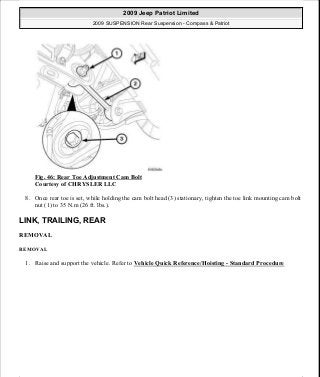

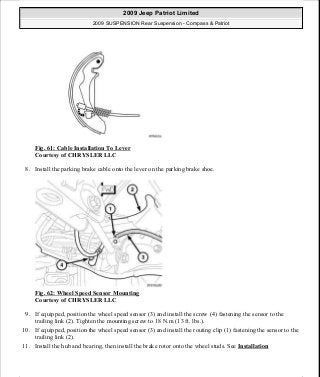

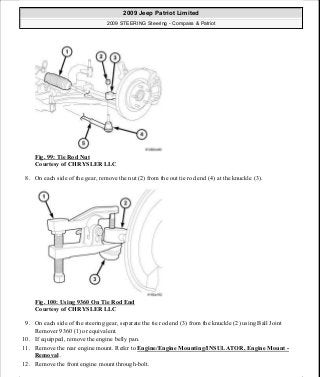

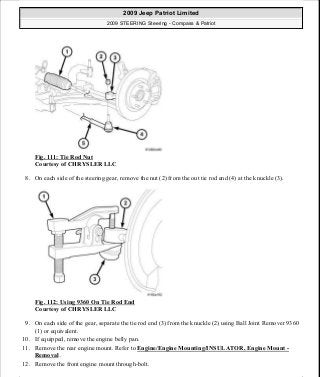

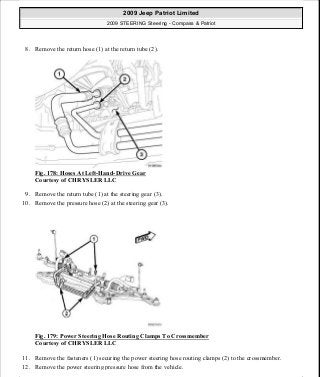

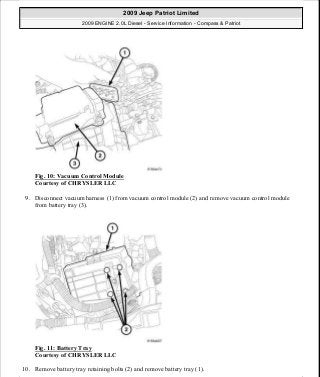

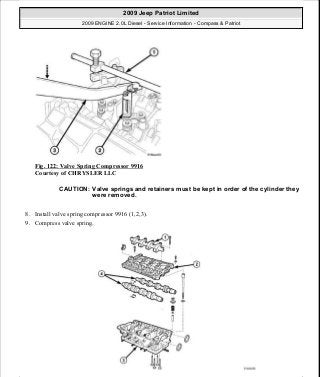

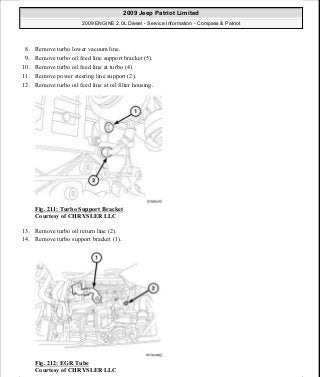

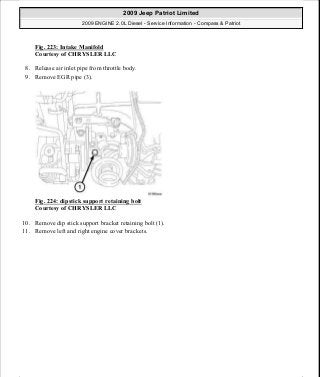

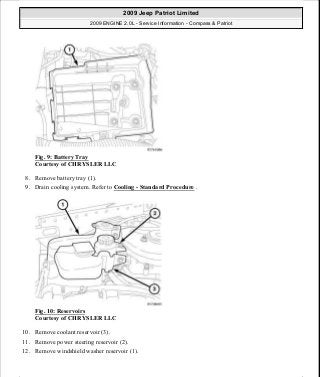

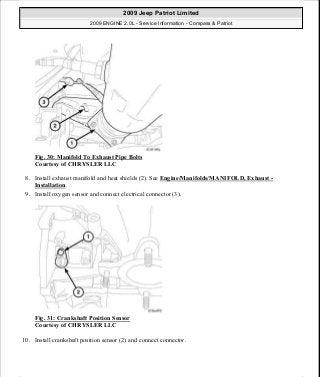

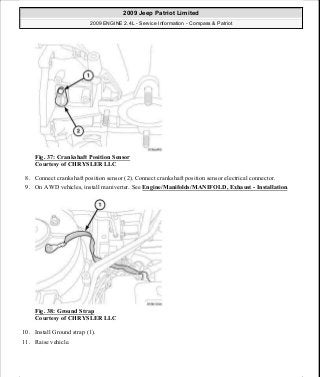

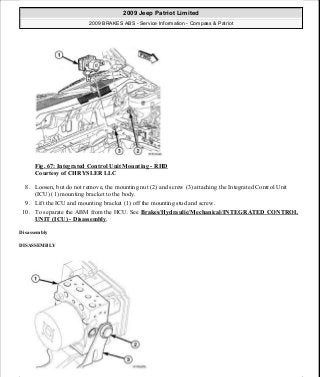

2009

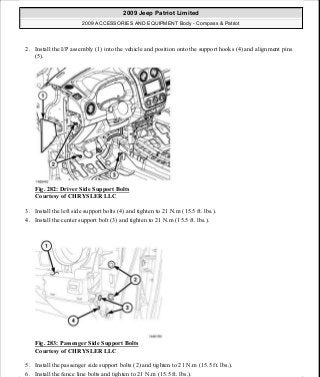

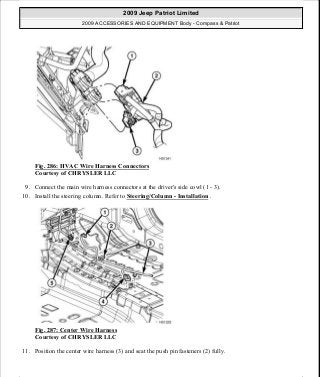

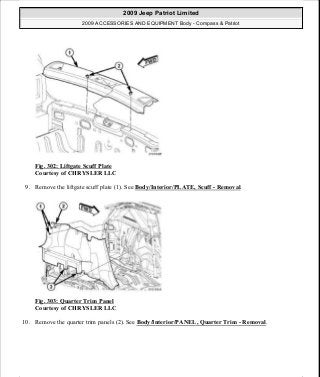

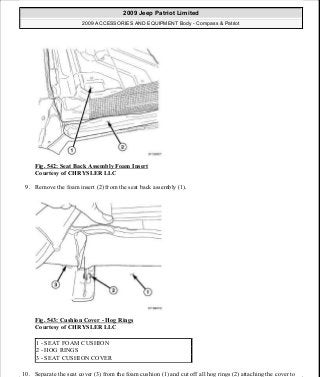

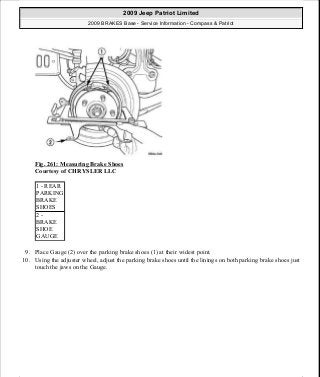

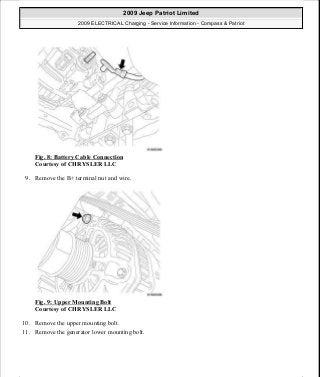

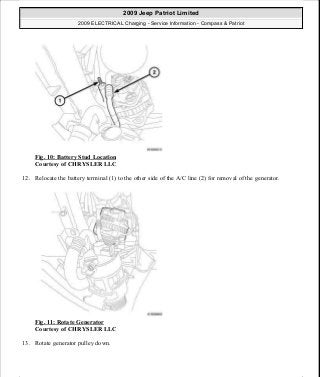

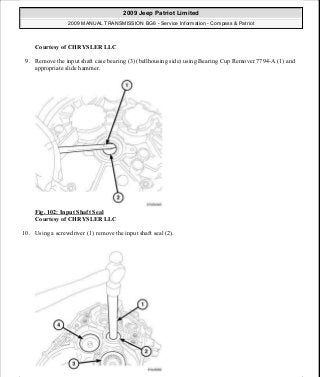

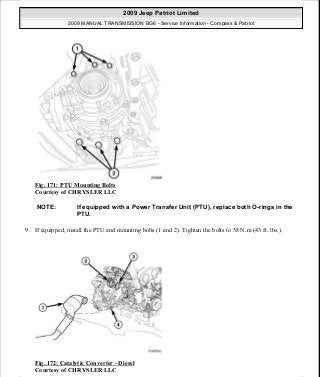

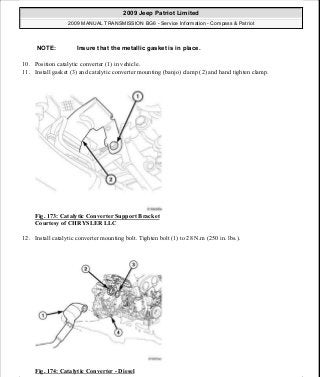

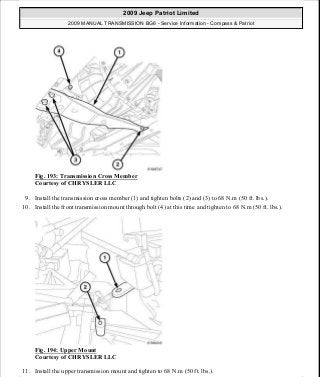

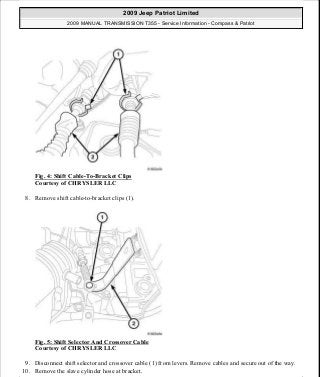

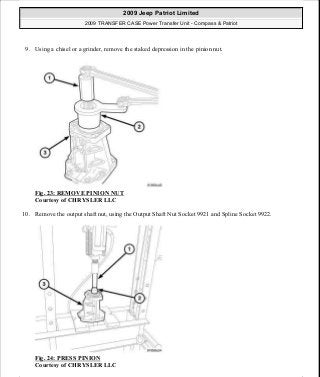

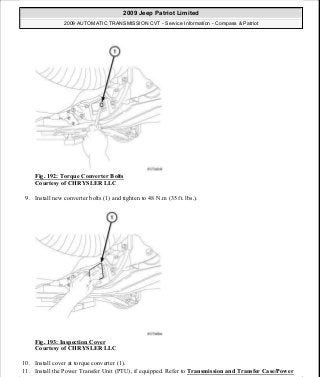

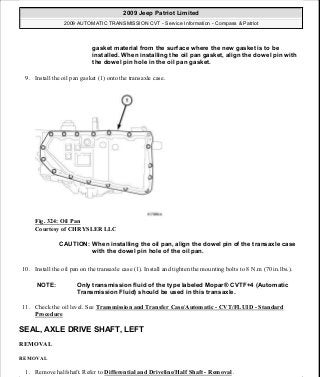

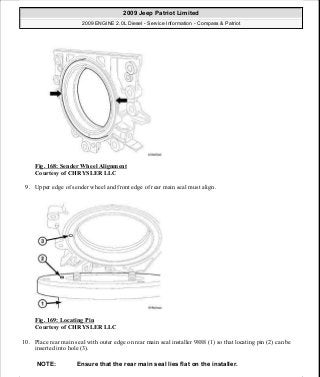

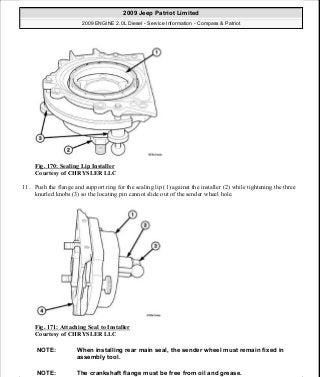

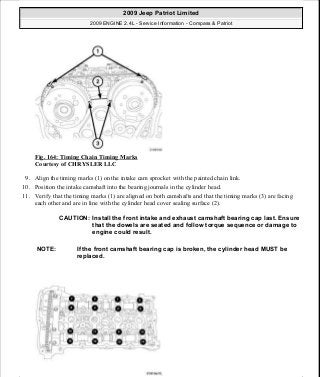

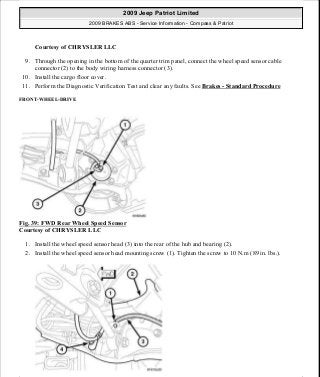

Model©

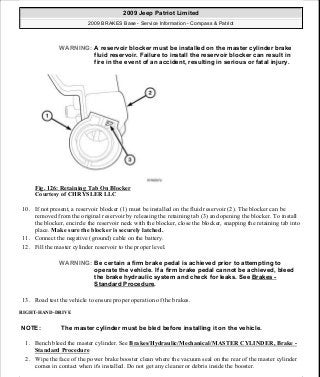

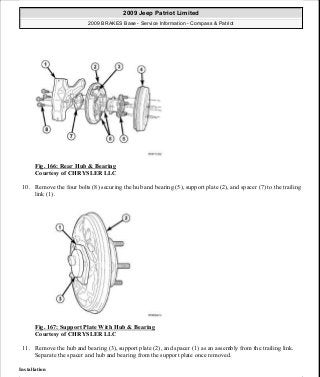

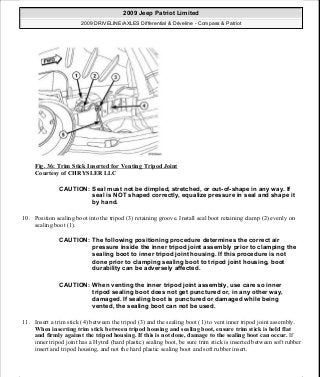

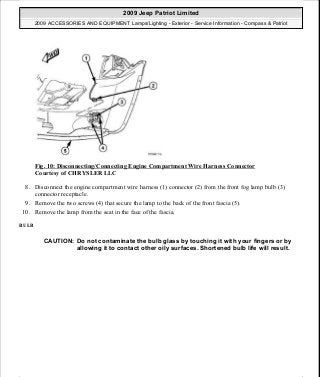

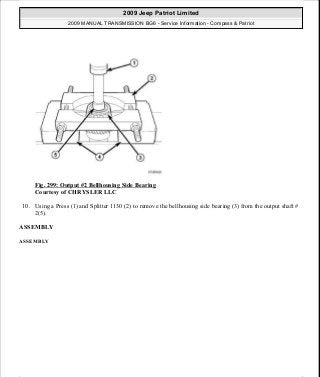

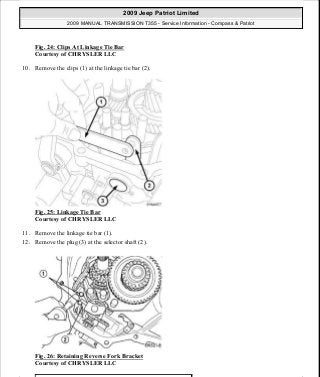

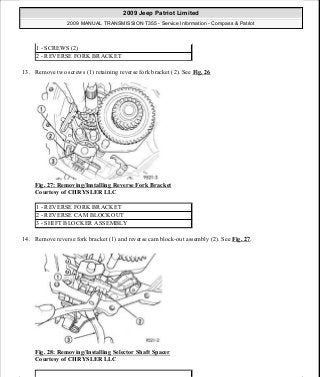

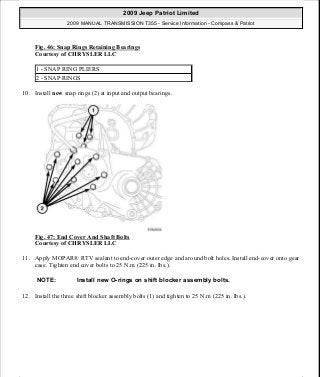

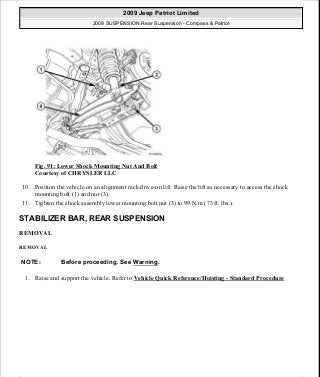

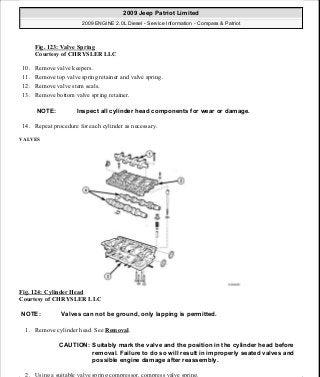

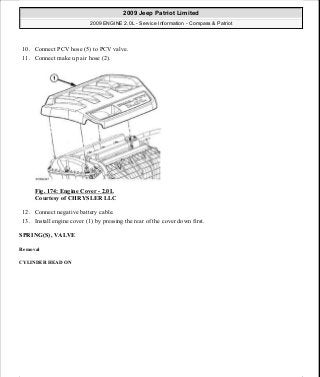

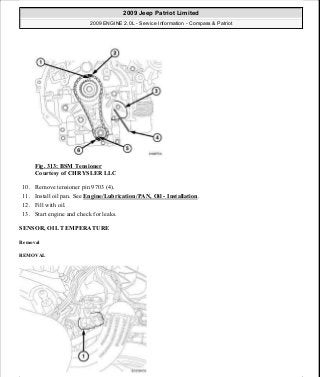

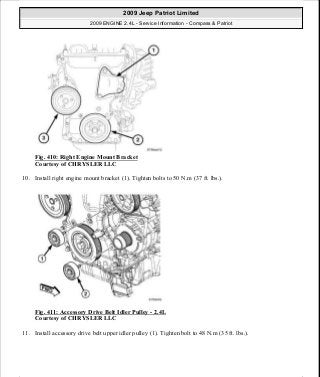

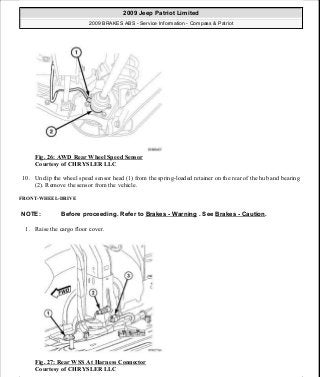

Compass/Patriot

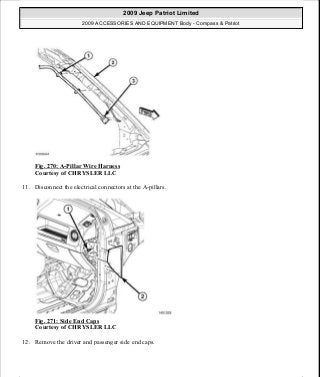

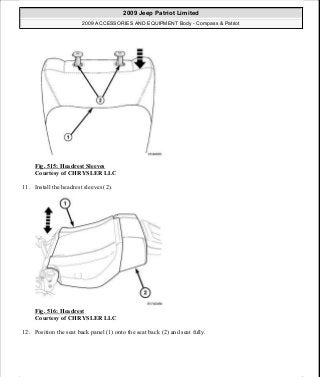

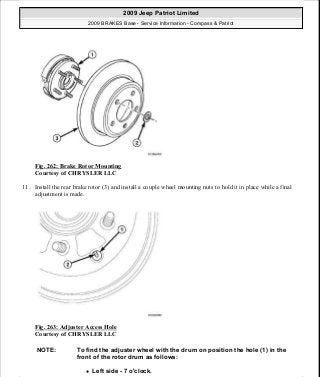

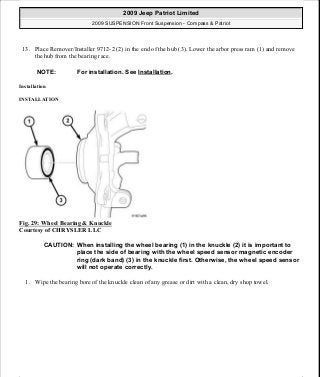

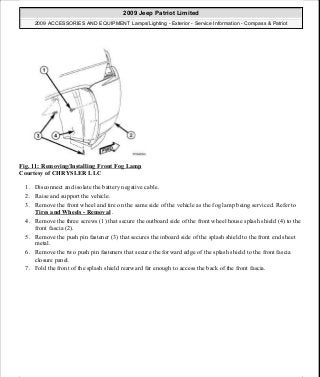

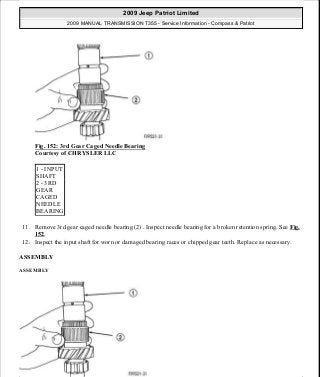

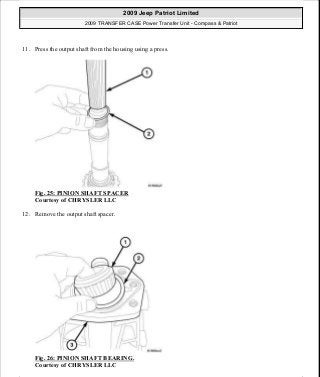

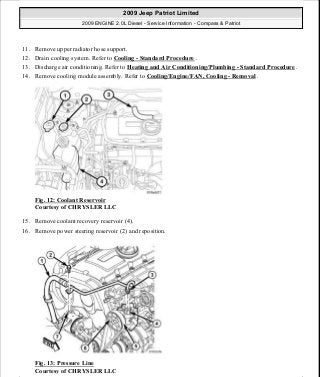

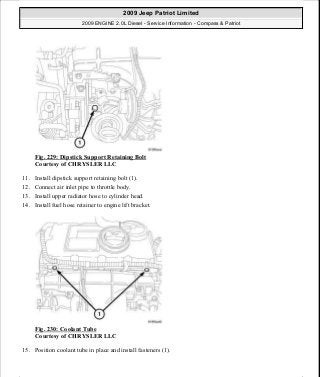

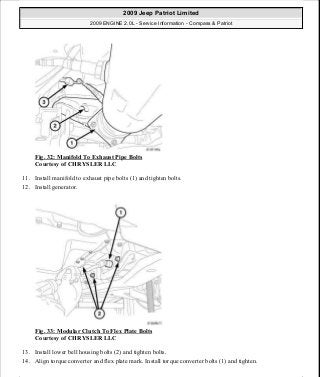

16 inch wheels

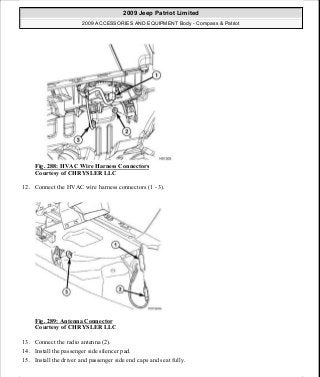

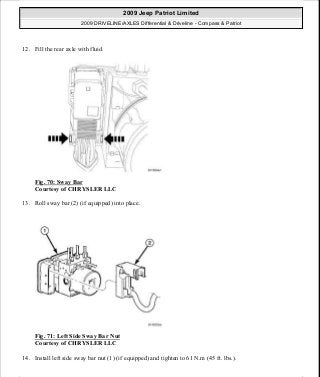

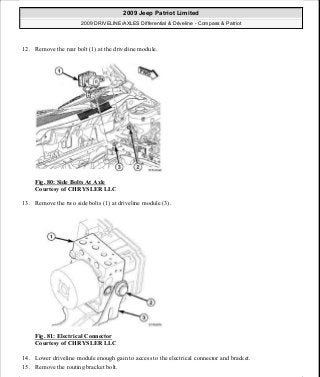

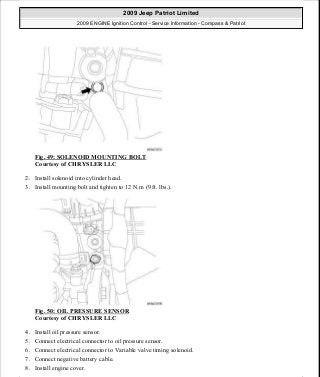

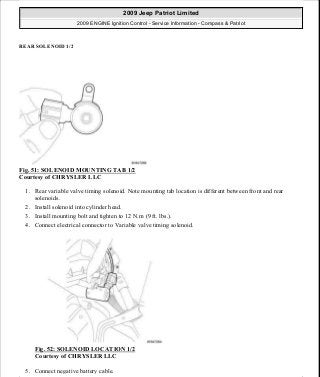

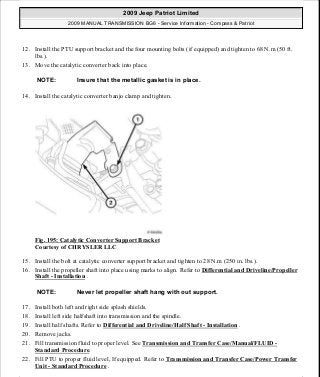

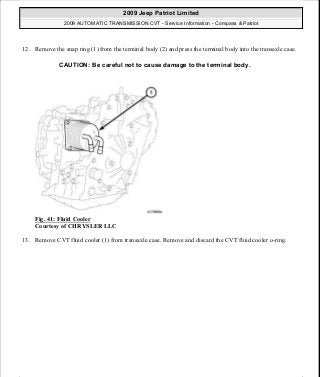

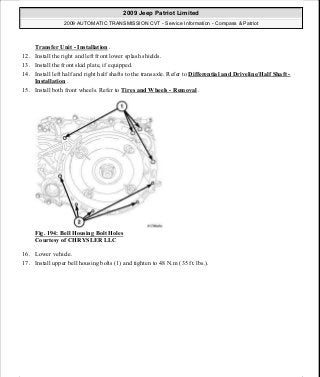

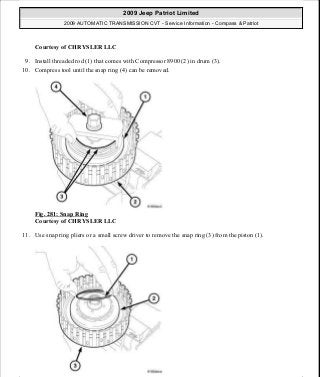

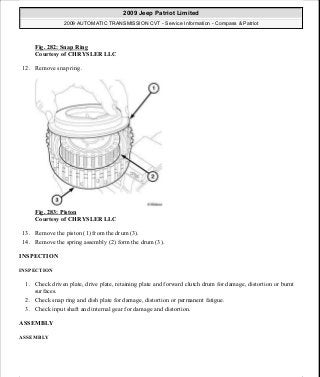

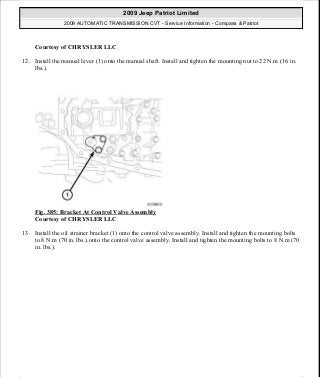

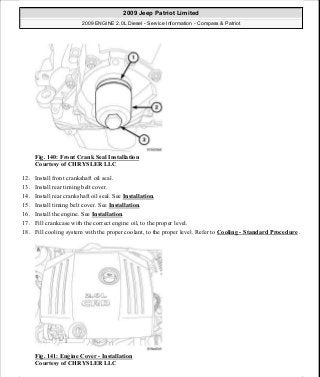

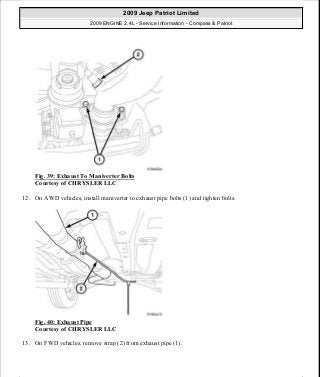

Compass/Patriot

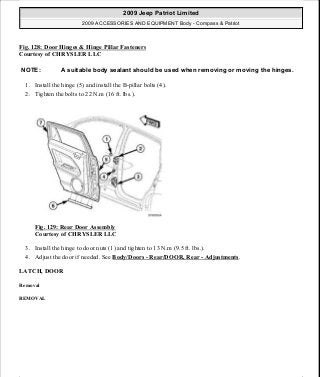

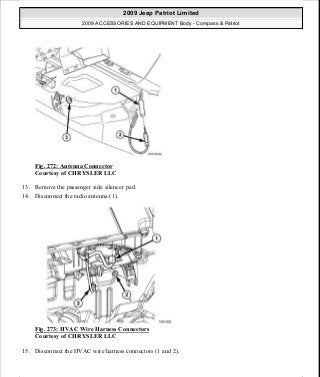

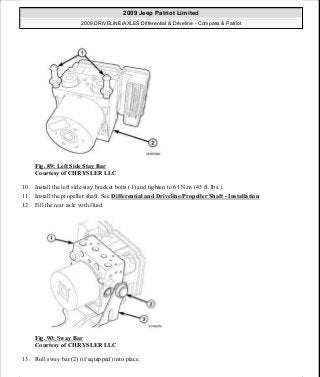

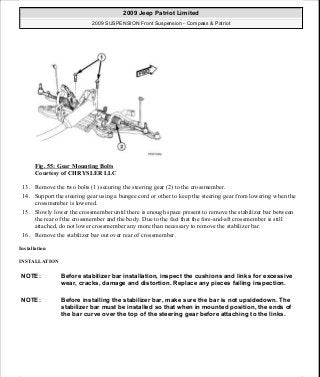

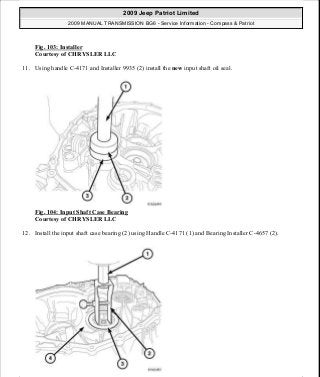

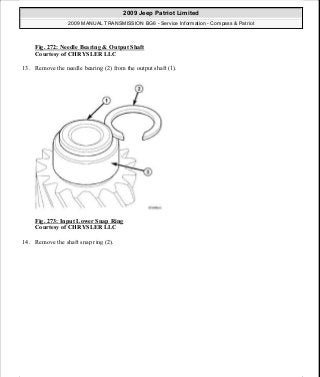

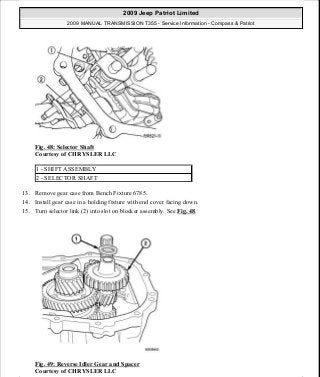

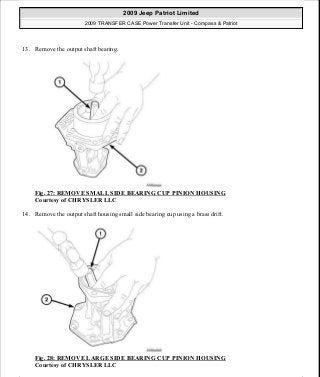

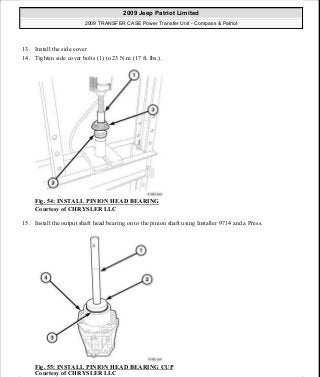

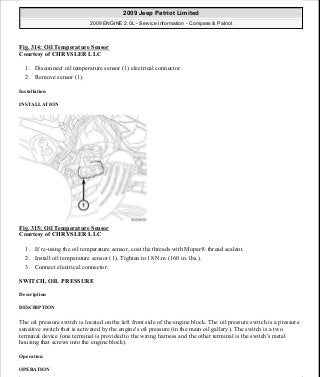

17 inch wheels®

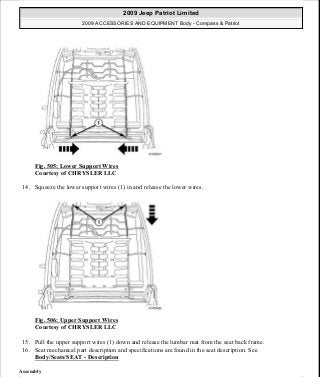

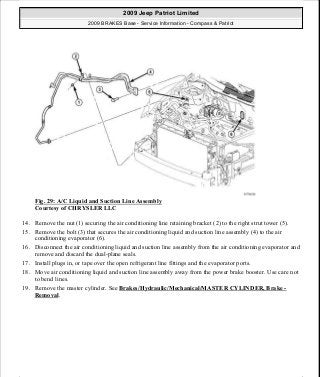

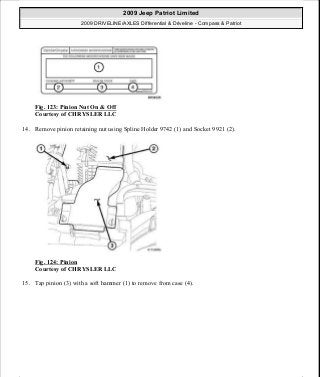

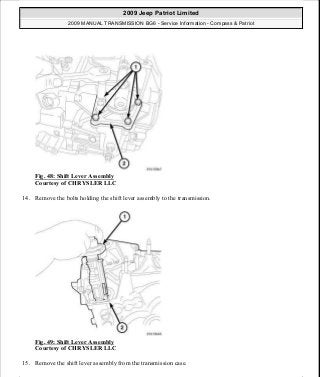

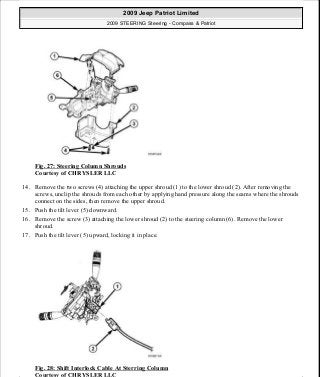

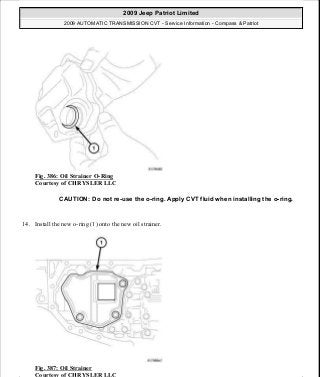

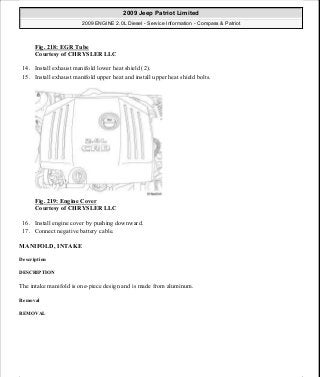

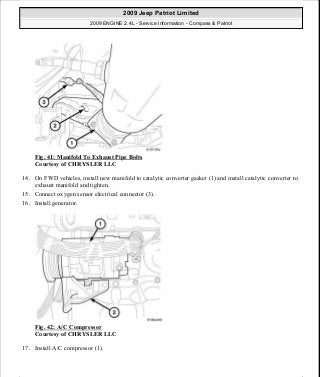

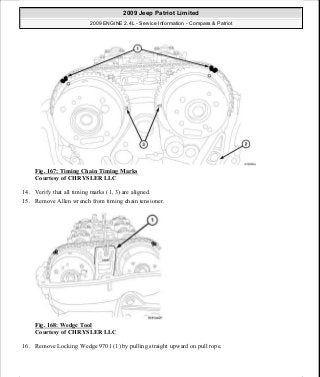

Compass/Patriot

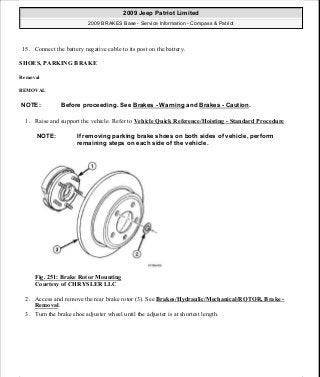

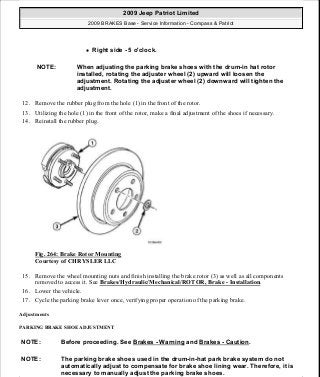

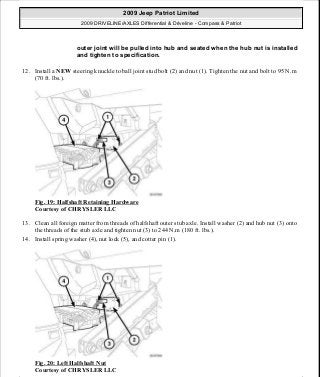

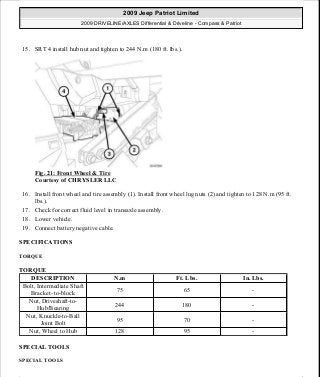

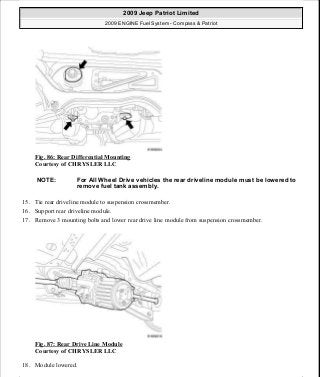

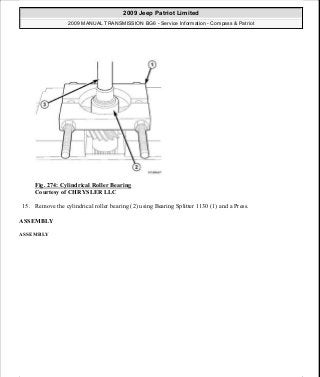

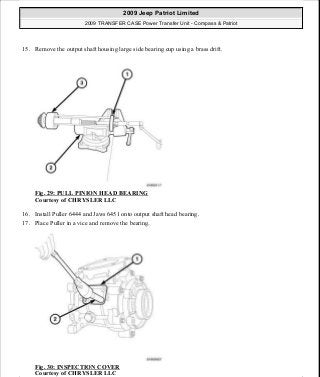

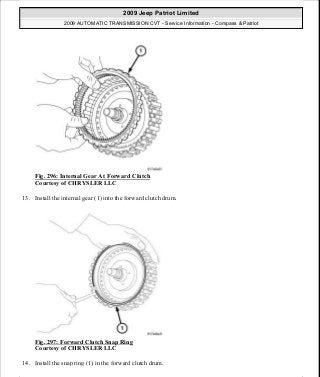

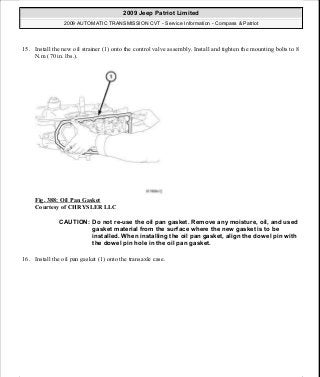

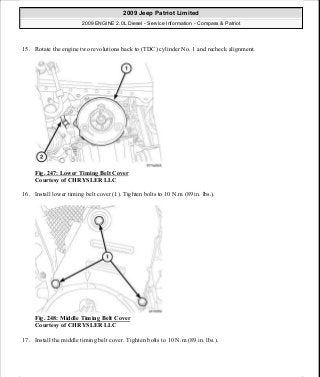

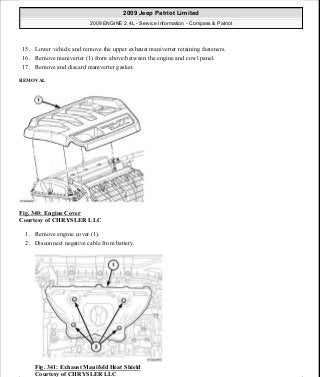

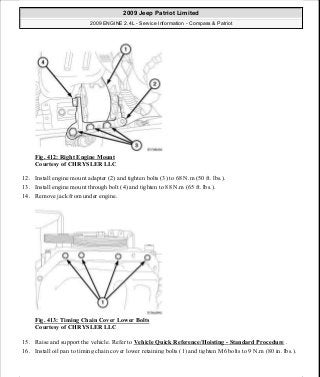

17 inch wheels©

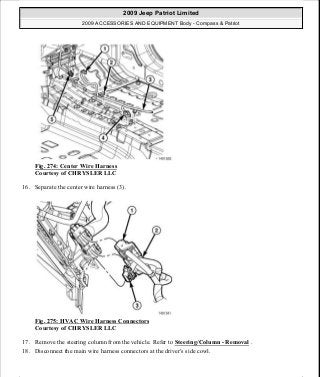

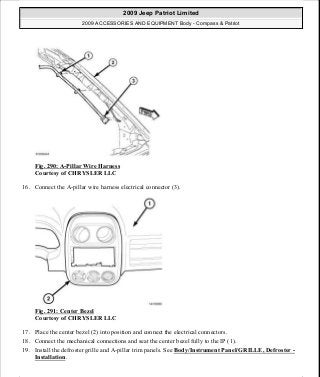

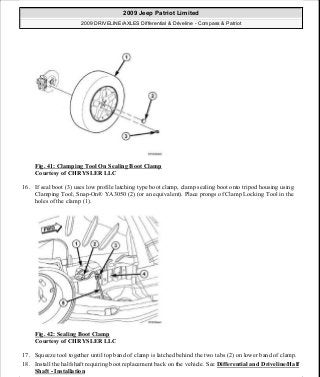

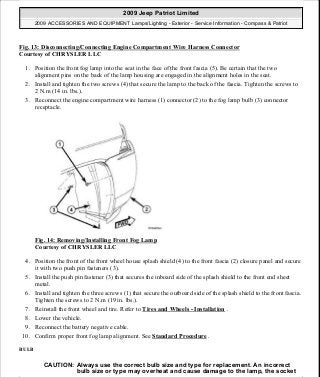

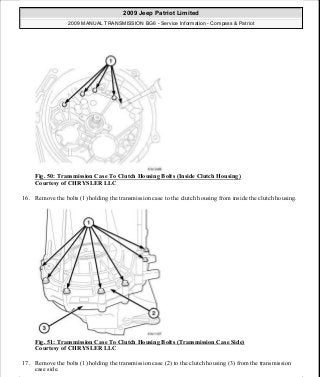

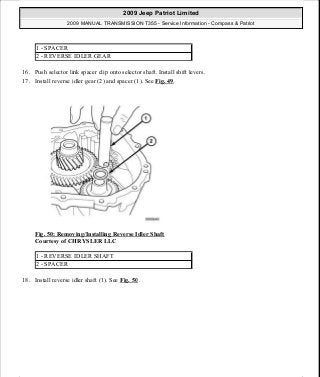

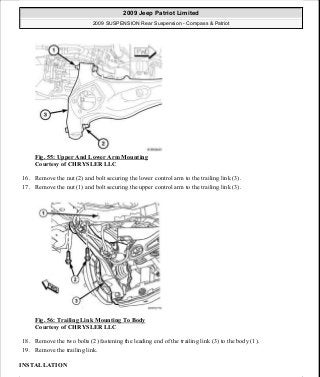

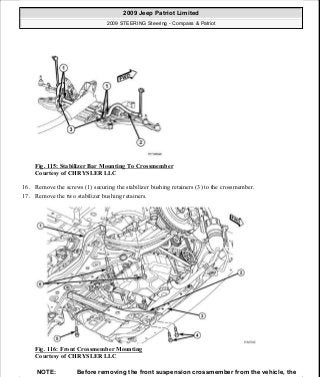

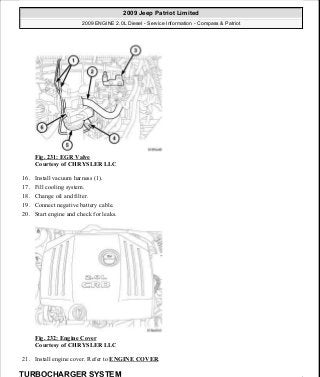

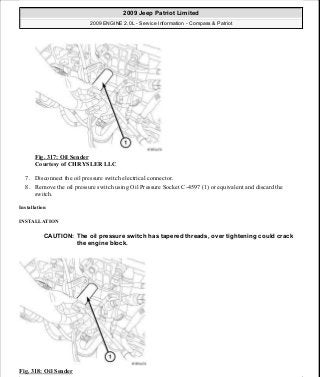

Compass/Patriot

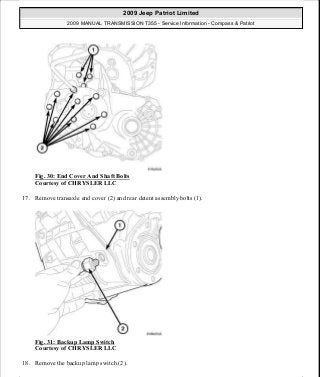

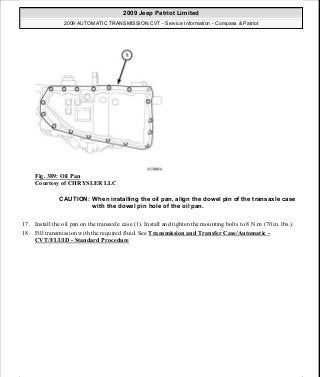

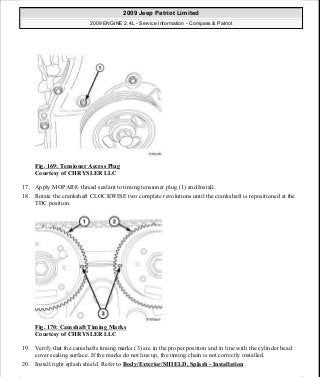

18 inch wheels

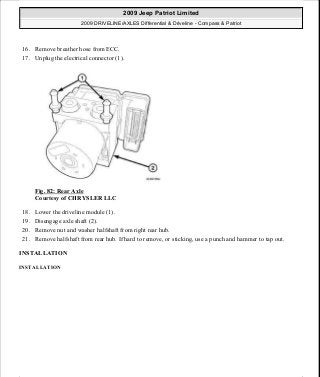

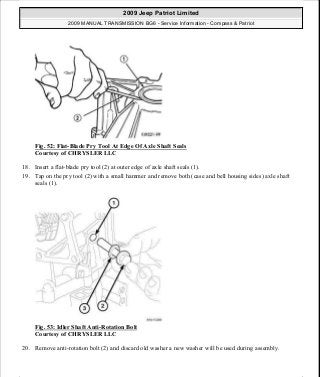

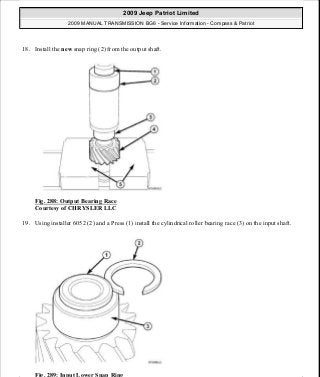

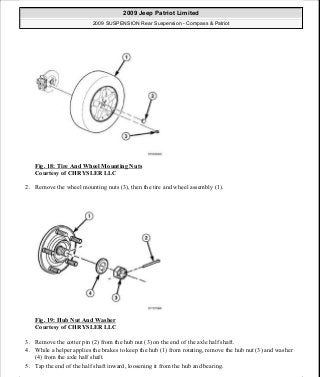

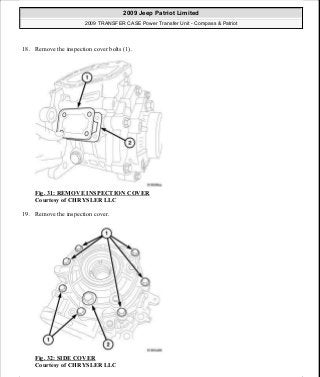

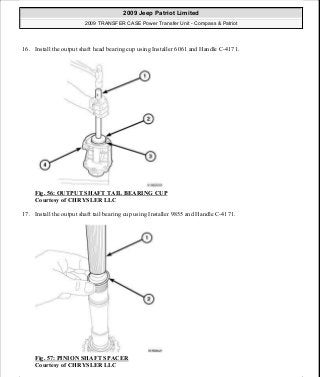

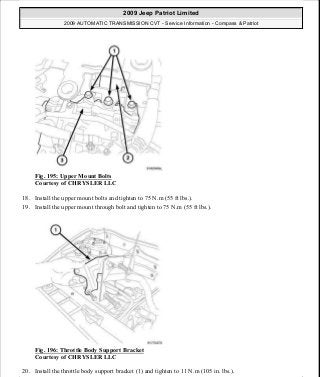

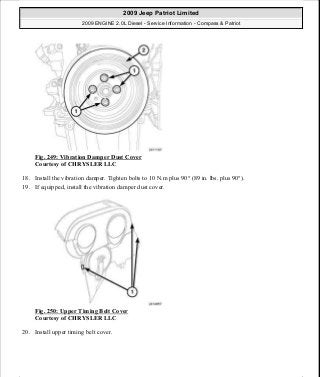

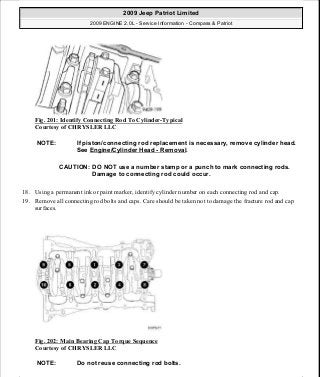

Compass/Patriot

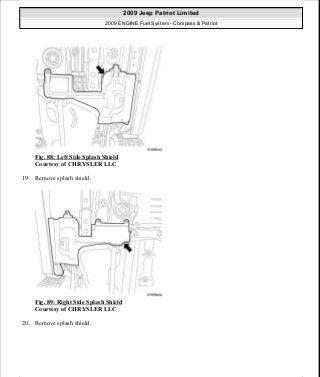

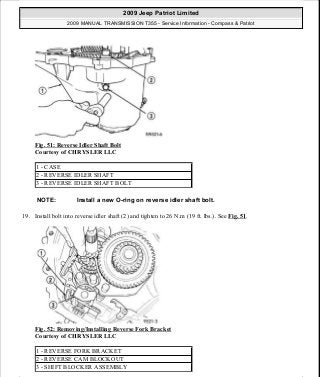

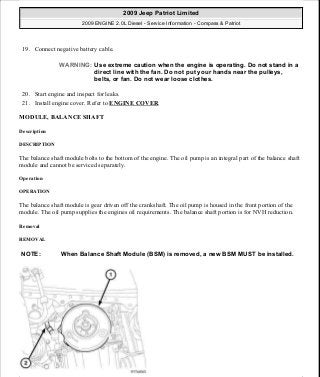

16 inch wheels

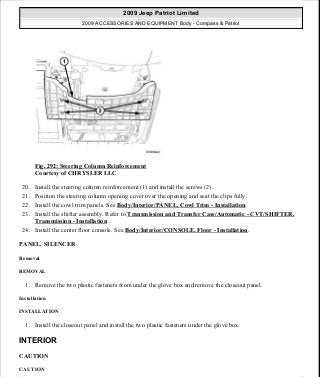

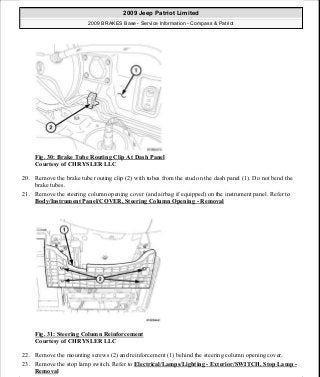

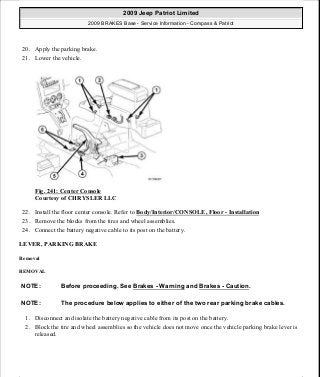

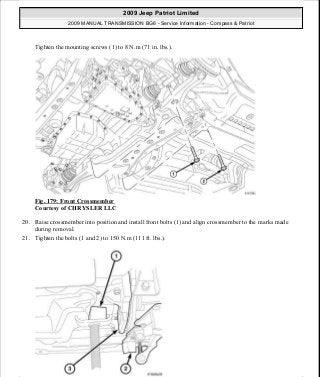

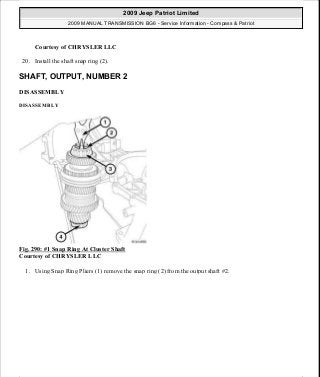

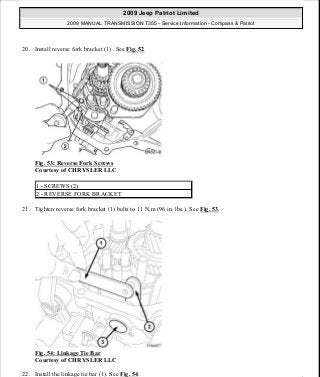

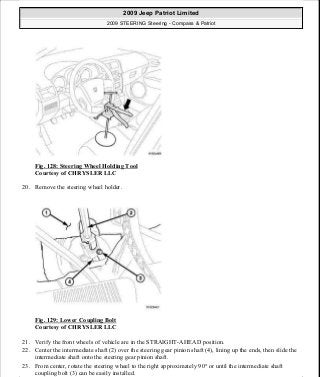

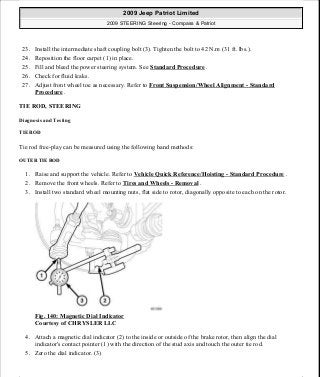

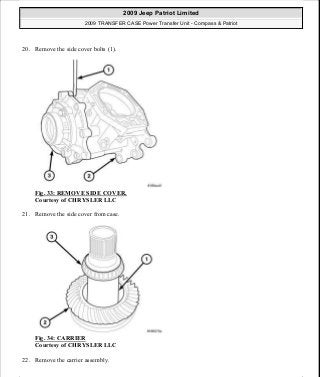

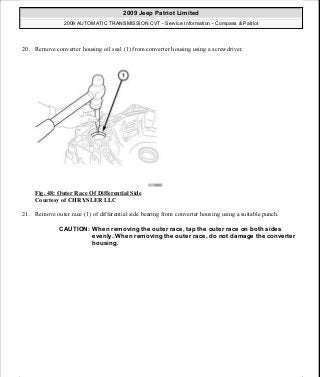

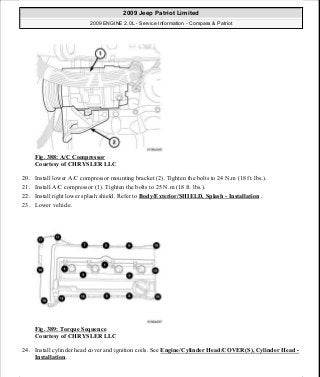

Compass/Patriot

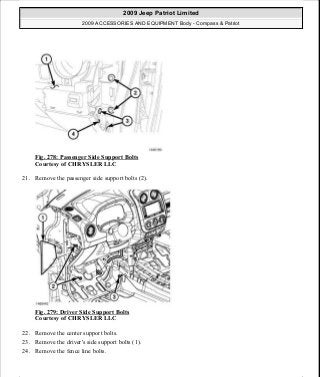

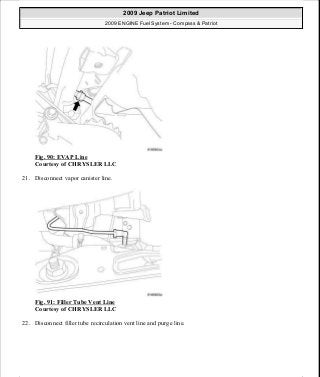

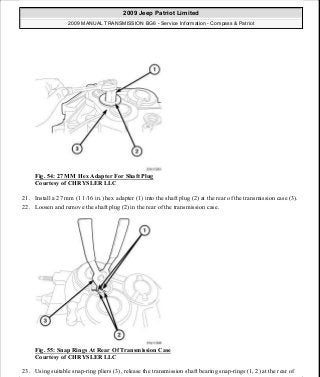

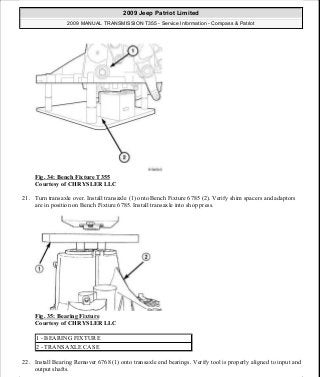

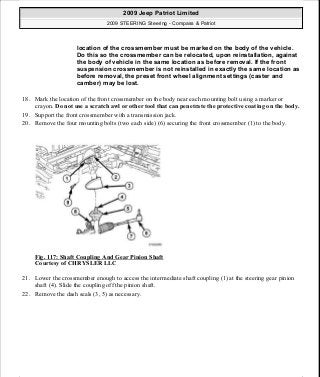

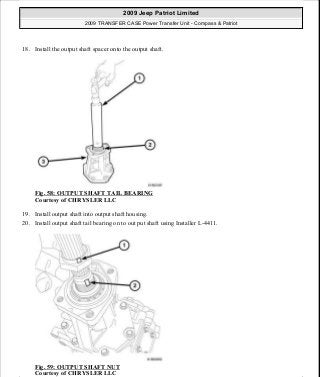

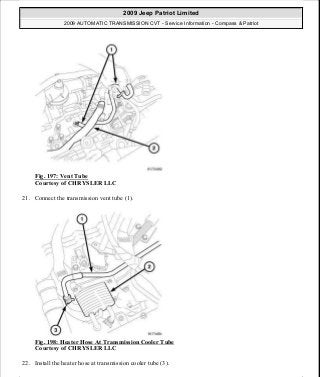

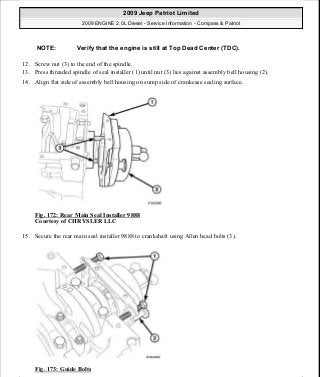

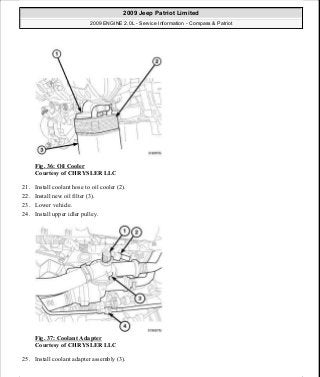

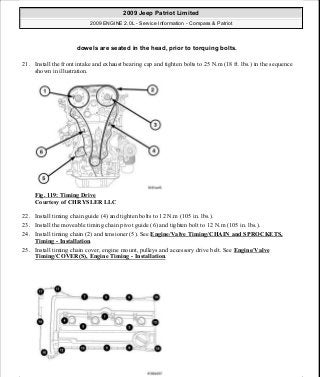

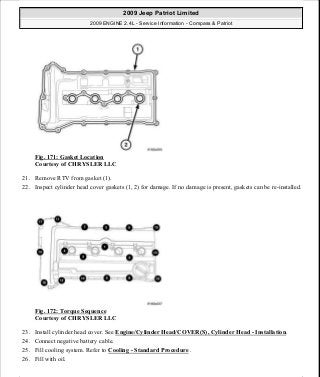

17 inch wheels®

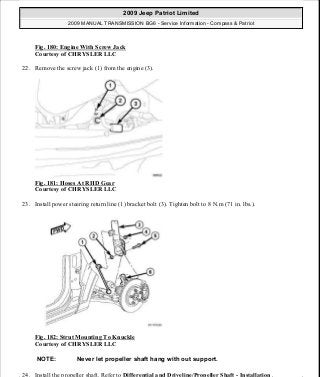

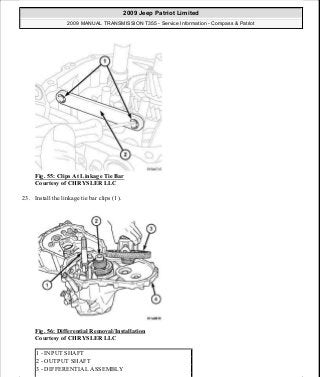

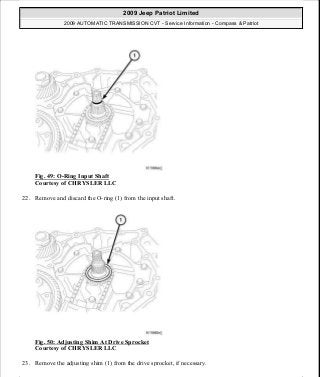

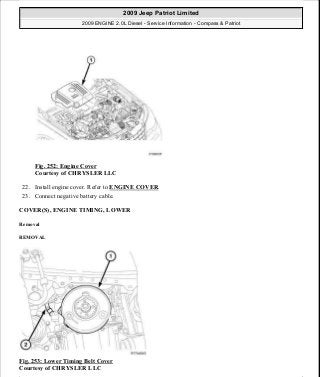

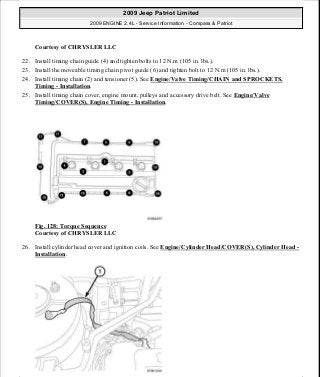

Compass/Patriot

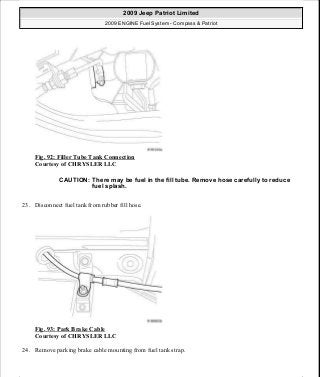

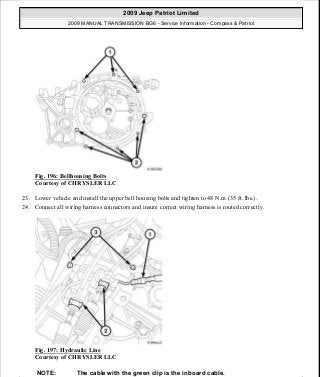

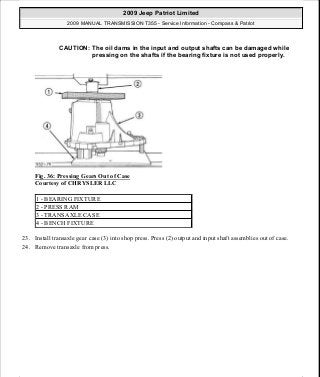

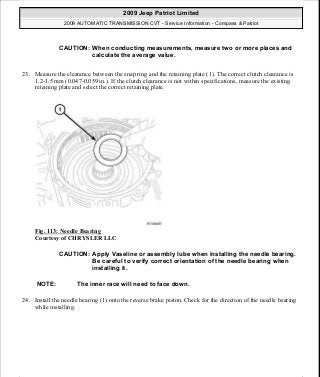

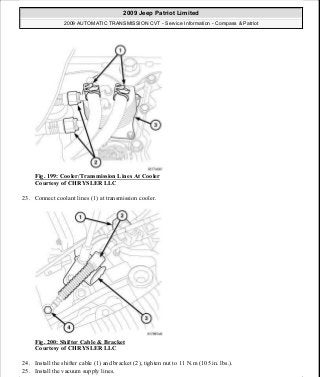

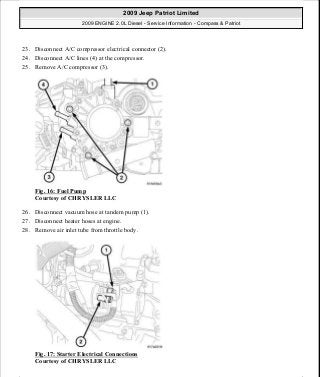

17 inch wheels©

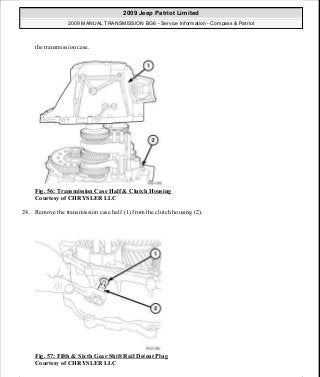

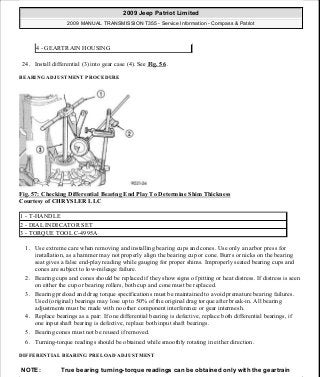

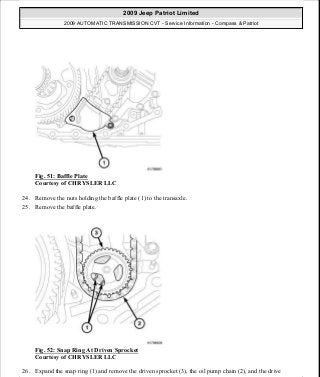

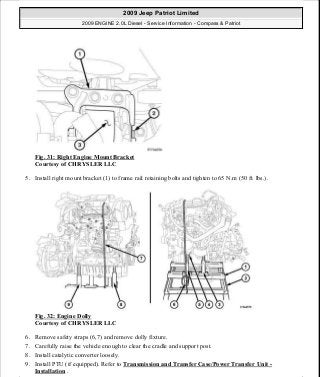

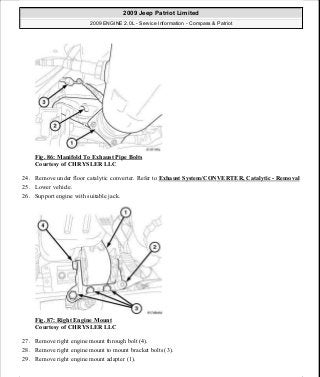

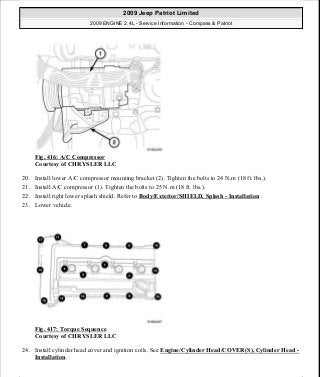

Compass/Patriot

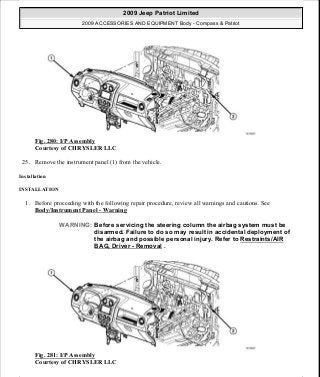

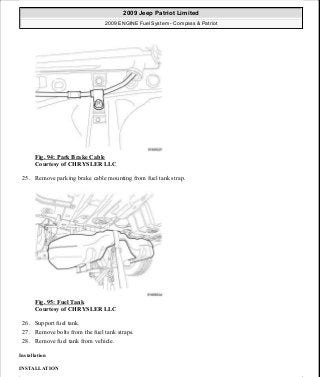

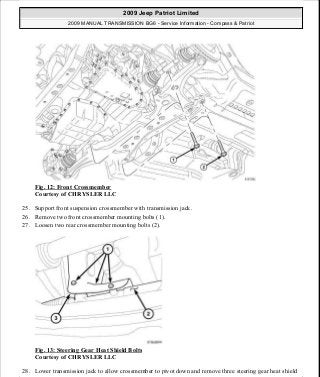

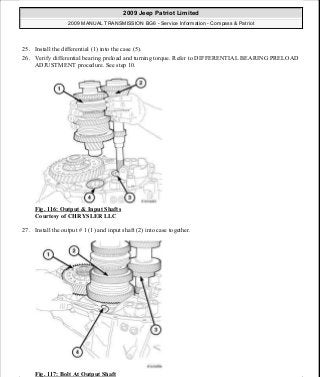

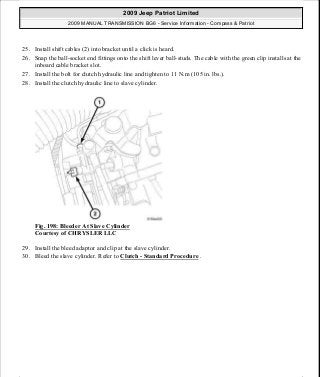

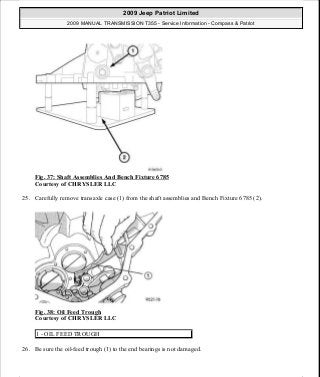

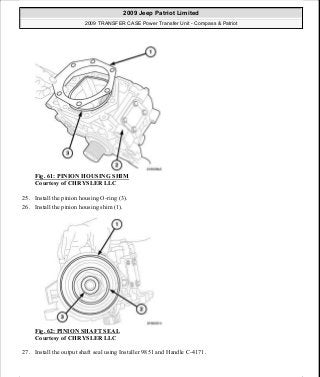

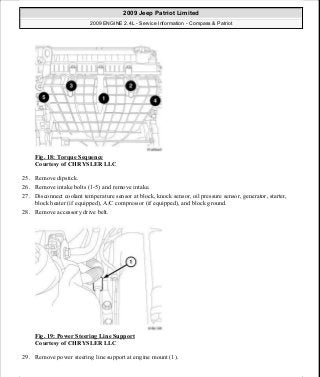

18 inch wheels

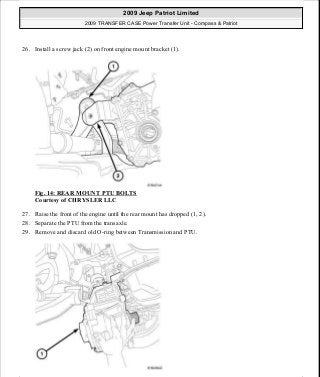

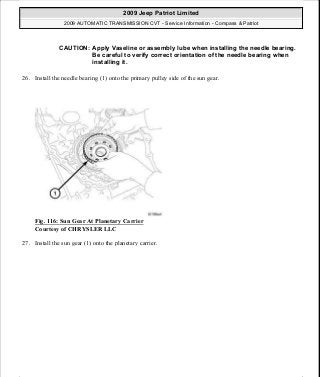

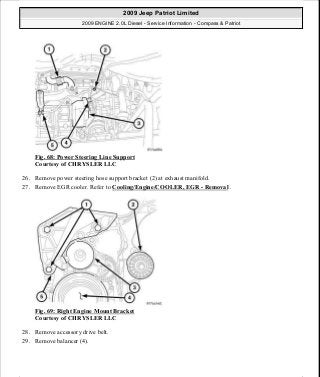

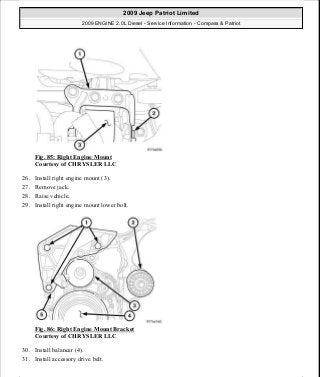

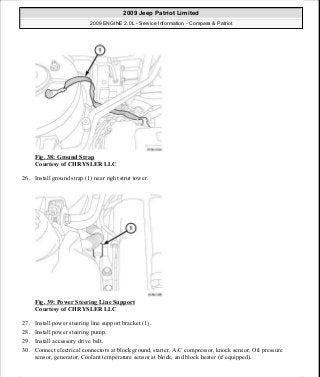

Compass/Patriot

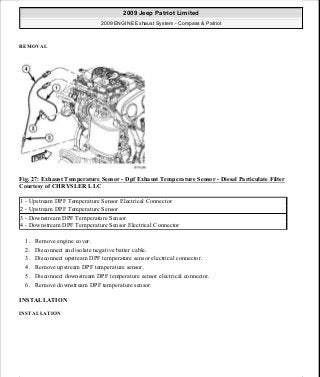

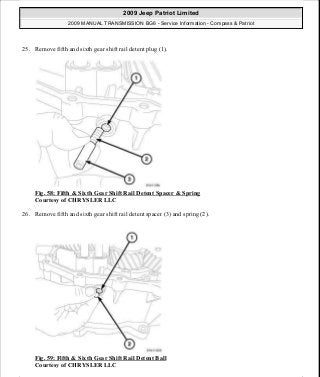

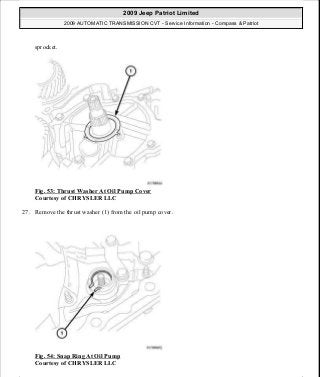

16 inch wheels

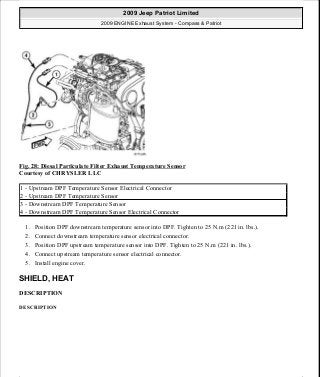

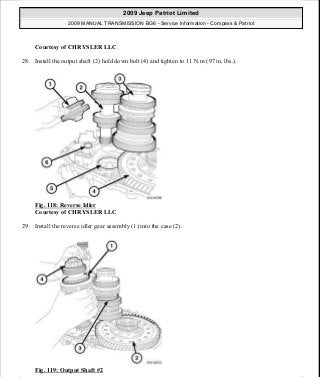

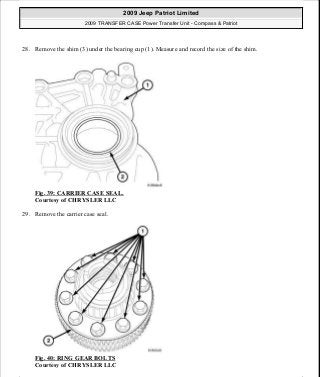

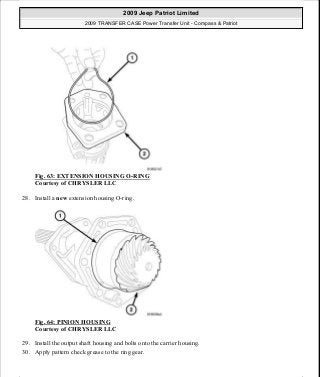

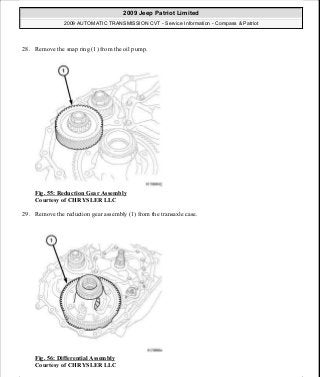

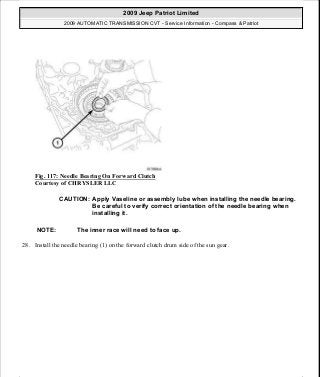

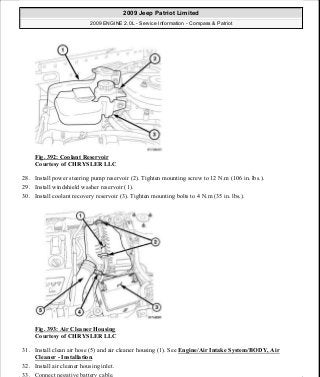

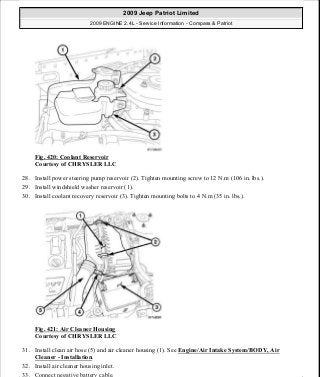

Compass/Patriot

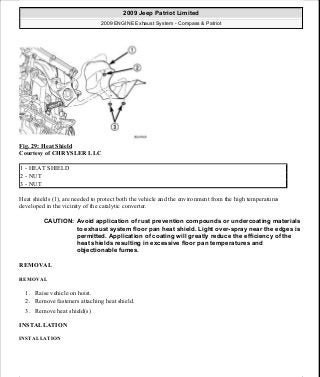

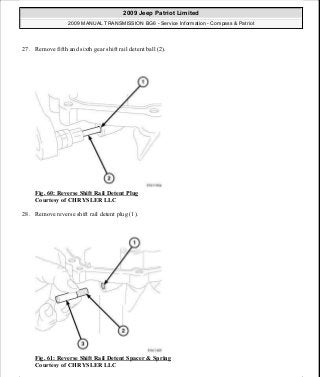

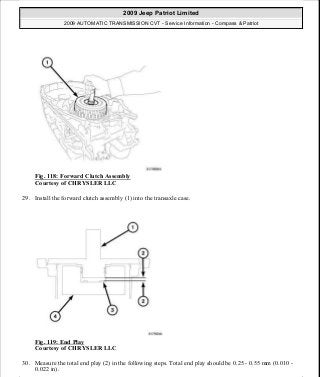

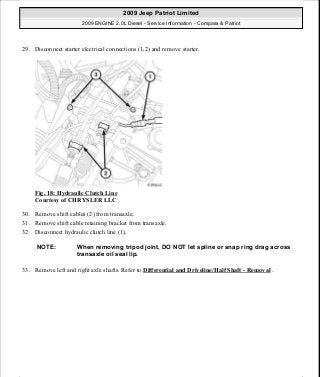

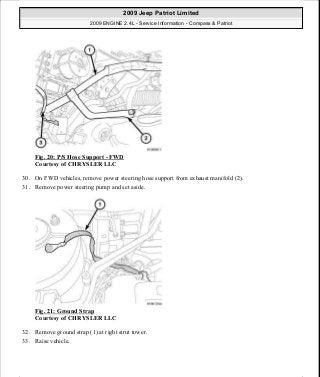

17 inch wheels®

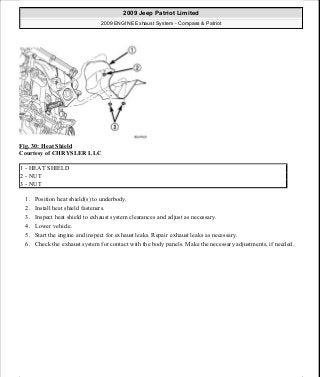

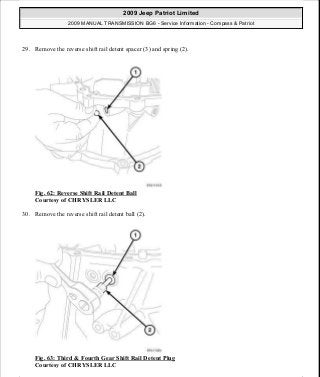

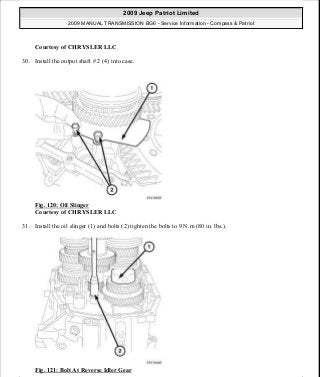

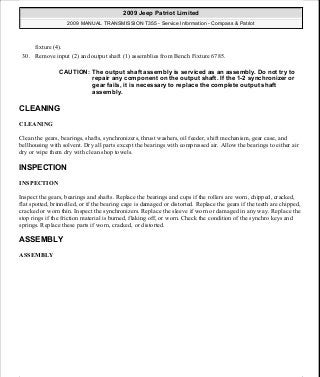

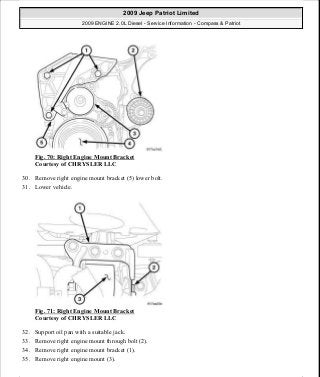

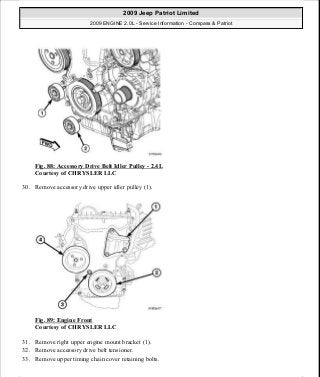

Compass/Patriot

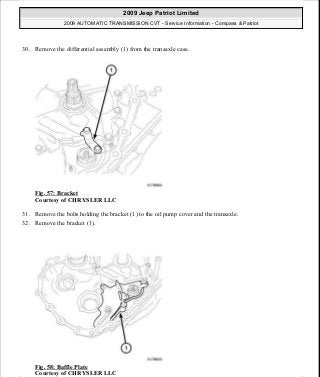

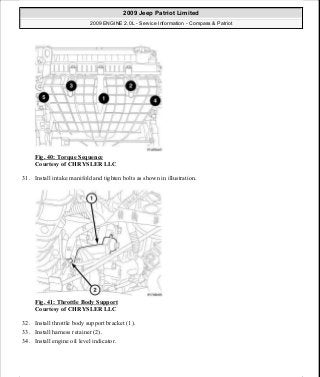

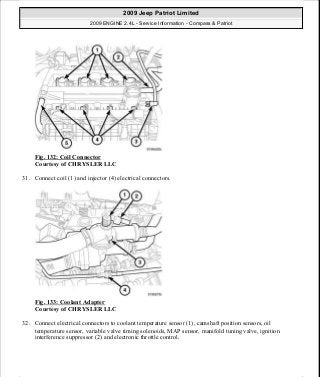

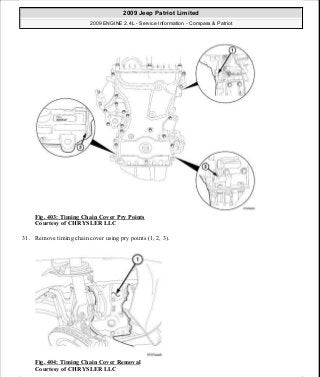

17 inch wheels©

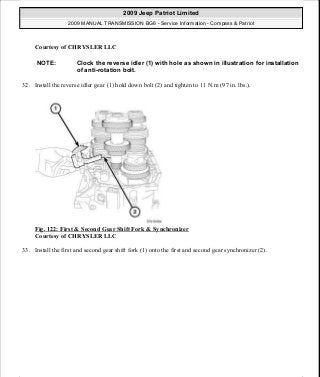

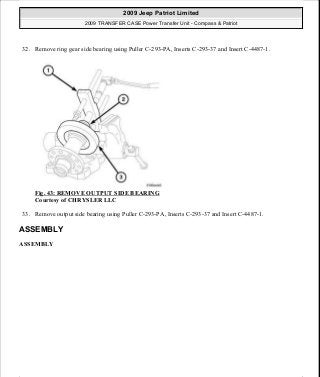

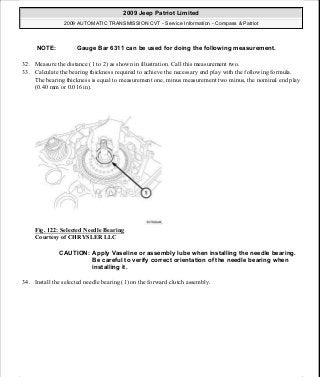

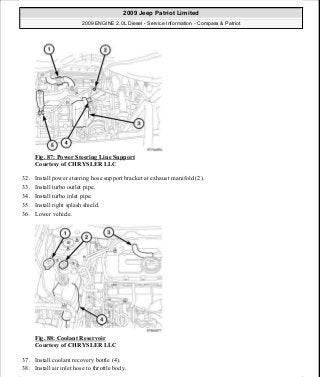

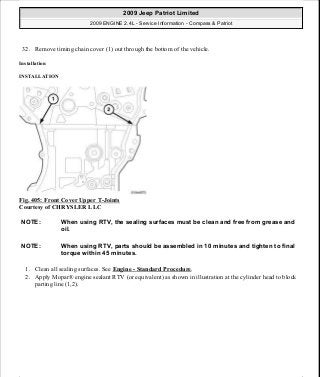

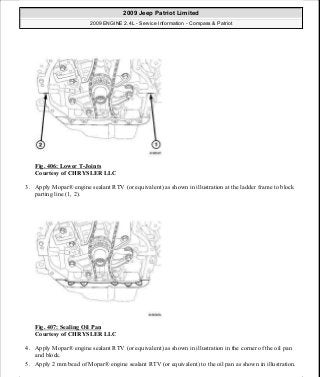

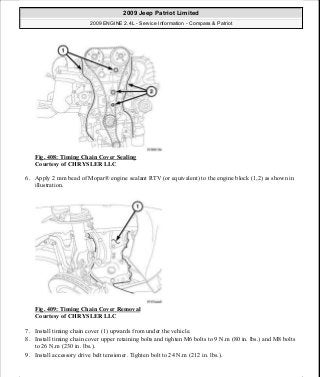

Compass/Patriot

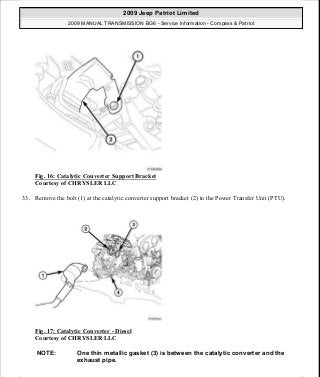

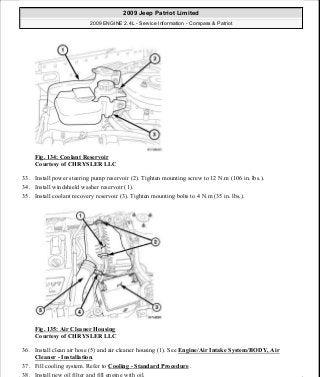

18 inch wheels

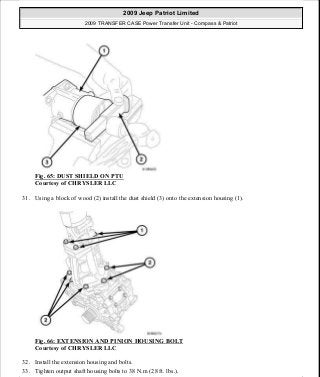

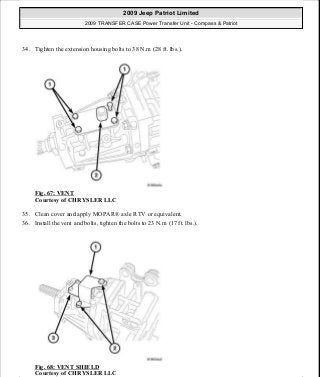

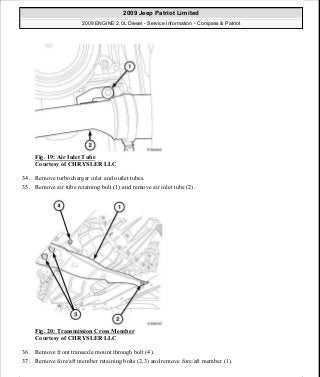

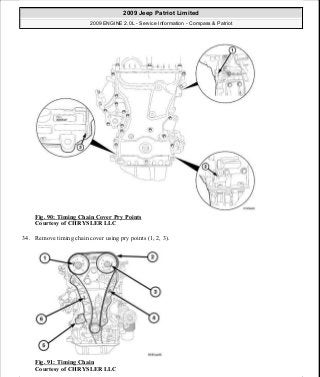

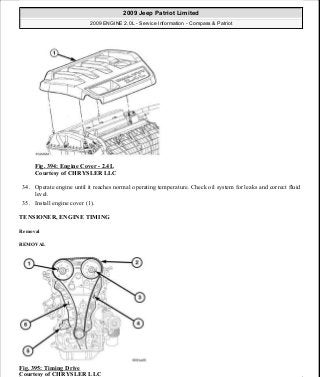

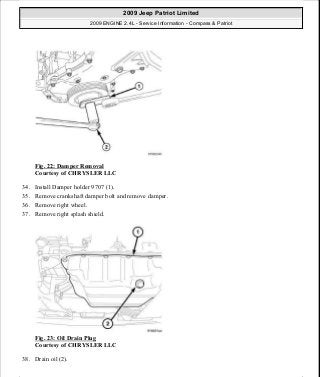

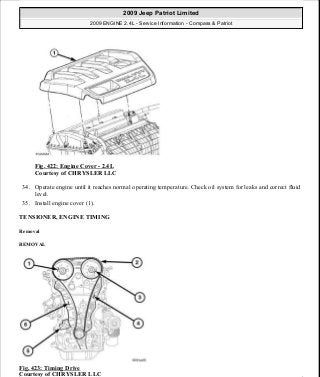

Front

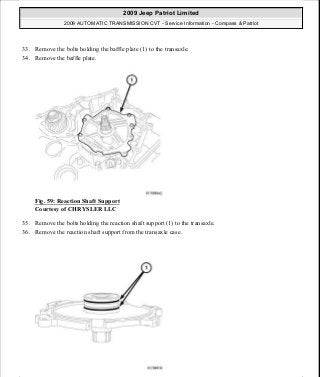

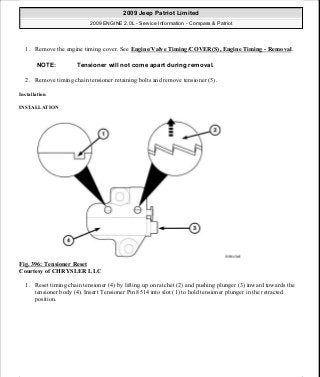

Rear

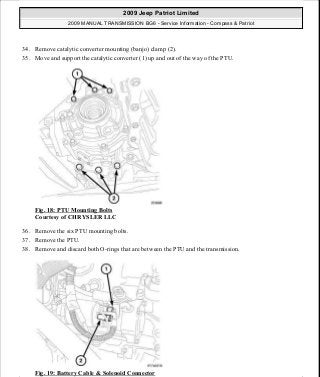

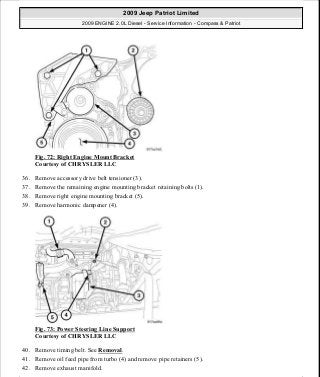

Front

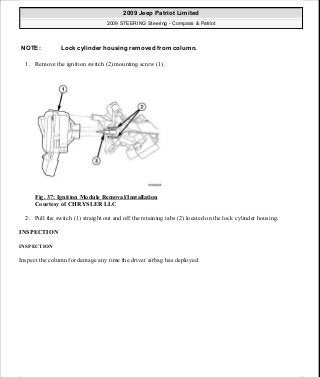

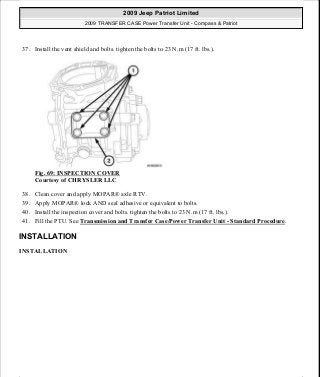

Rear

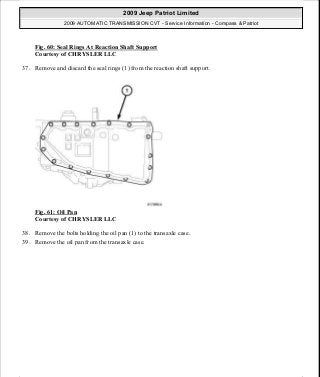

Front

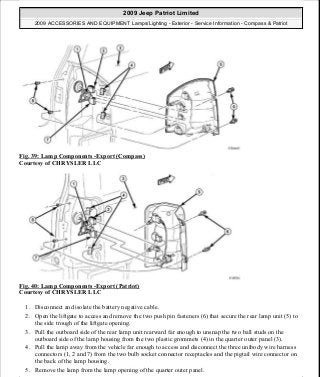

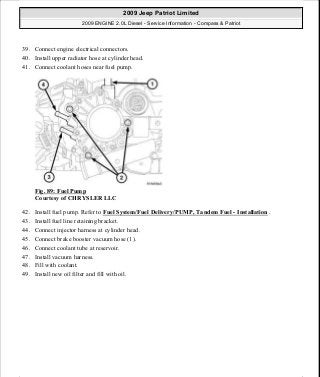

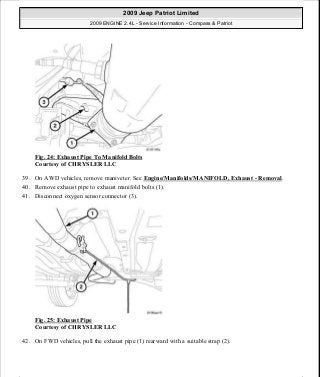

Rear

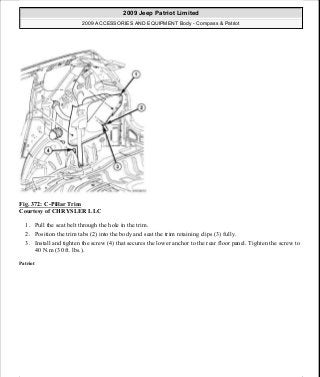

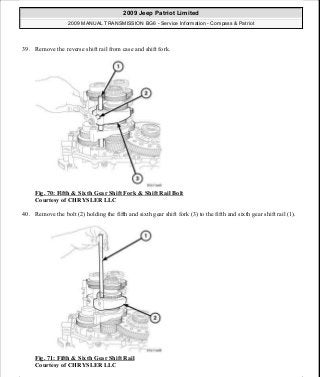

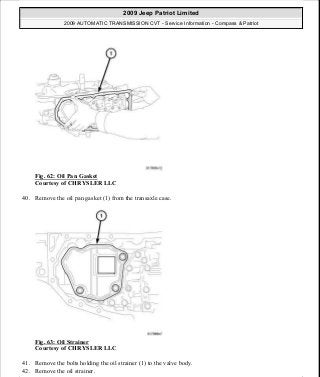

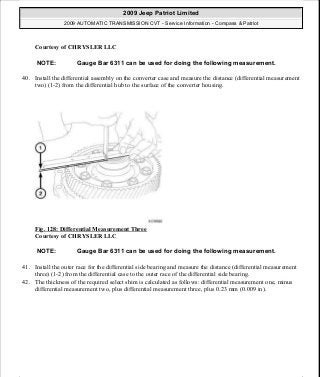

Front

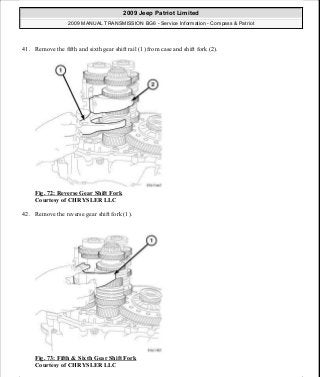

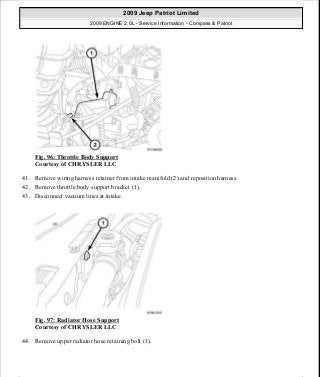

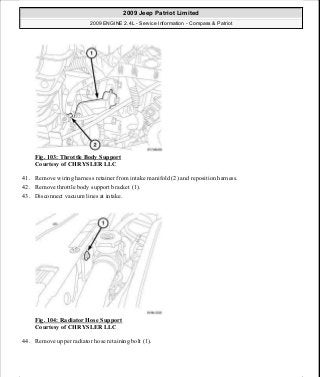

Rear

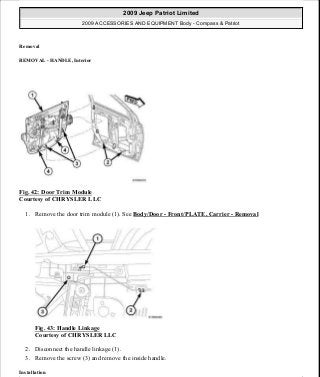

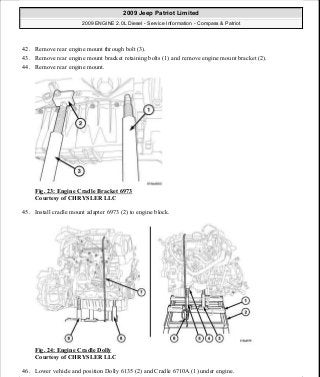

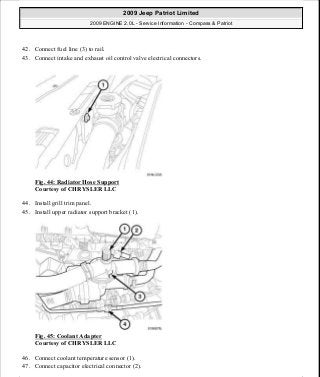

Front

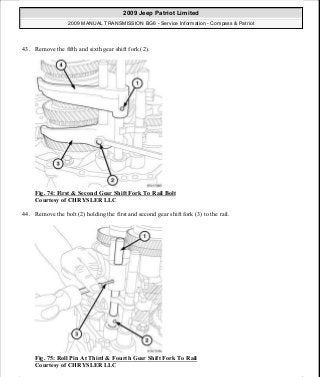

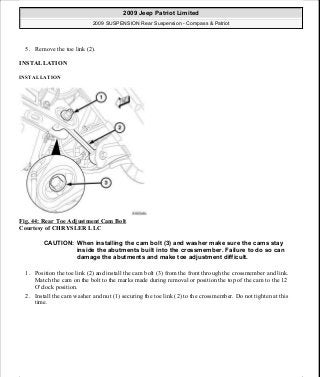

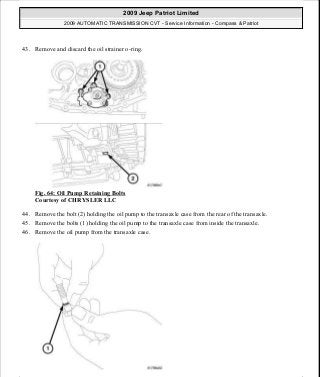

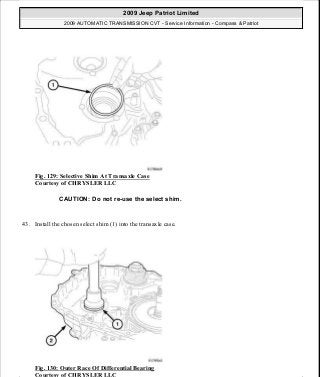

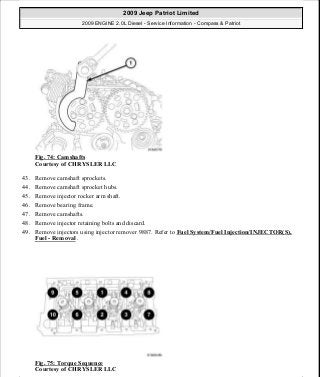

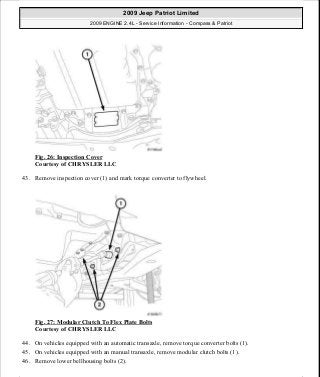

Rear

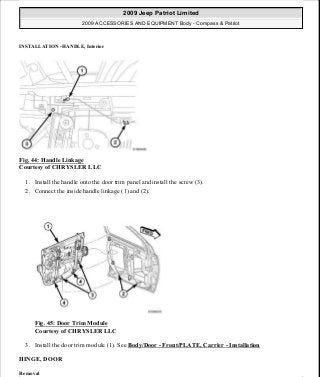

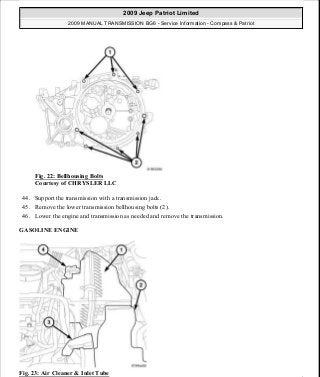

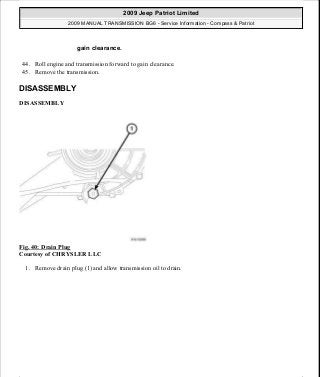

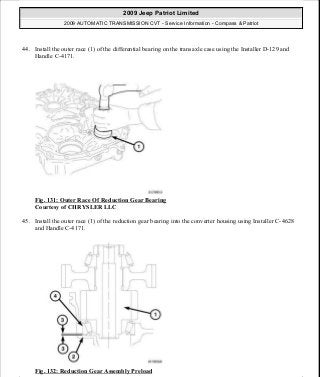

Front

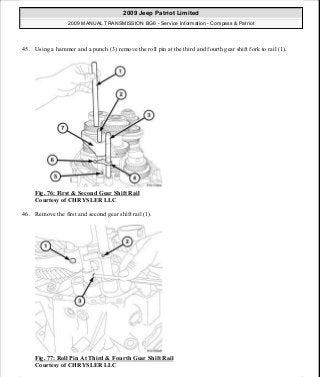

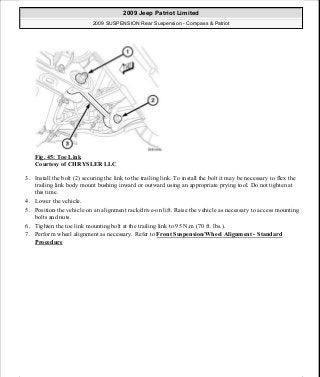

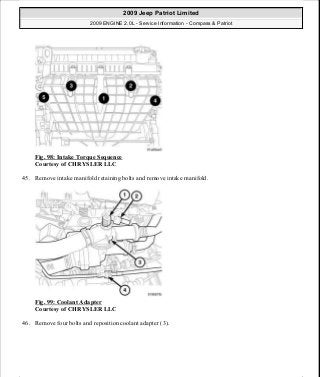

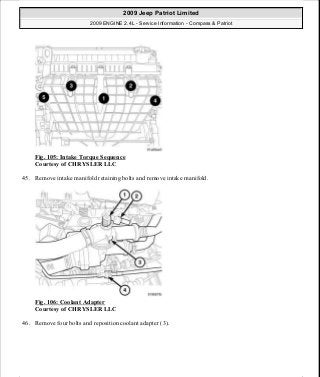

Rear

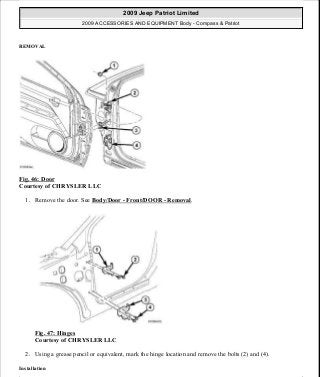

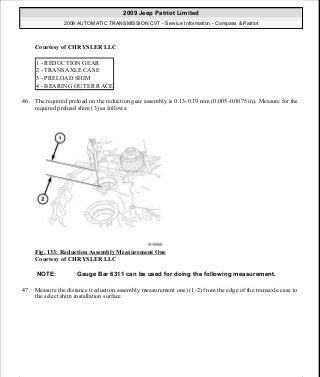

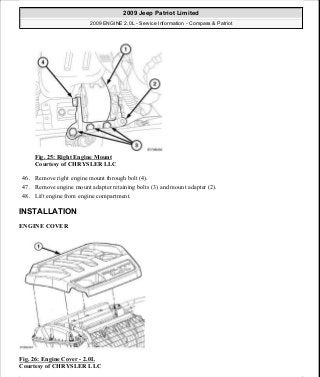

Front

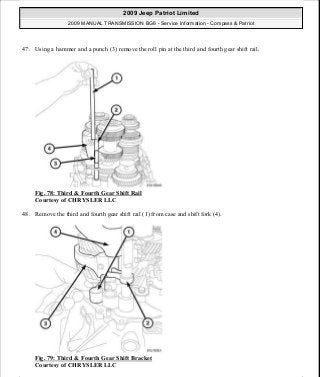

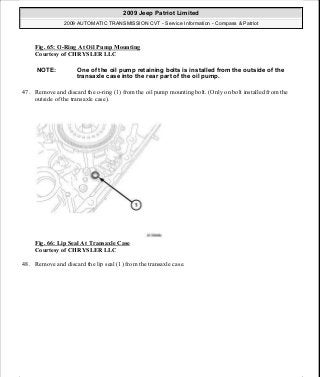

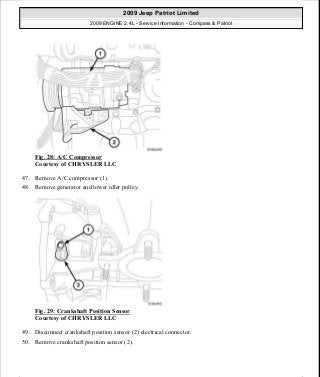

Rear

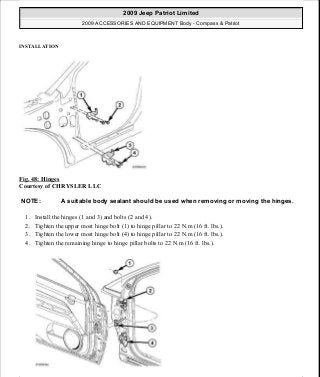

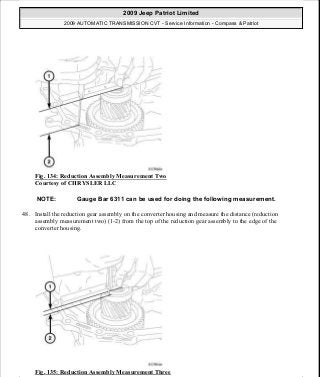

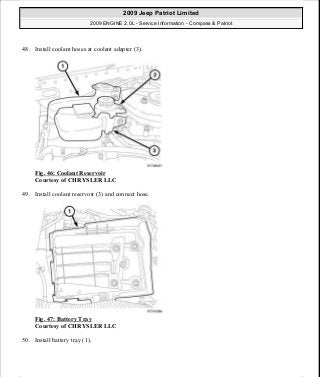

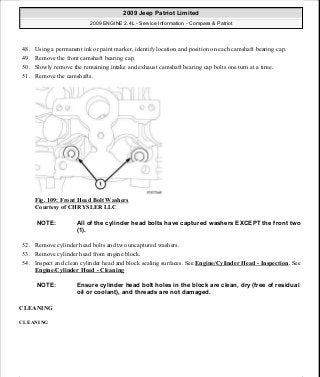

Front

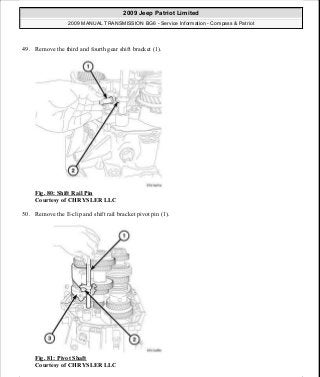

Rear

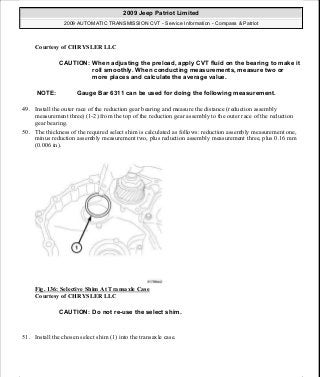

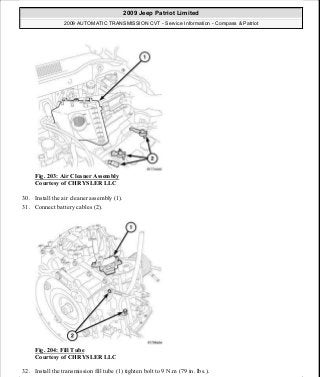

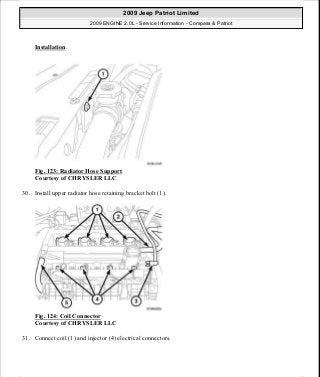

Front

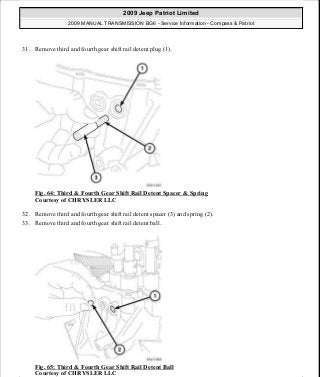

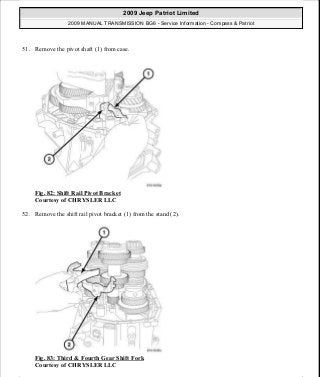

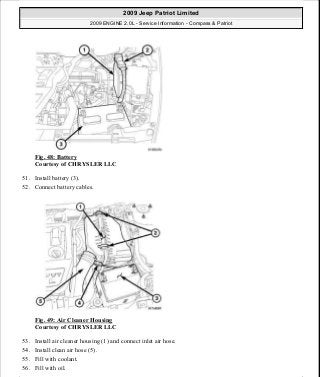

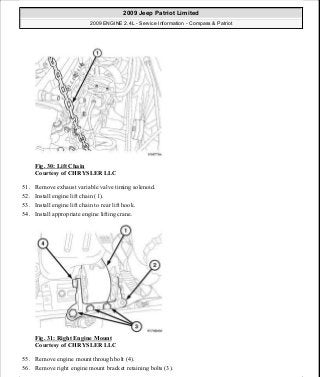

Rear

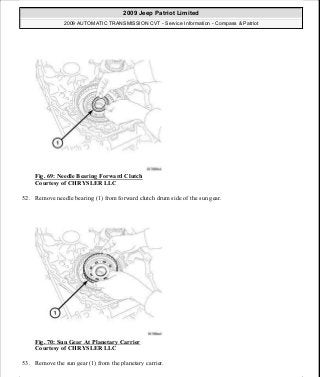

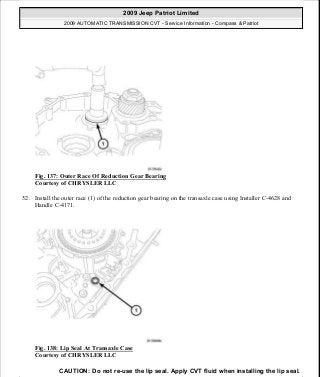

Front

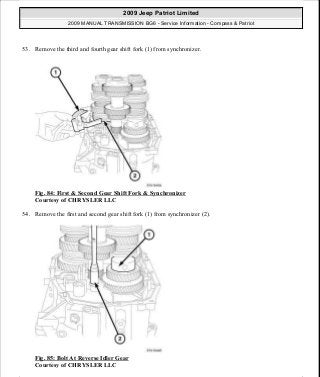

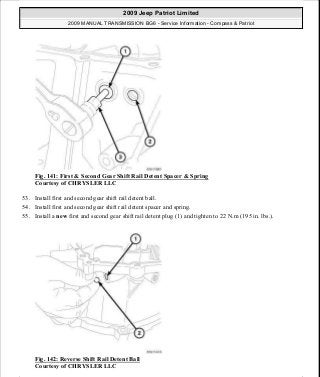

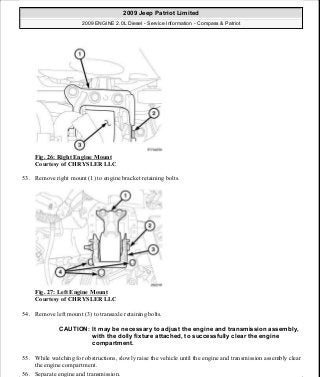

Rear

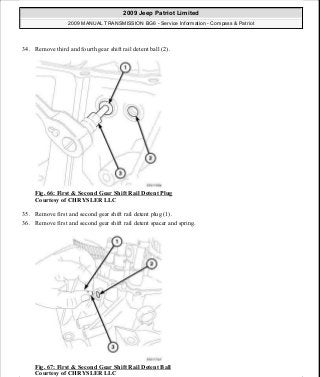

Front

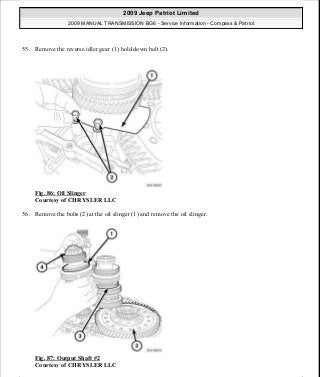

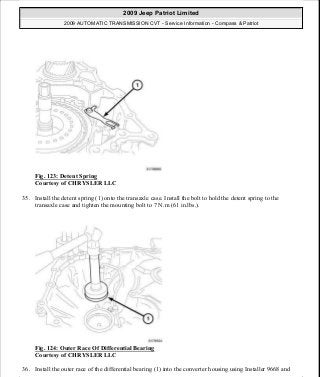

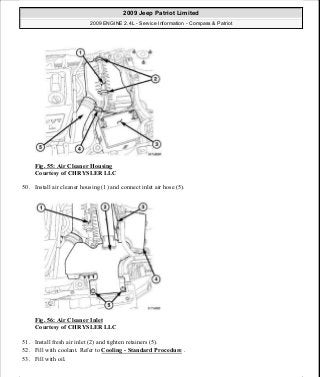

Rear

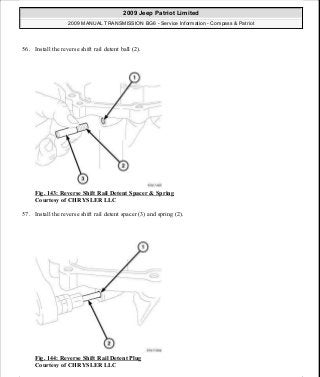

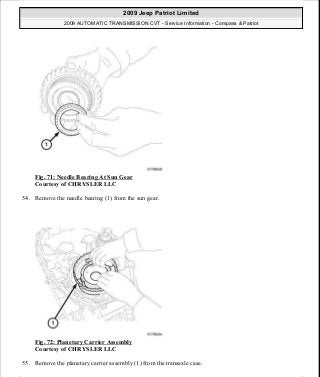

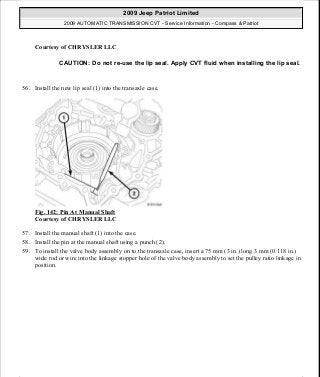

Front

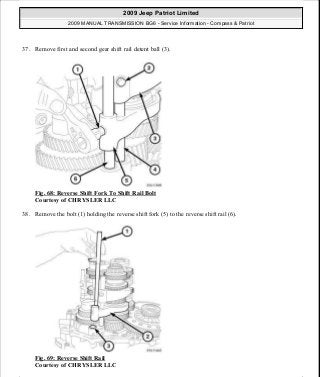

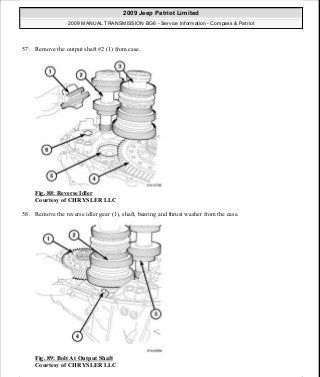

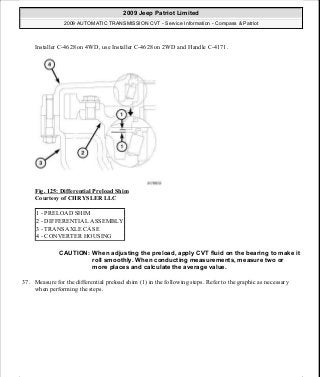

Rear

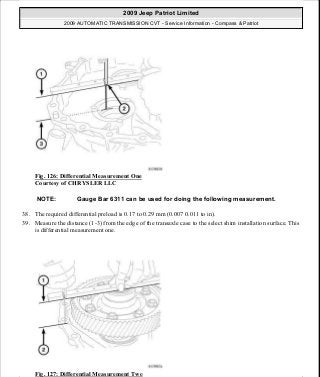

Range

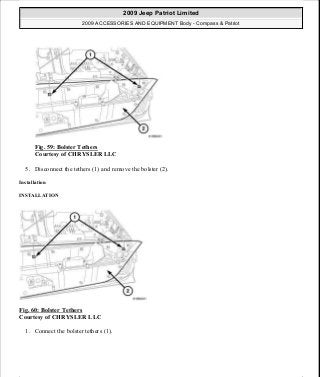

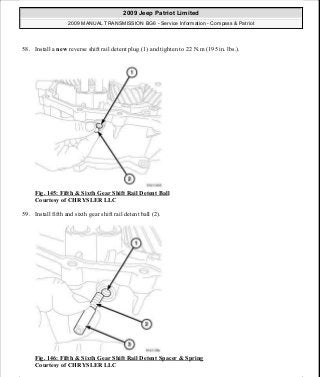

(+/-Deg|

1.00 I

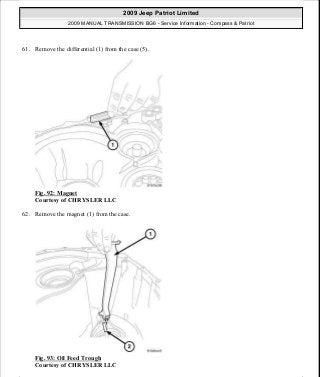

NA

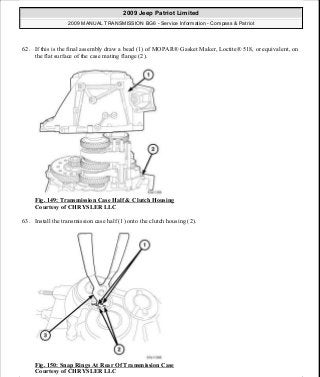

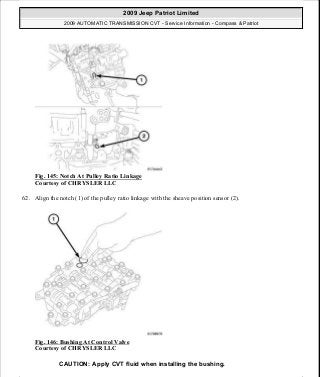

1.00

NA

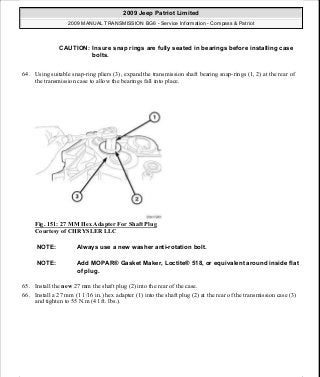

1.00 f

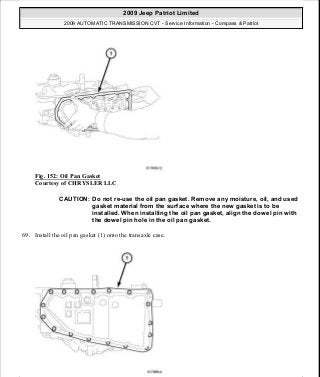

NA

1.00

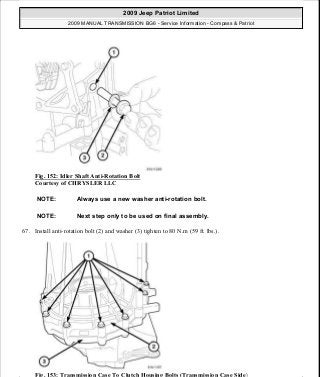

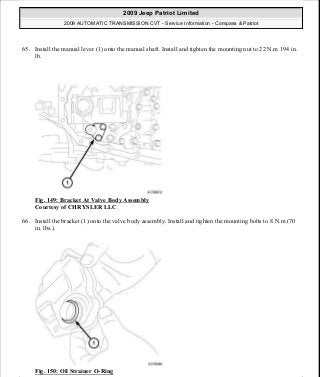

NA |

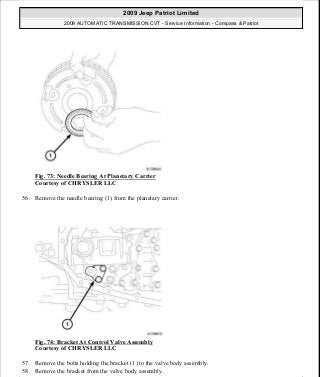

1.00

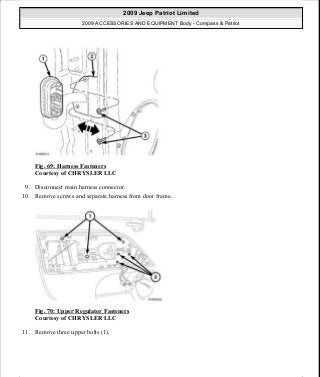

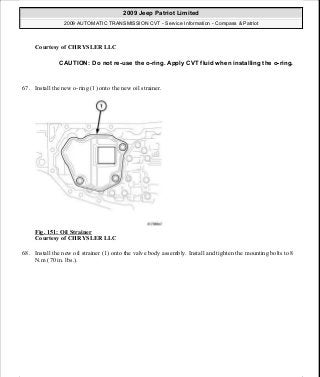

NA;

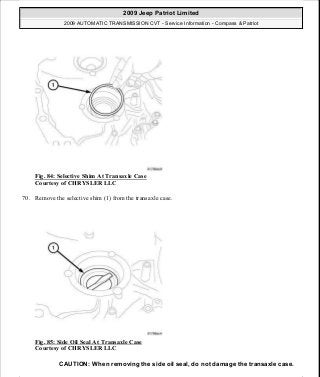

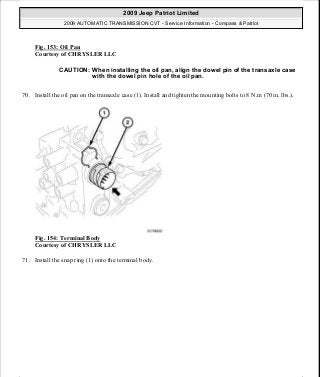

1.00]

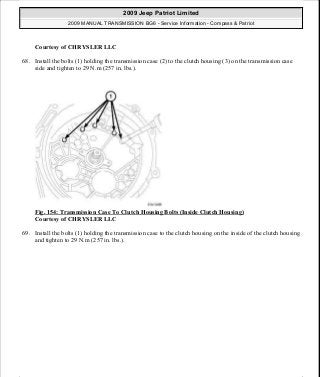

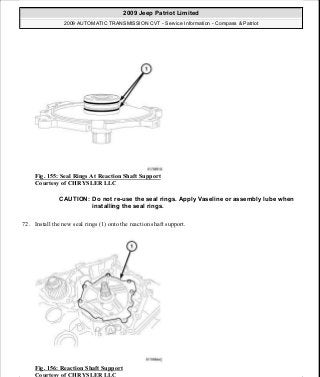

NAJ

1.0(f

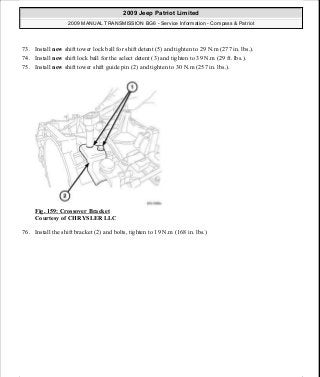

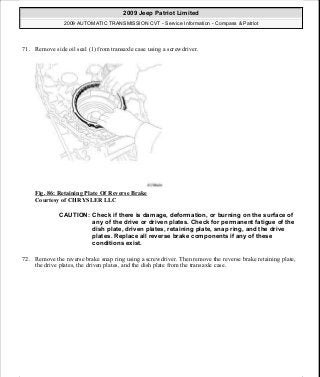

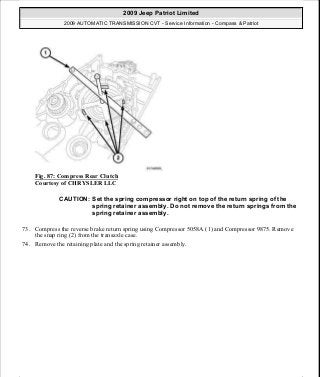

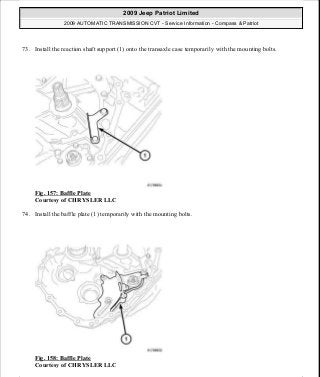

NA

1.0<f

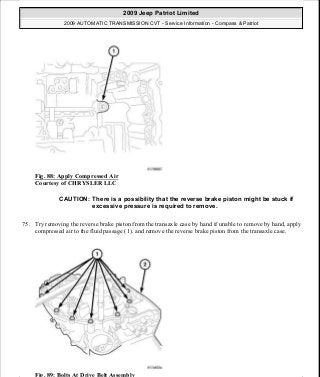

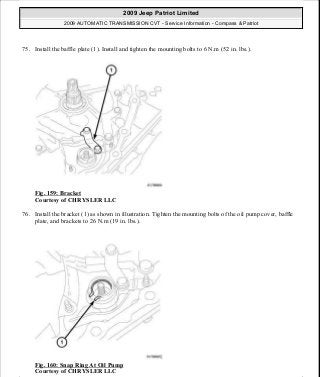

NA]

1.0}

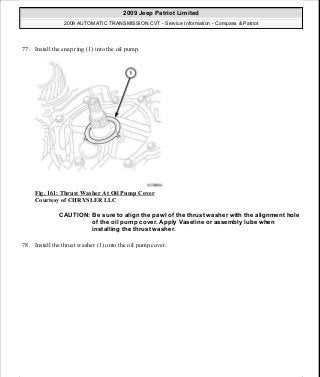

NA|

1.0|

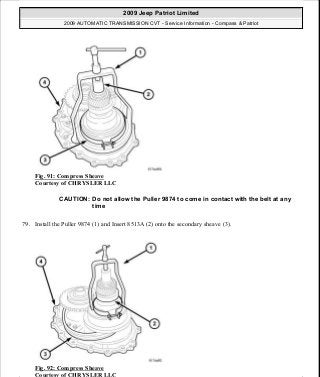

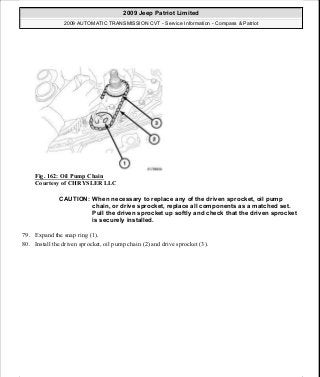

N/J

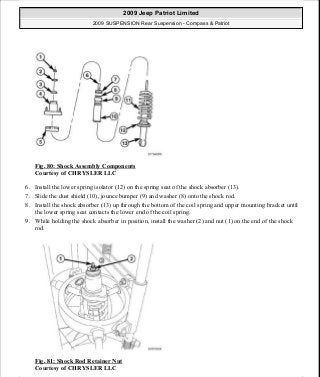

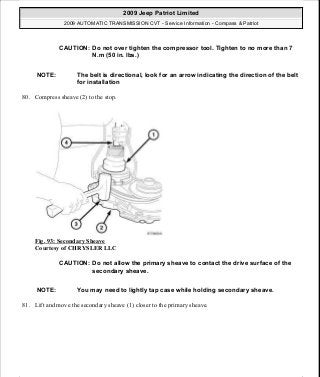

1.00

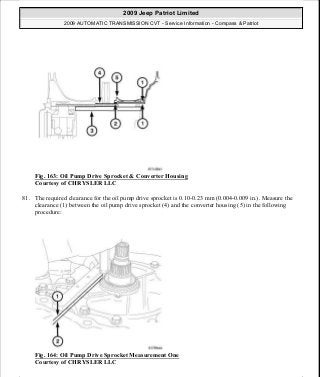

NA

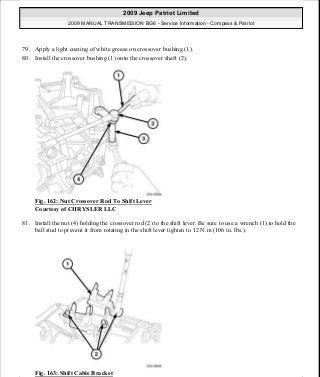

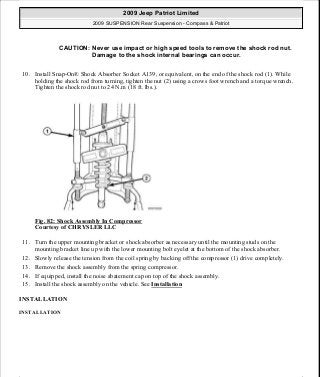

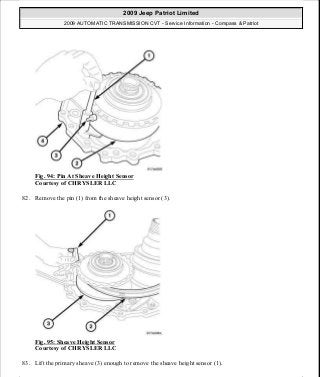

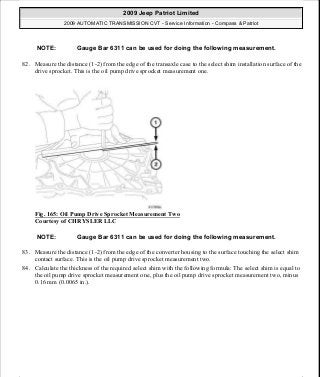

1.0D

NA

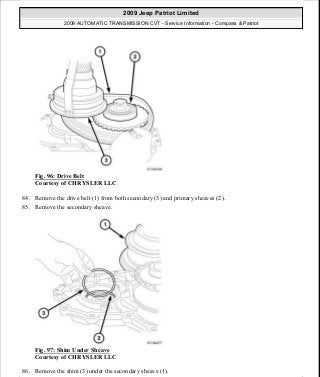

Preferred

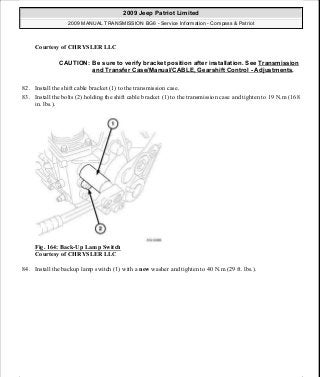

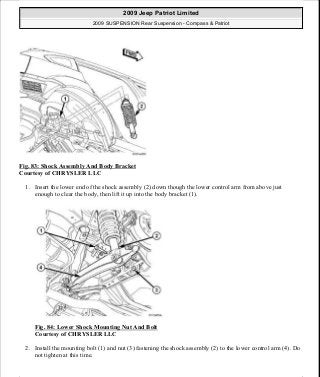

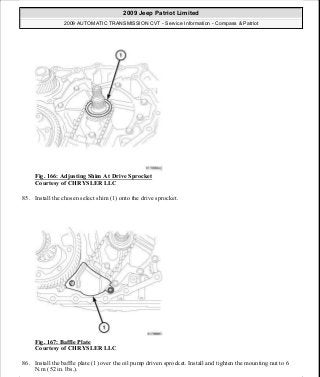

Setting

(Deg.)

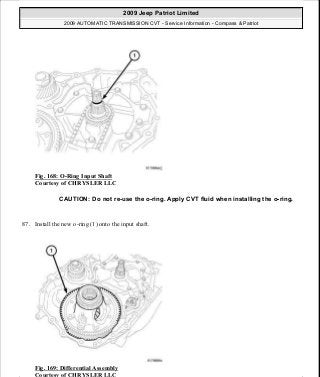

®

NA

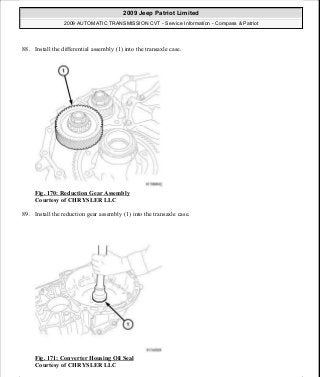

©

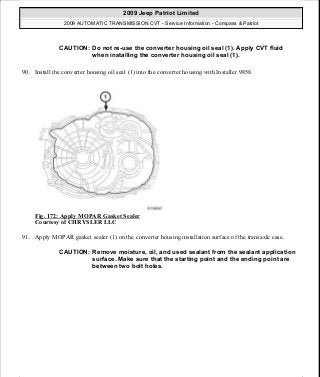

NA

©

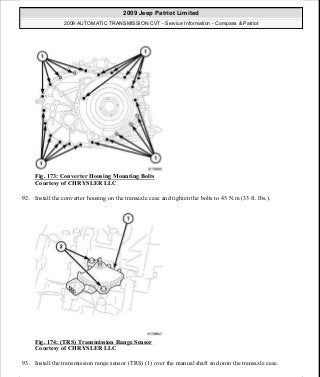

NA

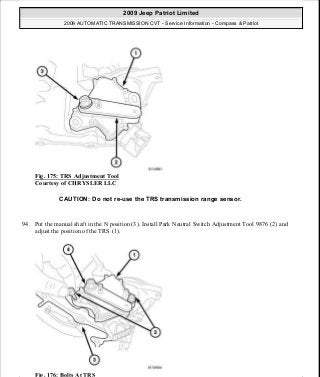

©

NA

©

NA

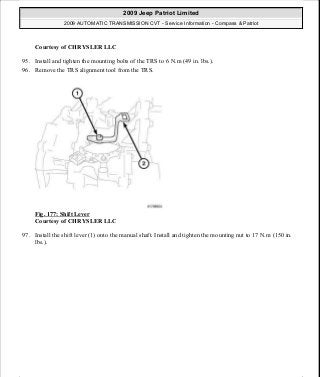

©

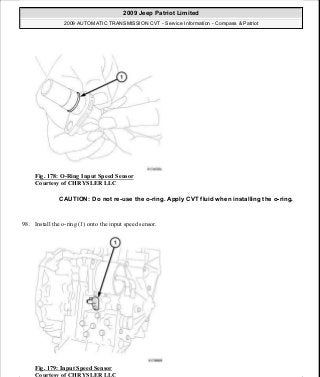

NA

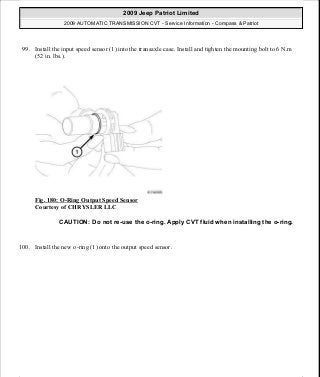

©

NA

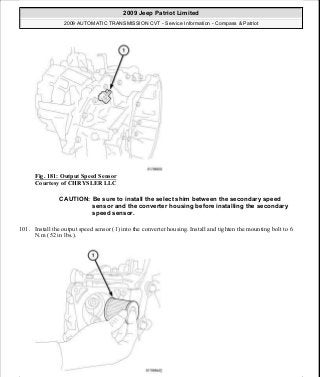

©

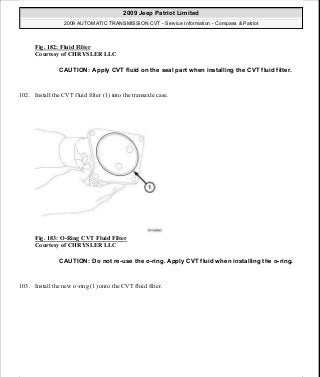

NA

©

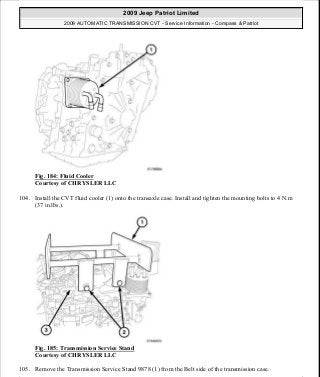

NA

©

NA

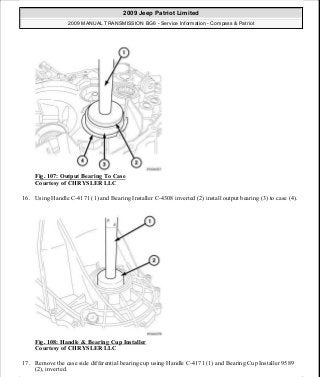

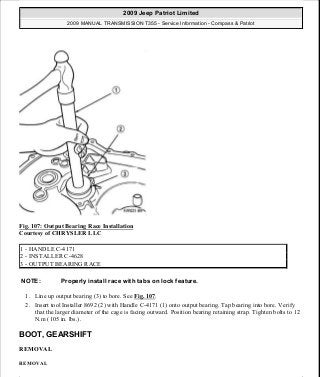

©

NA

©

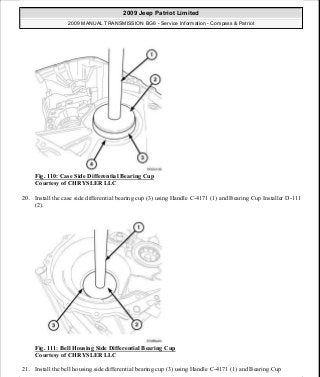

NA

Range

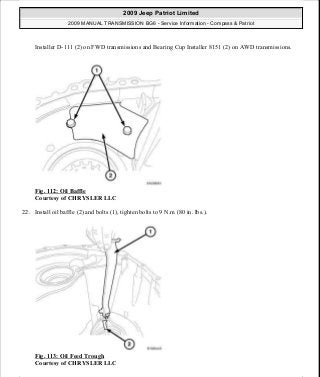

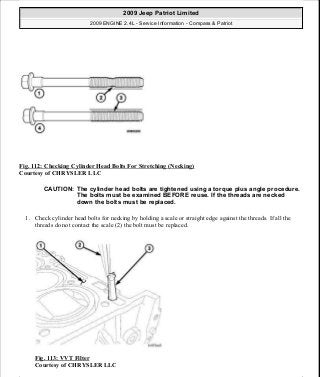

(+/-Deg.)

0.40

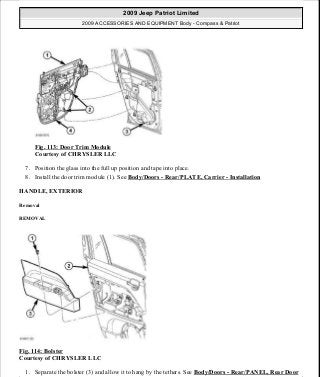

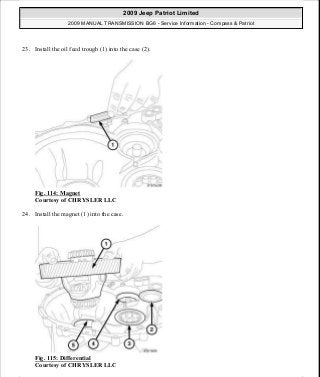

0.40

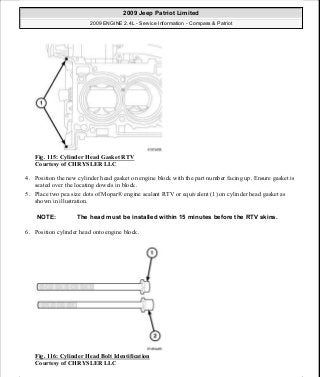

0.40

0.40

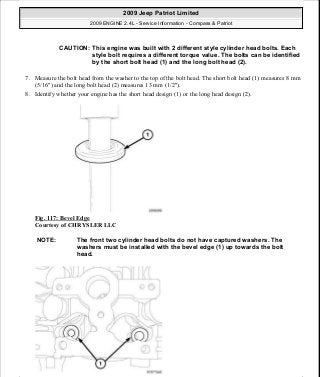

0.40

0.40

0.40

0.40

0.40

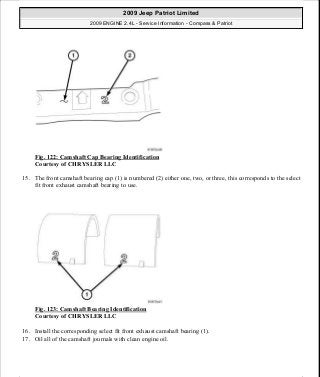

0.40

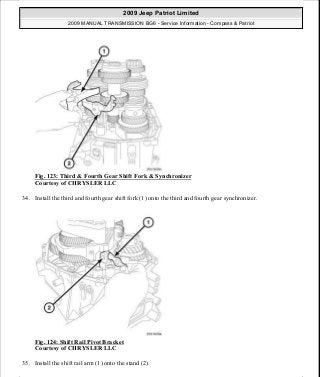

0.40

0.40

0.40

0.40

0.40

0.40

0.40

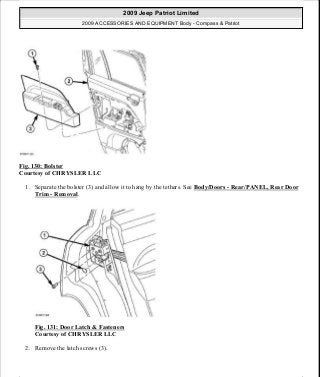

0.40

0.40

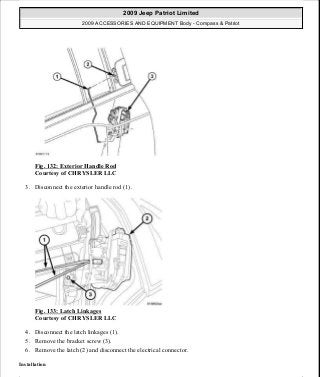

0.40

0.40

0.40

0.40

0.40

Preferred

Setting

(Deg.)

-0.80

-0.70

-0.70

-0.60

-0.90

-0.80

-0.70

-0.70

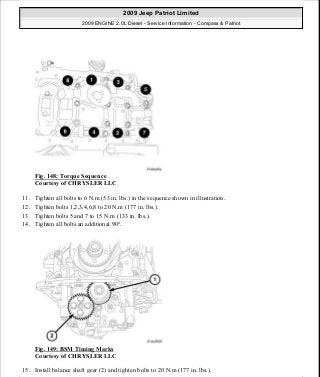

-0.80

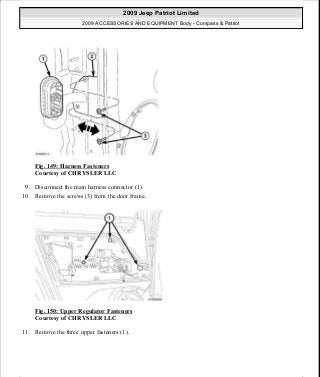

-0.70

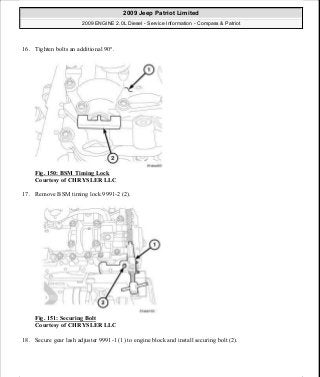

-0.70

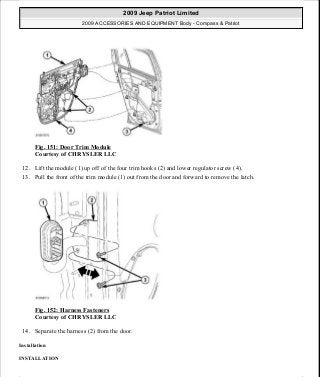

-0.60

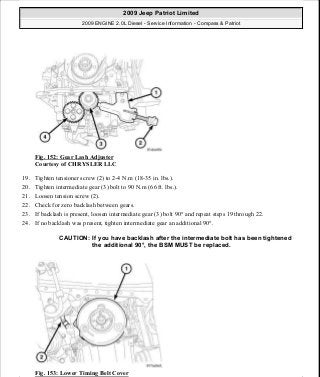

-0.90

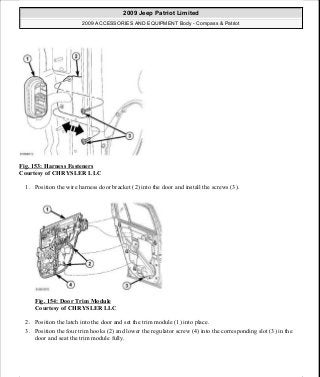

-0.80

-0.70

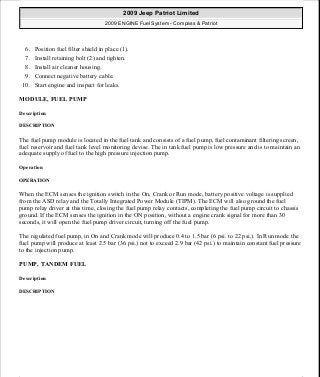

-0.70

-0.80

-0.70

-0.70

-0.60

-0.90

-0.80

-0.70

-0.70

Toe-in

(Deg.)

+0.10+/-0.10

+0.10+/-0.10

+0.10+/-0.10

+0.10+/-0.10

+0.10+/-0.10

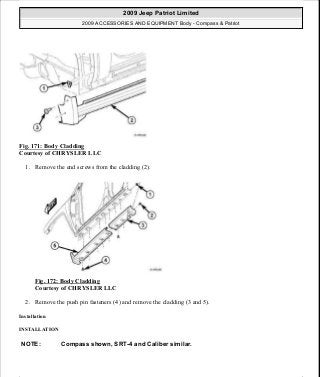

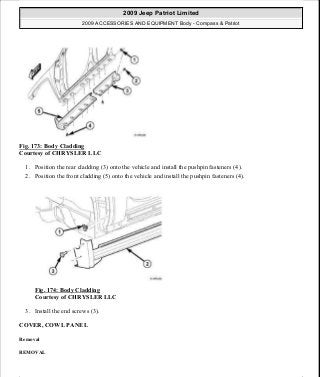

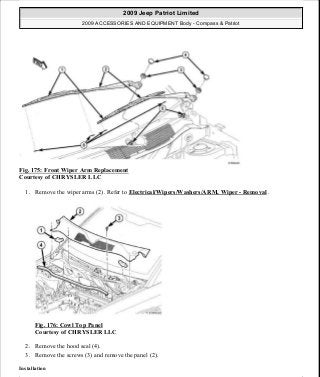

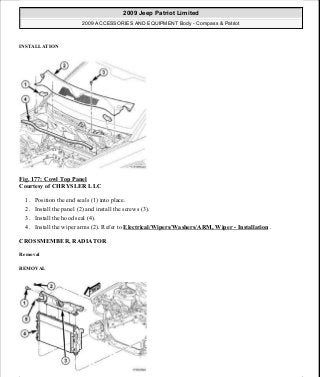

+0.10+/-0.10

+0.10+/-0.10

+0.10+/-0.10

+0.10+/-0.10

+0.10+/-0.10

+0.10+/-0.10

+0.10+/-0.10

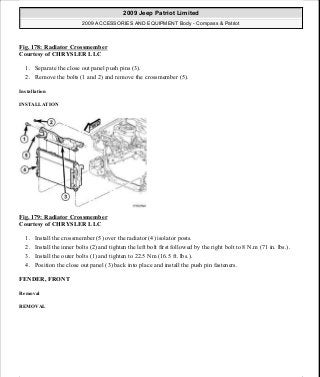

+0.10+/-0.10

+0.10+/-0.10

+0.10+/-0.10

+0.10+/-0.10

+0.10+/-0.10

+0.10+/-0.10

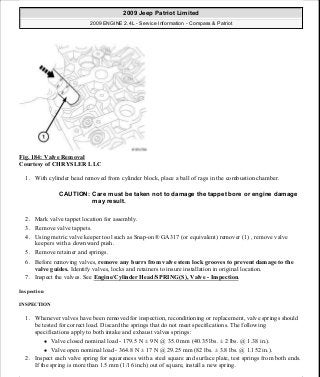

+0.10+/-0.10

+0.10+/-0.10

+0.10+/-0.10

+0.10+/-0.10

+0.10+/-0.10

+0.10+/-0.10

NA: Not Applicable

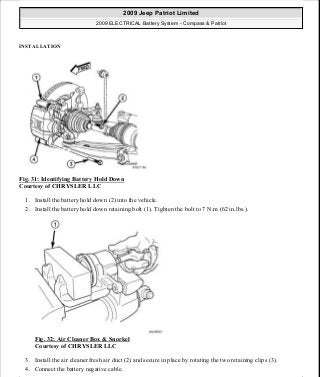

NOTE: Measurements are given for unladen vehicle: fuel, engine coolant, and fluid levels are full. Spare tire, jack, hand tools, and mats are in designated posi

© Wheel size refers to OEM wheels only

© Left: +3.00

Right: +2.70

© Left: +2.90

Right: +2.60

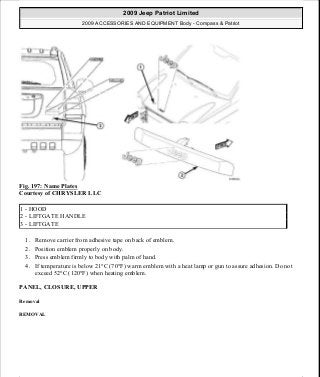

® All P215/60R17 and P215/65R17AT with OFF-ROAD GRO|JP (AWL)

©All P215/65R17AT without OFF-ROAD GROUP (AWL)](https://image.slidesharecdn.com/manualesreparacionesjeepcompass-patriotlimited2007-2009-150729164945-lva1-app6891/85/Manuales-de-reparaciones-jeep-compass-y-patriot-limited-2007-2009-797-320.jpg?cb=1438196953)

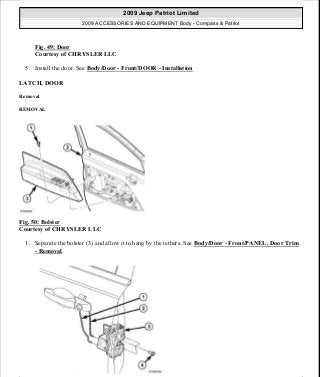

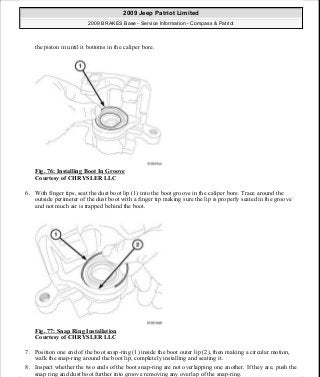

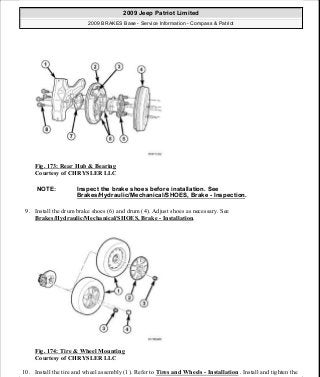

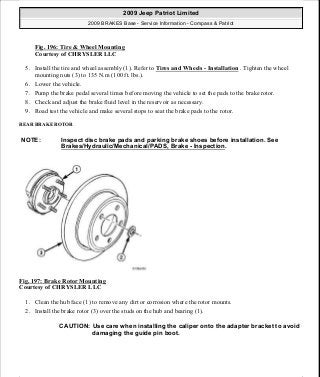

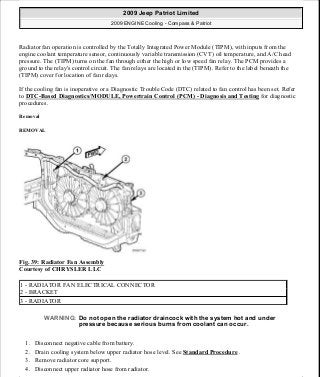

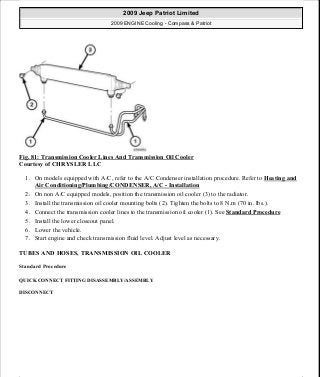

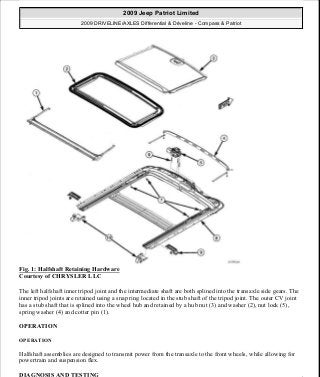

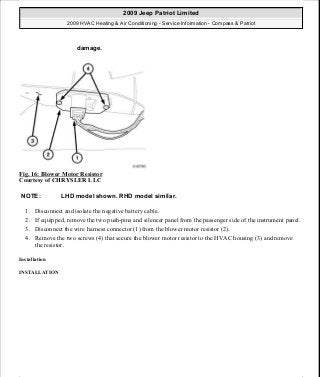

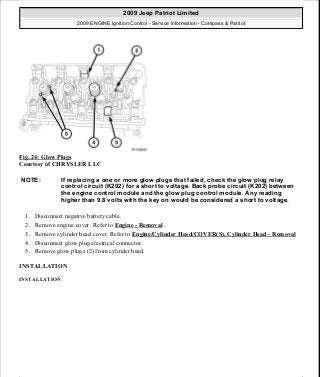

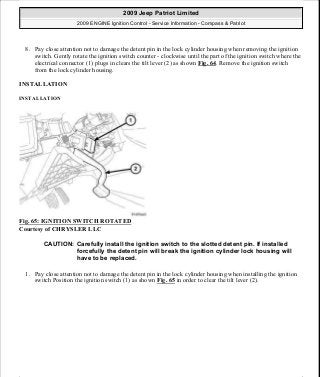

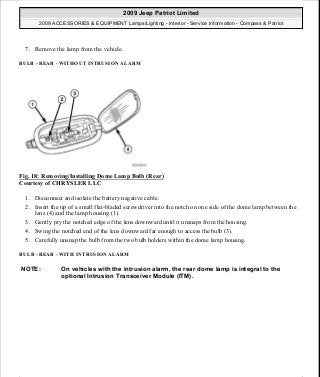

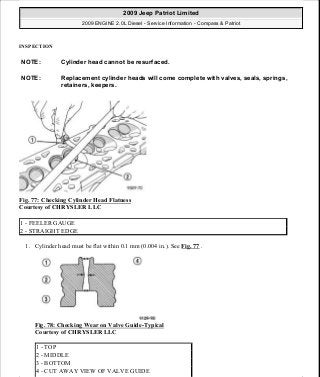

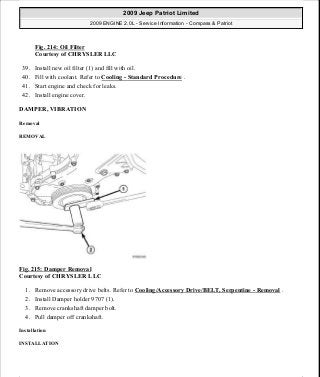

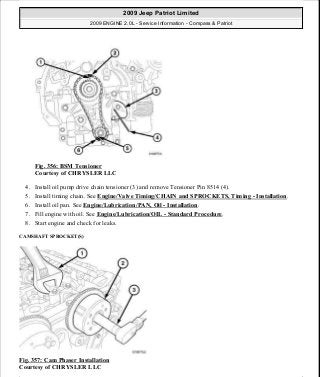

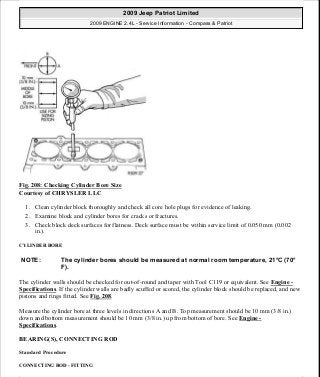

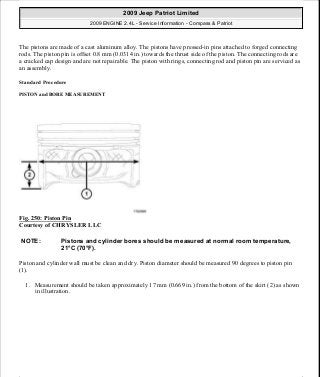

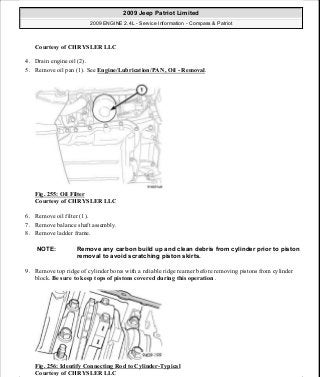

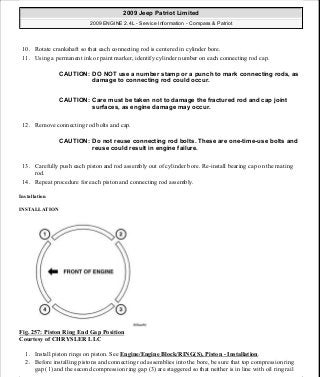

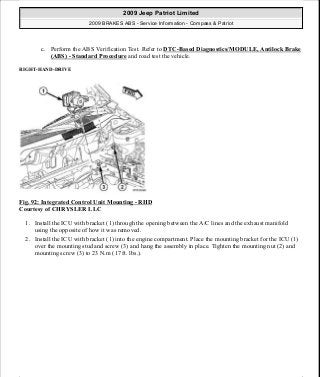

![9-20 JEEP

COMPASS • PATRIOT

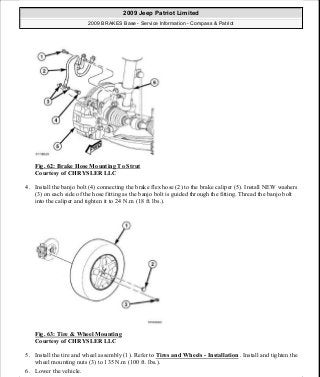

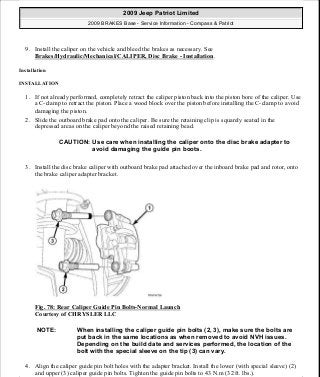

18. Thread the brake tube nut into brake

hose and tighten to 150 inch Ibs. (17 Mm).

19. Install the rear tire and wheel assem-

bly. Tighten the mounting nuts to 100 tt.

Ibs. (135 Nm).

20. Lower the vehicle.

21. Remove the brake pedal holding

tool.

22. Bleed the brake system, as necessary.

23. Test drive the vehicle to ensure

nrnnpr hrakp nnpratinn(JIU|JCI Uldr UpClauUII.

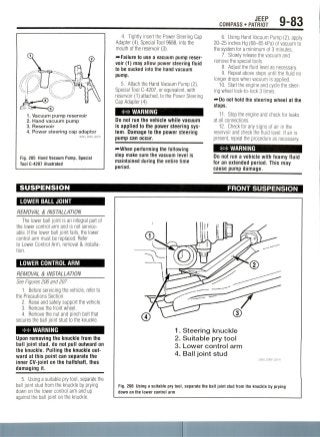

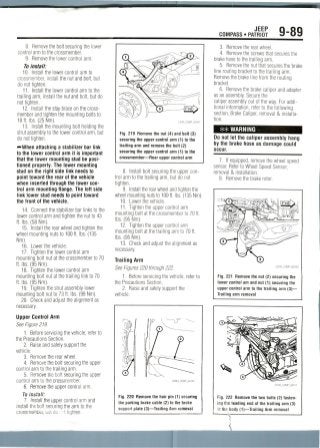

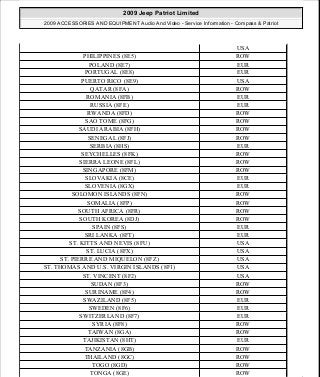

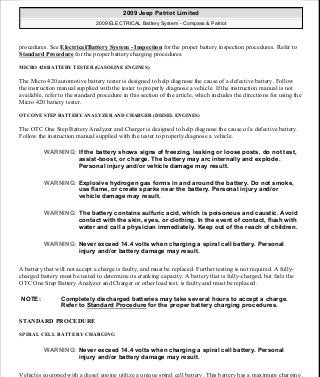

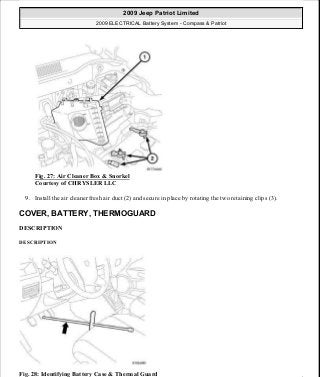

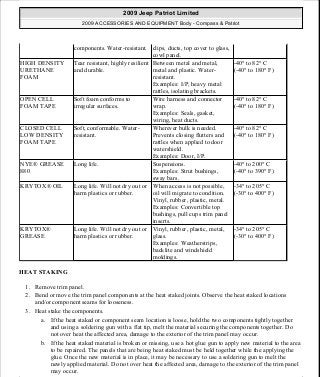

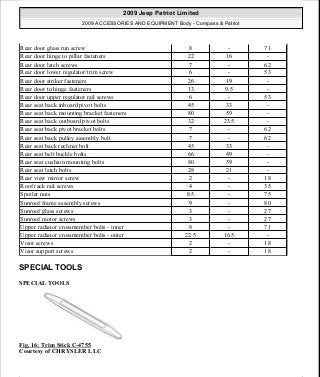

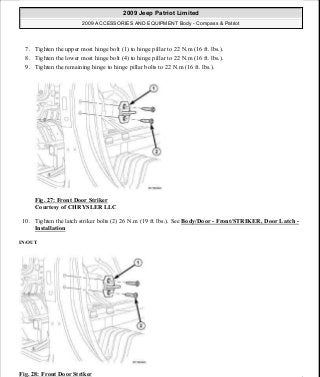

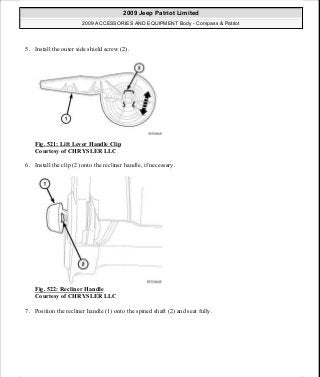

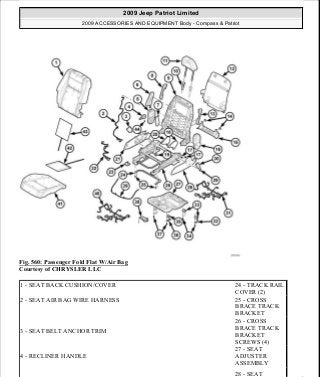

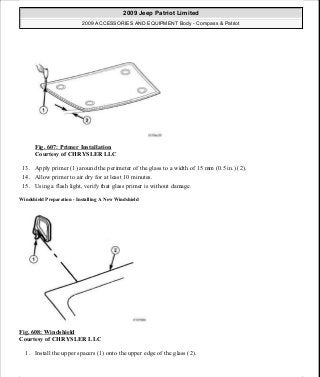

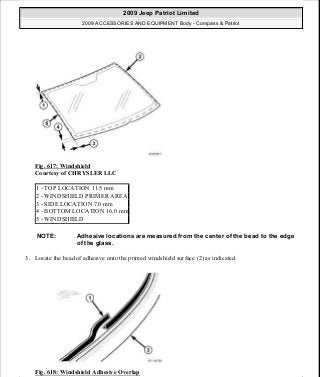

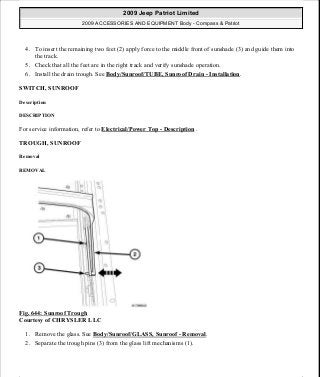

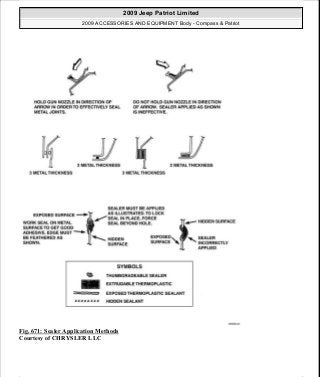

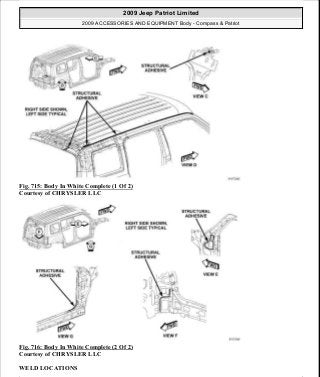

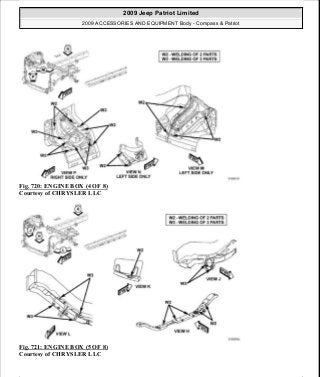

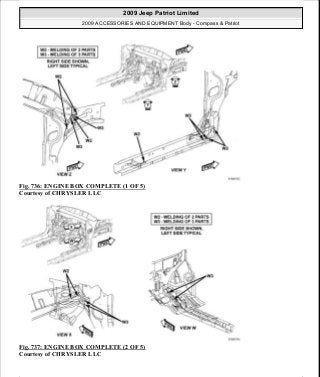

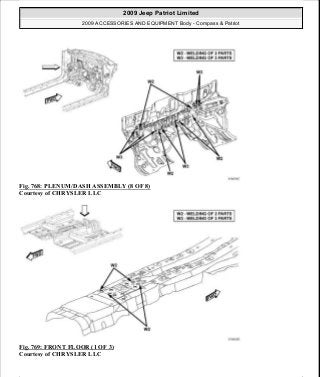

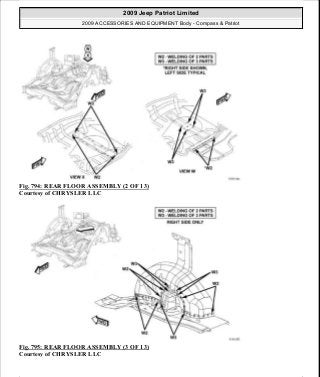

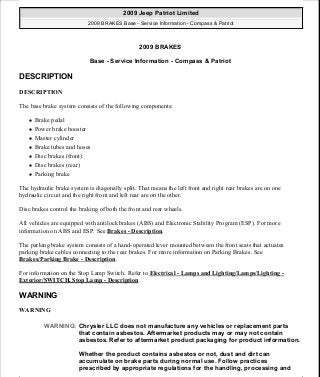

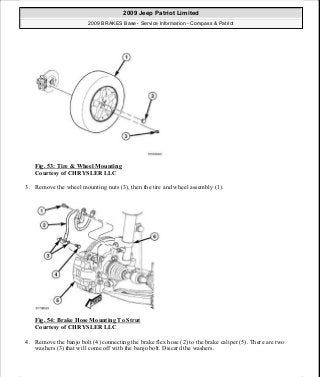

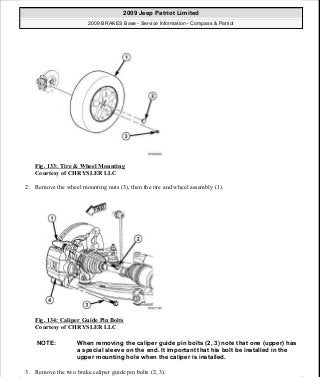

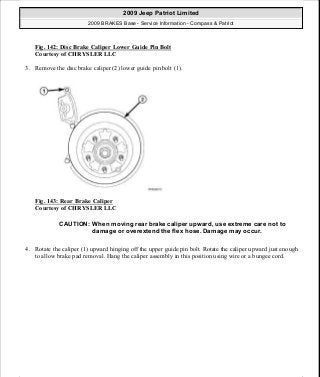

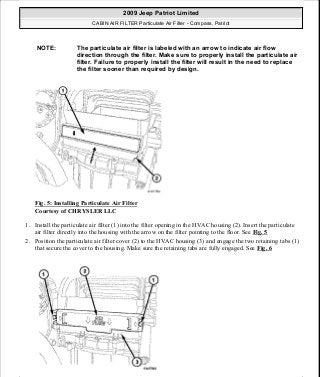

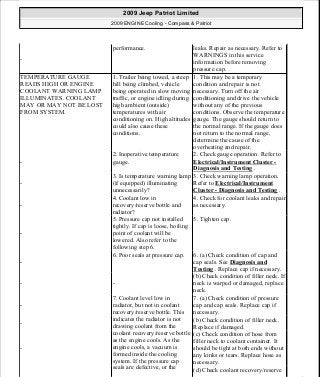

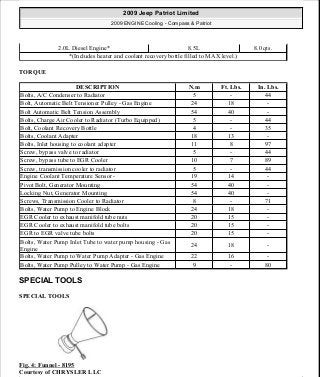

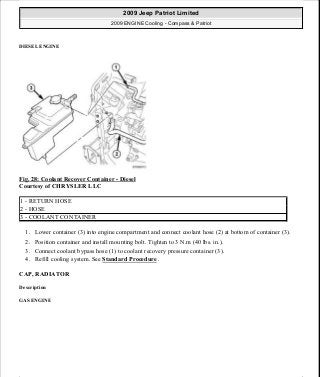

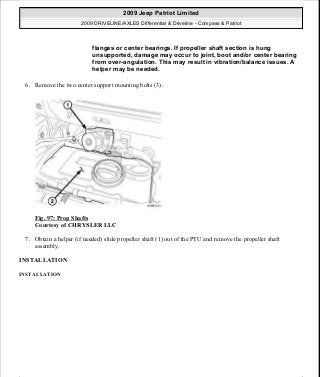

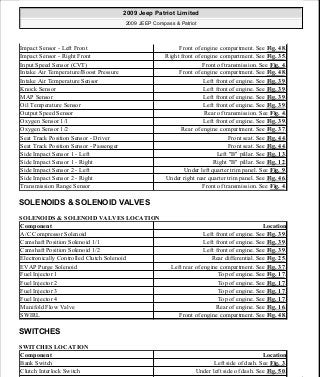

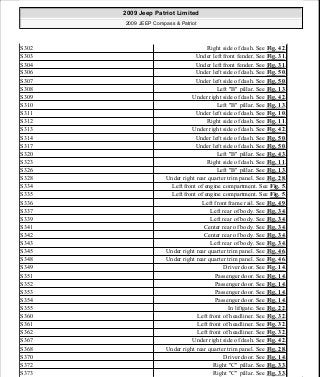

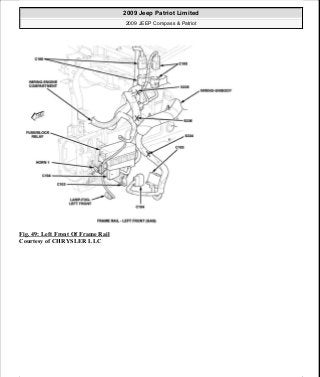

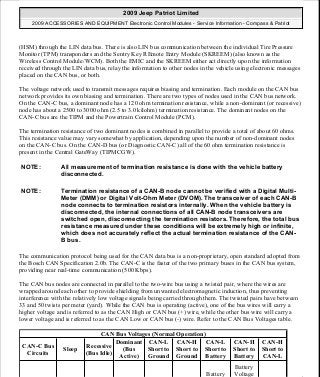

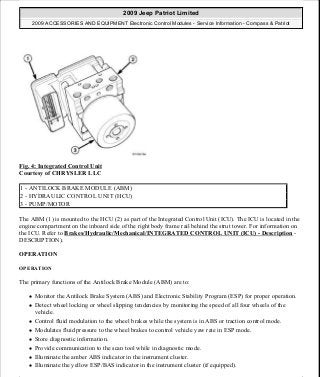

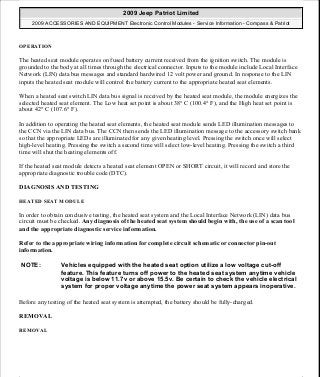

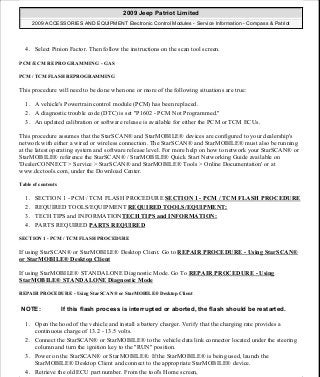

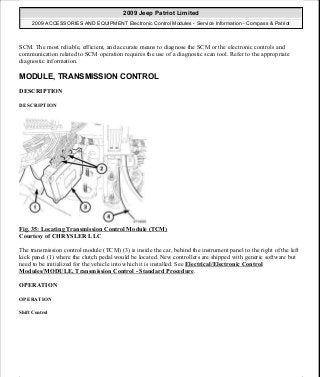

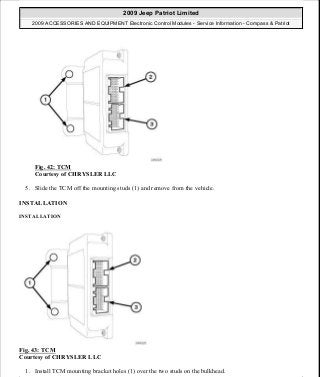

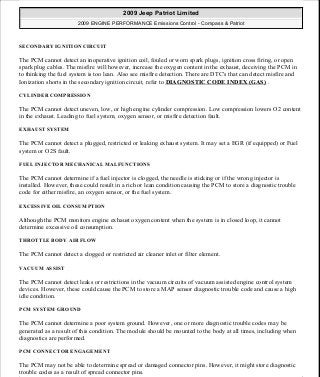

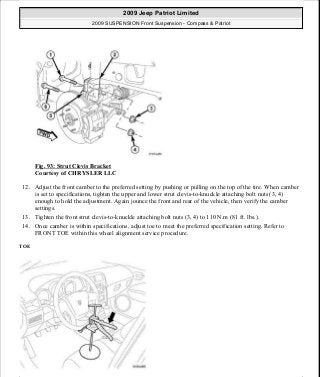

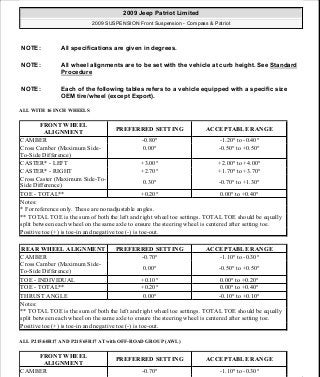

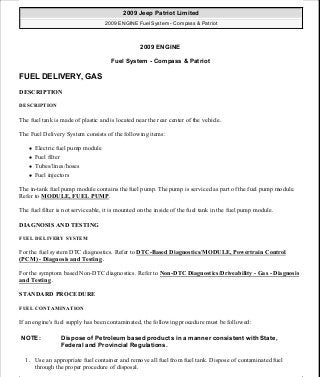

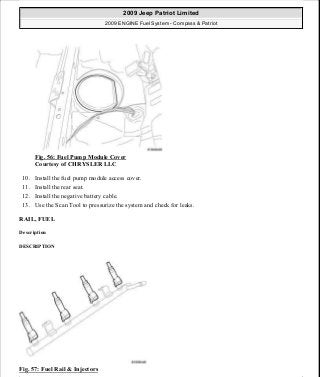

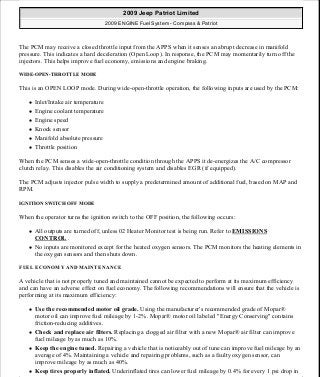

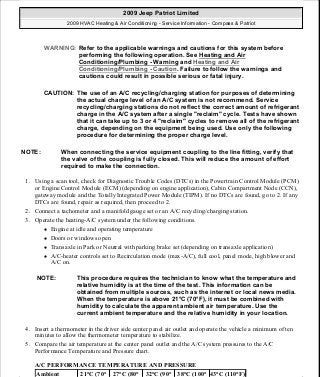

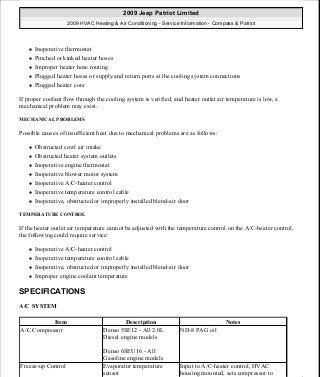

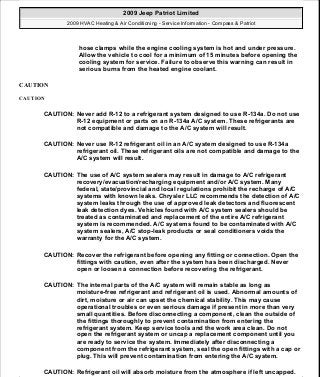

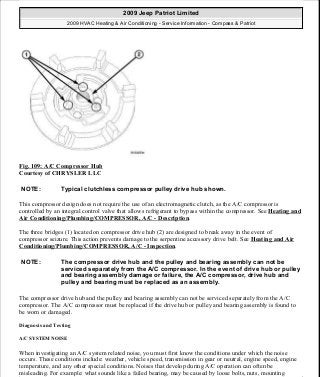

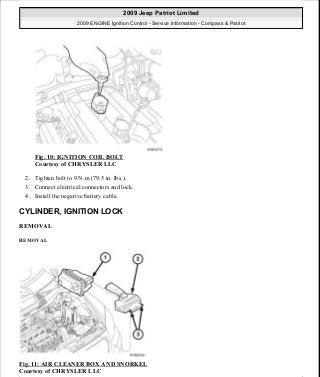

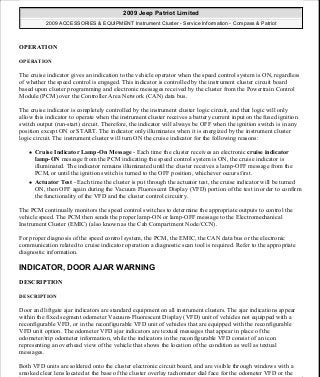

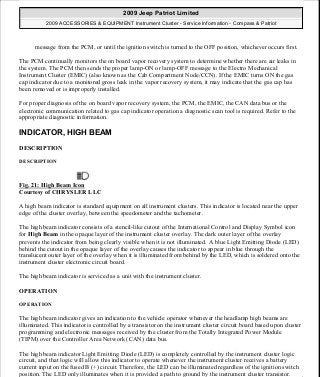

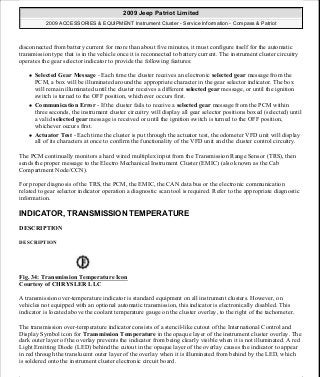

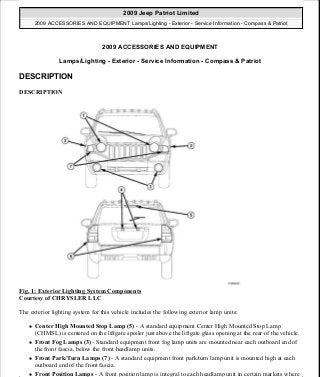

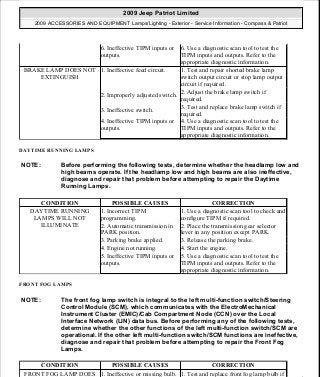

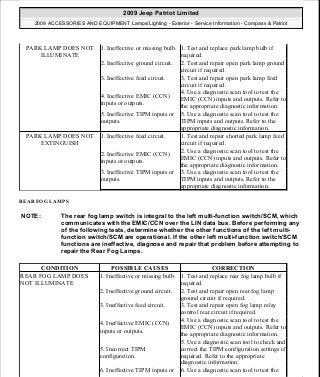

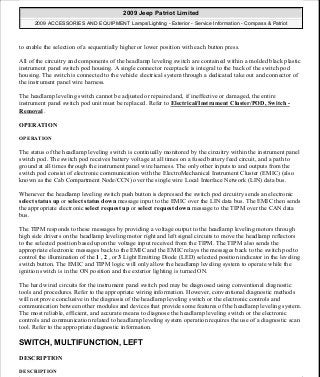

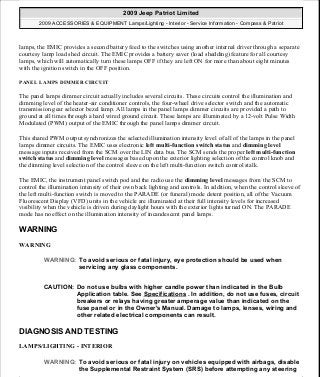

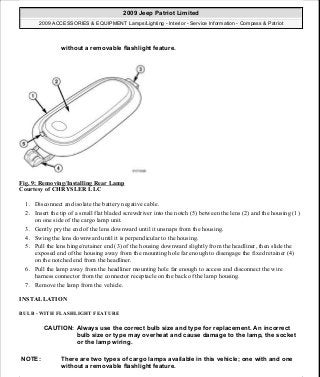

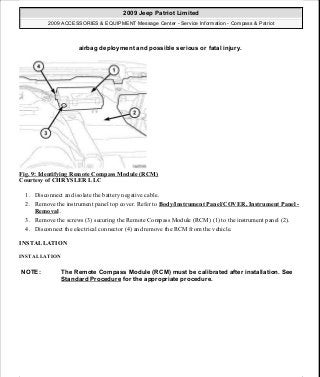

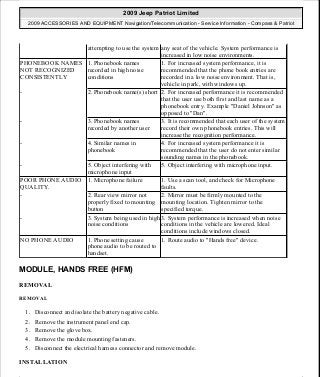

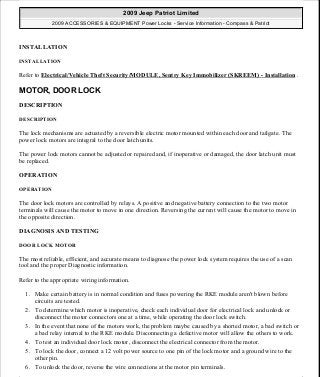

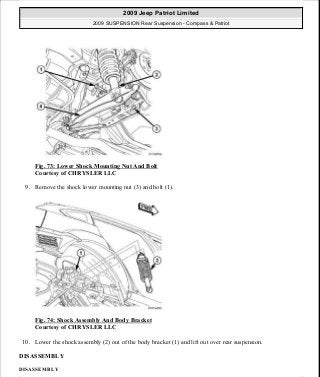

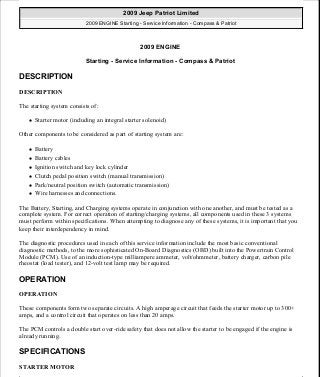

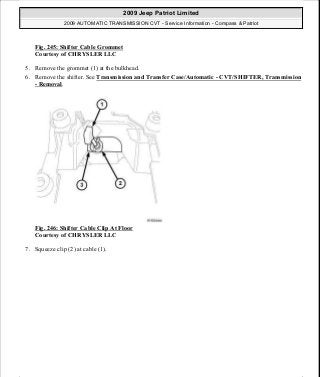

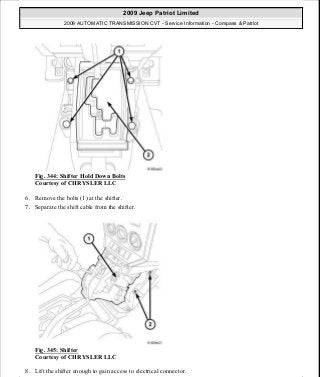

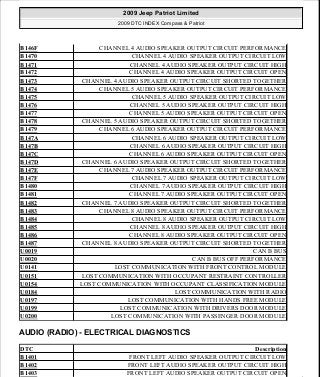

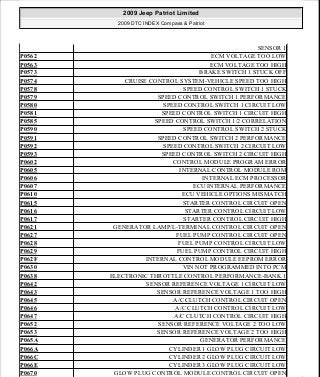

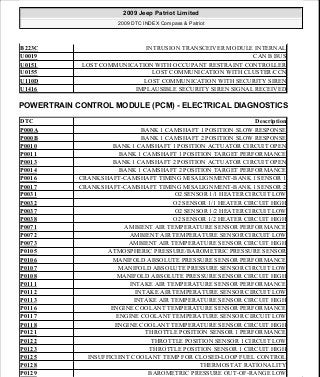

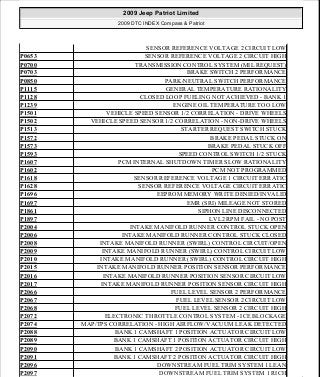

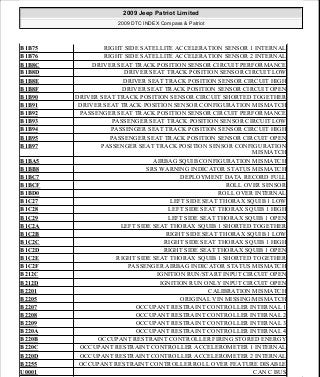

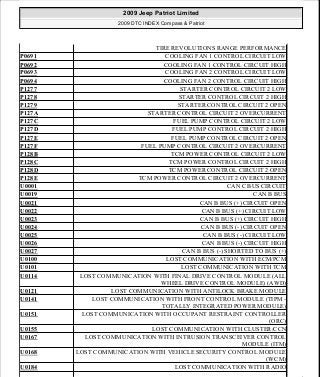

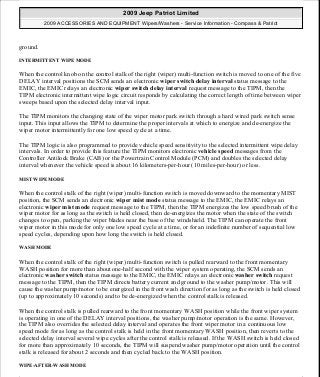

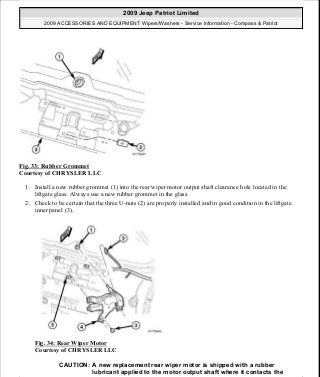

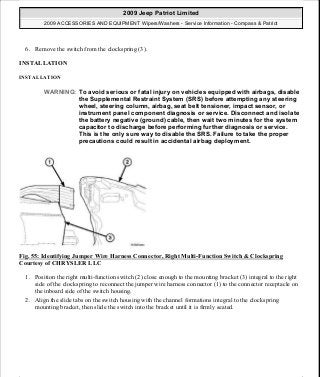

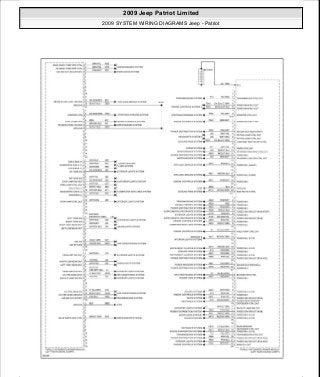

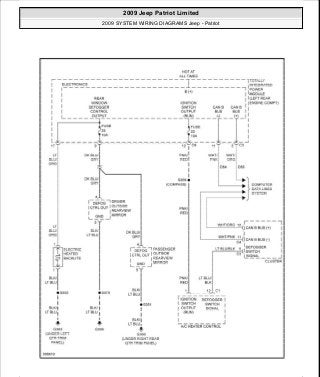

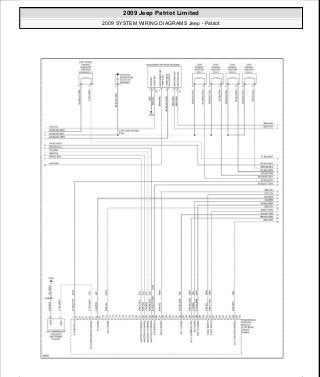

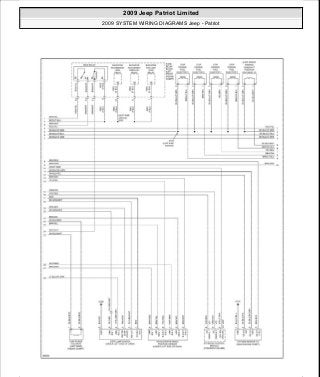

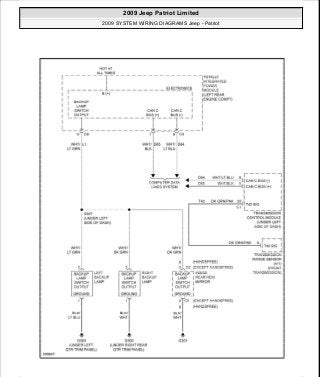

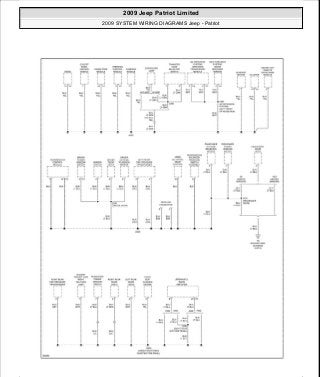

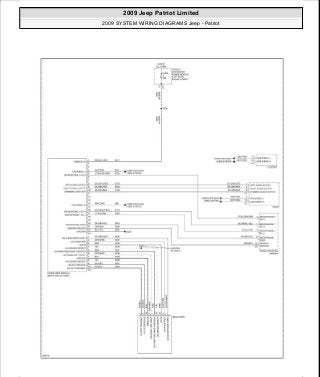

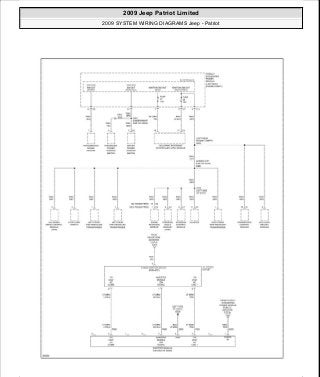

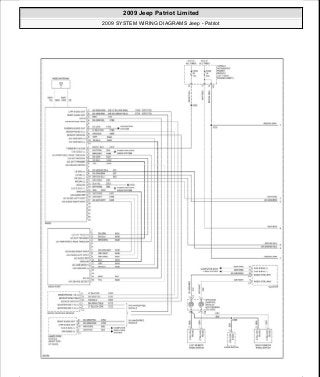

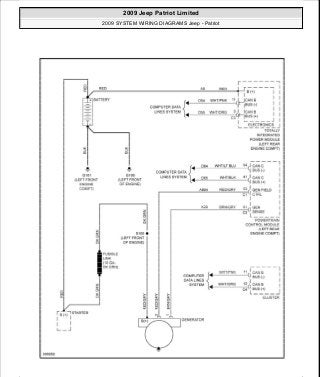

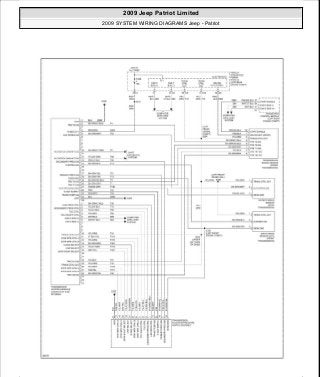

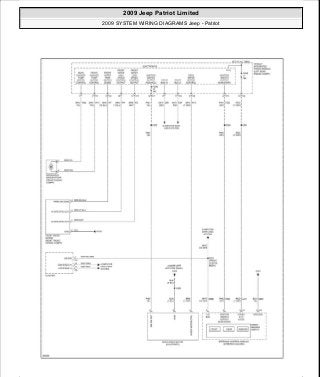

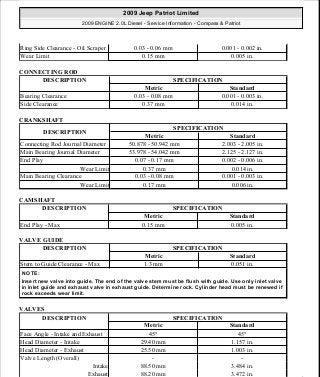

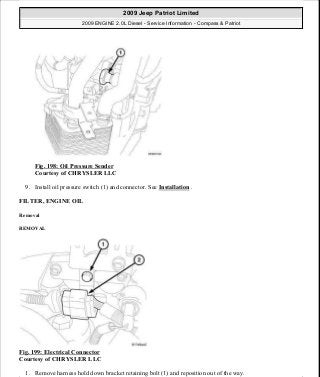

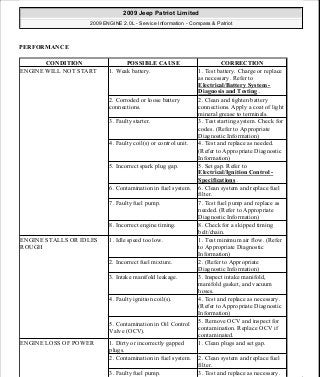

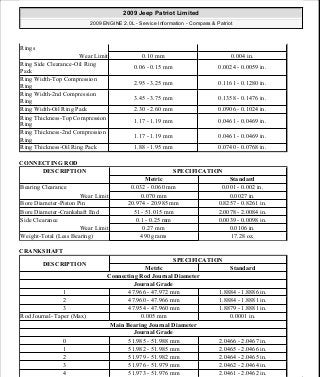

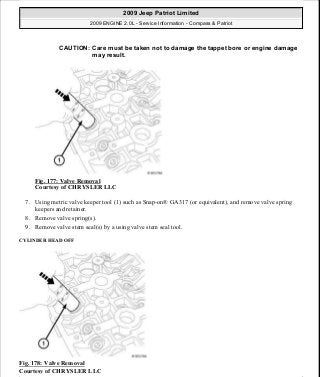

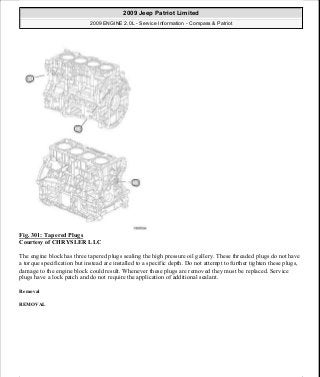

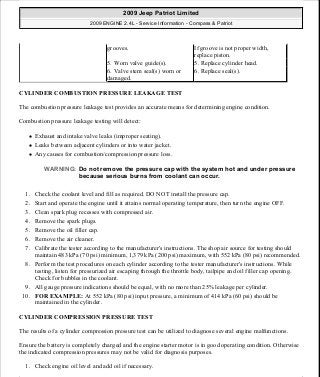

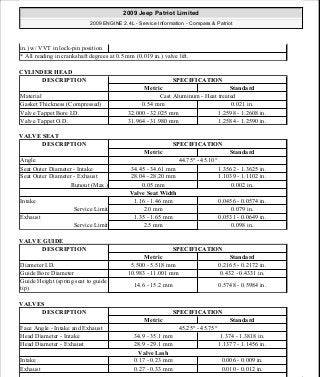

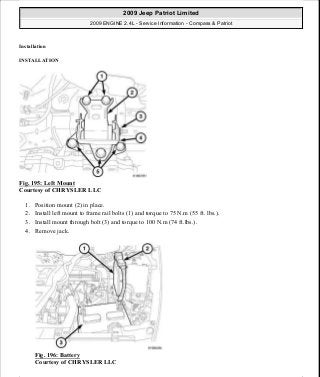

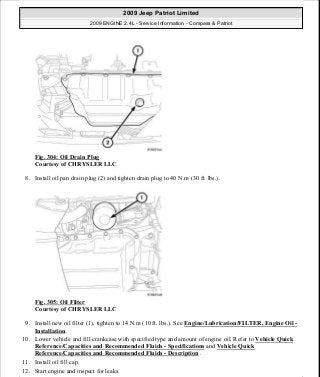

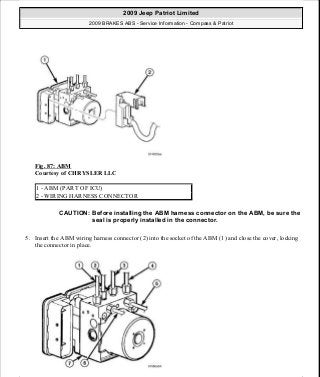

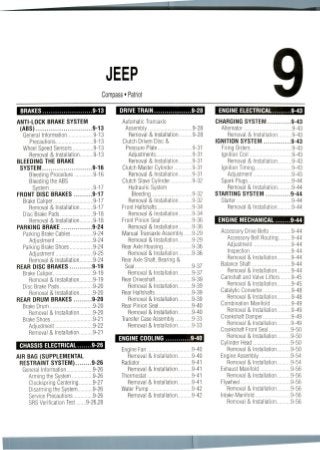

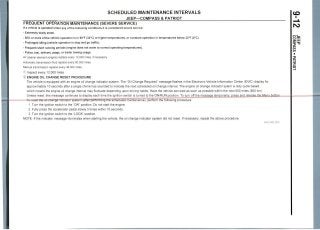

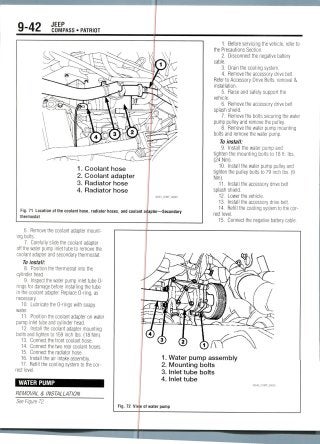

I DISC BRAKE PADS ^B

REMOVAL & INSTALLATION

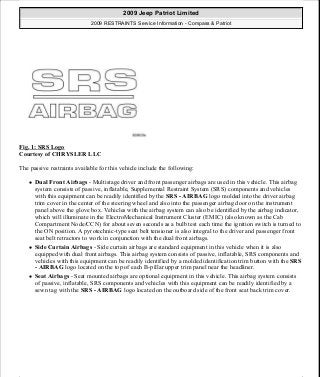

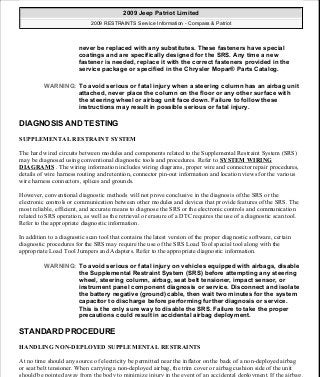

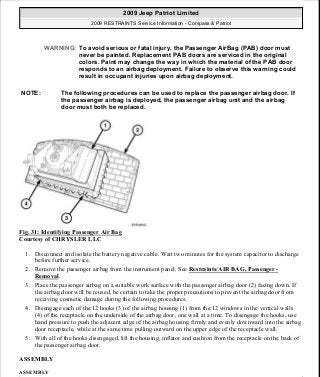

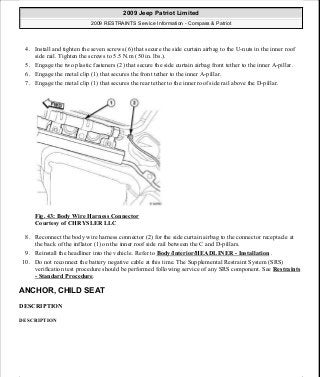

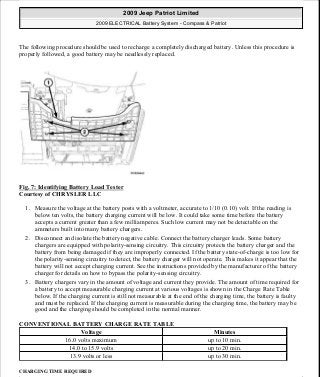

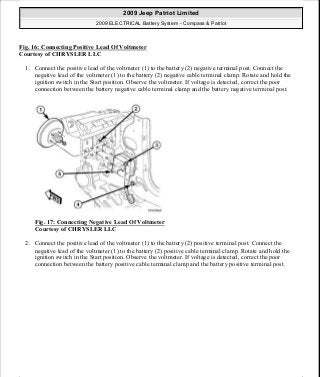

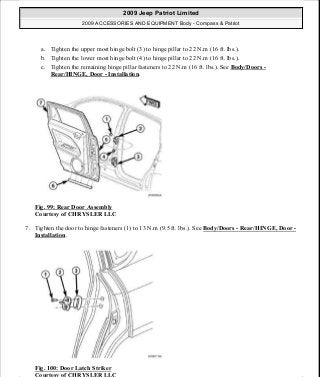

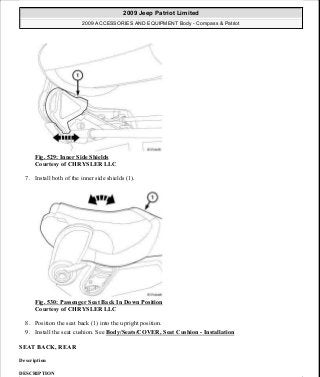

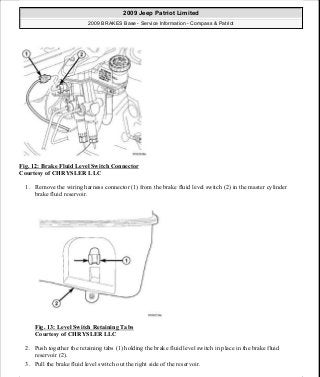

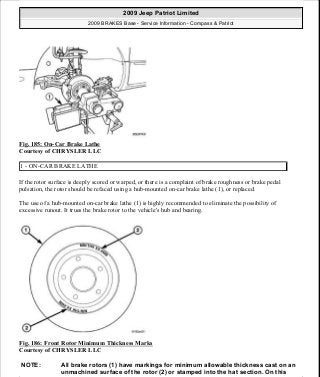

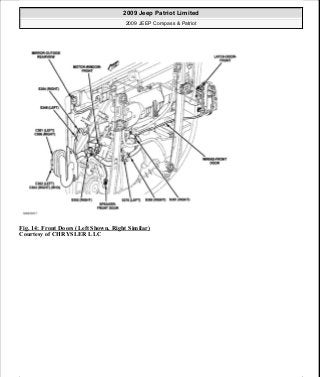

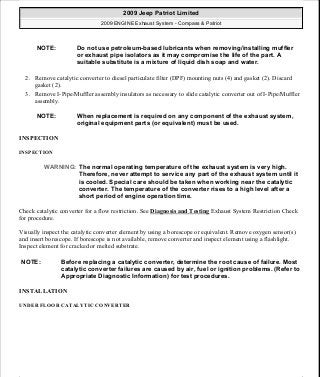

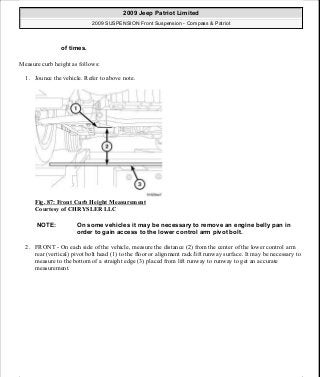

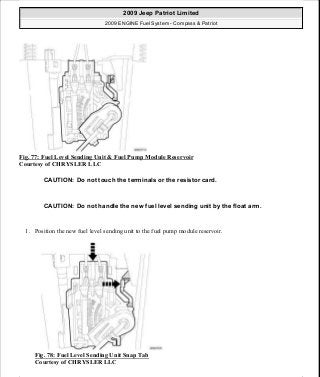

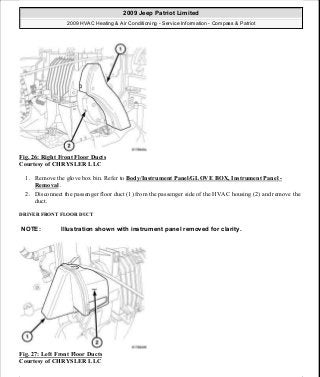

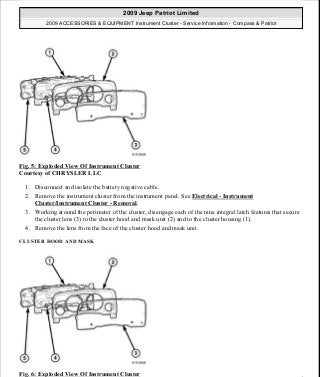

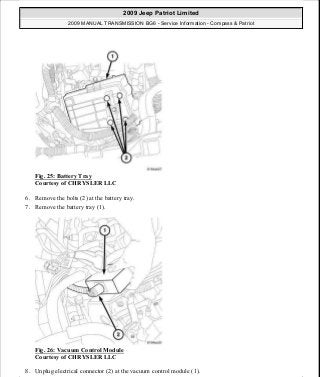

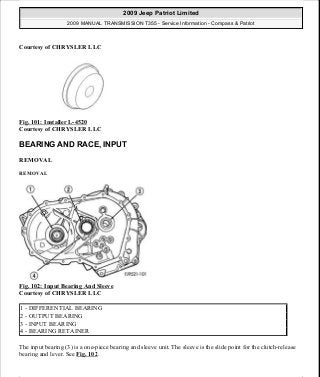

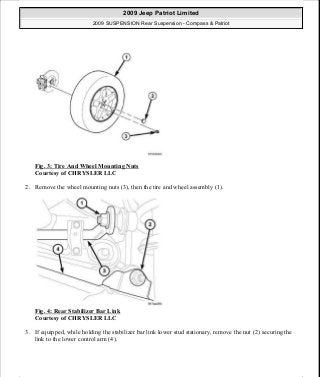

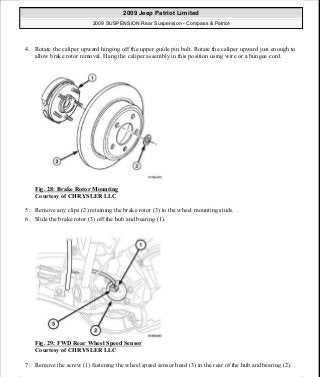

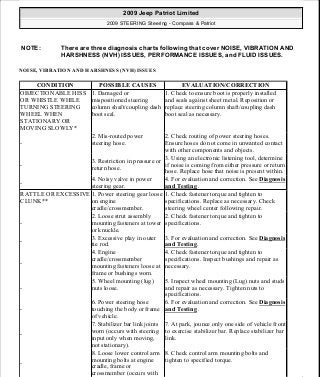

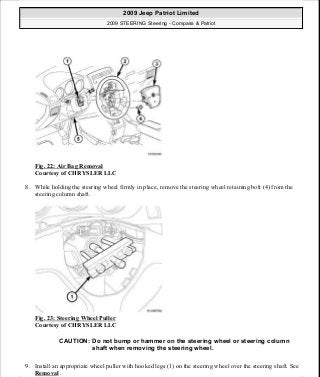

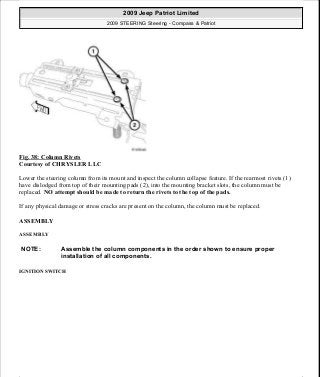

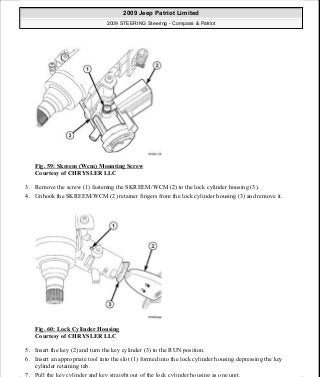

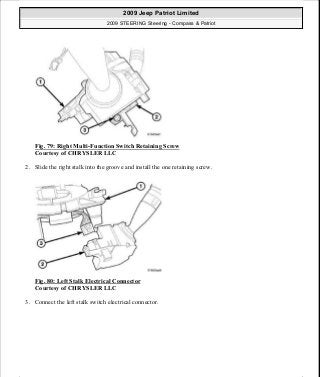

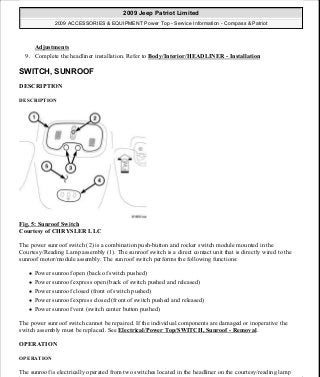

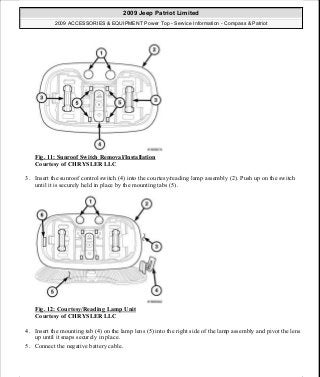

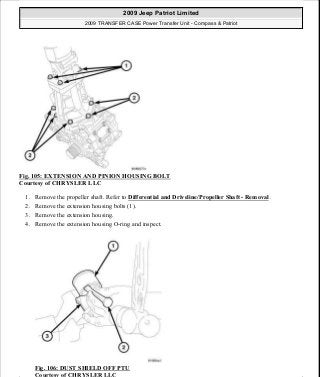

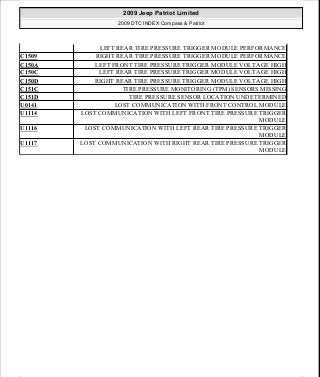

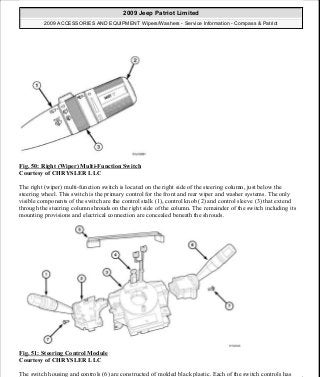

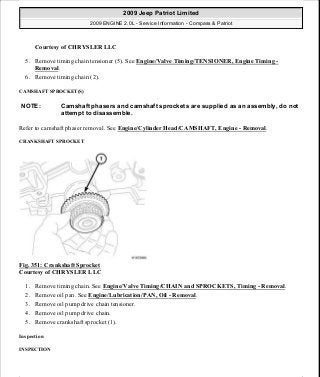

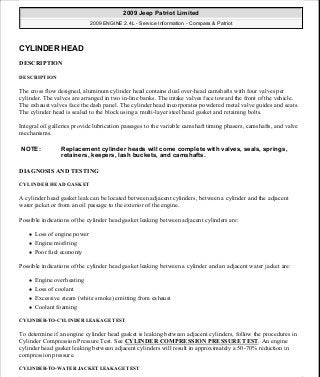

See Figure 14.

1. Before servicing the vehicle, refer to

the Precautions Section.

2. Raise and safely support the vehicle.

Q Romnv/p the roar A/hool

C;

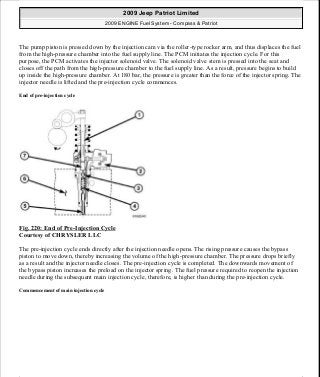

Q~^-Cr

X>w

..frrc:

ofe^Ok

^

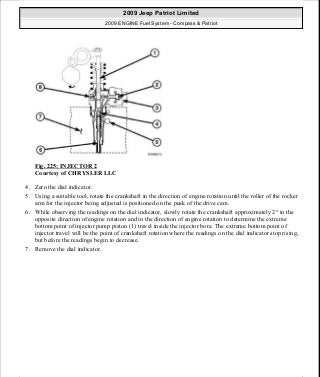

;^:O

1

2

2

4

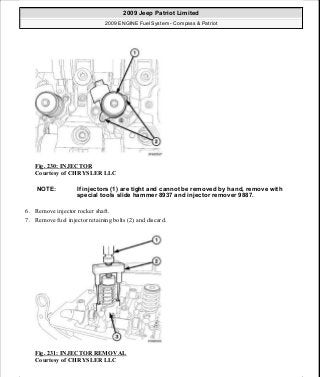

c

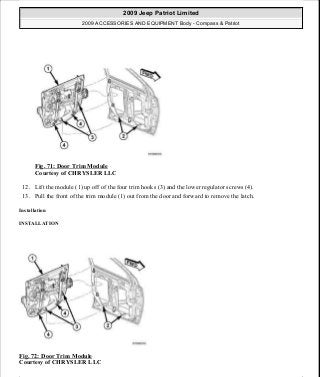

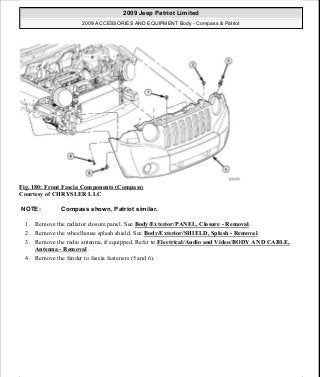

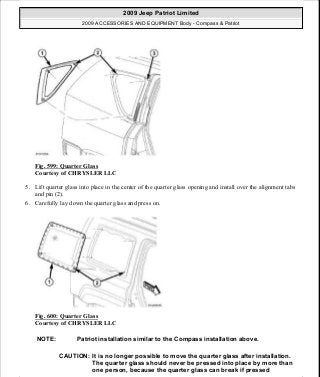

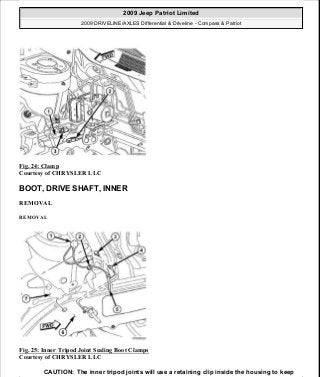

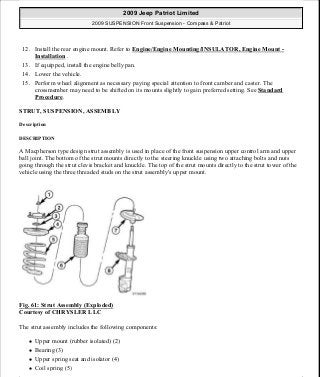

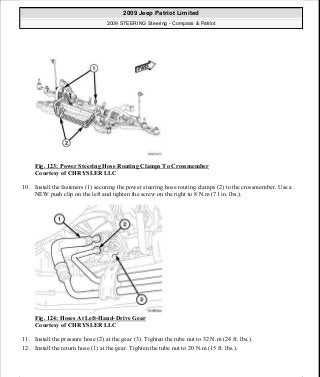

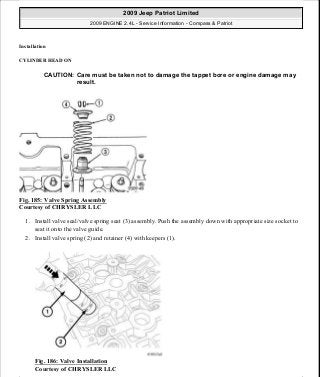

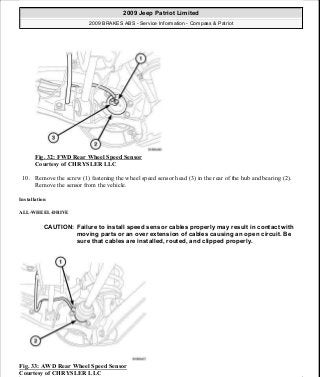

Fig. 14 R

adapter b

pad from

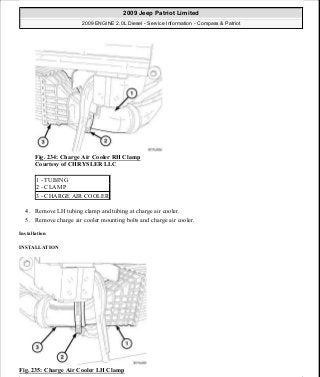

Ssi<^ jr}

^^^A/P^^rl J$>

T>) u )i)ju r^

'=^^m^mM

^-t<^p

^^^4^^Wv b p

?f ^ ^

^""""---} ] I-' I Z/

jLs*. 'J /

© i/e* I/

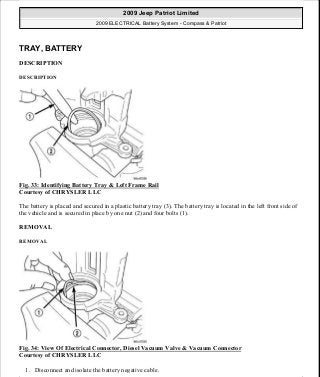

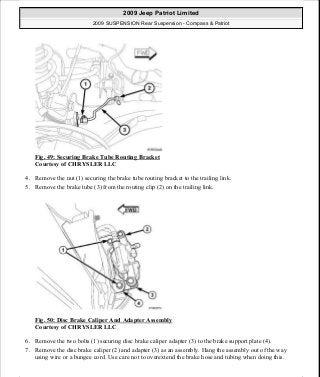

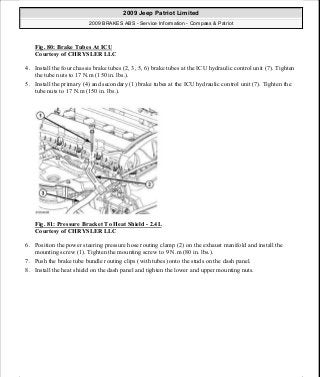

Rear brake caliper

Outboard pad

Adapter bracket

Abutment shims

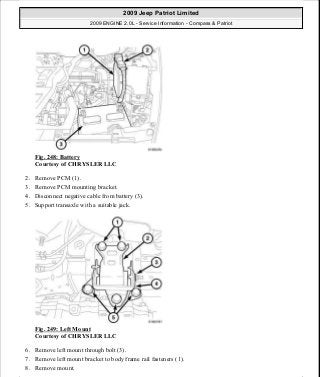

Inboard pad

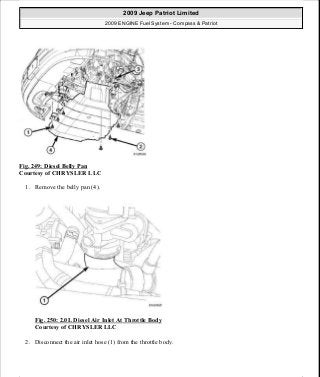

36543 COMP GOO]?

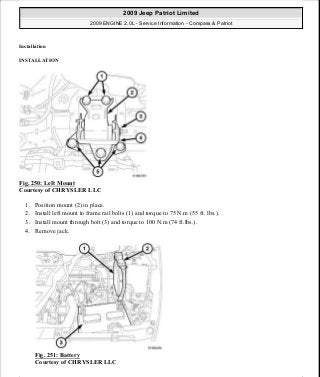

move the inboard pad from the

acket and remove the outboard

le caliper—Rear brake assembly

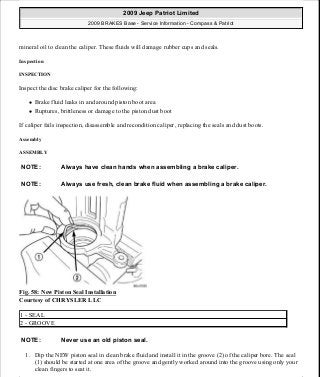

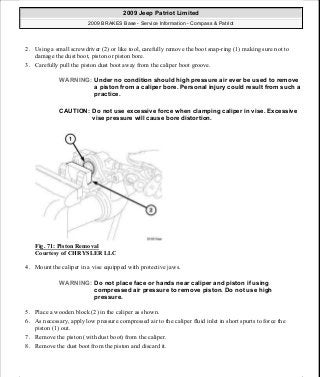

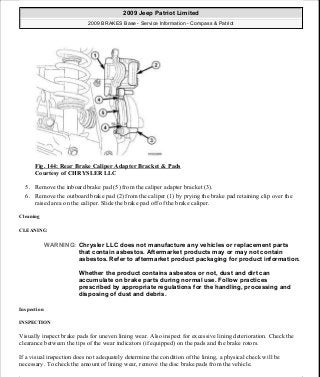

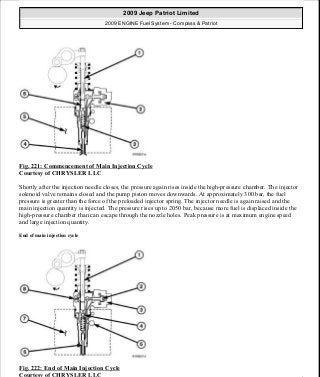

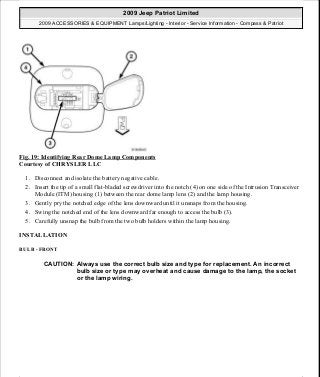

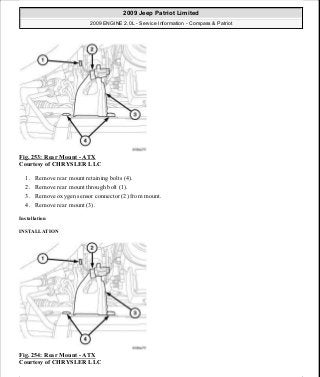

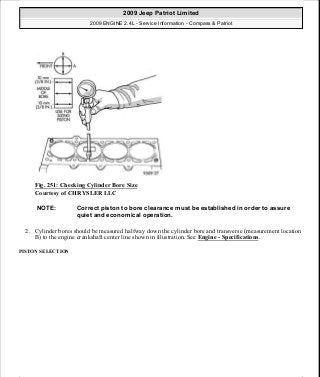

9. Slide the outboard pad onto the

caliper. Ensure the retaining clip is seated

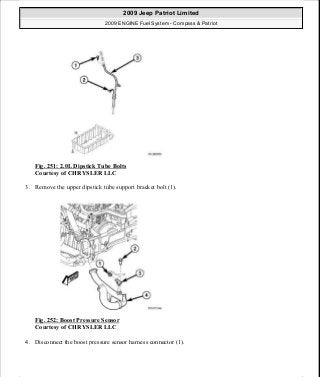

properly in the depressed areas of the

caliper.

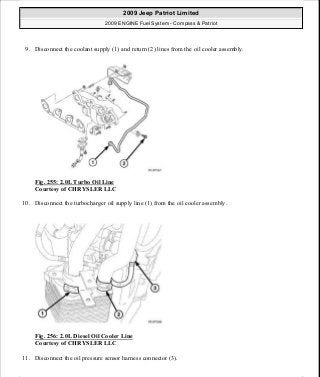

10. Place the inboard pad in the brake

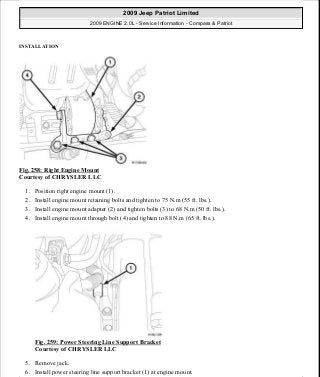

shims clipped into the caliper adapter

bracket.

11 . Rotate the caliper assembly down-

ward over the rotor into the caliper adapter

bracket.

^^^^B _ _ _ _ __ _ _ _ _ _ __

B ** WARNING

Use care when installing the caliper

onto the adapter bracket to avoid

damaging the guide pin boot.

12. Install the lower guide pin bolt and

tighten to 32 ft. Ibs. (43 Nm).

13. Inspect the outboard brake pad to

make sure it is correctly positioned. The

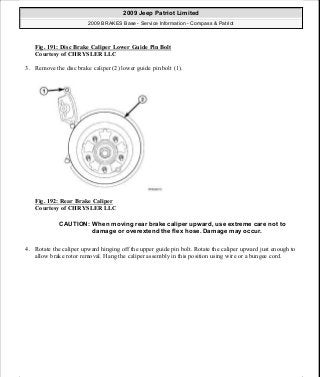

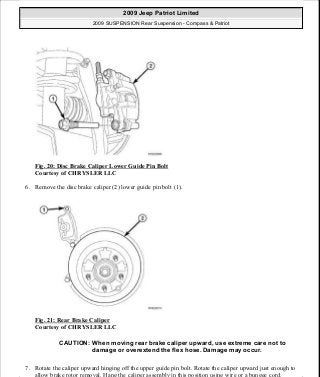

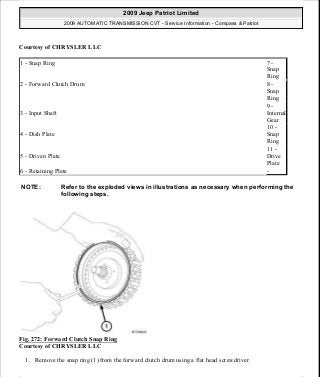

4. Remove the brake caliper lower

guide pin bolt.

5. Rotate the caliper upward, using the

top guide bolt as a hinge. Hang the caliper

assembly with mechanics wire or equivalent.

## WARNING

Do not let the caliper hang by the

brake hose.

6. Remove the inboard brake pad from

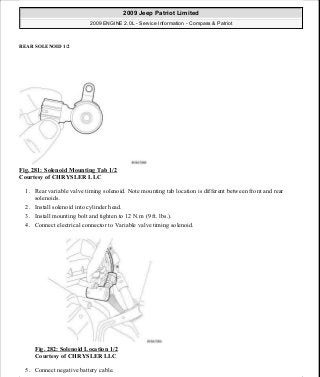

the caliper adapter bracket.

7. Remove the outboard brake pad from

the caliper by prying the retaining clip over

the raised area on the caliper.

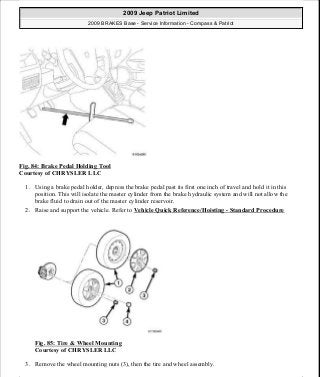

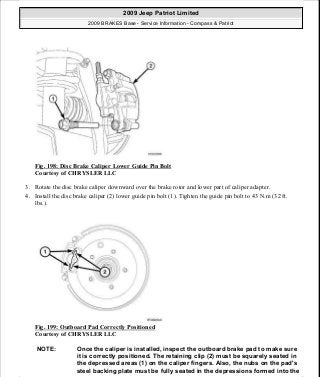

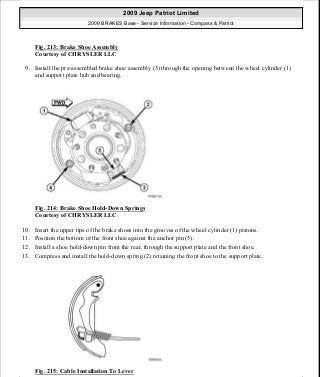

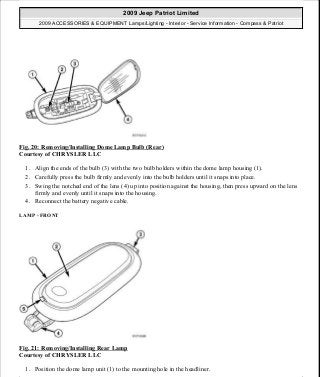

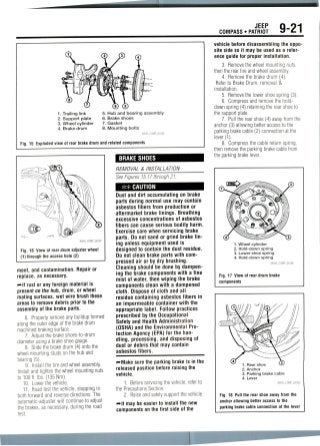

BRAKES

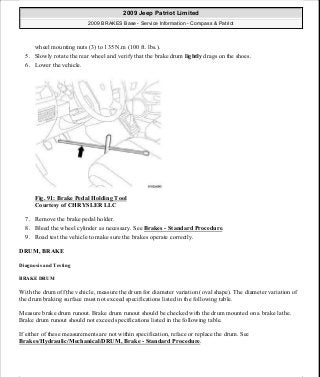

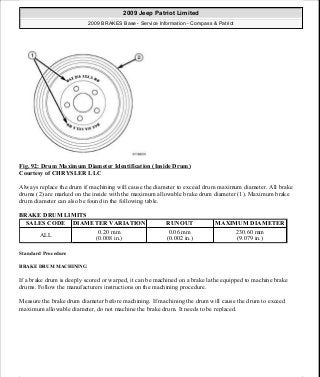

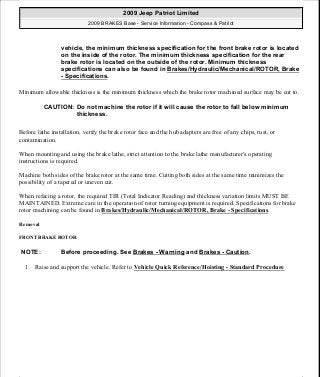

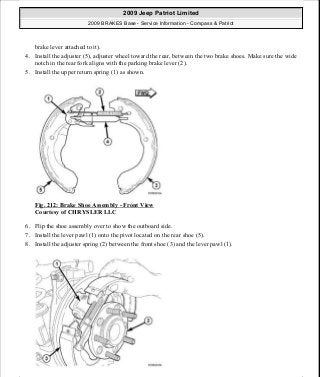

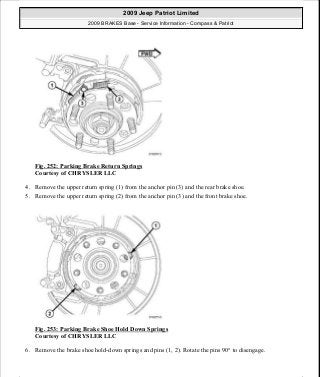

BRAKE DRUM

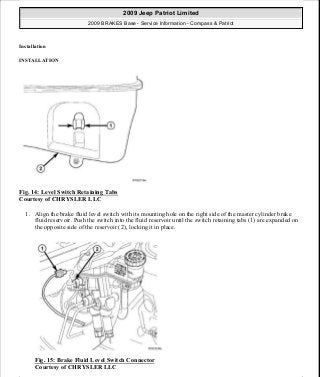

REMOVAL & INSTALLATION

See Figures 15 dnd 16.

** CAUTION

Dust and dirt accumulating on brake

parts during normal use may contain

asbestos fibers from production or

aftermarket brake linings. Breathing

excessive concentrations of asbestos

fibers can cause serious bodily harm.

Exercise care when servicing brake

parts. Do not sand or grind brake lin-

ing unless equipment used is

designed to contain the dust residue.

Do not clean brake parts with com-

pressed air or by dry brushing.

Cleaning should be done by dampen-

ing the brake components with a fine

mist of water, then wiping the brake

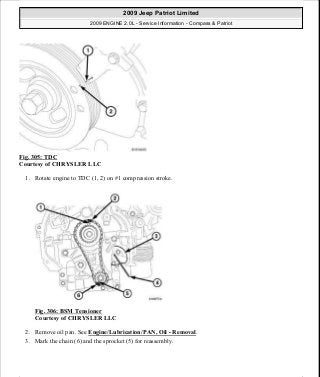

components clean with a dampened

To inst

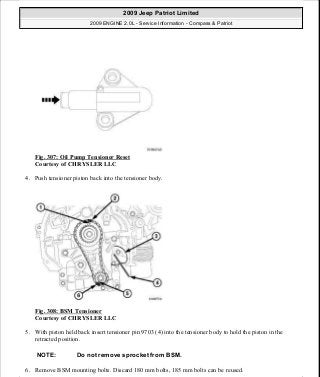

8. Usi

the caliper

caliper.

g a C-clamp, completely retract

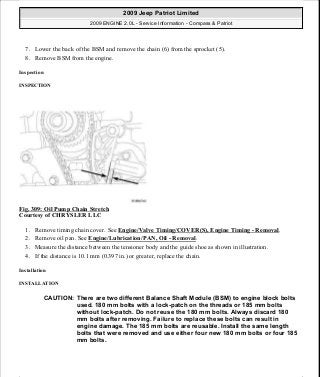

)iston back into the bore of the

** WARNING

Place a b

before us

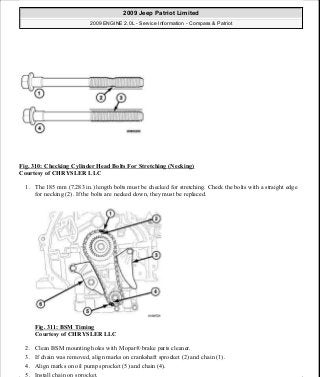

damage t

("*-The brake

tor, shouli

side. The

positionec

installed.

ock of wood over the piston

ng the C-clamp to prevent

) the piston.

pad, with the wear indica-

be installed on the inboard

wear indicator should be

at the bottom when

cloth. Dh pose of cloth and all

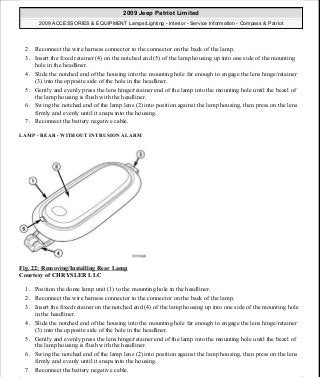

residue ontaining asbestos fibers in

impermeable container with the

label. Follow practices

by the Occupational

Health Administration

the Environmental Pro-

Ariency (EPA) for the han-

pn cessing, and disposing of

bris that may contain

and

an

appropriate

prescribed

Safety

(OSHA)

tection

dling,

dust or d

aid

asbestos fibers

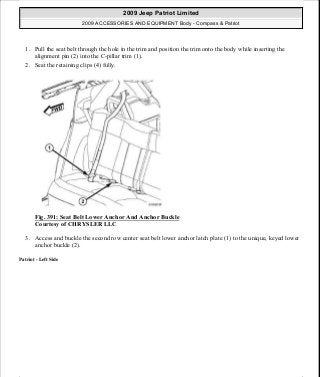

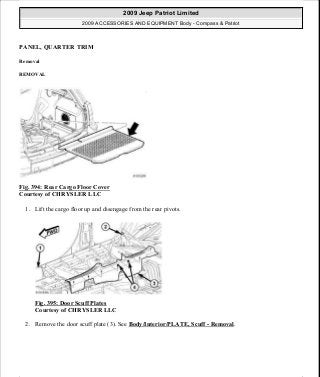

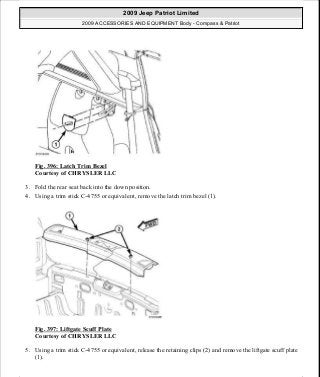

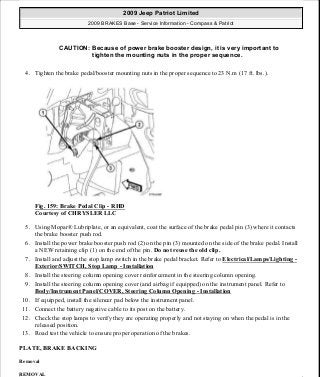

1. Bef'

the Precau

2. Rai

vehicle.

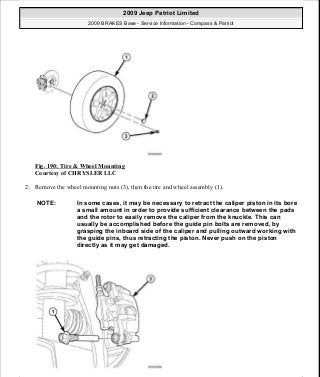

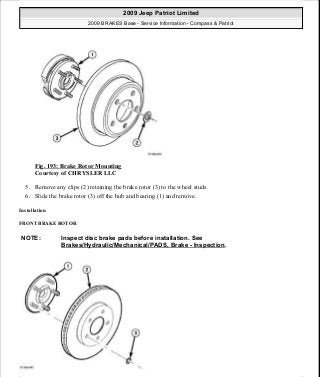

3. Re

then the til

4. Slii

wheel mounting

ing (5) am

5. IftJ

further bra

re servicing the vehicle, refer to

ions Section.

e and safely support the

ove the wheel mounting nuts,

) and wheel assembly.

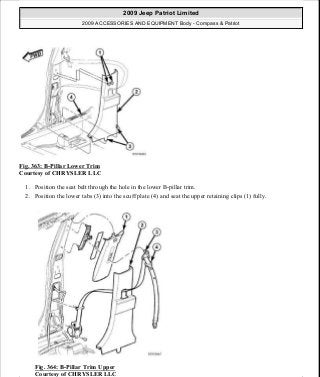

3 the brake drum (4) off the

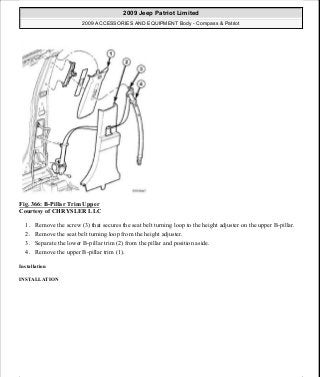

studs of the hub and bear-

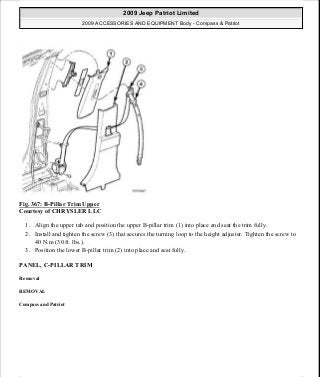

remove it from the vehicle.

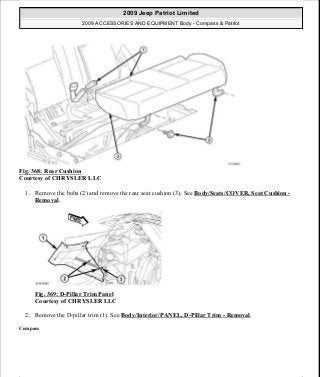

) drum does not come off,

e clearance can be obtained

retaining clip must be squarely seated in

the depressed areas on the caliper fingers.

Also, the nubs on the pad's steel backing

plate must be fully seated in the depres-

sions formed into the inside of the caliper

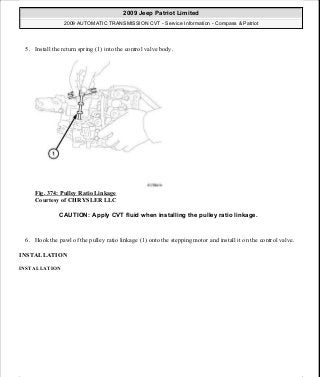

fingers. There should be no gap between

the pad backing plate and the caliper

fingers.

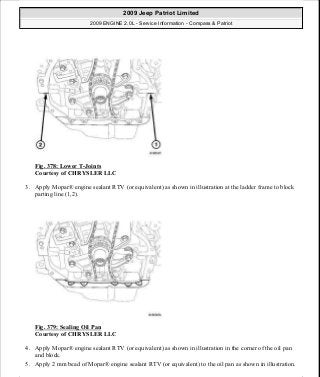

14. Install the rear wheel. Tighten the

mounting nuts to 100 ft. Ibs. (135 Nm).

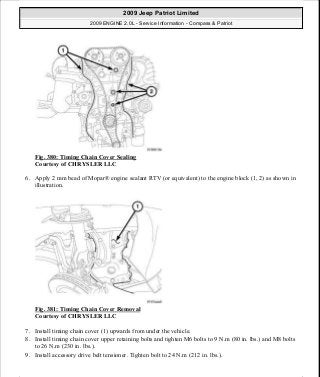

15. Lower the vehicle.

16. Pump the brake pedal several times

to ensure the vehicle has a firm brake pedal

before moving thevehicle.

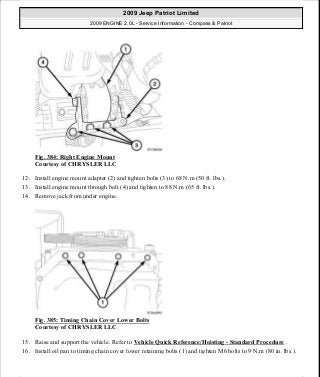

17. Test drive the vehicle to ensure

proper brake operation.

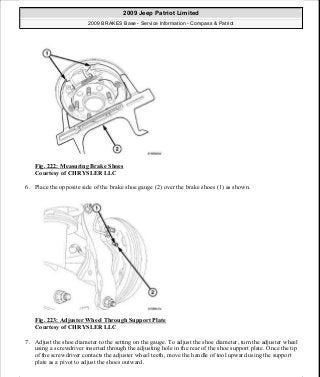

REAR DRUM BRAKES

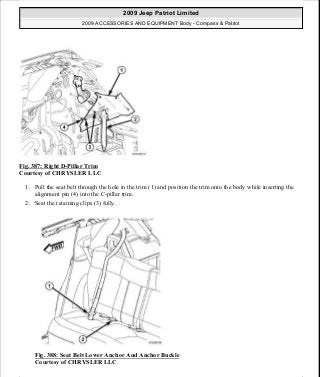

by backing off the brake adjuster screw.

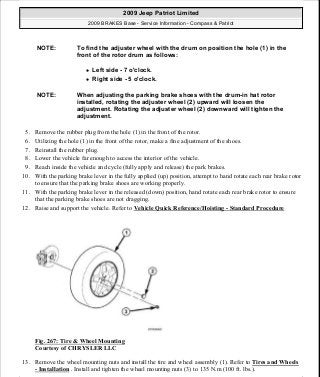

To do so, perform the following

procedure:

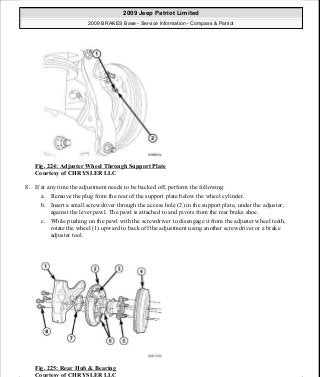

a. Remove the plug from the rear of

the support plate below the wheel cylinder.

b. Insert a small screwdriver through

the access hole (2) in the support plate,

under the adjuster, against the lever pawl.

The pawl is attached to and pivots from

the rear brake shoe.

c. While pushing on the pawl with

the screwdriver to disengage it from the

adjuster wheel teeth, rotate the wheel

(1) upward to back off the adjustment

using another screwdriver or a brake

adjuster tool.

d. Once the adjuster screw is backed

off a sufficient amount, slide the drum off

the wheel mounting studs.

To install:

•—Before installing the drum, Inspect

the brake shoe linings for wear, align-](https://image.slidesharecdn.com/manualesreparacionesjeepcompass-patriotlimited2007-2009-150729164945-lva1-app6891/85/Manuales-de-reparaciones-jeep-compass-y-patriot-limited-2007-2009-809-320.jpg?cb=1438196953)

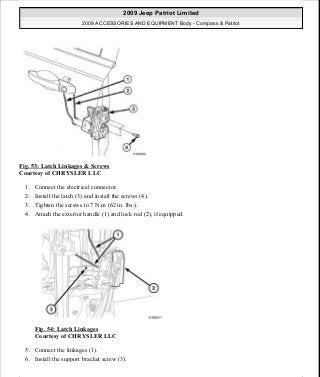

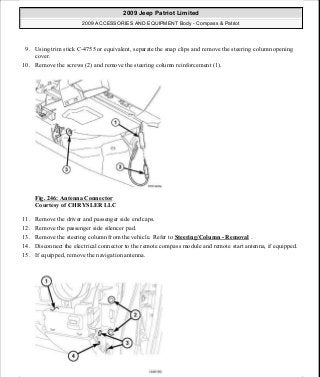

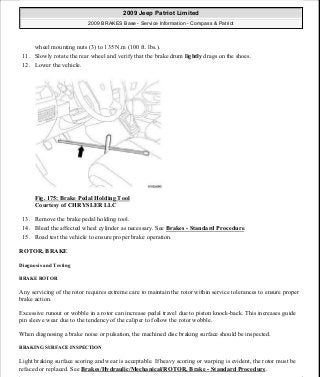

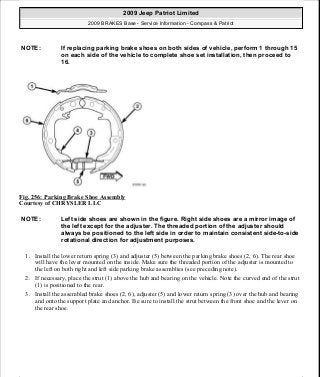

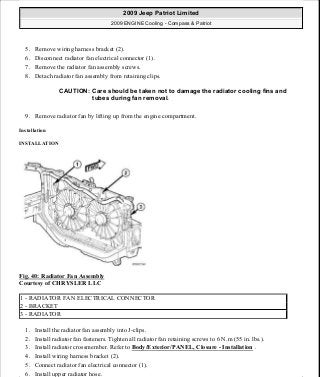

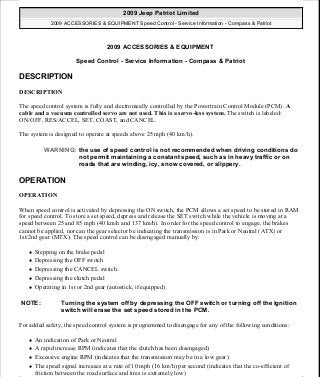

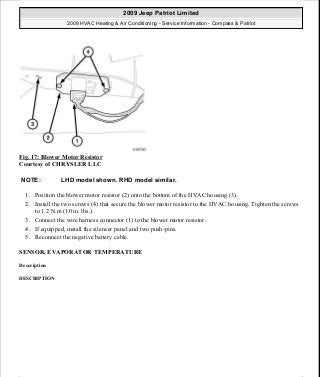

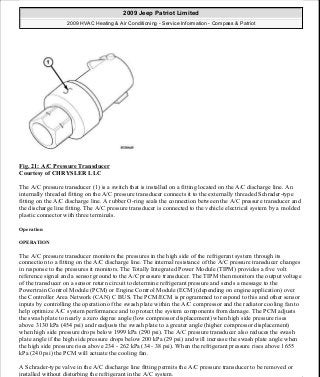

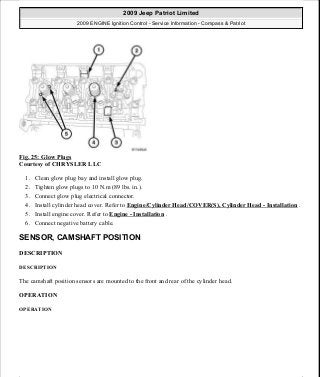

![9-28 JEEP

COMPASS • PATRIOT

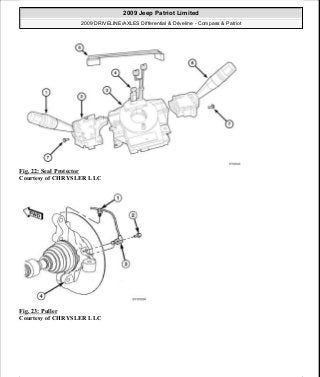

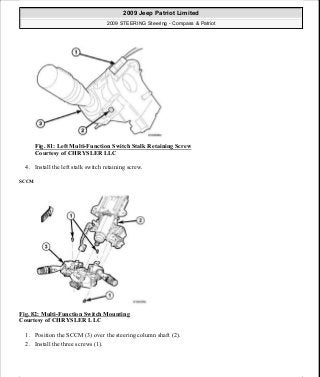

clockspring case using a locking pin (2) or

some similar device to maintain clockspring

centering until the steering wheel is rein-

stalled on the steering column.

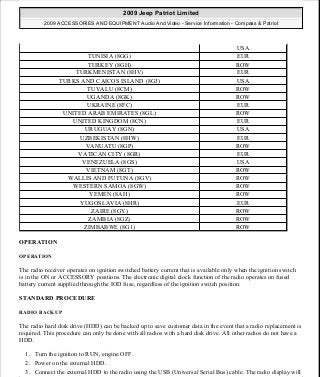

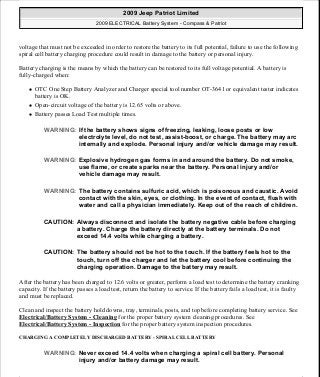

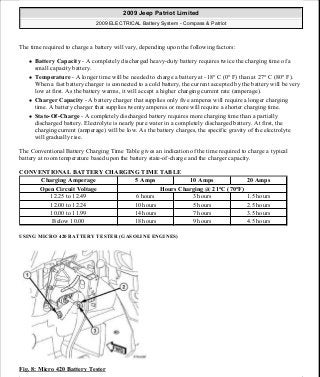

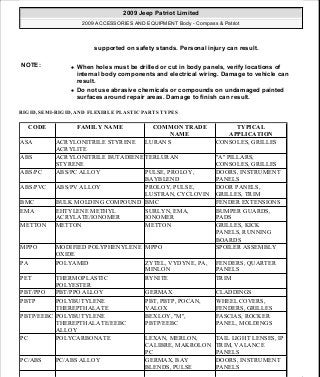

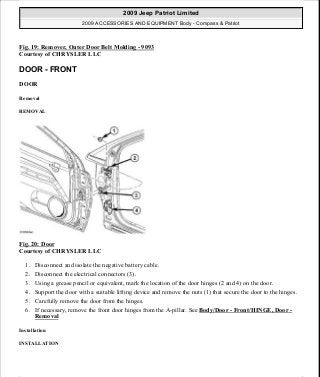

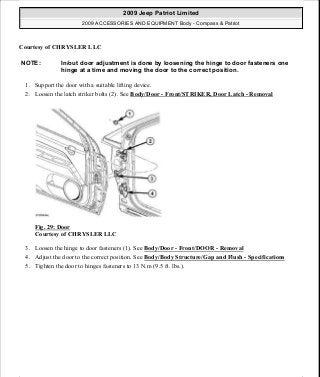

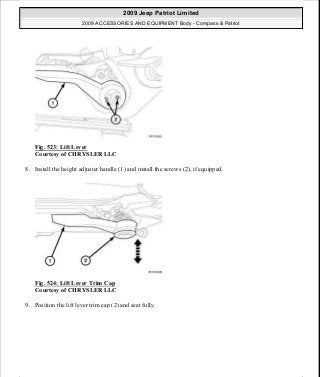

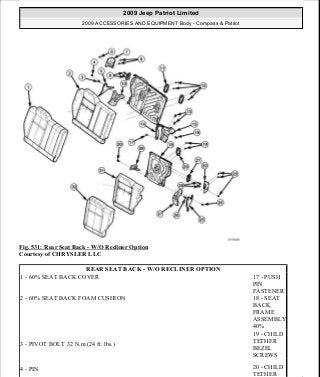

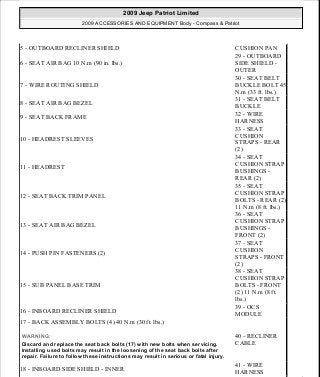

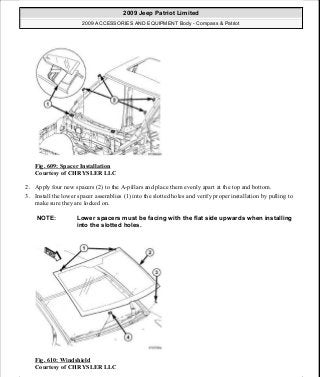

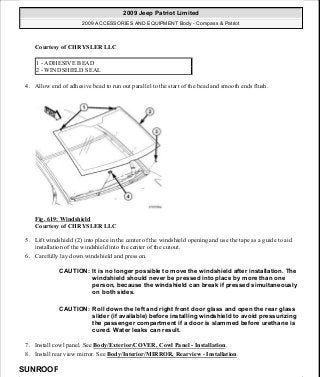

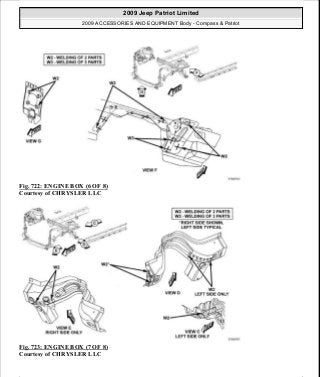

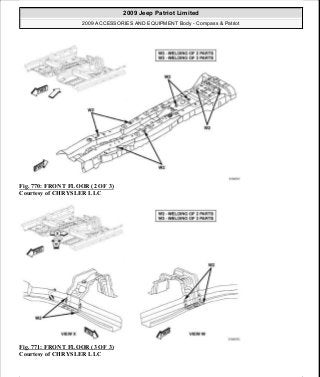

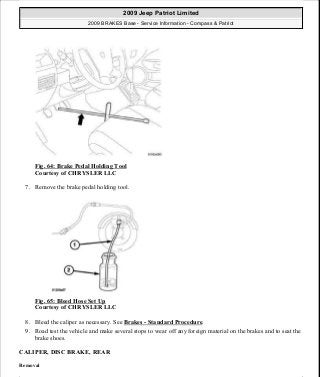

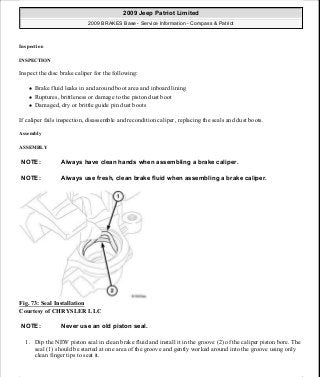

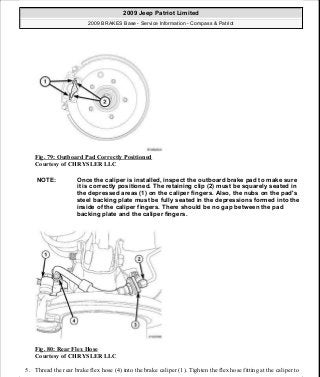

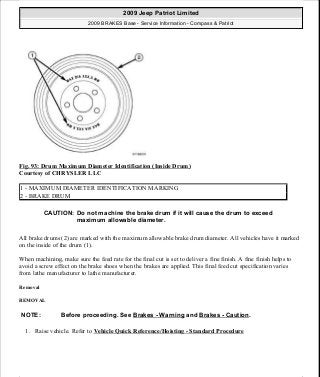

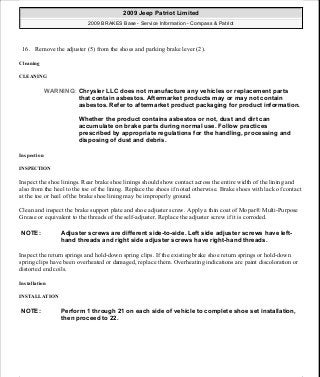

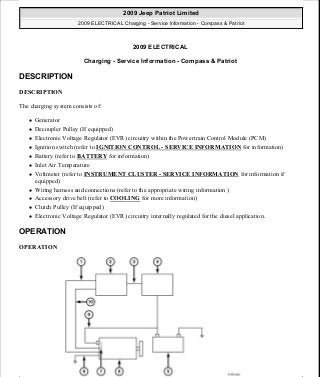

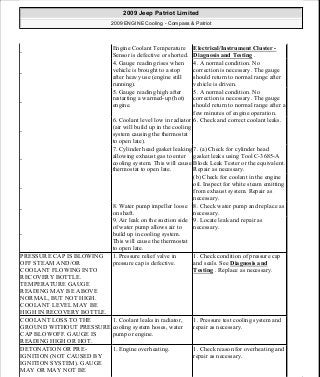

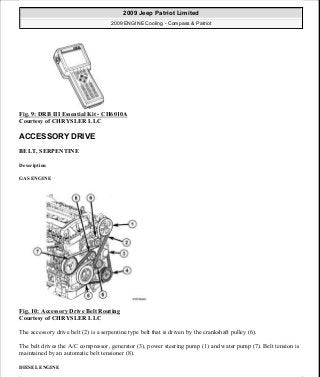

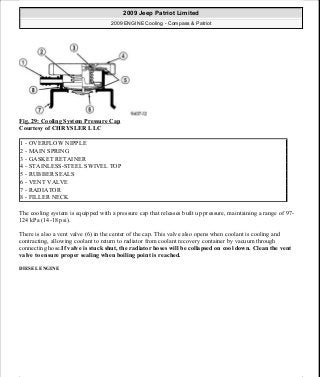

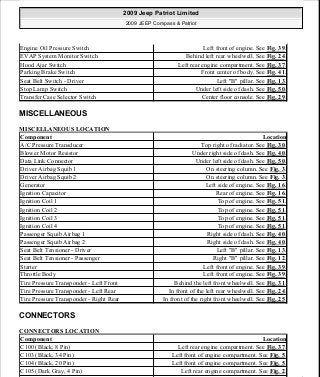

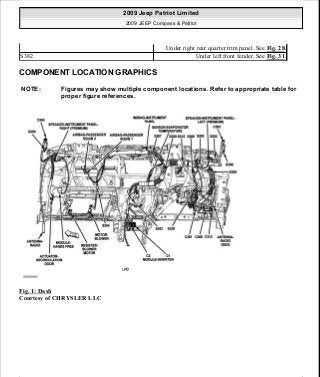

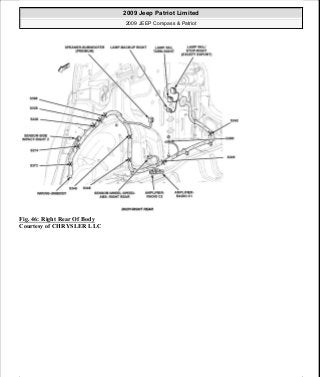

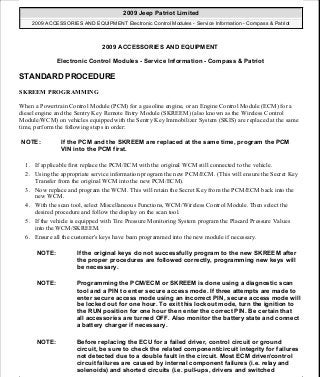

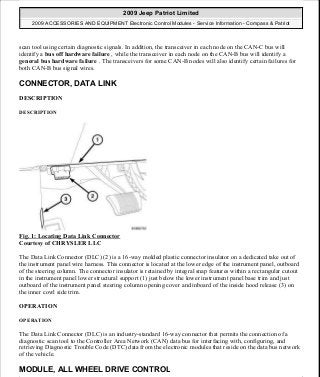

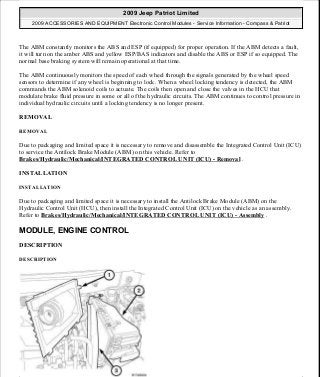

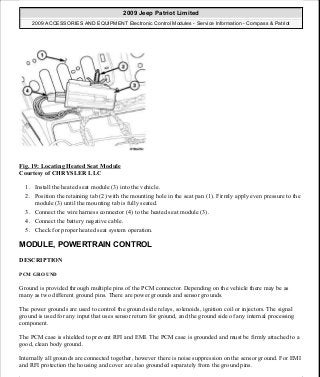

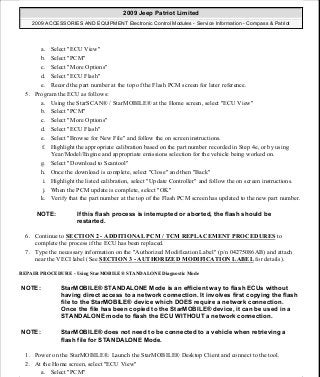

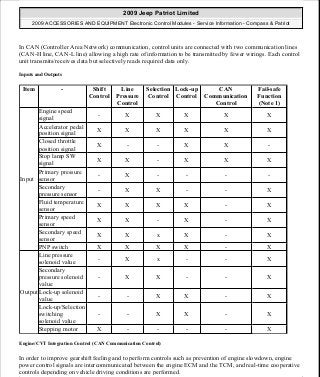

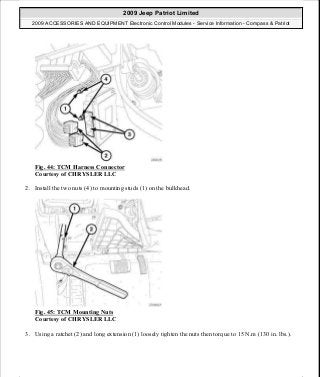

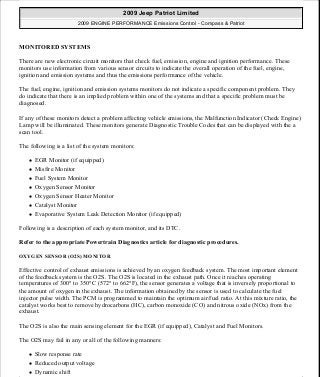

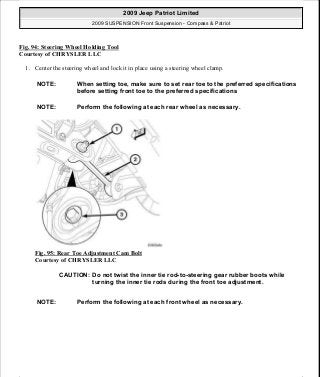

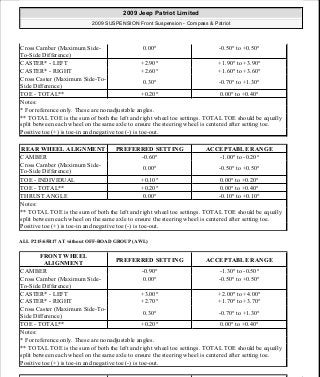

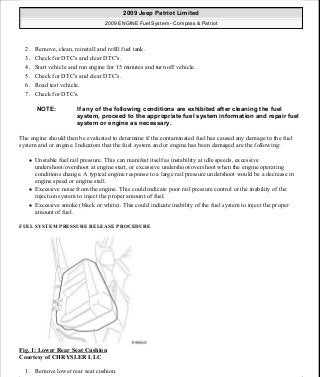

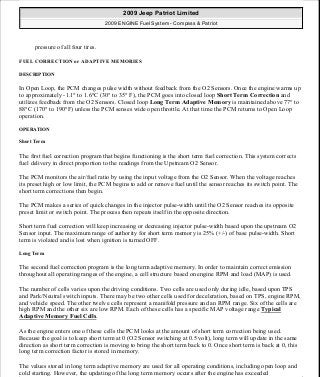

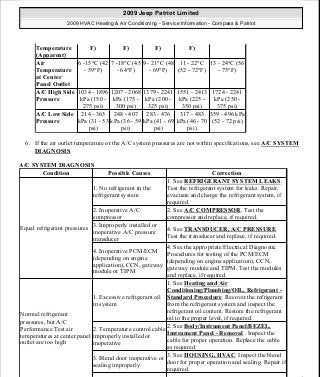

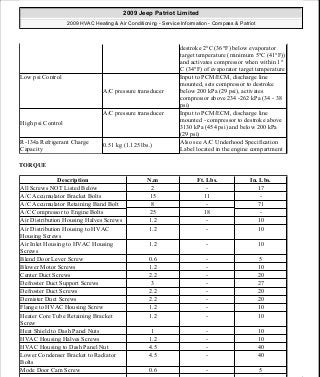

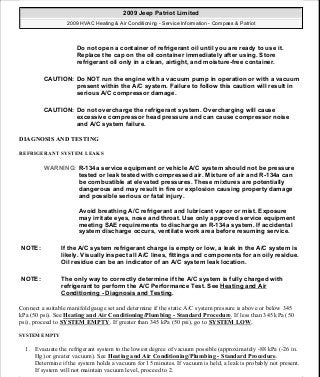

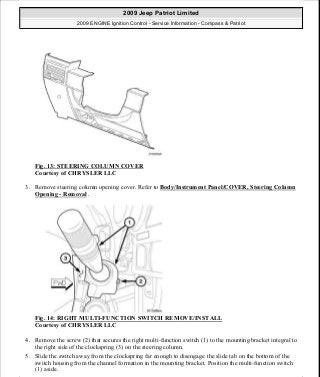

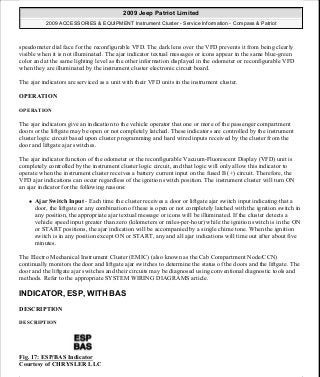

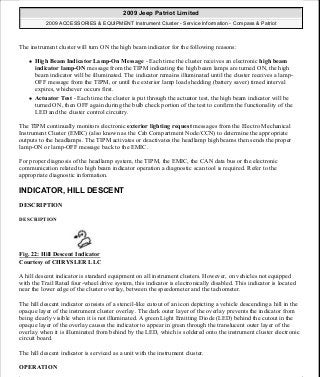

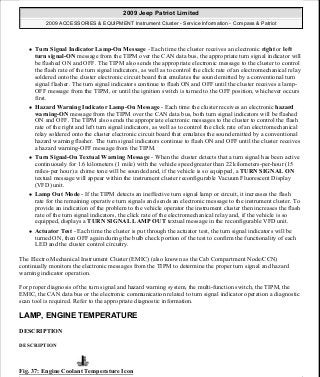

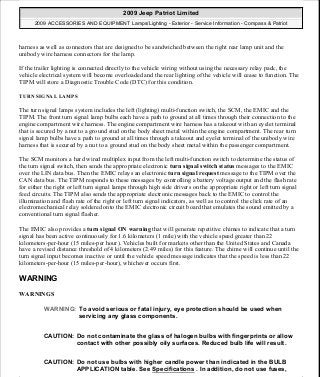

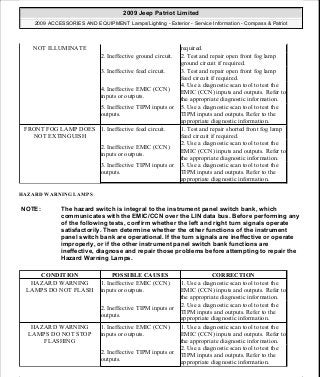

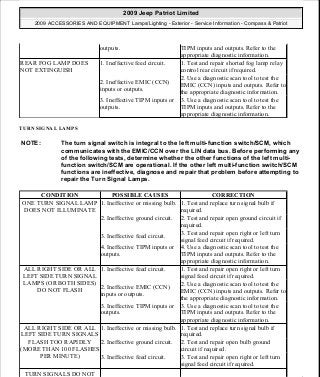

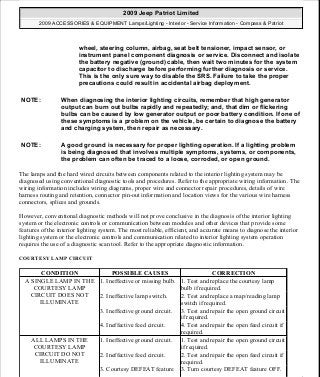

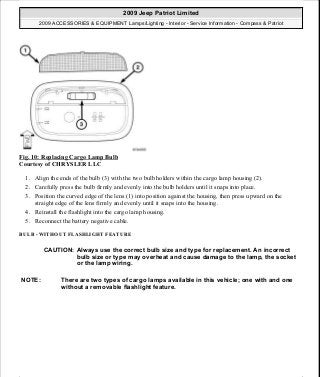

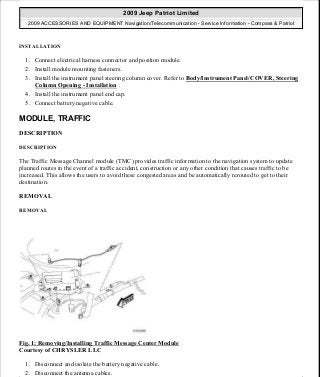

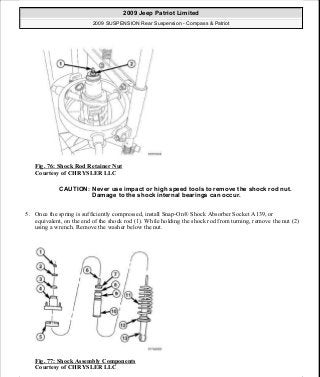

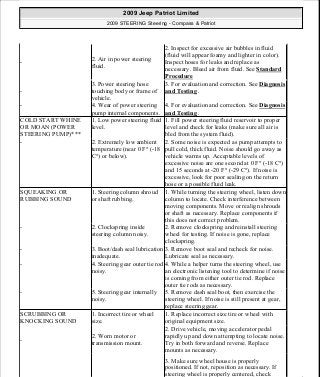

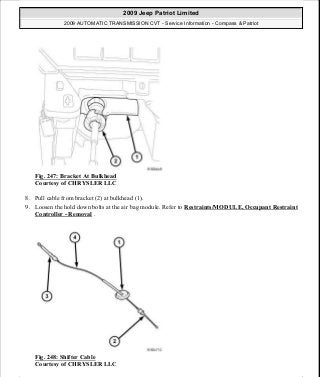

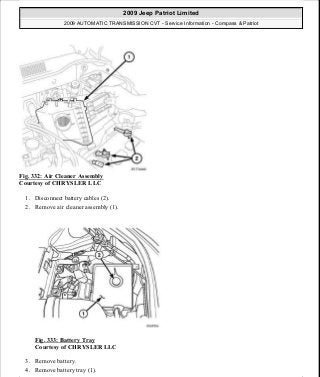

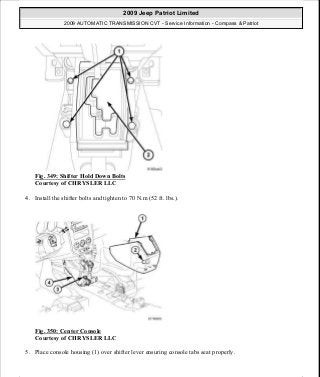

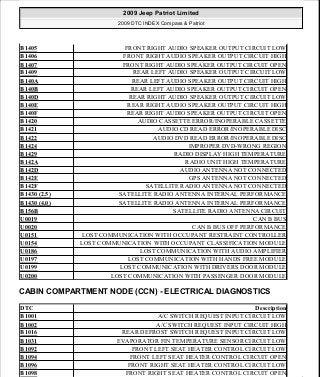

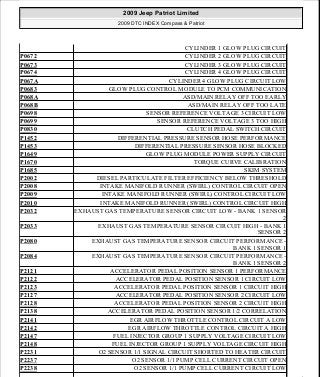

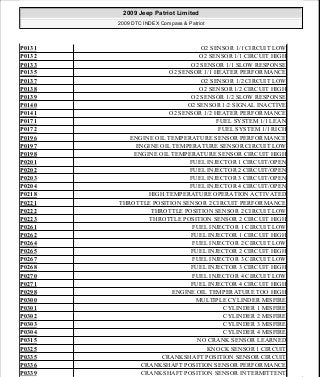

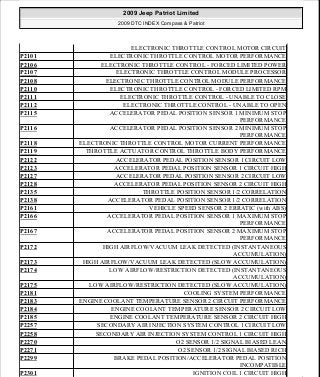

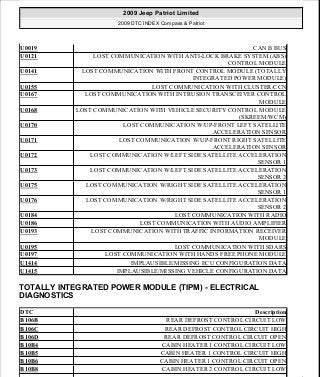

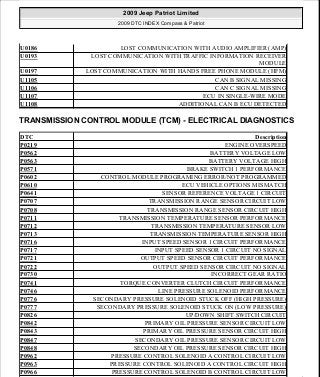

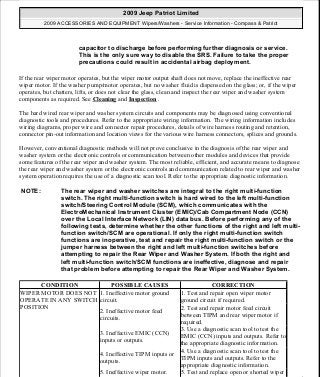

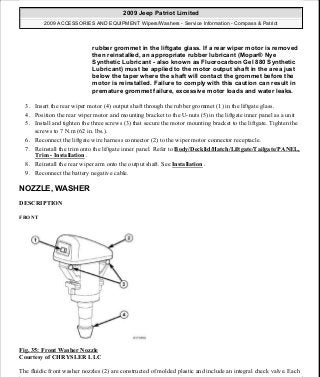

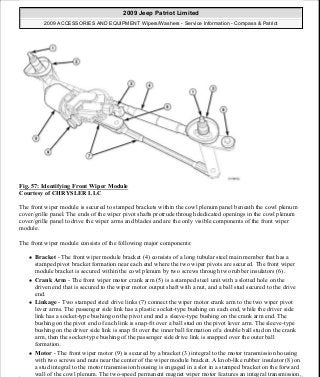

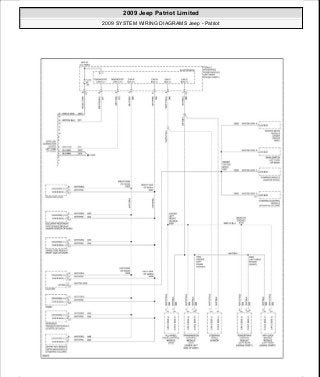

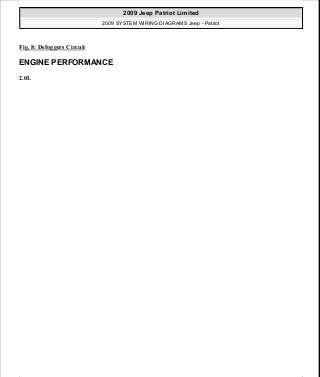

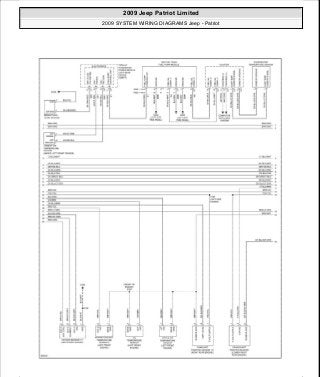

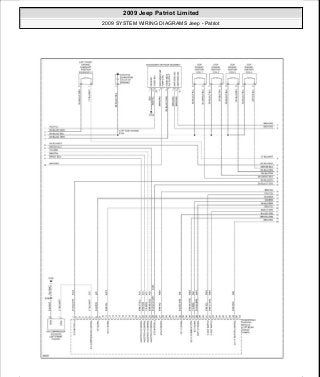

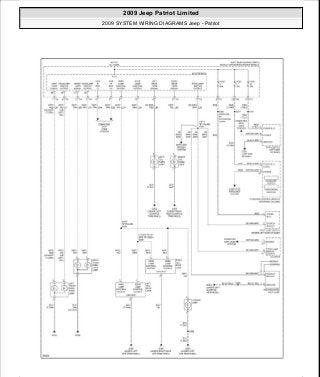

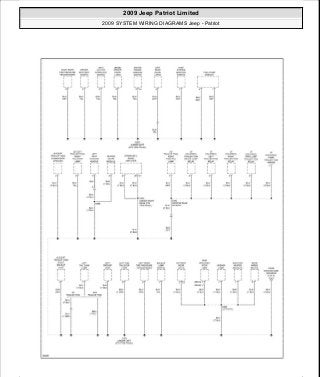

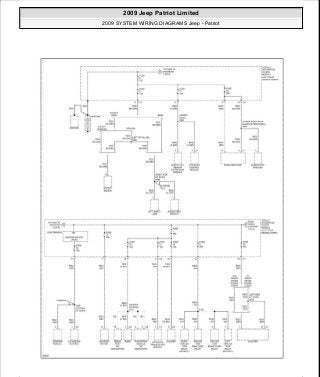

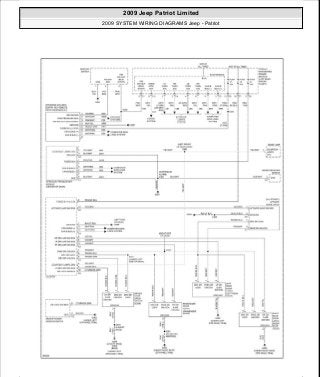

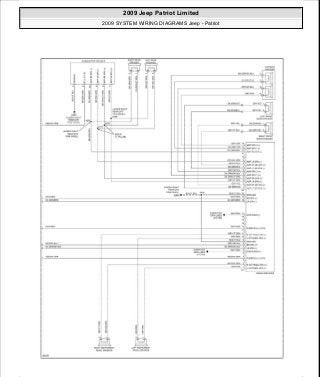

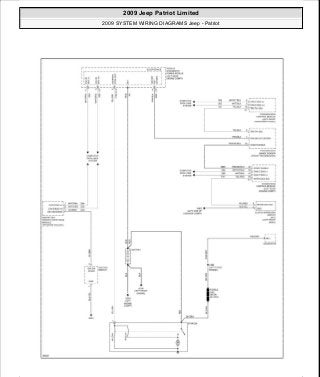

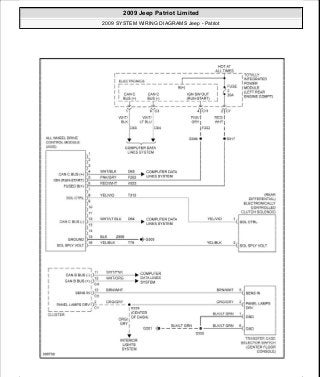

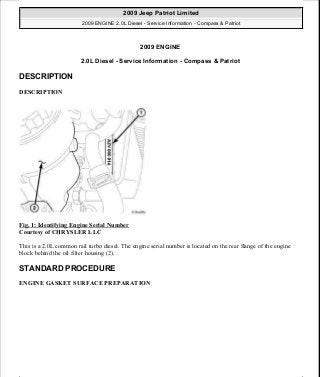

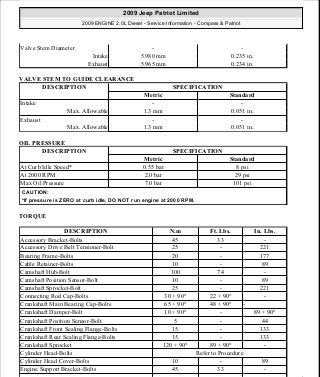

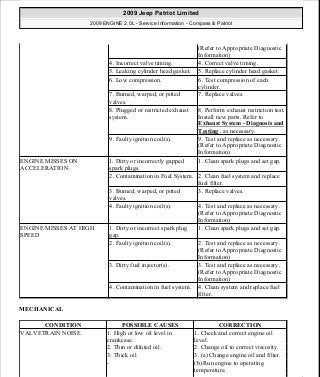

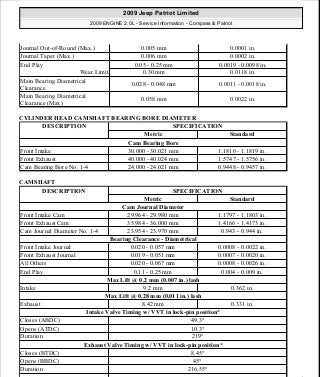

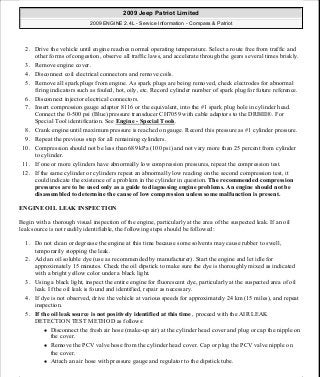

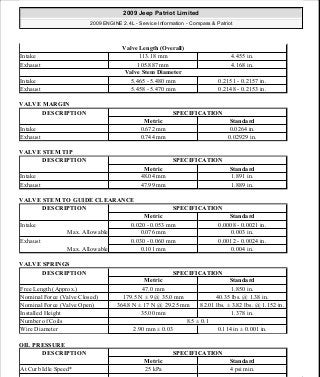

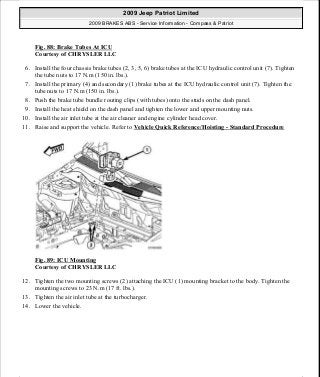

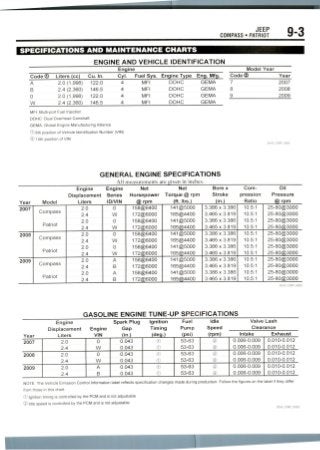

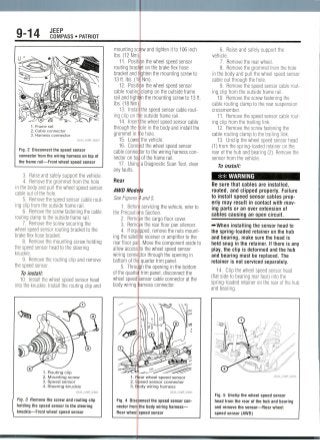

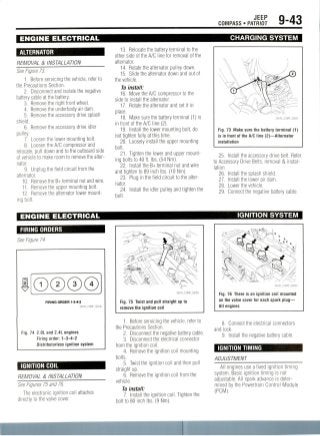

SRS VERIFICATION TEST

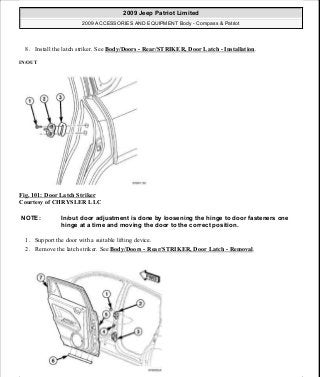

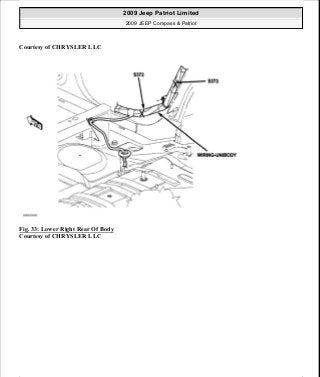

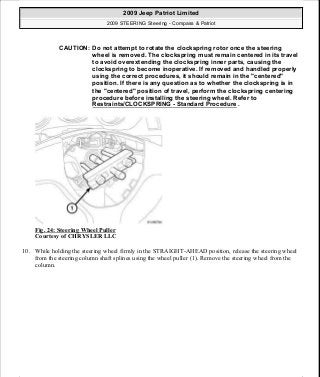

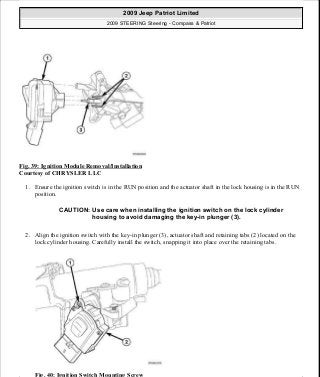

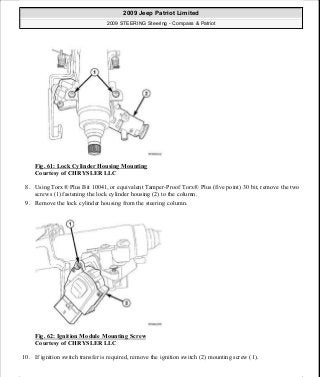

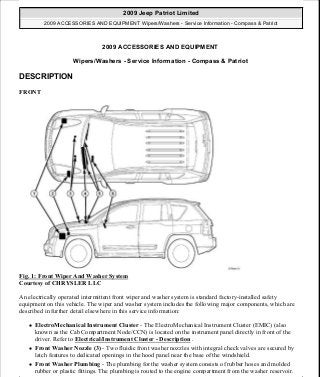

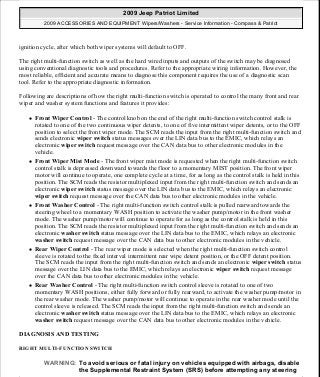

See Figure 32.

** CAUTION

To avoid serious or fatal injury on

vehicles equipped with airbags, dis-

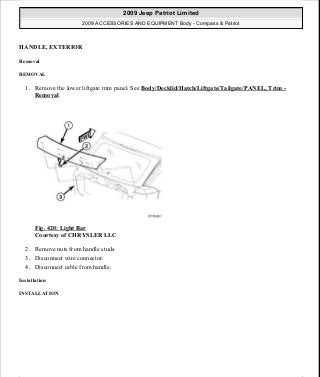

able the Supplemental Restraint

System (SRS) before attempting any

steering wheel, steering column,

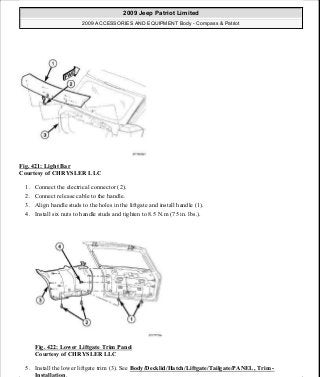

airbag, seat belt tensioner, impact

sensor, or instrument panel compo-

nent diagnosis or service. Discon-

nect and isolate the battery negative

(ground) cable, then wait 2 minutes

for the system capacitor to dis-

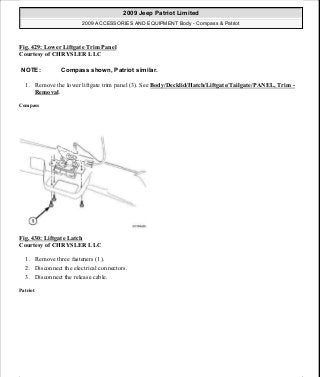

charge before performing further

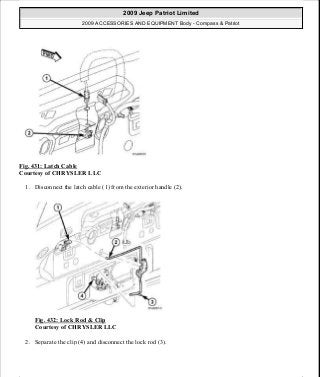

diagnosis or service. This is the only

sure way to disable the SRS. Failure

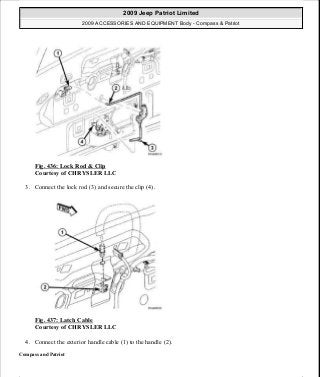

to take the proper precautions could

result in accidental airbag deploy-

ment.

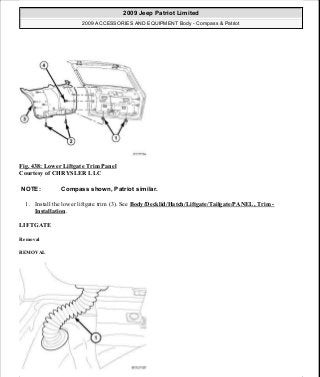

*# CAUTION

The following procedure should be

performed using a diagnostic scan

tool to verify proper Supplemental

Restraint System (SRS) operation fol-

lowing the service or replacement of

any SRS component.

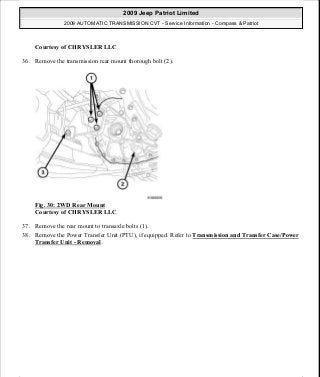

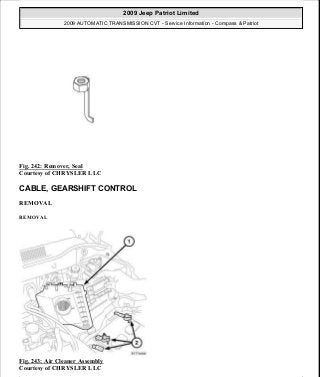

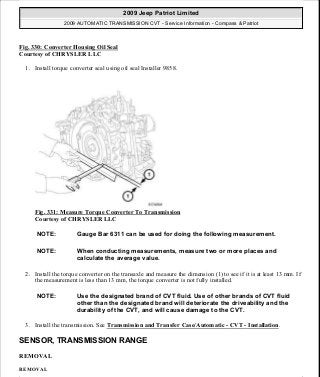

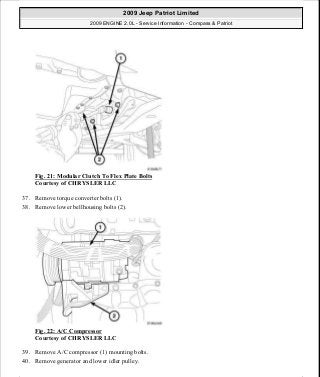

DRIVE TRAIN

AUTOMATIC TRANSAXLE

ASSEMBLY

REMOVAL & INSTALLATION

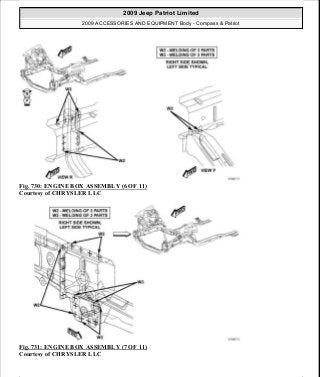

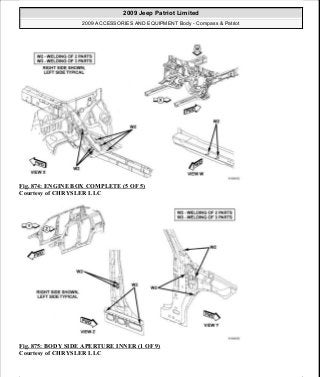

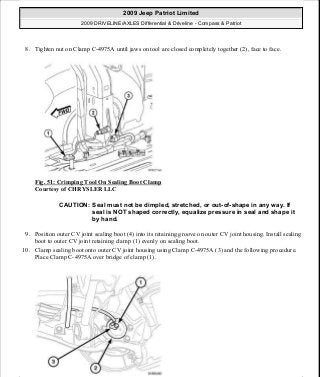

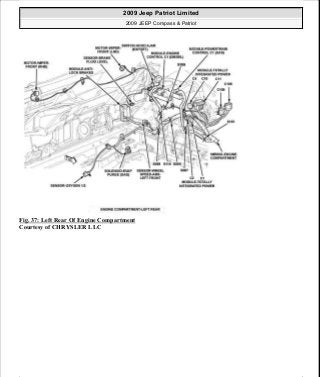

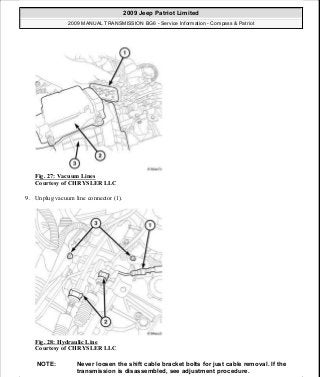

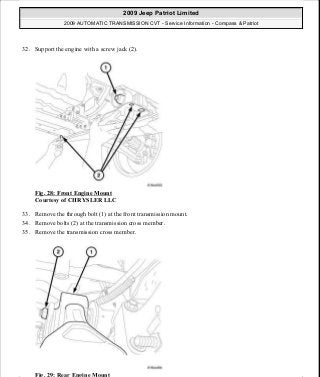

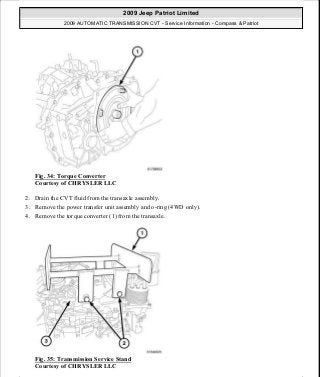

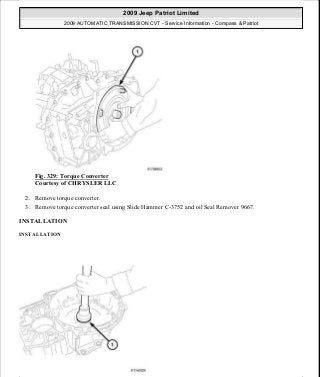

See Figures 33 through 36.

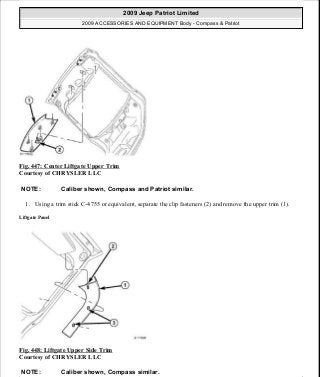

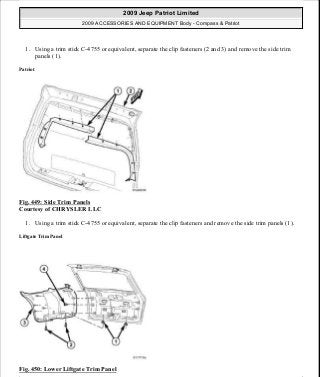

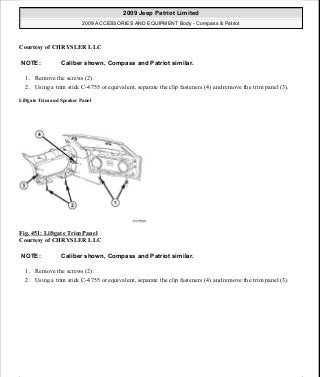

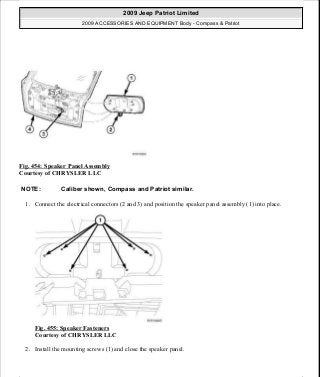

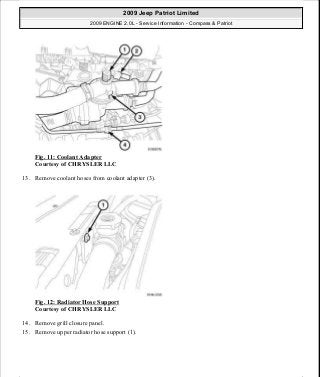

1. Before servicing the vehicle, refer to

the Precautions Section.

2. Disconnect the negative battery cable.

3. Drain the cooling system.

4. Drain the automatic transaxle.

5. Remove the air intake assembly.

6. Remove the battery.

7. Remove the battery tray.

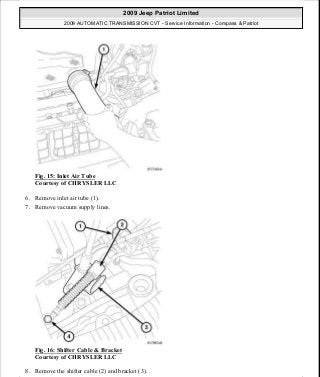

8. Remove the air intake tube and vac-

uum supply lines.

9. Remove the shifter cable and mount-

ing bracket.

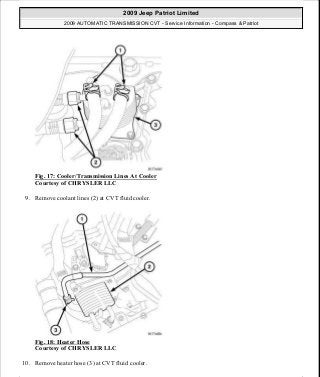

10. Remove the coolant lines from the

CVT fluid cooler.

11. Remove the heater hose from the

CVT fluid cooler.

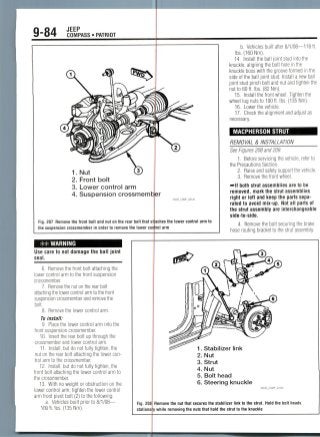

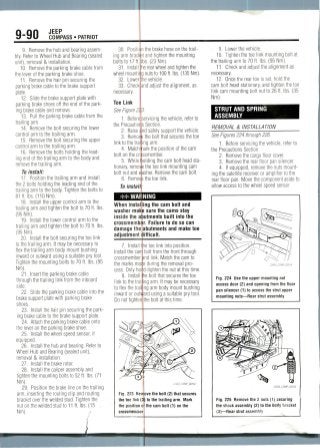

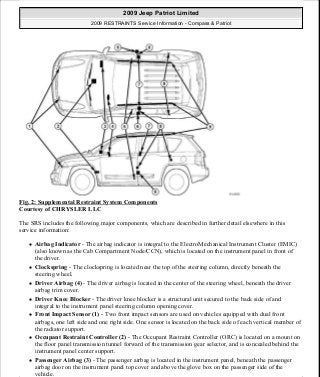

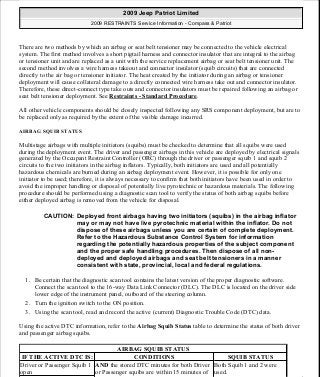

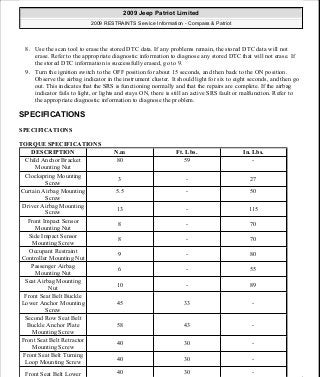

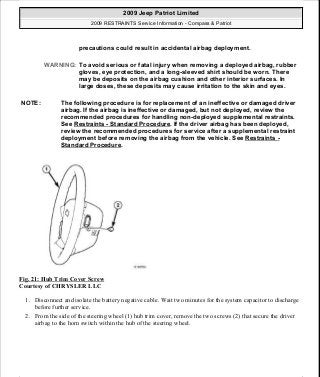

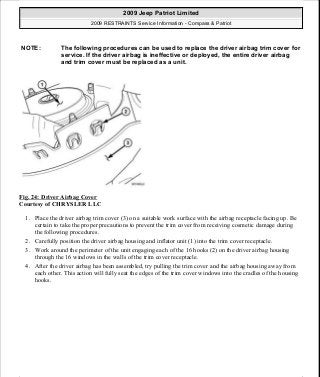

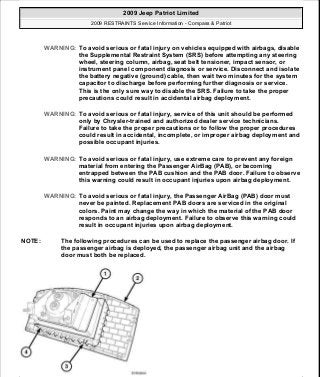

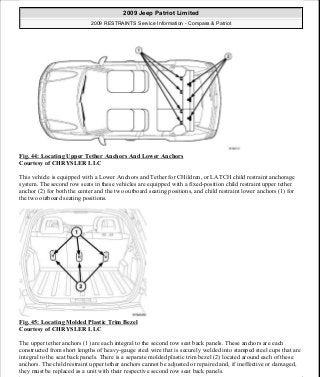

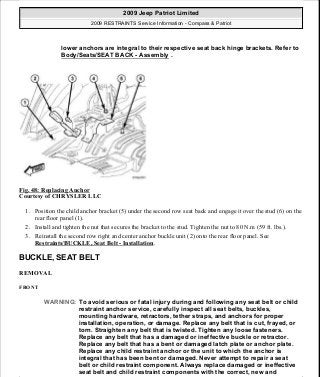

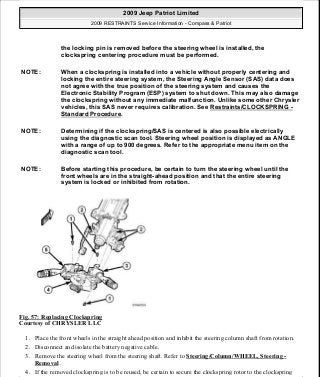

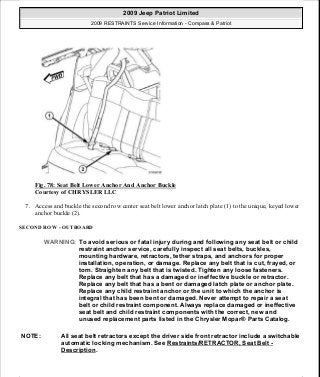

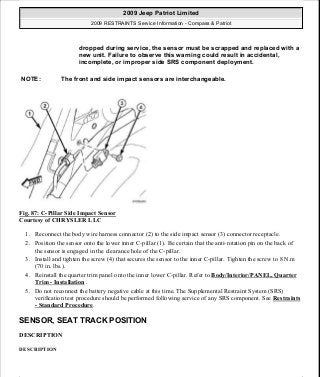

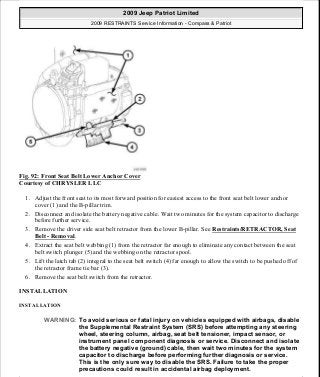

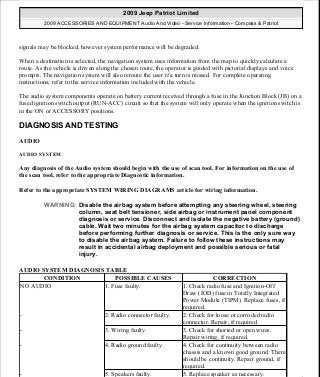

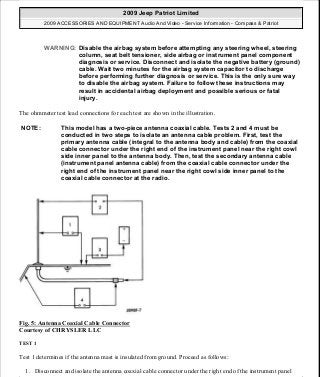

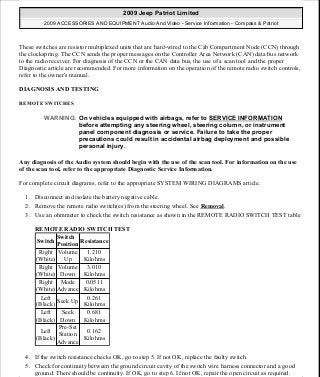

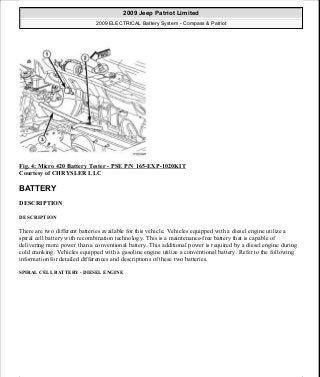

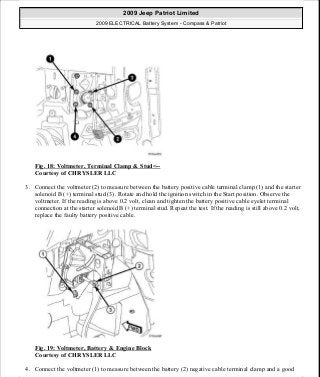

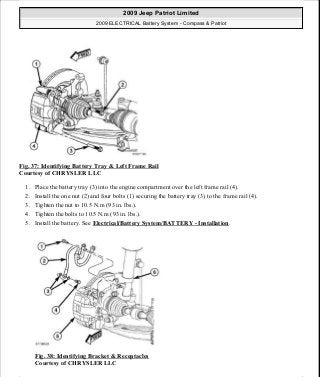

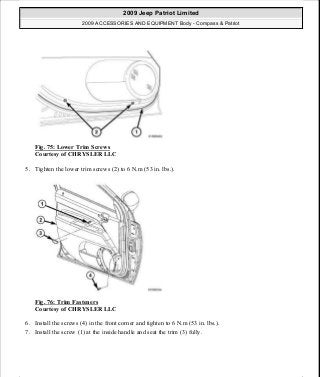

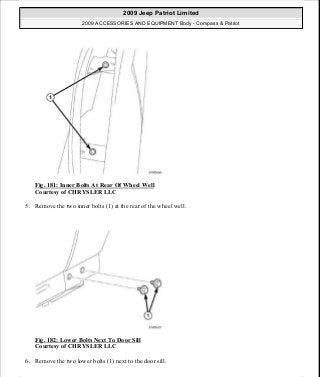

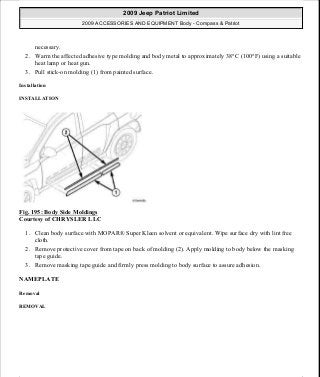

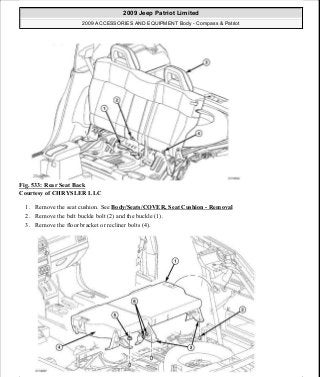

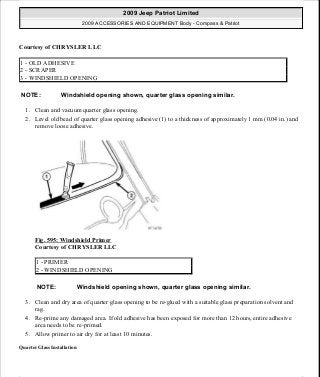

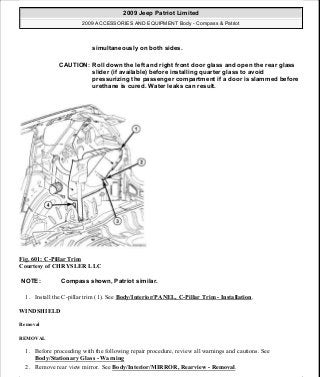

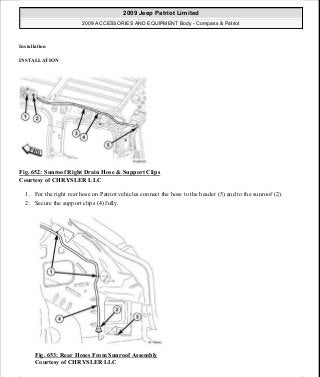

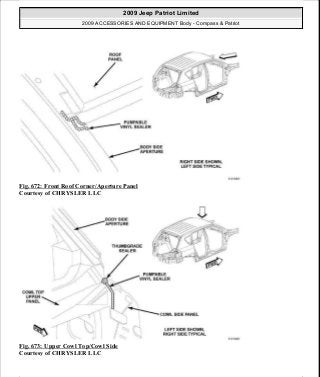

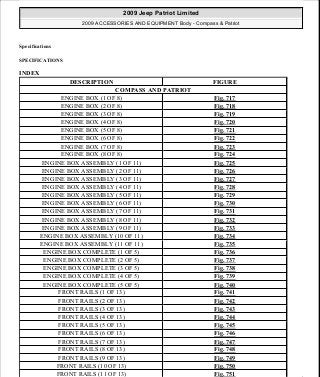

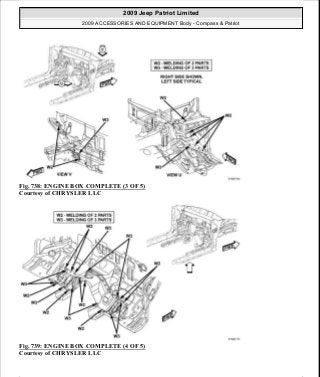

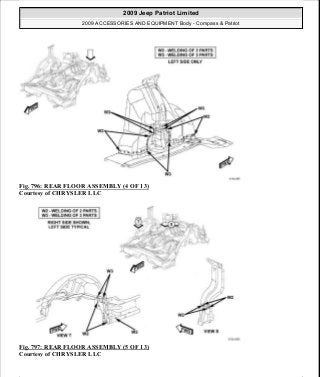

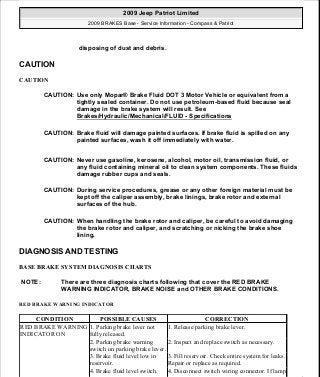

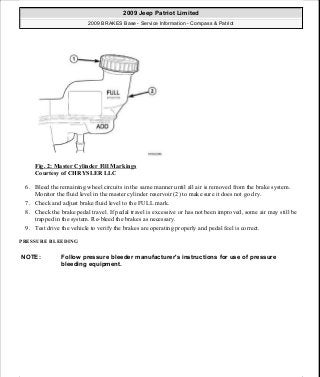

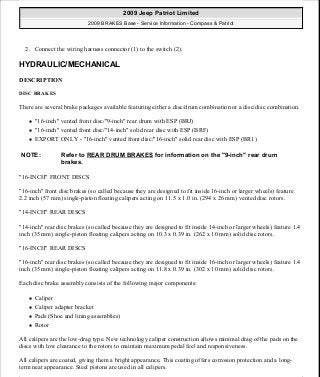

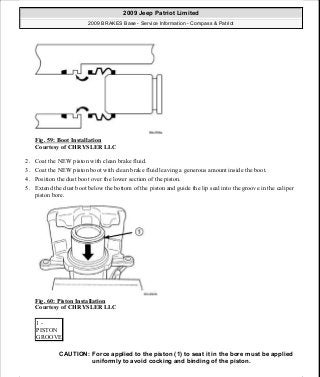

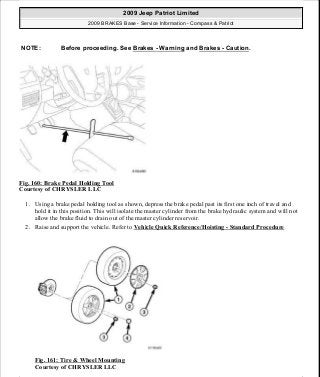

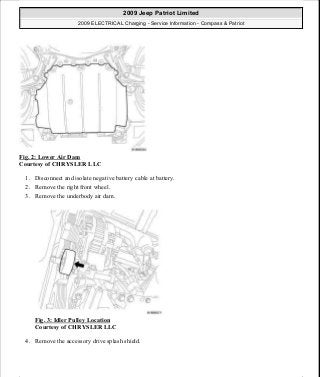

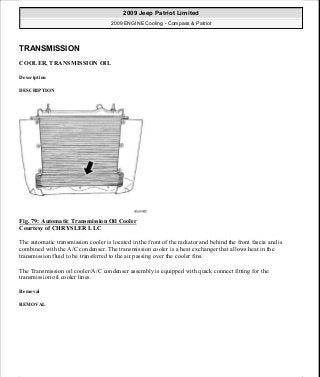

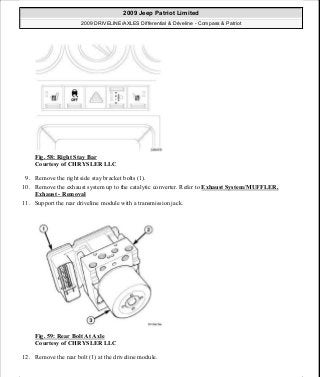

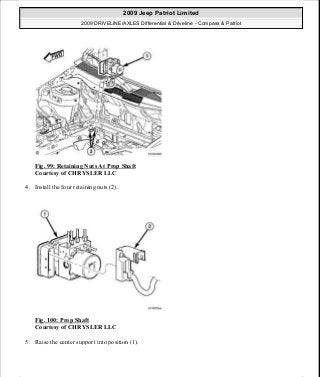

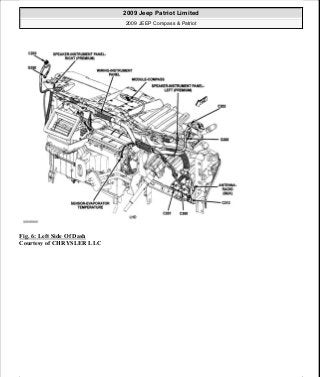

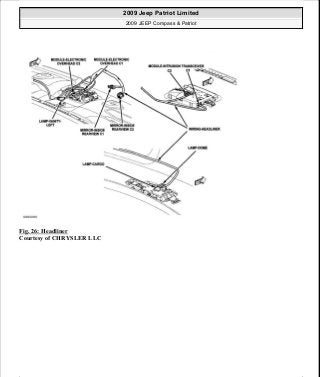

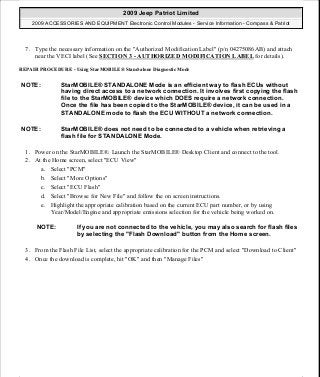

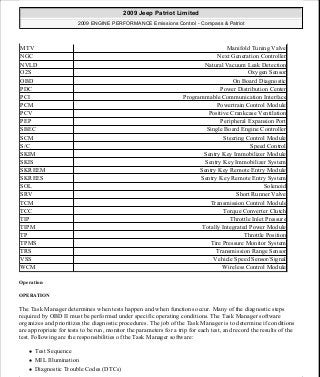

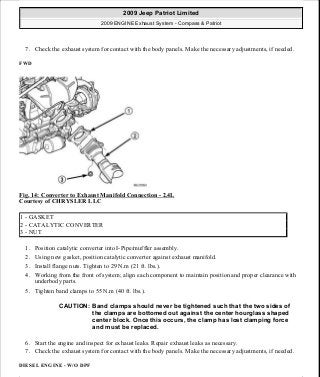

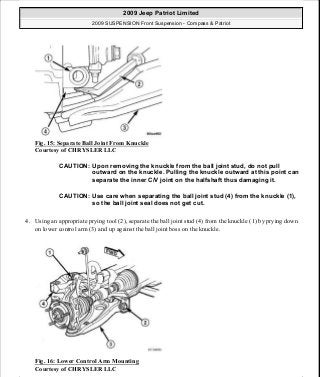

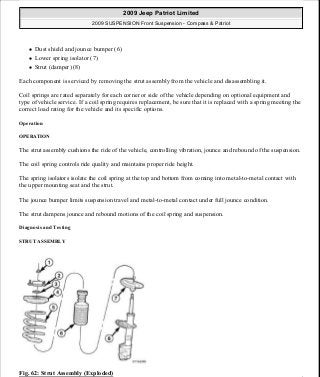

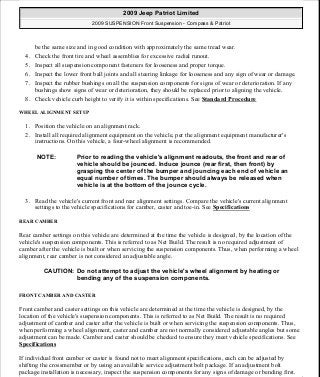

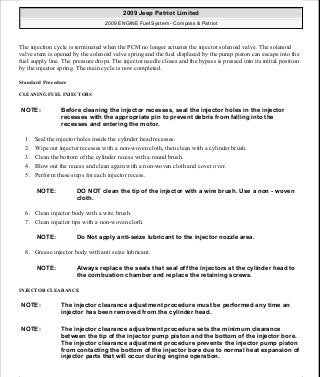

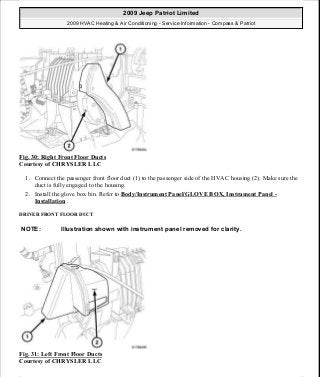

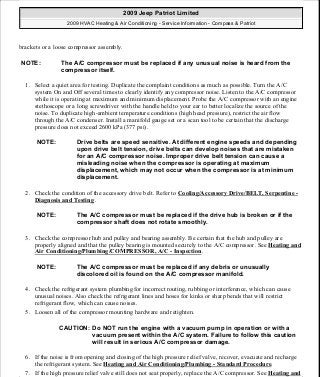

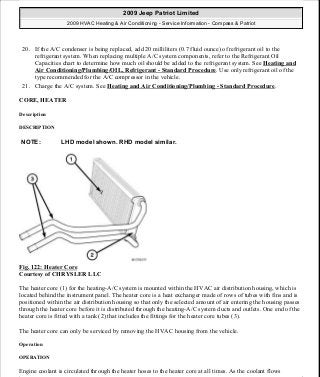

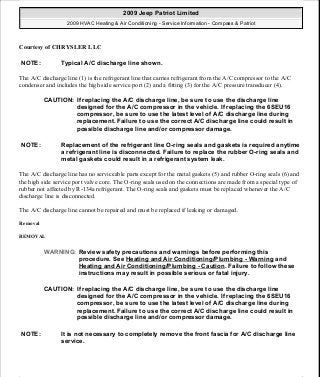

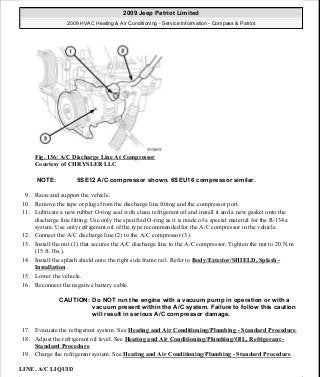

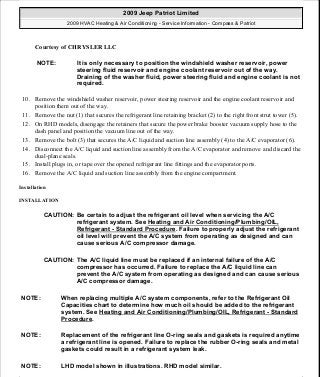

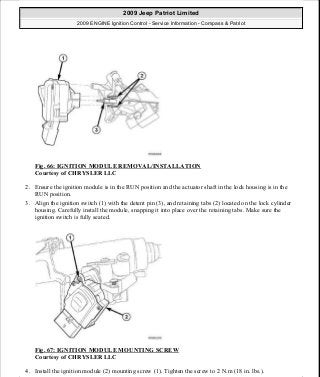

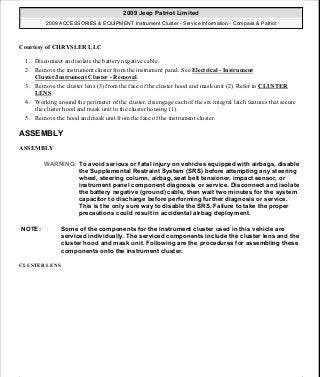

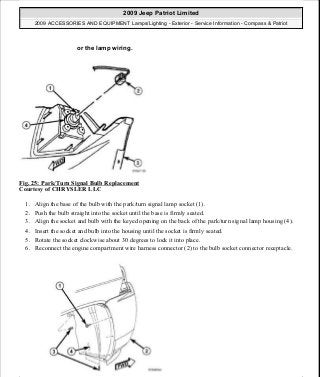

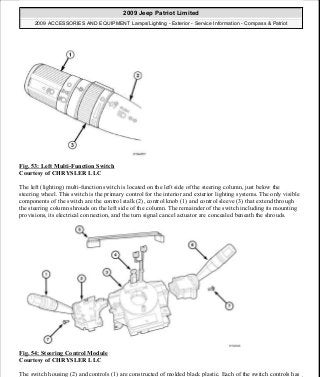

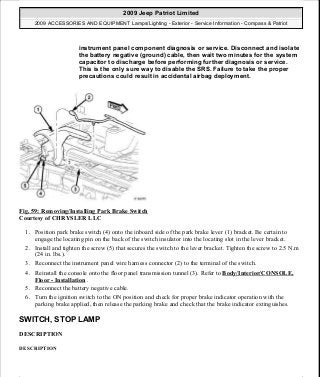

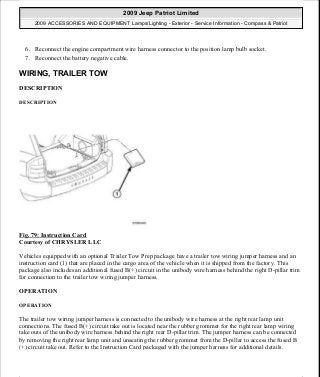

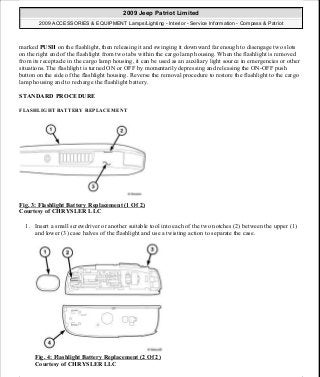

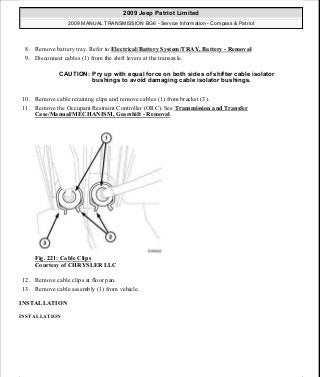

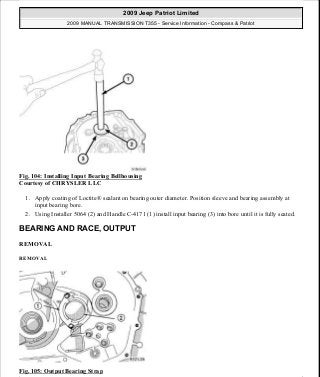

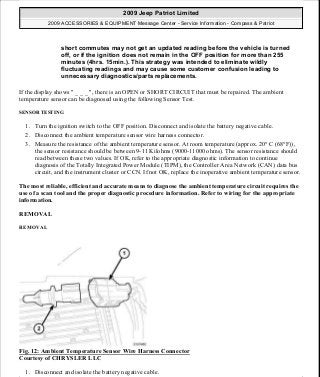

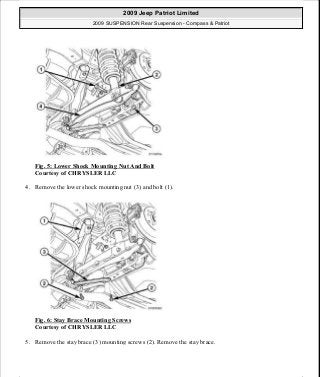

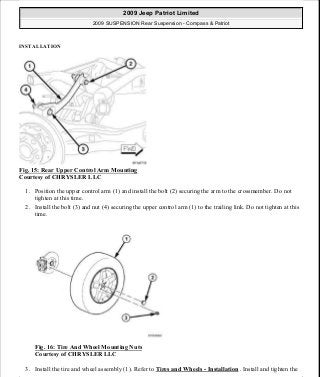

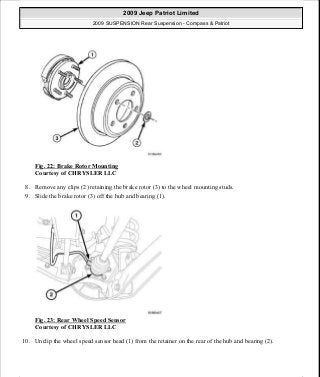

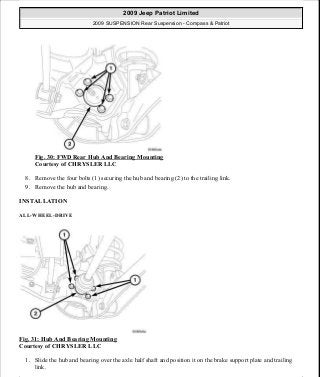

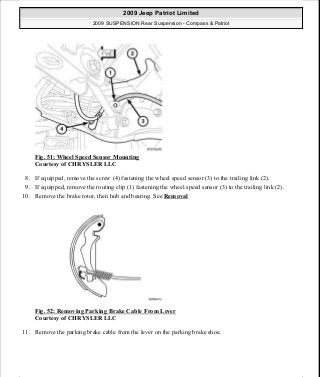

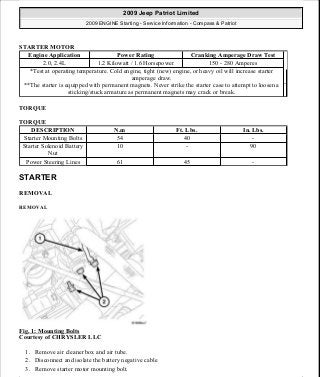

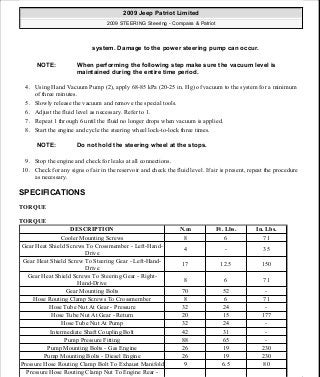

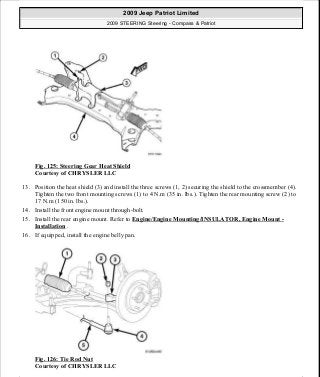

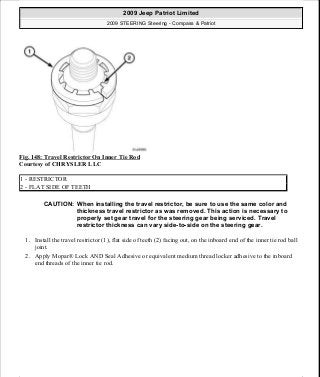

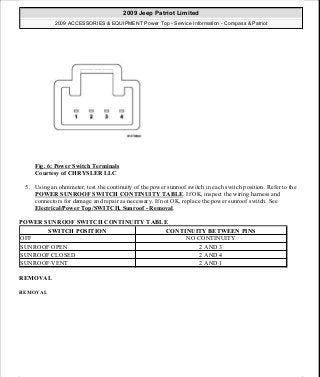

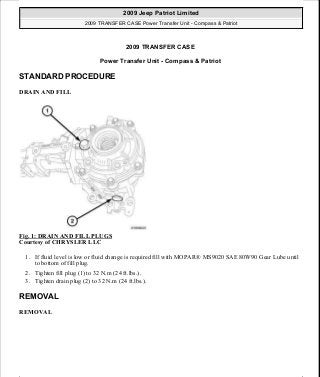

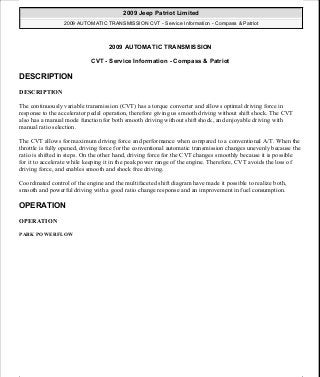

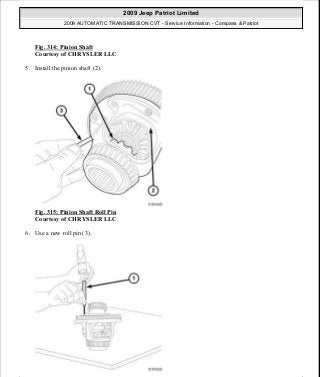

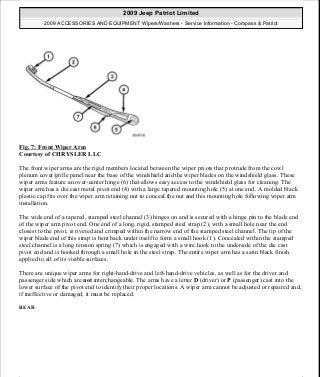

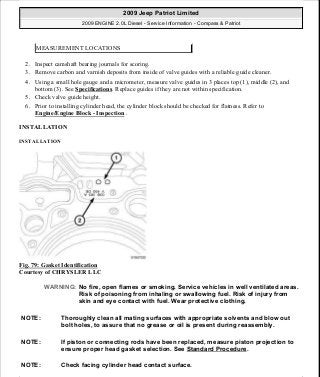

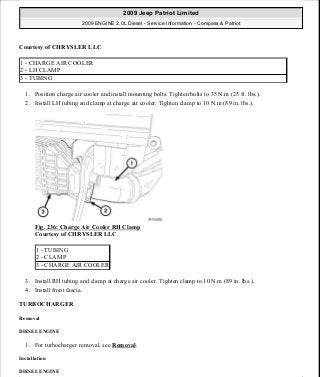

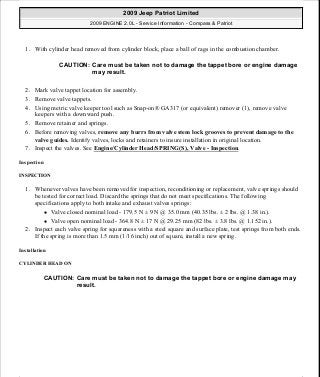

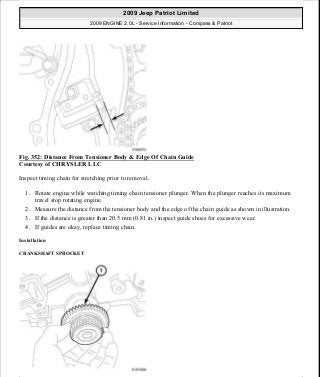

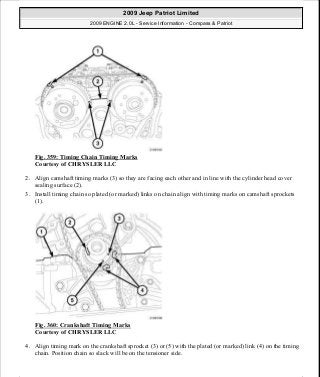

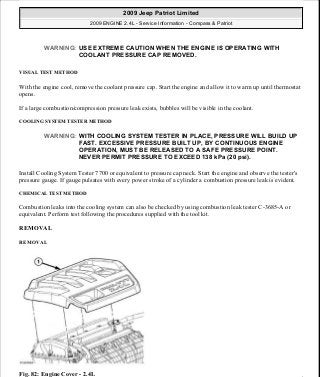

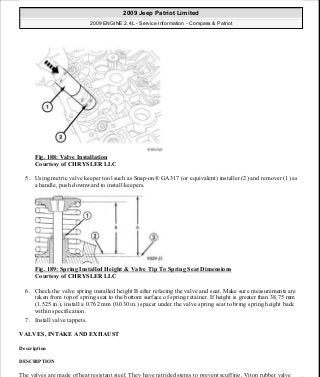

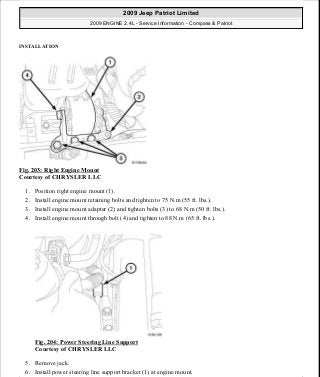

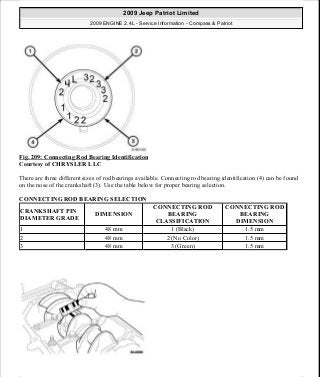

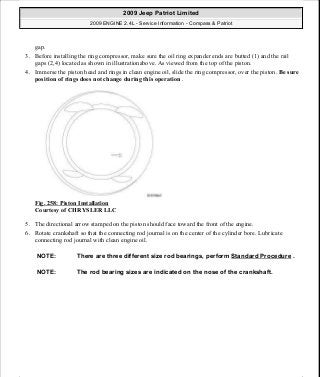

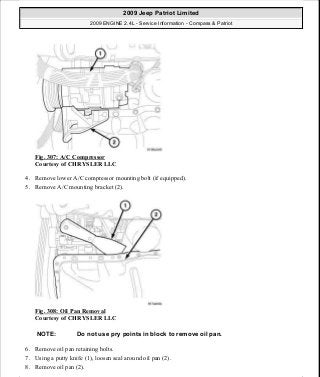

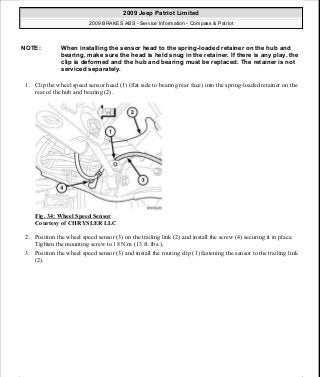

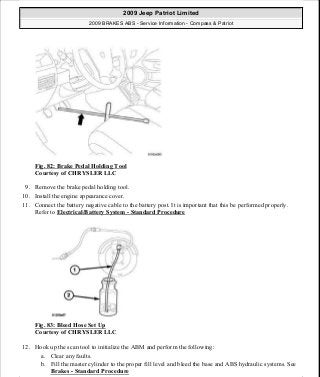

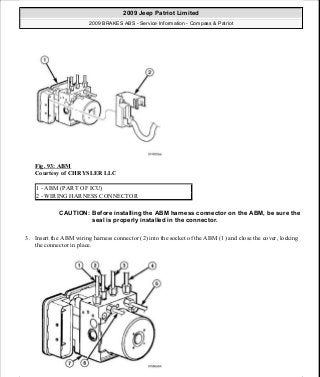

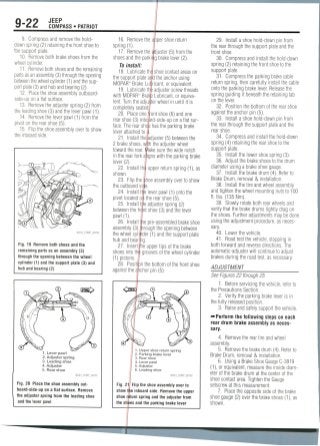

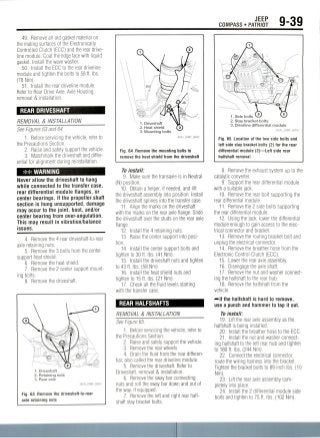

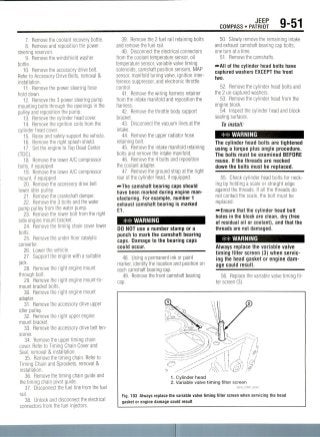

Fig. 32 D

location

nstrument panel

Data Link Connector (DLC)

Cowl side inner panel

ta Link Connector (DLC)

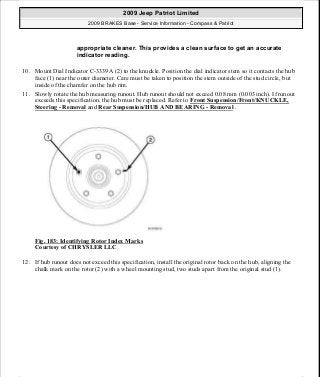

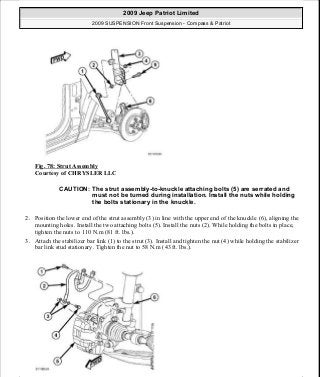

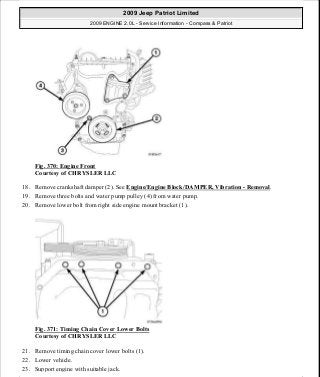

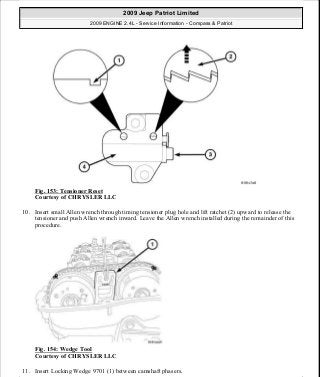

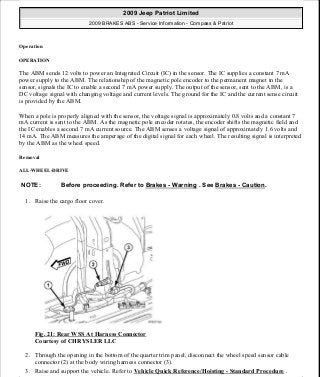

1. During the following test, the bat-

tery negati cable remains disconnected

and isolated, as it was during the SRS

component removal and installation

procedure

2. Be ciirtain that the diagnostic scan

tool contairs the latest version of the proper

diagnostic: oftware. Connect the scan tool

to the 16-wiy Data Link Connector (DLC)

(2). The DL ] is located on the driver side

lower edge )f the instrument panel (1), near

the cowl site inner panel (3).

3. Turn the ignition switch to the ON

position an exit the vehicle with the scan

tool.

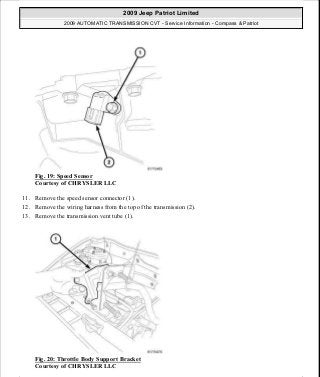

12. Ren

13. Dis

harness fron

ove the speed sensor connector,

onnect and remove the wiring

the top of the transaxle.

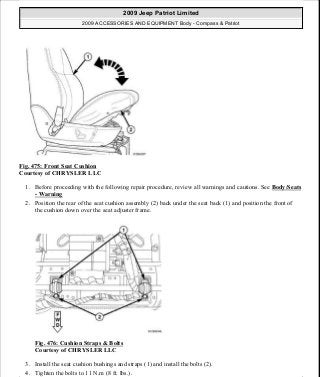

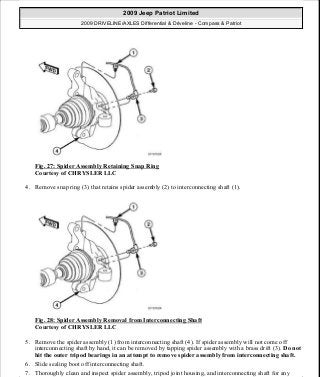

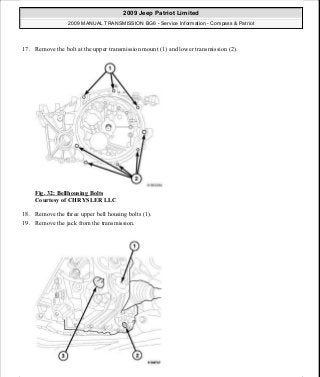

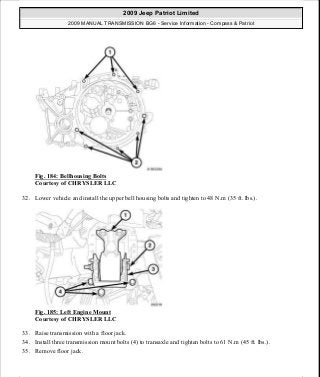

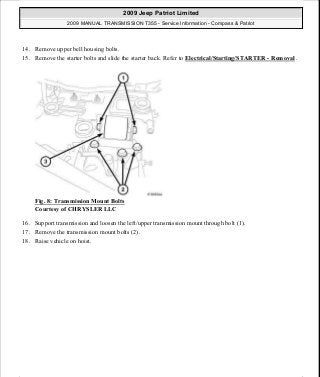

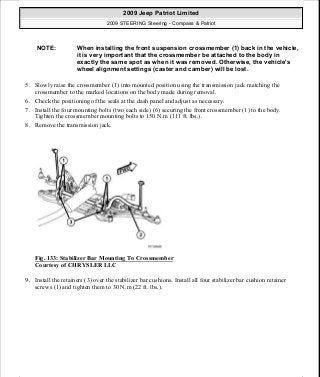

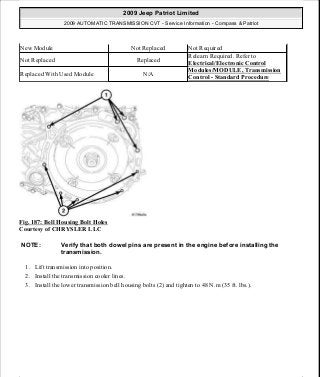

Fig. 33 V

bolts (1)

(2)—Automatic Transaxle

ew of the upper bell housing

nd lower bell housing bolts

4. Check to be certain that nobody is in

the vehicle, then reconnect the battery nega-

tive cable. Wait 2 minutes before proceed-

ing.

** CAUTION

Failure to follow these instructions

may result in possible serious or

fatal injury.

5. Using the scan tool, read and record

the active (current) Diagnostic Trouble Code

(DTC) data.

6. Use the scan tool to read and record

any stored (history) DTC data.

7. If any DTC is found in Step No. 5 or

Step No. 6, refer to the appropriate diagnos-

tic information.

8. Use the scan tool to erase the stored

DTC data. If any problems remain, the

stored DTC data will not erase. Refer to the

appropriate diagnostic information to diag-

nose any stored DTC that will not erase. If

the stored DTC information is successfully

erased, go to Step 9.

9. Turn the ignition switch to the OFF

position for about 15 seconds, and then back

to the ON position. Observe the airbag indi-

cator in the instrument cluster. It should light

for 6-8 seconds, and then go out. This indi-

cates that the SRS is functioning normally

and that the repairs are complete. If the

airbag indicator fails to light, or lights and

stays ON, there is still an active SRS fault or

malfunction. Refer to the appropriate diag-

nostic information to diagnose the problem.

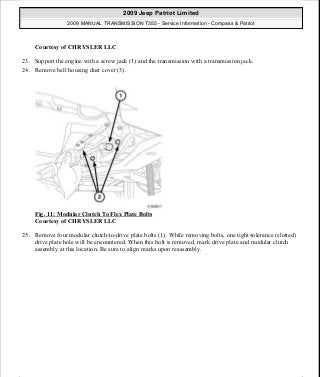

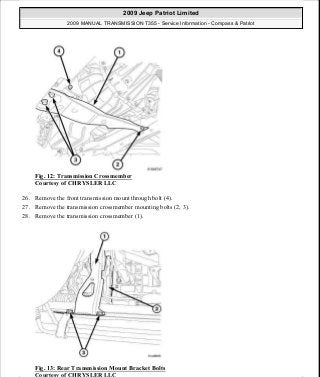

14. Remove the transmission vent tube.

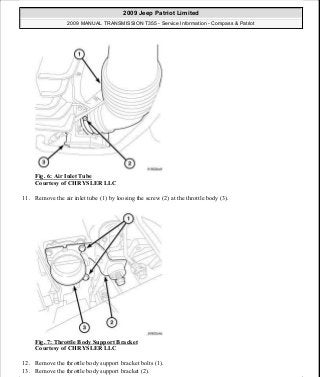

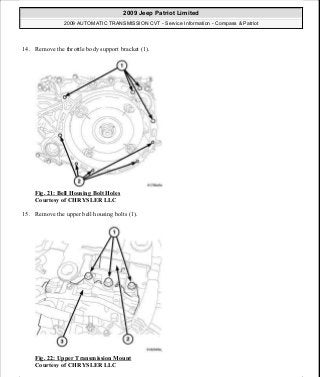

15. Remove the throttle body support

bracket.

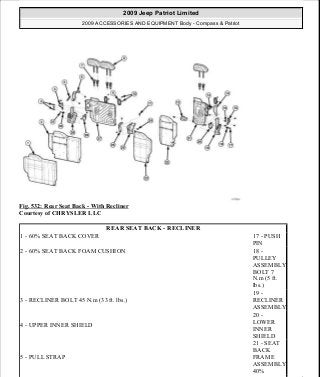

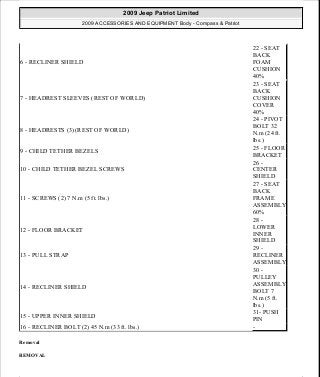

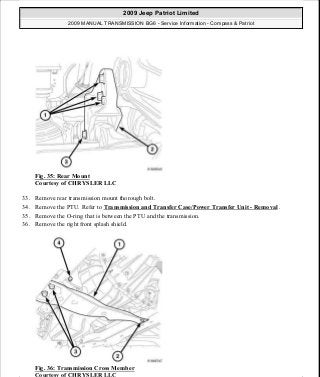

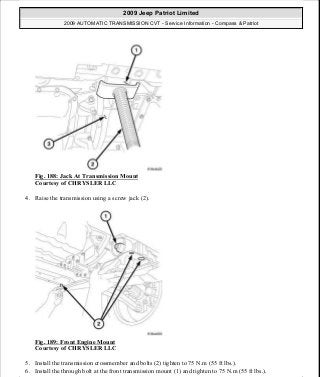

Fig. 34 View of the transaxle (3) upper

mounting bolts (1) and upper mount (2)—

Automatic Transaxle](https://image.slidesharecdn.com/manualesreparacionesjeepcompass-patriotlimited2007-2009-150729164945-lva1-app6891/85/Manuales-de-reparaciones-jeep-compass-y-patriot-limited-2007-2009-817-320.jpg?cb=1438196953)

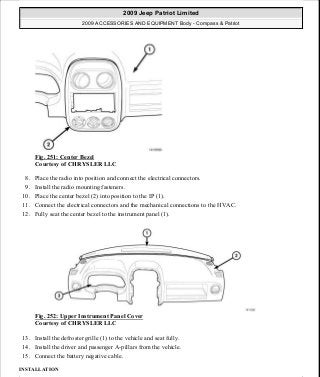

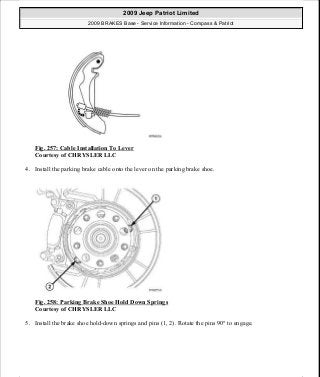

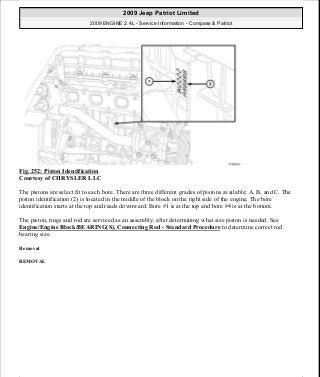

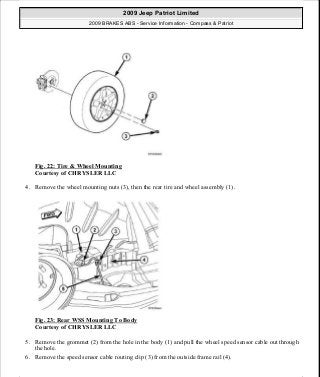

![9-66 JEEP

COMPASS • PATRIOT

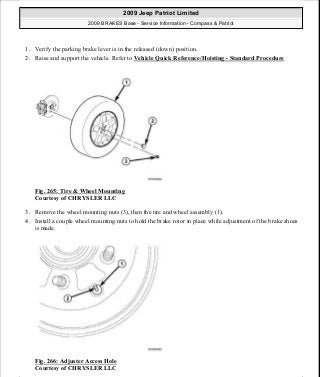

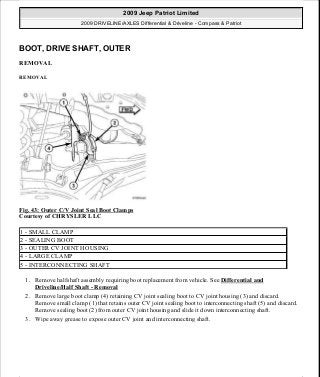

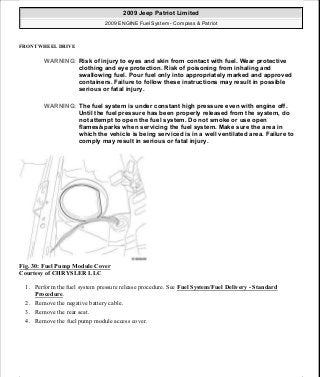

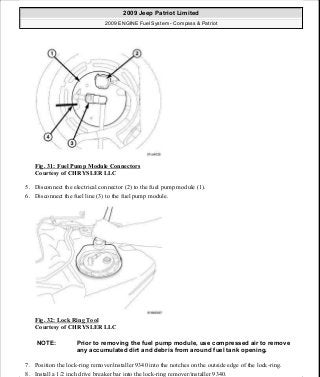

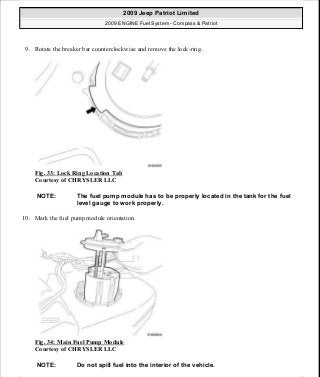

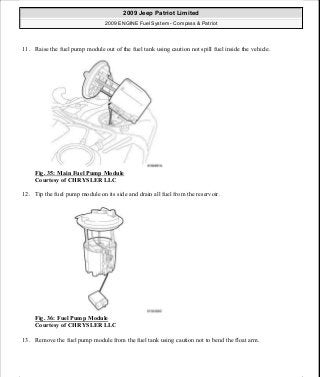

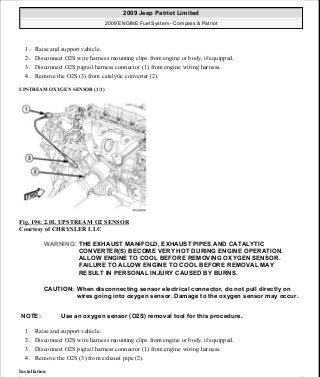

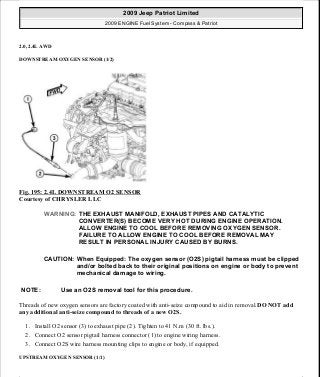

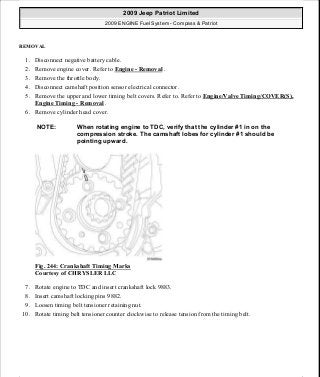

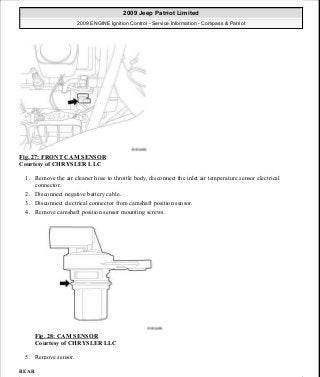

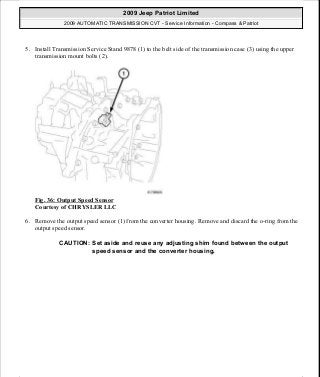

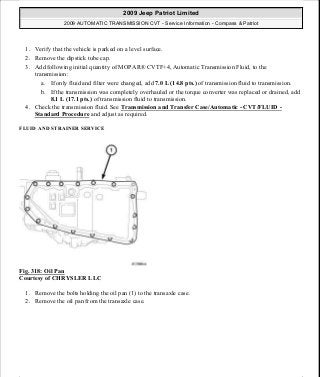

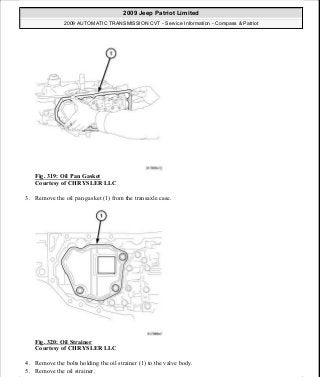

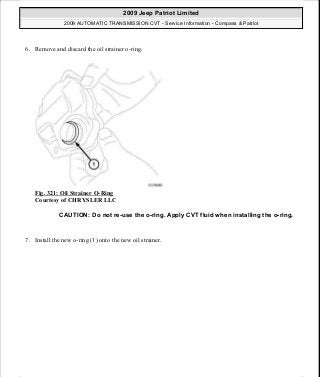

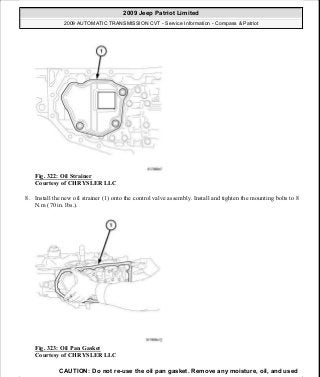

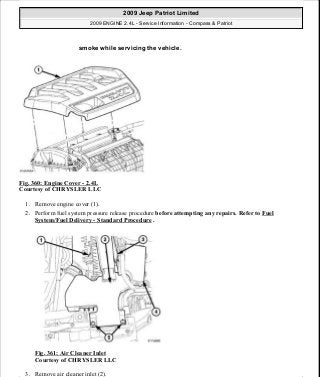

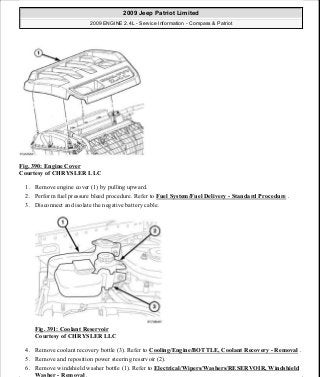

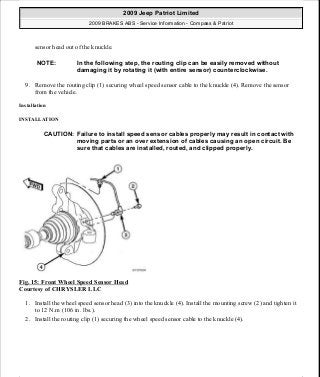

1. Before servicing the vehicle, refer to

the Precautions Section.

2. Disconnect the negative battery cable.

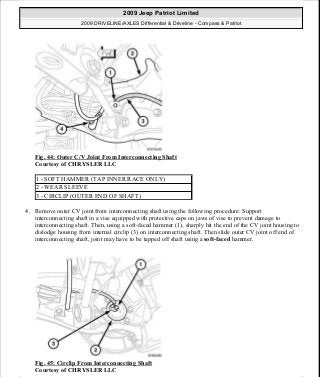

3. Disconnect the sensor electrical con-

nector.

4. Remove the heat shield retaining nut

and remove the heat shield to uncover the

Camshaft Position (CMP) sensor.

5. Remove the CMP sensor mounting

bolt and remove the sensor.

To install:

6. Lubricate the CMP sensor 0-ring.

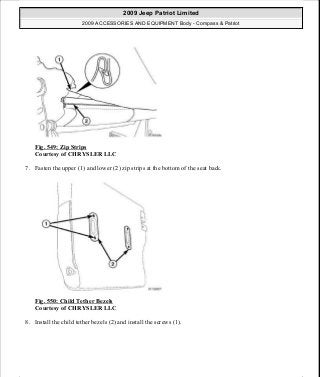

7. Install the CMP sensor using a twist-

ing motion. Make sure the sensor is fully

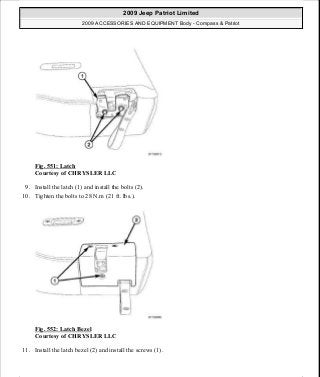

seated.

** WARNING

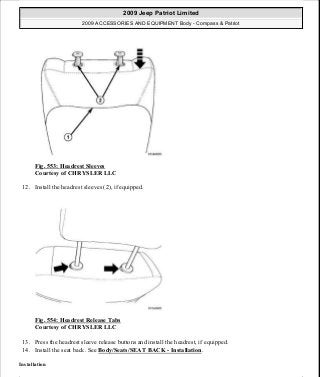

Do not drive the senor into the bore

with the mounting screws. This can

cause the sensor to be incorrectly

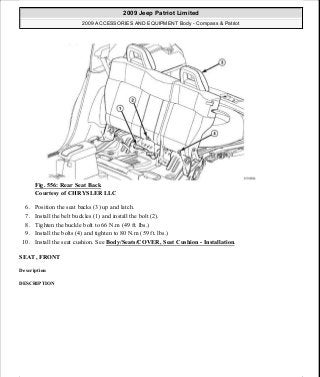

seated causing the engine to fail.

8. Tighten the mounting bolt to 80 inch

Ibs. (9 Nm).

9. Carefully attach the electricalcon-

nector to the CMP sensor. Take care not to

damage the sensor pins.

10. Install the heat shield onto the

mounting stud and tighten the retaining nut.

11. Connect the negative battery cable.

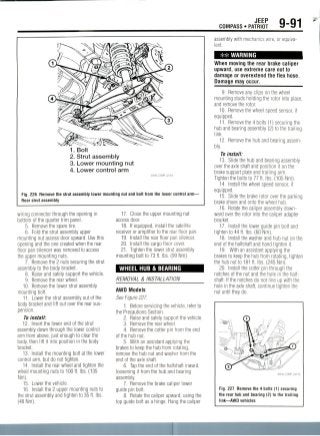

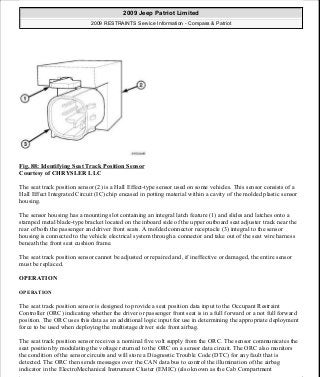

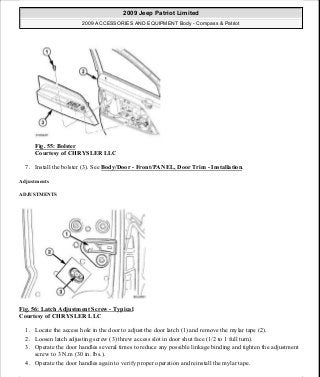

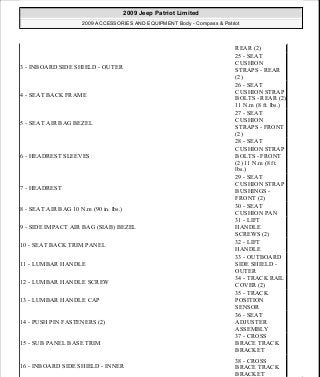

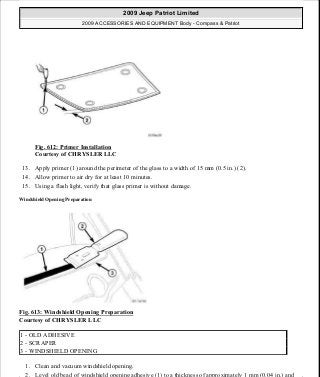

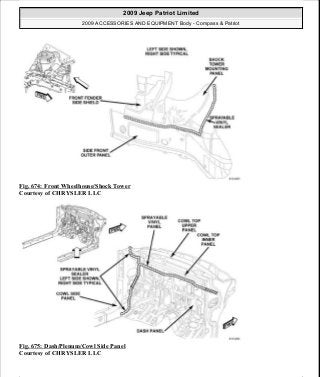

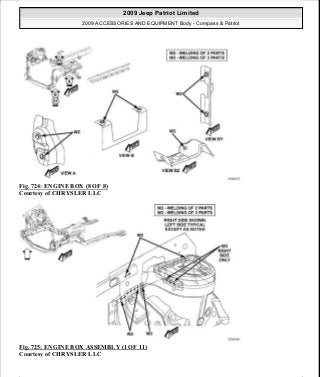

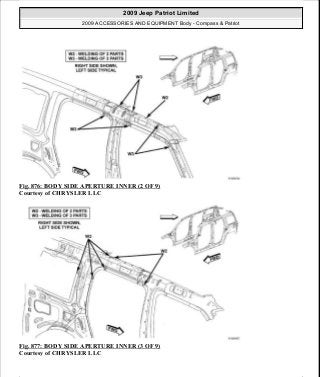

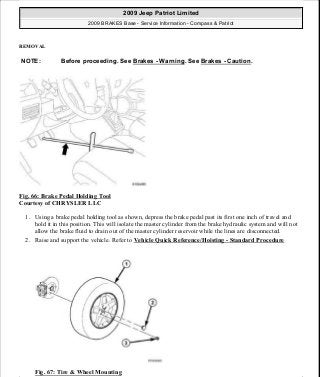

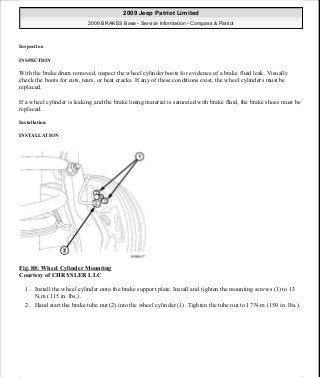

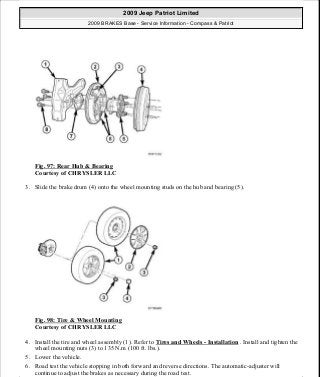

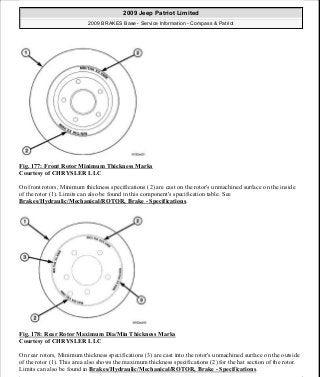

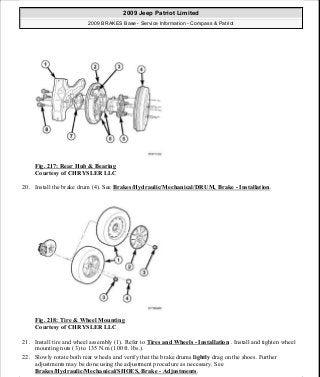

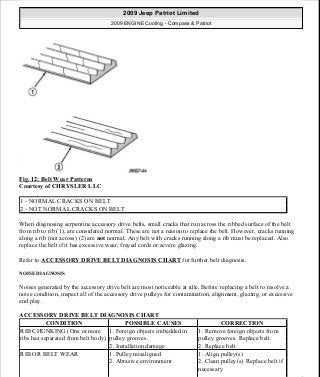

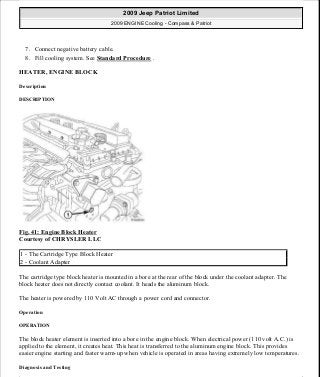

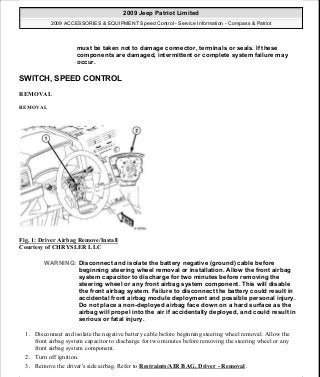

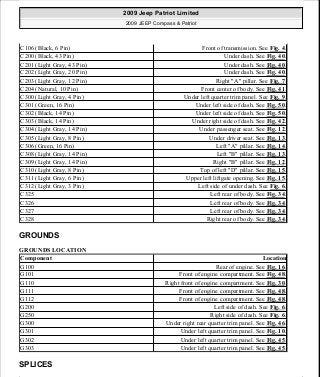

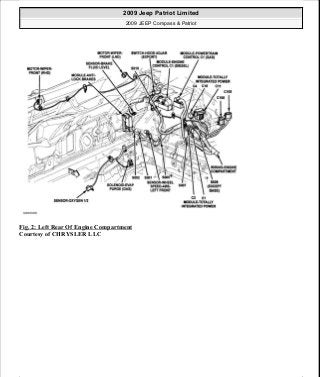

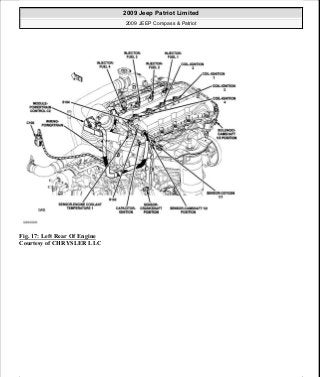

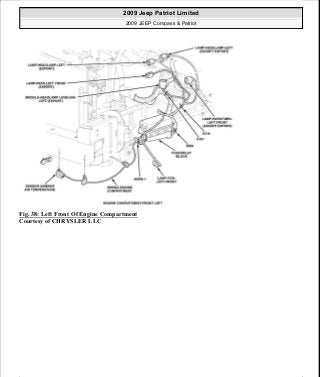

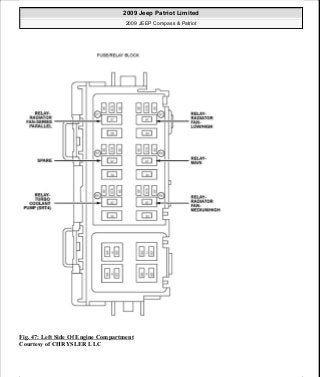

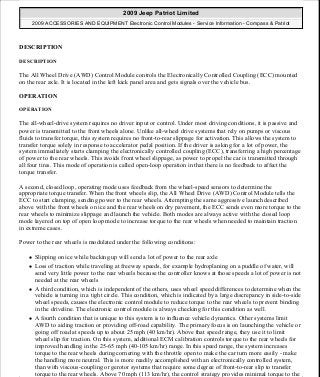

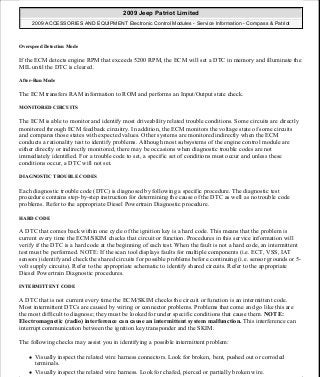

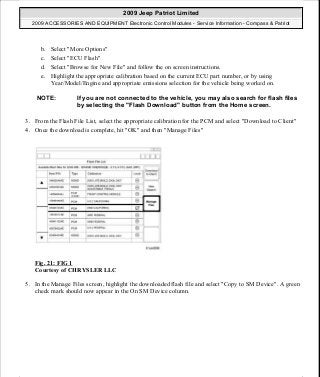

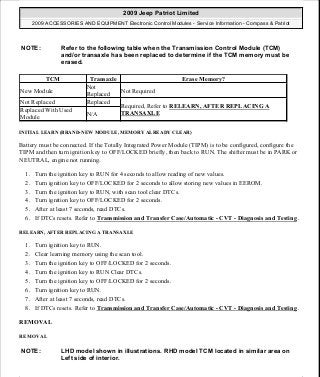

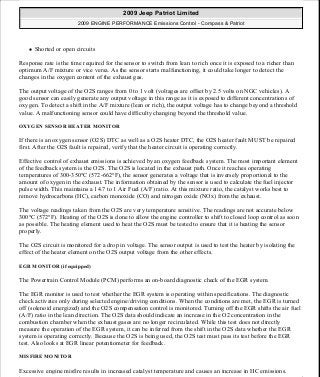

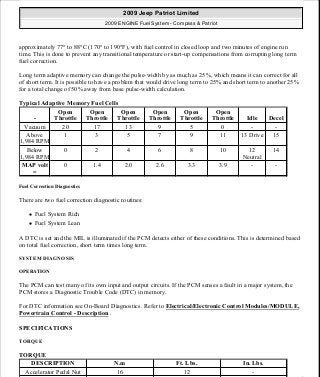

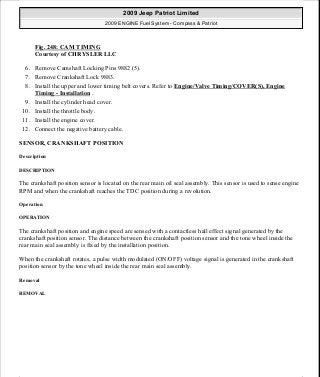

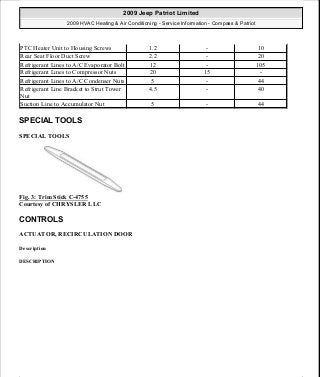

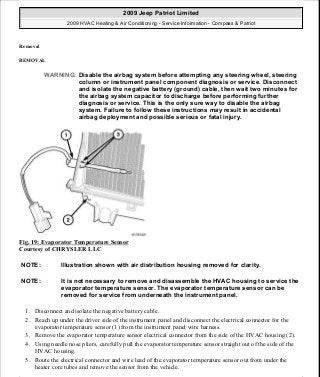

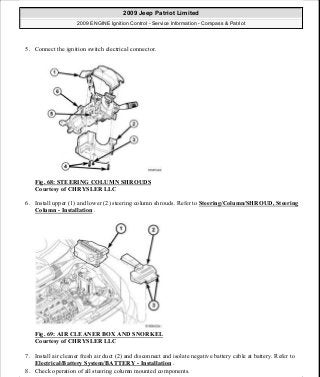

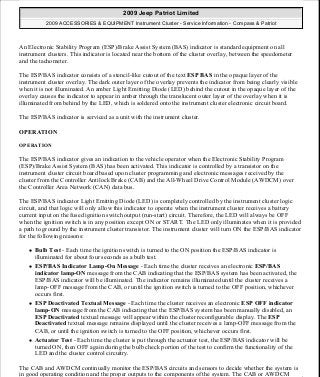

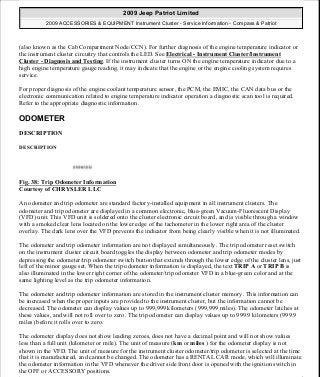

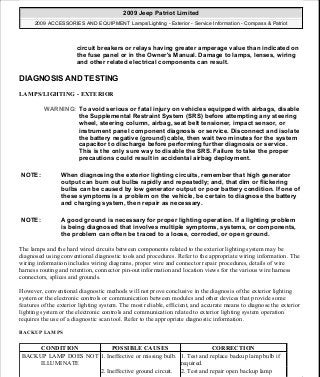

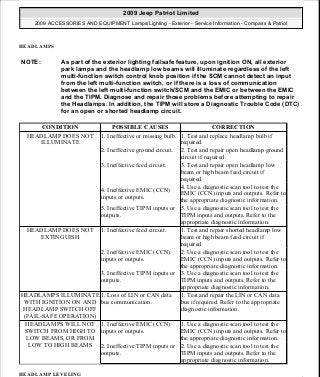

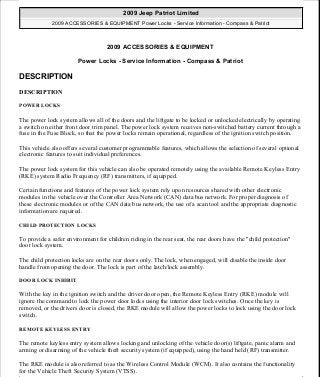

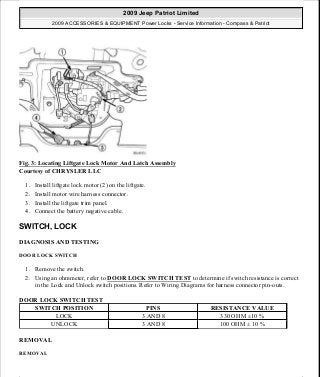

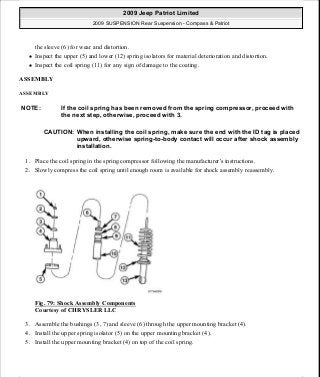

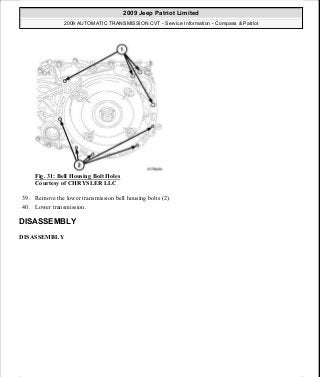

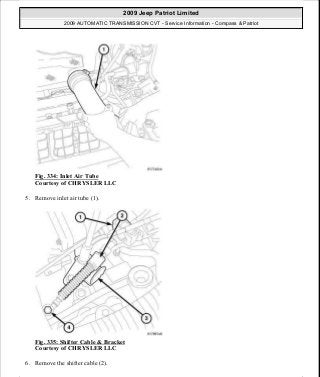

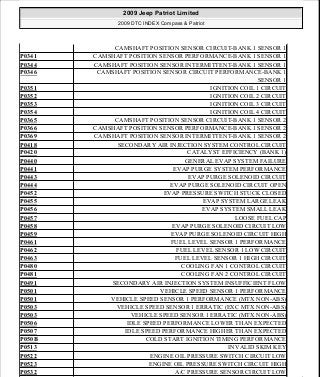

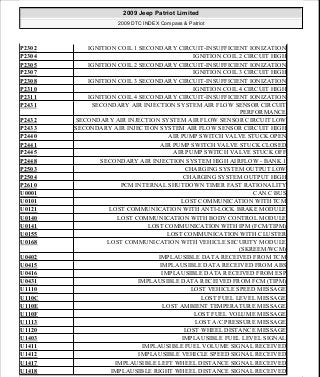

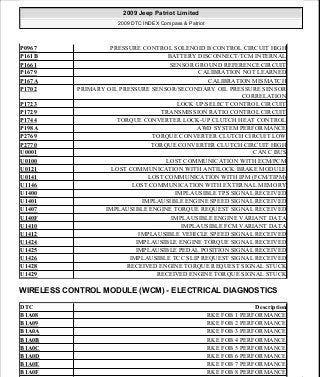

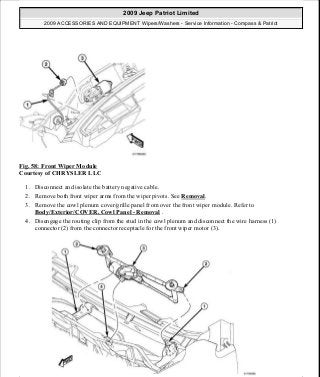

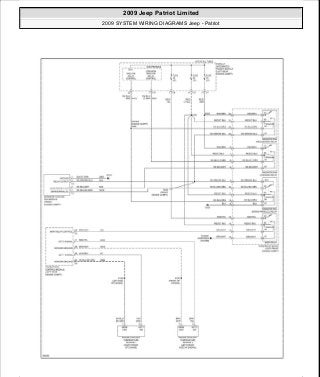

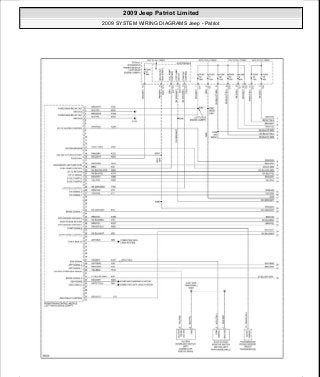

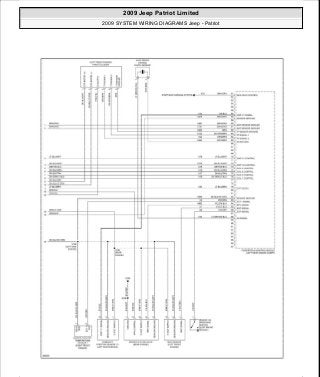

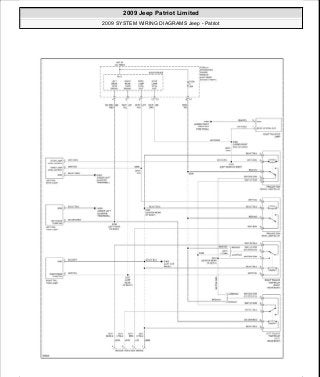

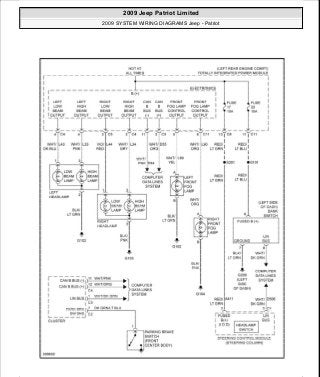

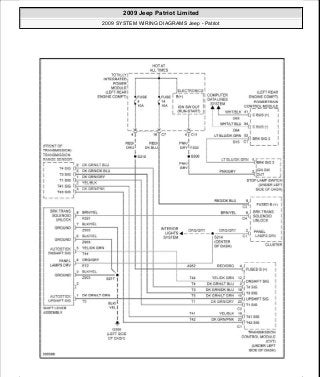

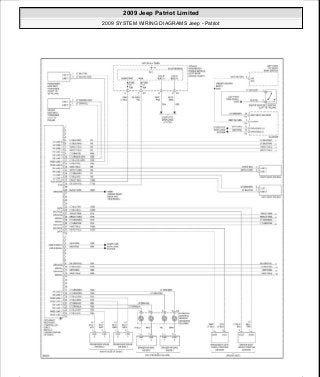

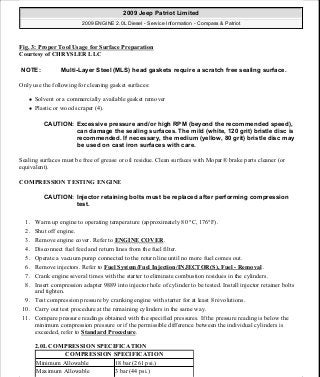

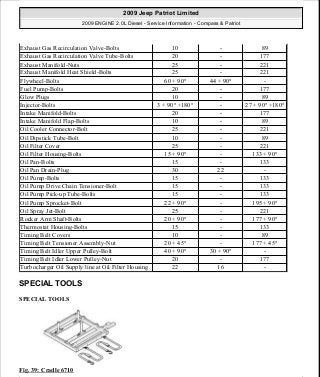

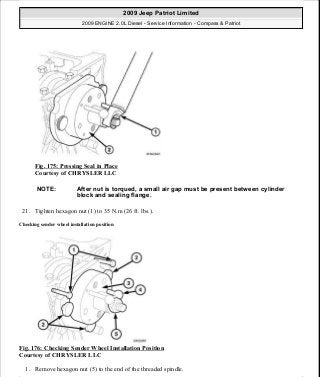

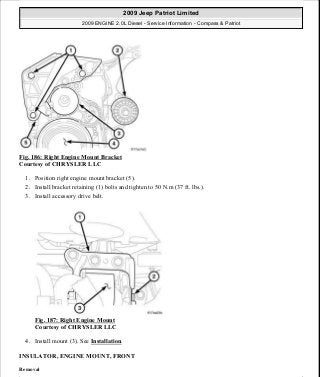

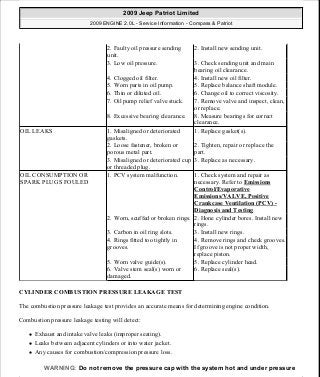

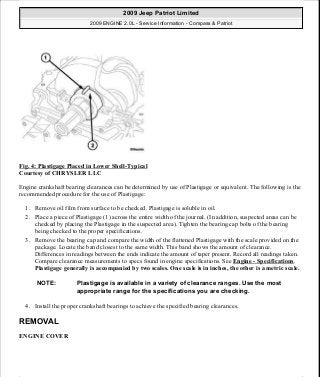

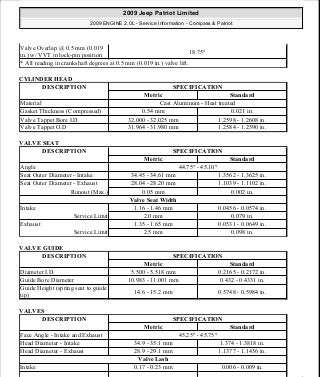

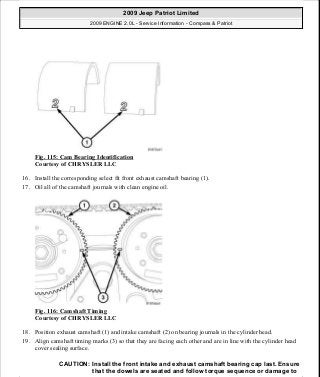

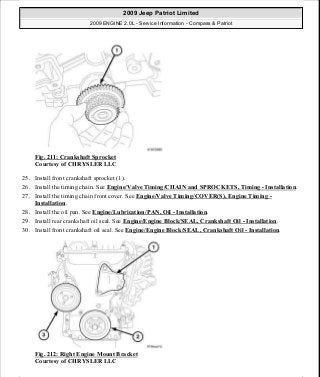

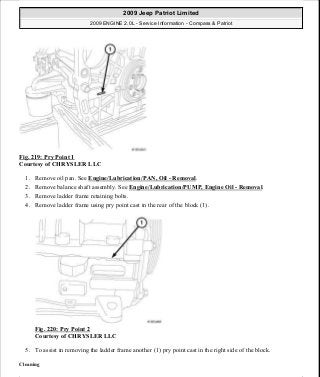

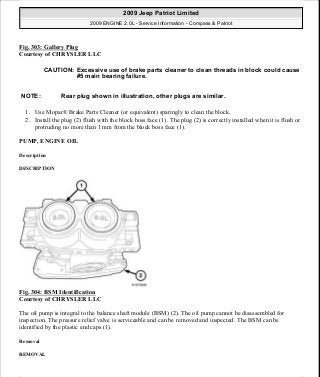

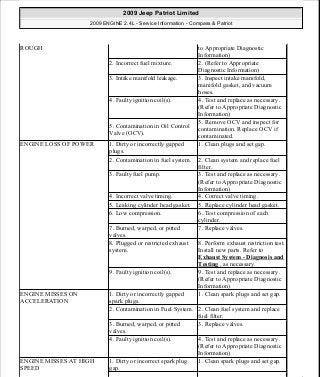

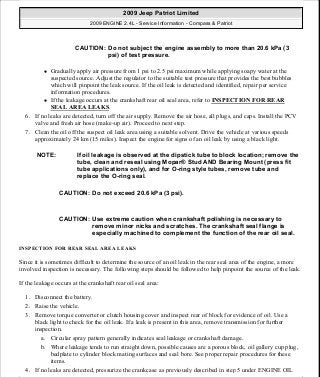

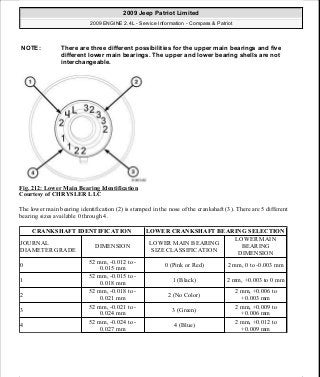

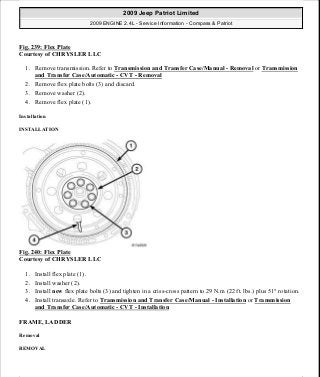

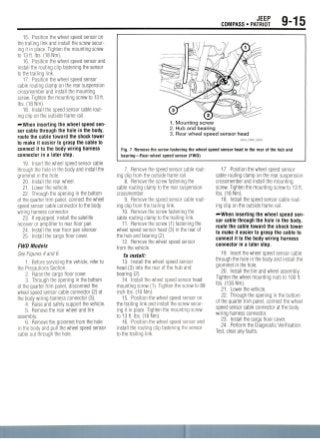

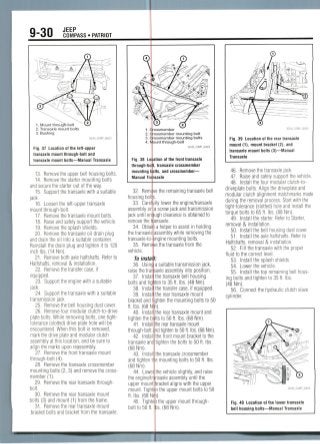

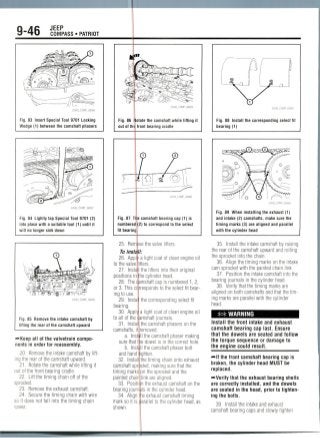

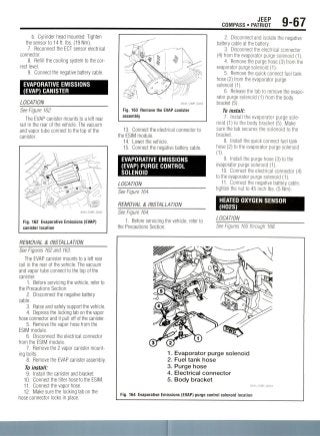

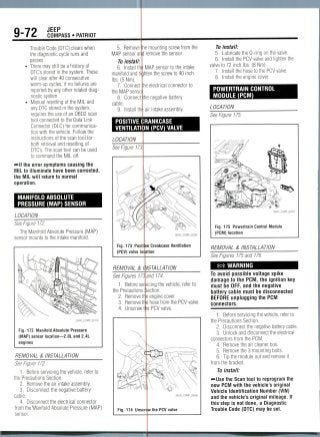

CRANKSHAFT POSITION (CKP)

SENSOR

LOCATION

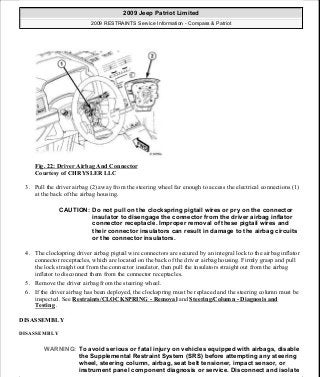

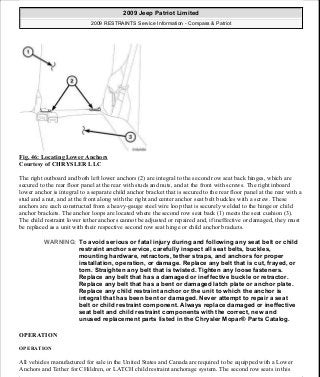

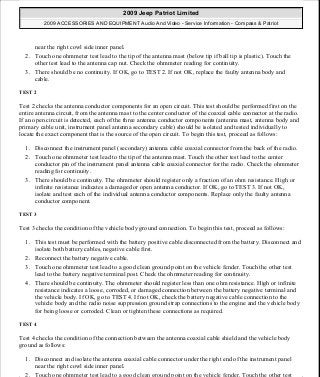

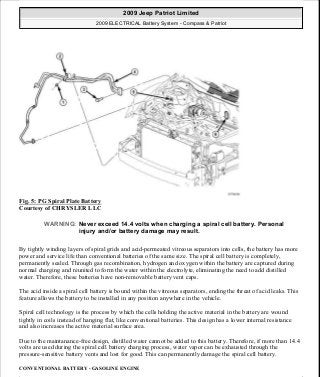

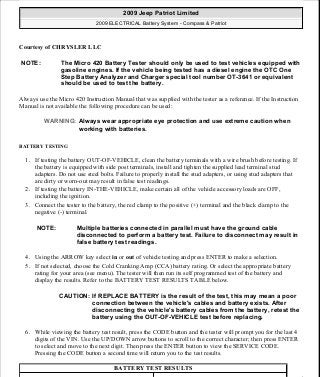

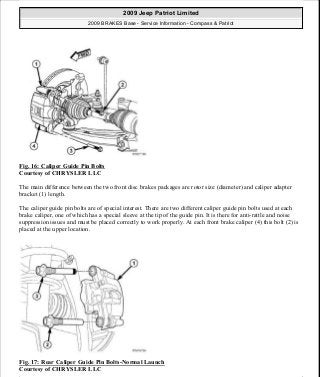

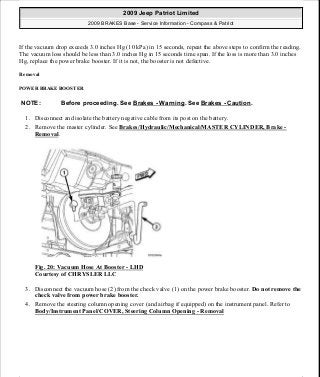

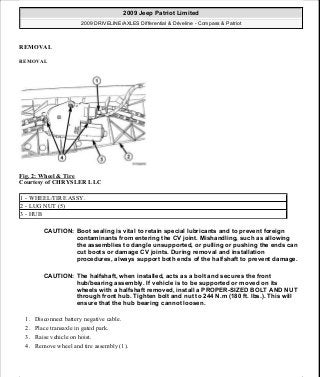

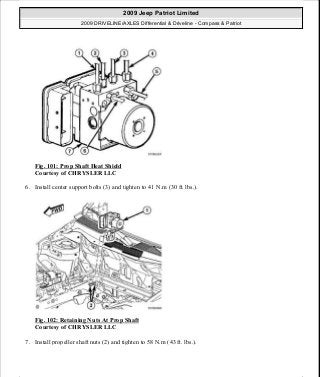

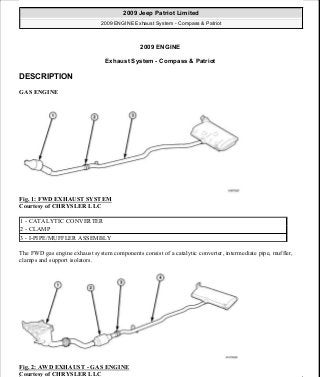

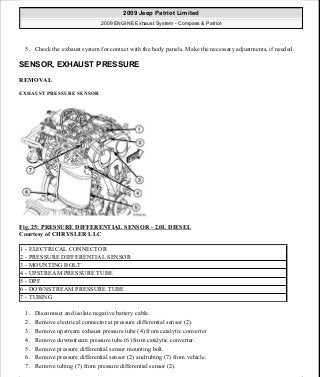

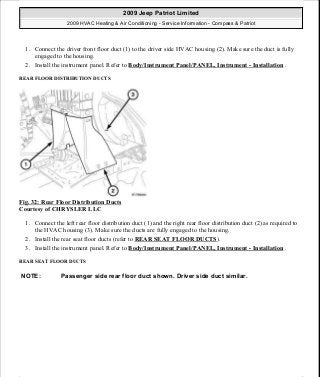

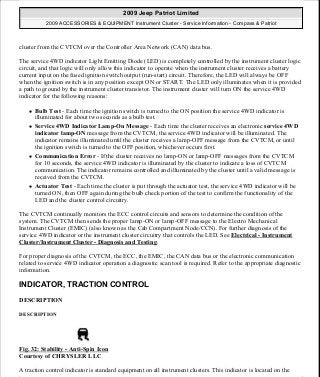

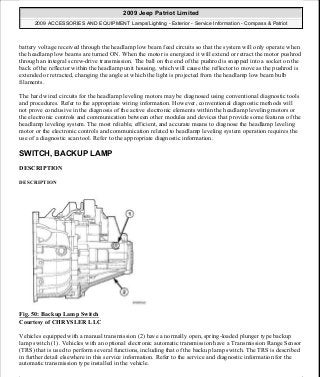

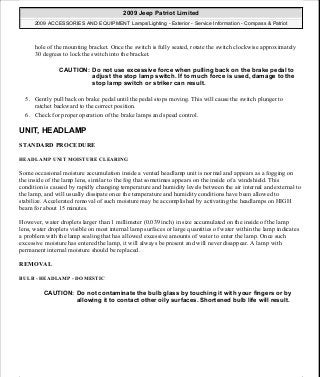

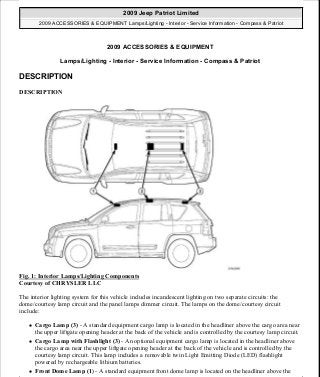

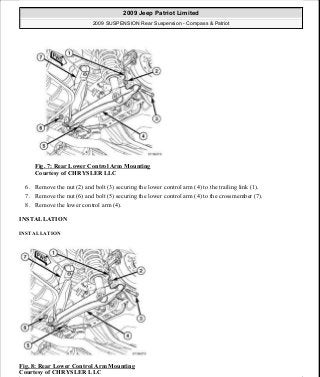

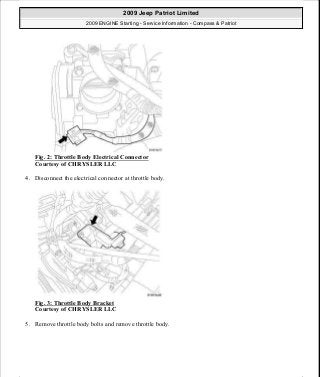

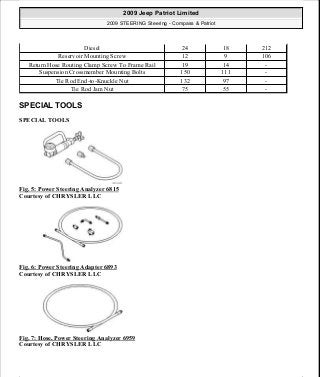

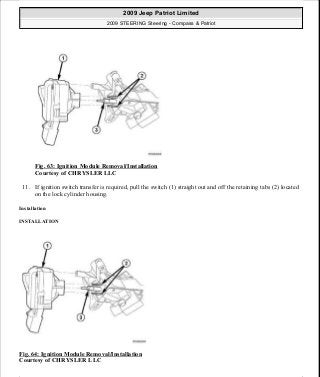

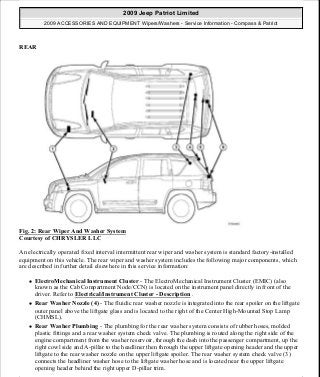

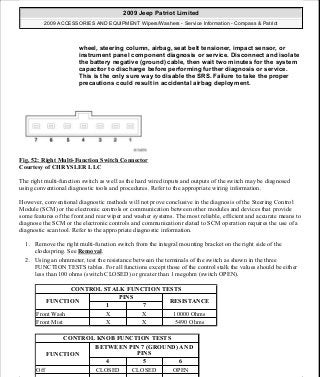

See Figure 158.

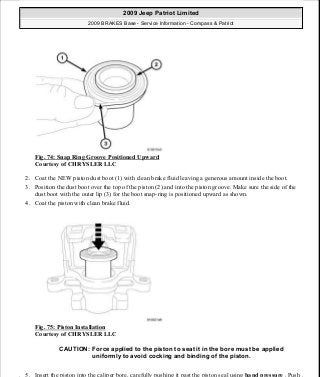

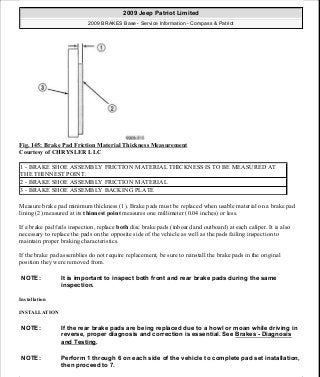

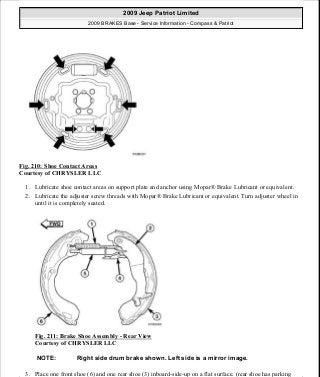

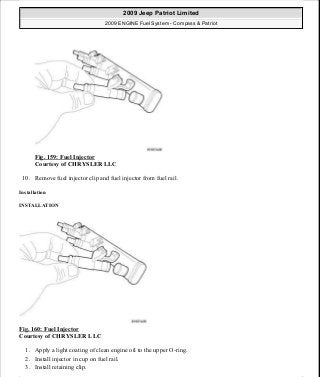

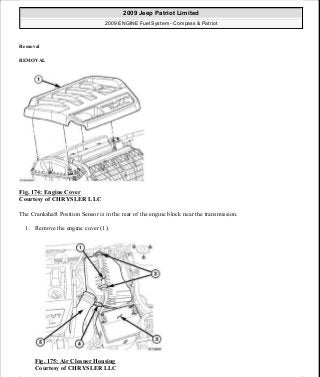

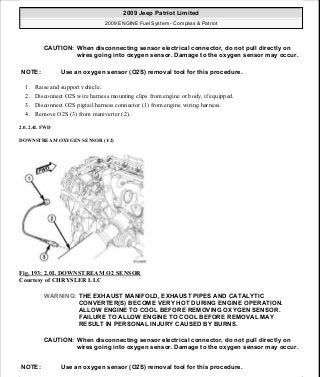

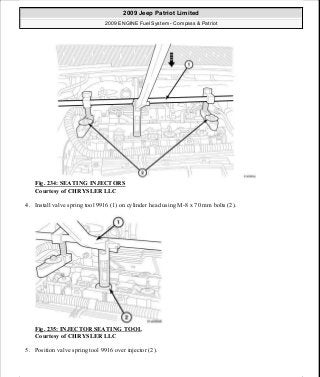

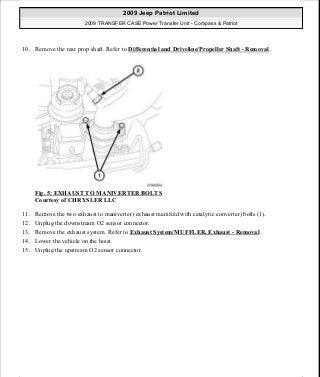

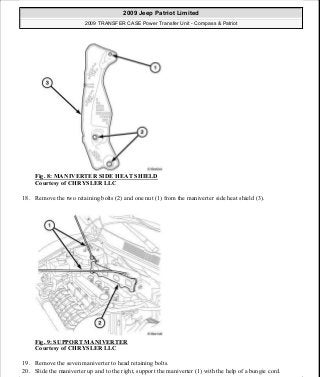

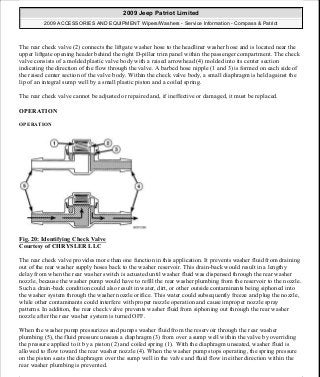

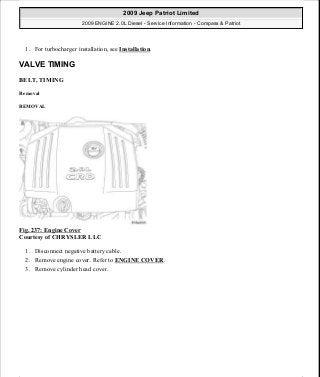

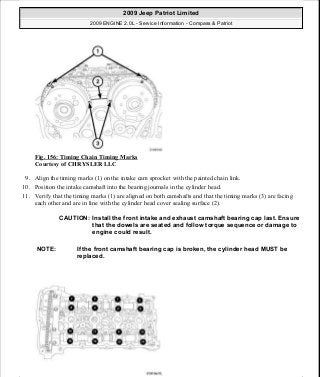

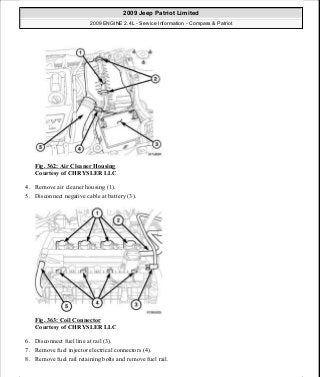

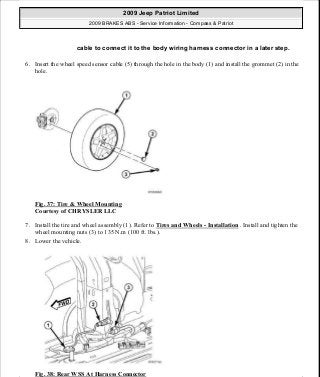

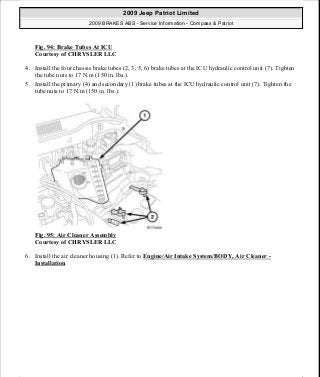

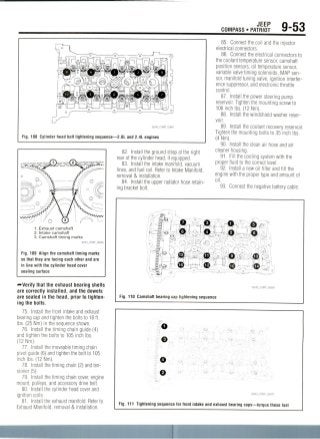

The Crankshaft Position (CKP) sensor

mounts to the rear of the engine block near

the transmission.

REMOVAL & INSTALLATION

See Figures 158 and 159.

The crankshaft position sensor mounts to

the rear of the engine block near the trans-

mission.

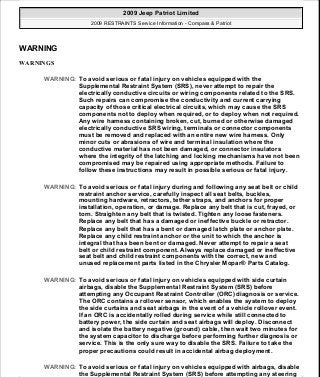

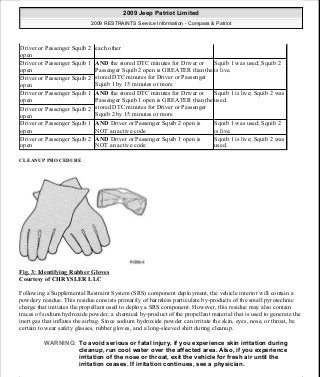

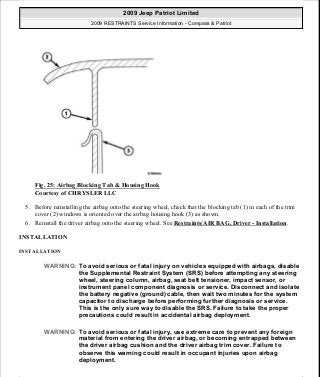

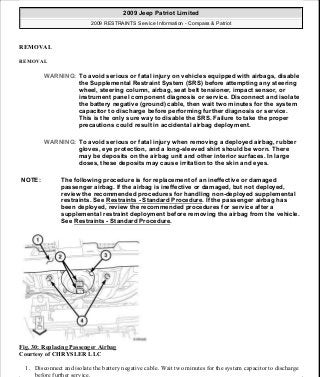

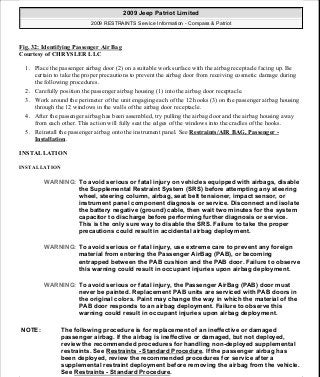

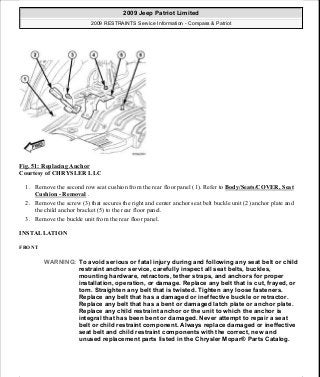

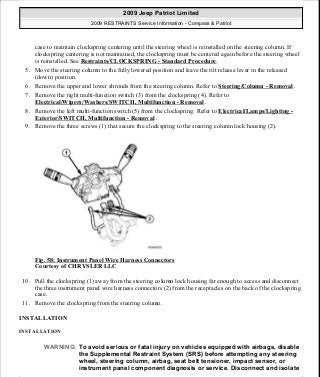

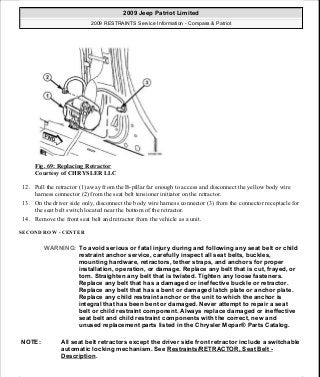

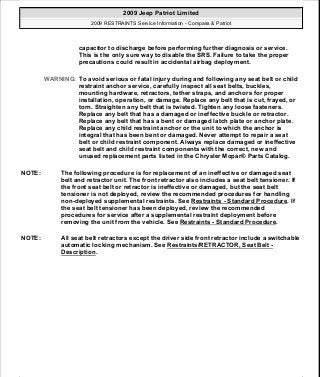

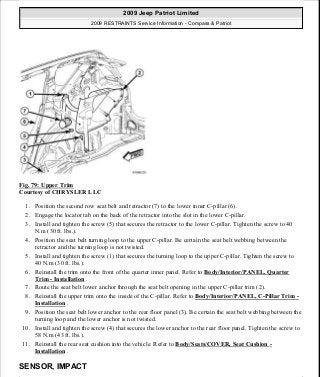

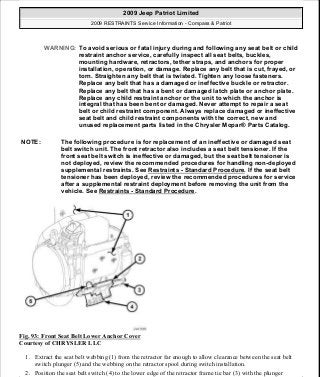

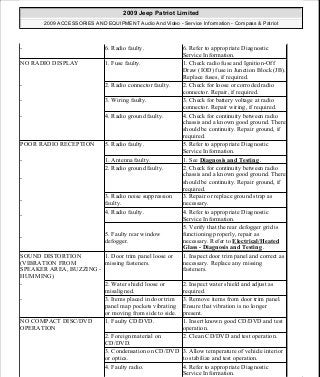

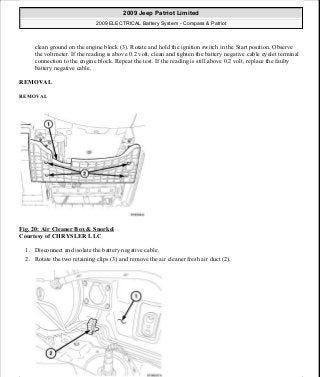

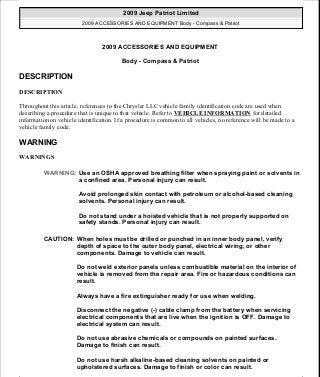

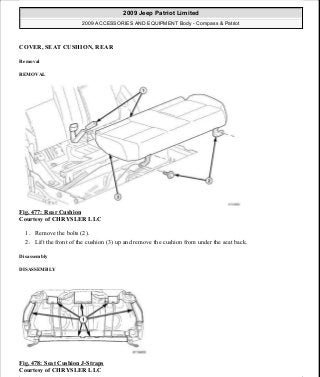

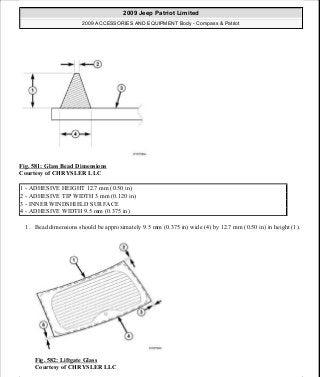

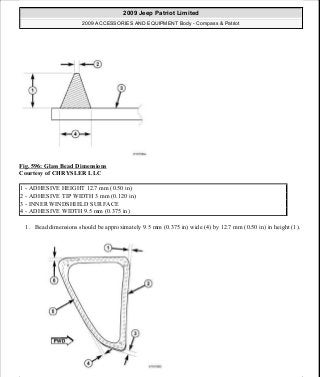

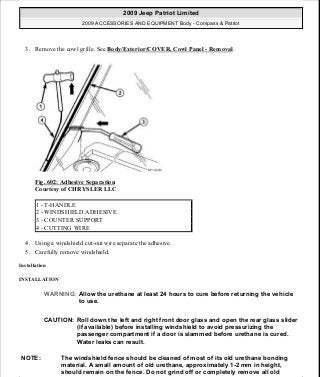

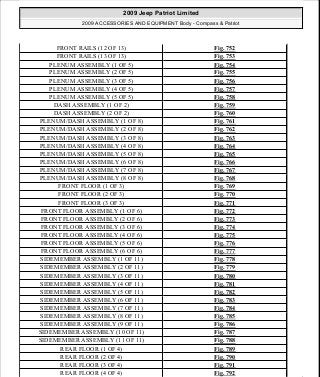

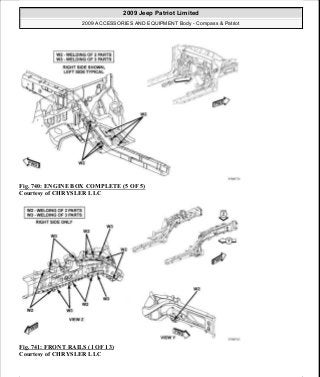

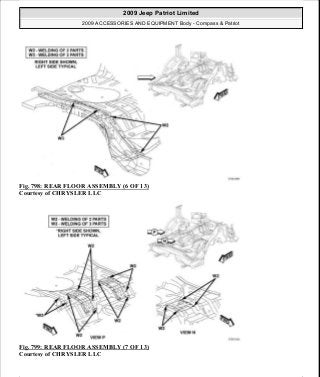

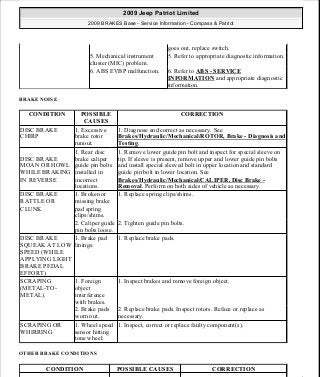

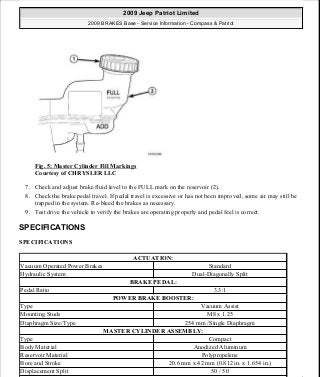

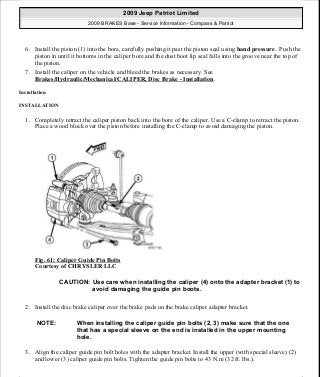

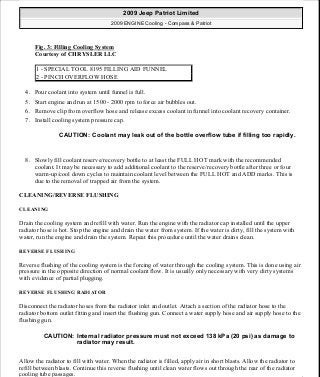

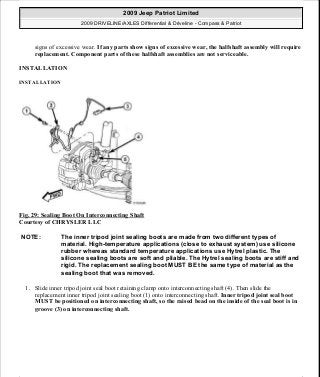

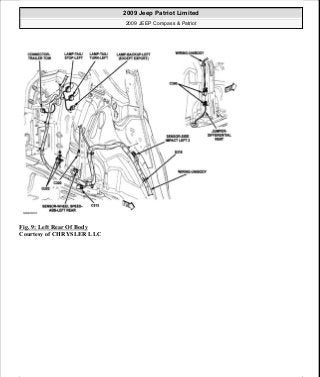

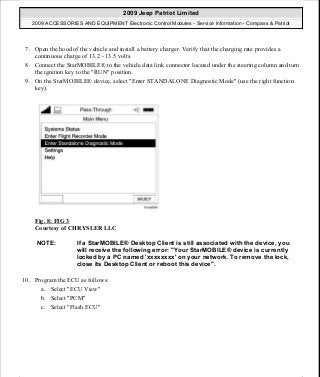

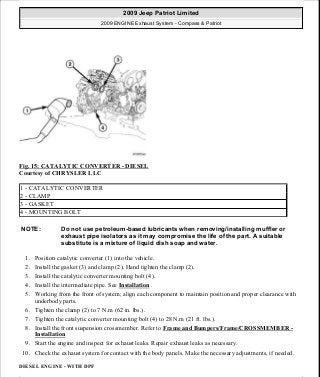

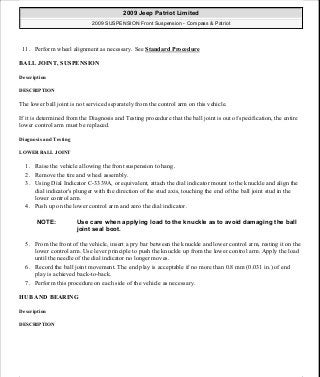

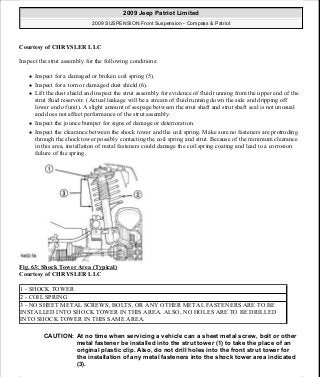

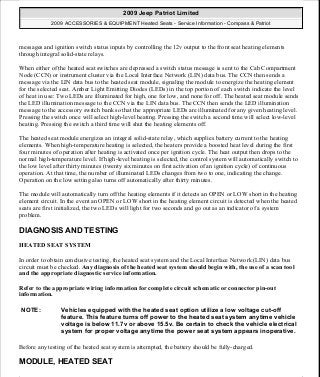

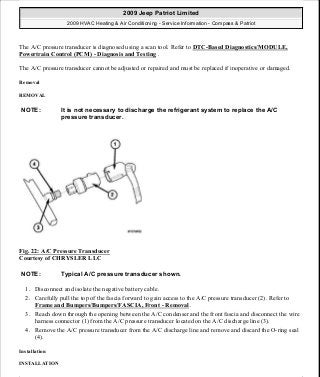

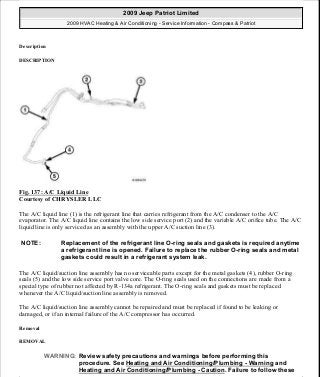

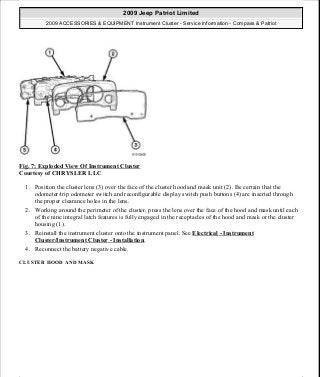

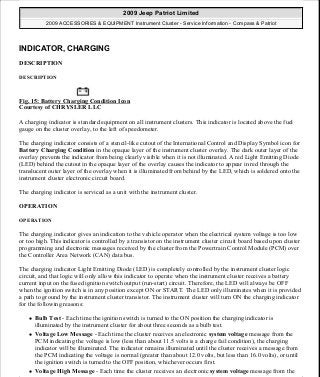

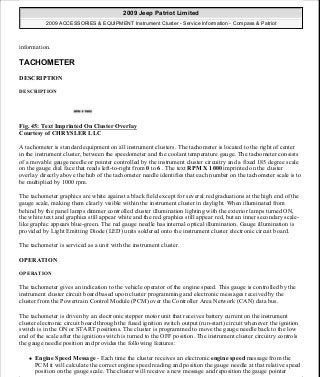

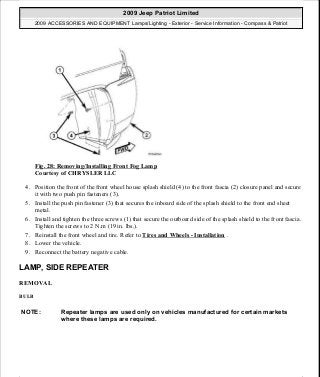

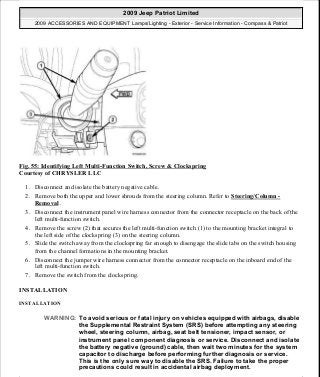

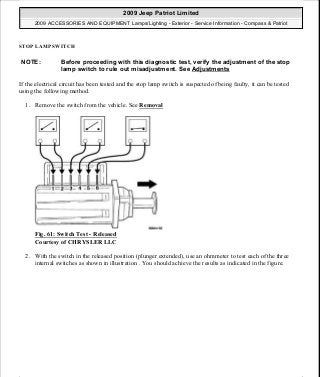

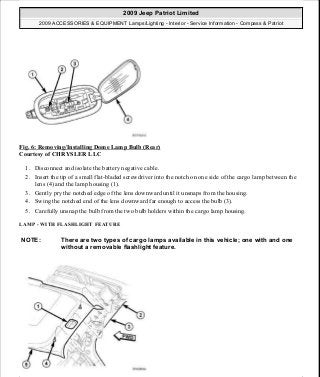

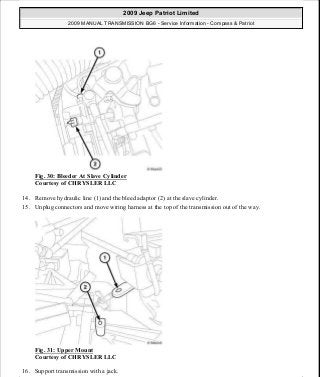

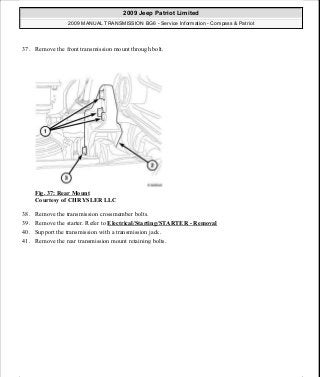

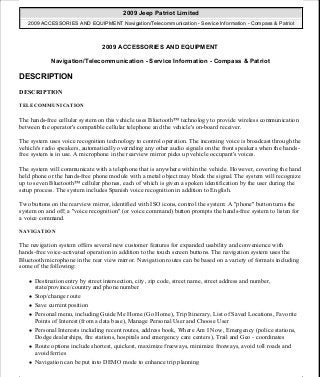

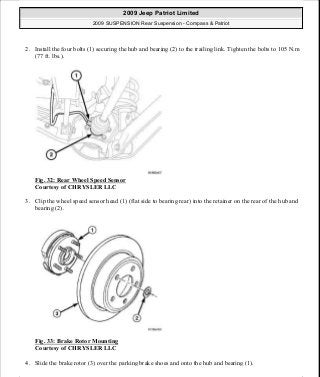

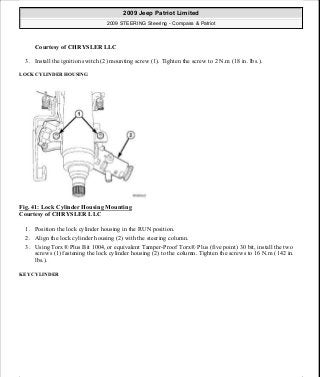

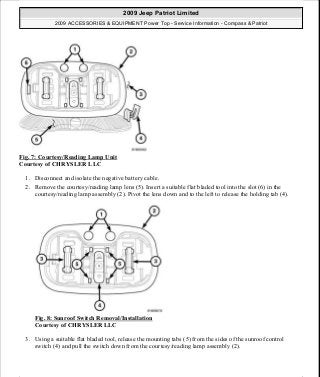

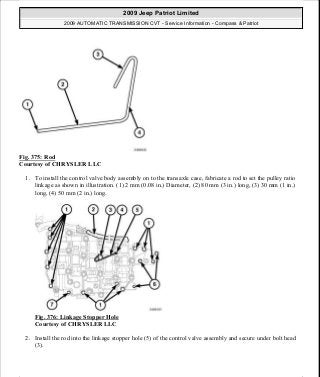

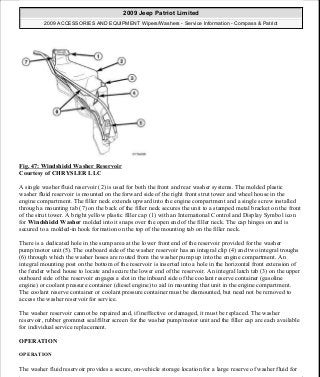

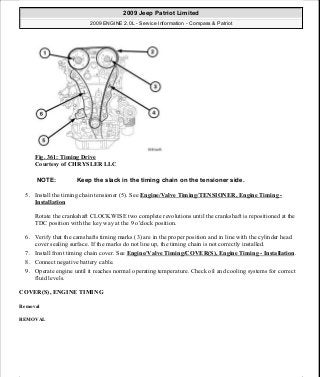

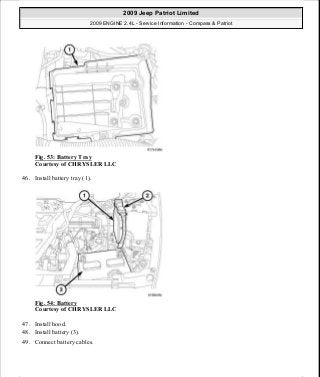

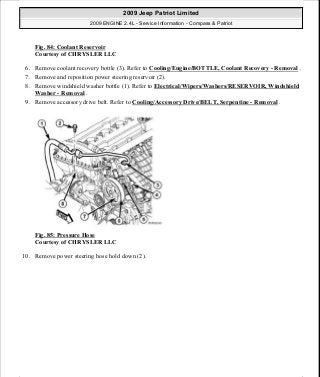

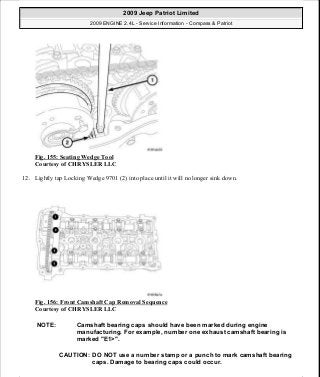

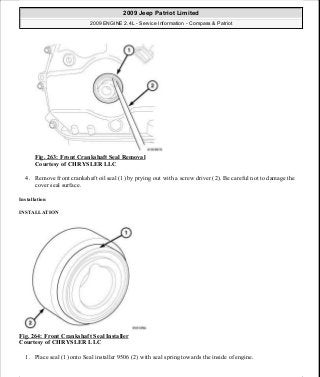

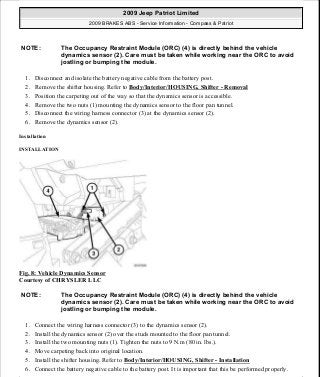

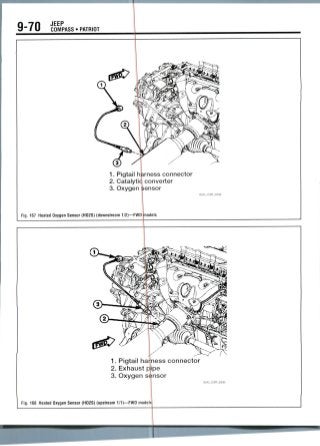

Fig. 158 Crankshaft Position (CKP) sensor

location—2.0L and 2.4L engines

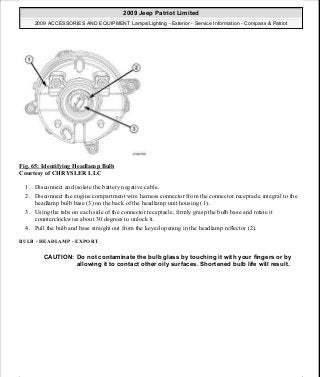

1. Before servicing the vehicle, refer to

the Precau ions Section.

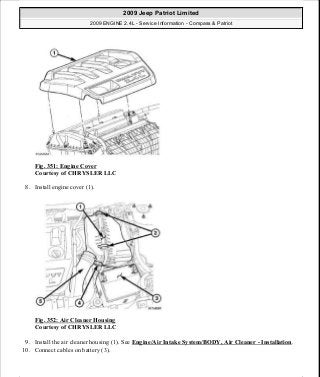

2. Rermove the engine cover.

3. Disconnect and isolate the negative

battery cable.

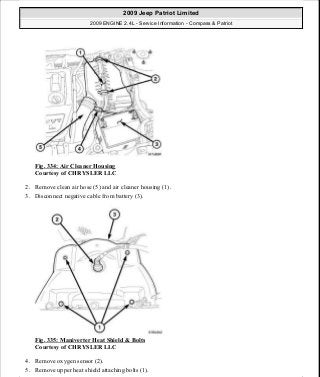

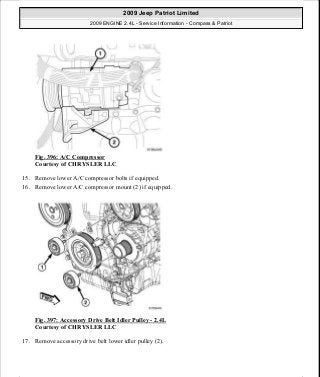

4. Remove the air cleaner body.

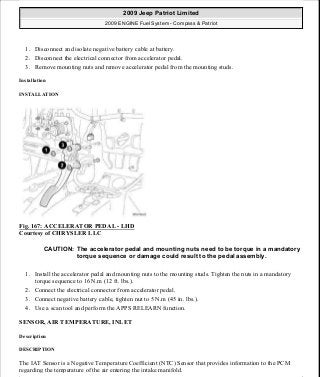

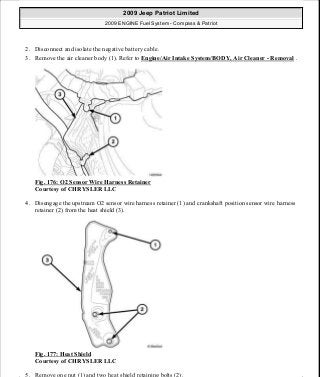

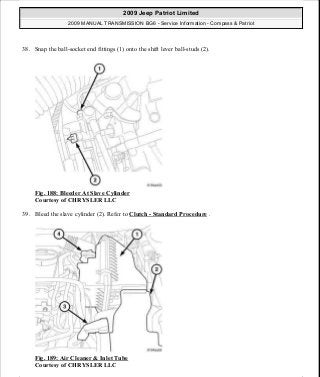

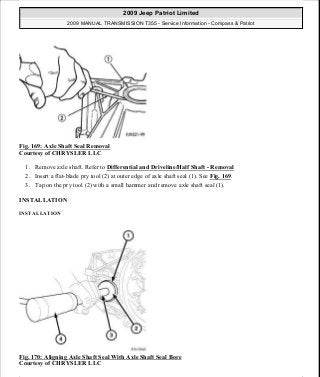

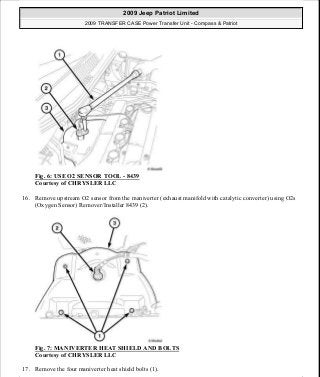

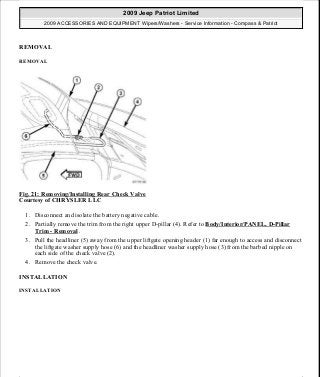

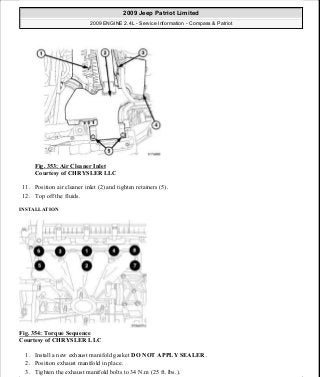

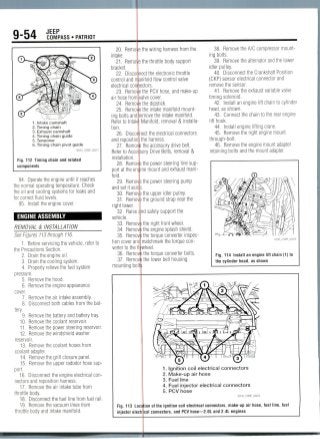

5. Disengage the upstream 02 sensor

wire harness retainer (1) and the Crankshaft

Position (CKP) sensor wire harness retainer

(2) from thd heat shield(3).

6. Remove the one nut and two heat

shield retaining bolts.

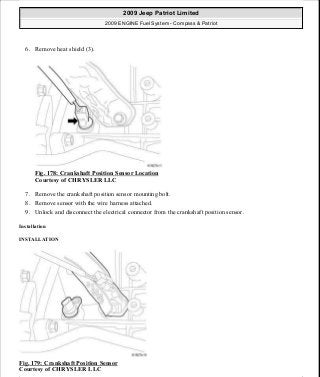

7. Remove the heat shield.

8. Remove the CKP sensor mounting

bolt.

9. Rerm ve the CKP sensor with the

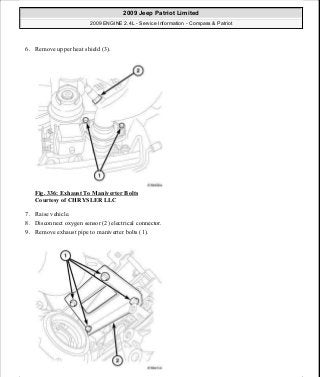

wire harness!attached.

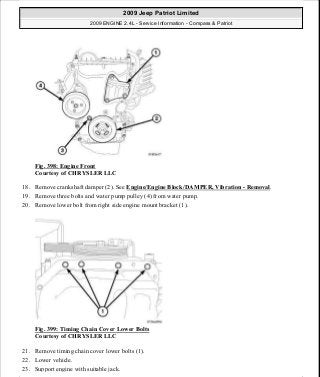

10. Unloqk and disconnect the electrical

connector frqm the CKP sensor.

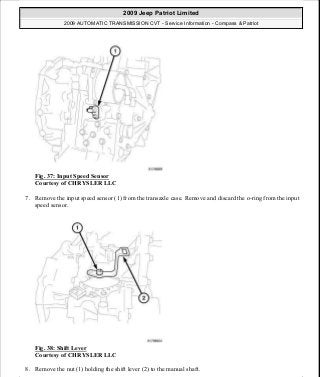

To instal

11. ChecMthe 0-ring for damage and

lubricate the fi-ring with engine oil before

installing thepensor.

12. Using|a twisting motion, install the

CKP sensor.

13. Install the CKP sensor bolt. Tighten

the bolt to 80 inch Ibs. (9 Nm).

14. Connect and lock the electrical con-

nector to the (JKP sensor.

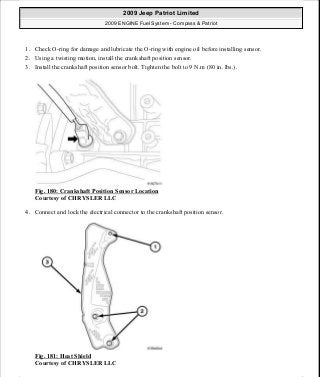

15. Install Ihe heat shield with the one

nut and two haat shield retaining bolts.

16. Install the upstream 02 sensor wire

harness retainer (1) and the CKP sensor

wire harness retainer (2) to the heat shield

(3).

17. Install tlie air cleaner body.

18. Conned] the negative battery

cable.

19. Install the engine cover.

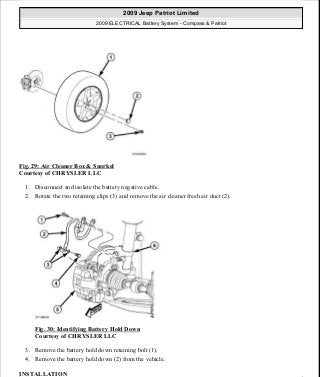

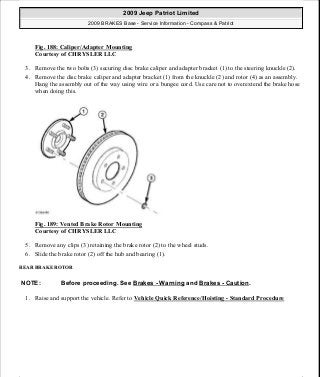

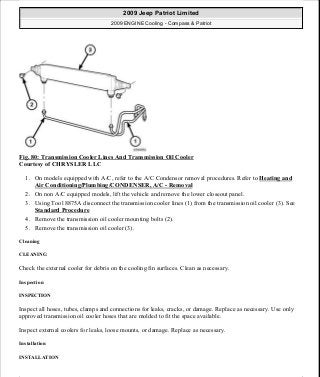

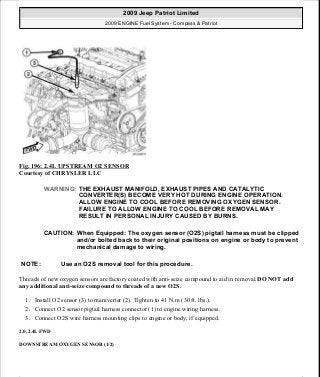

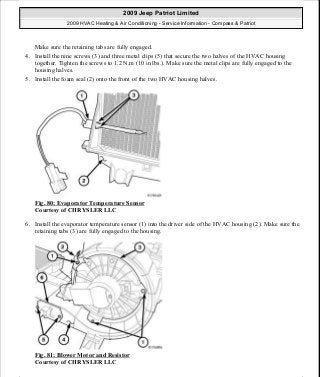

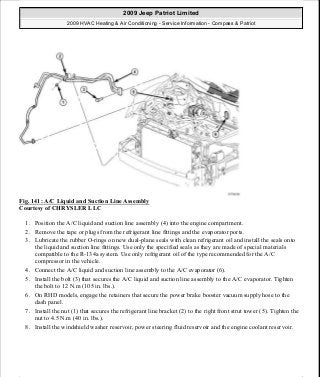

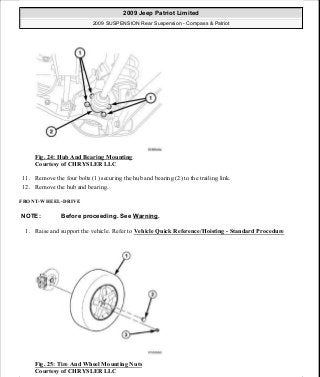

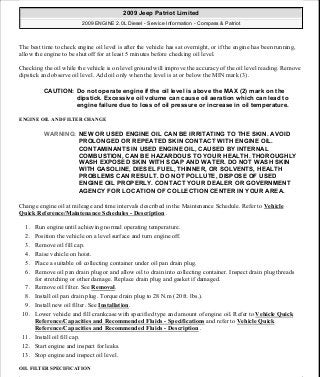

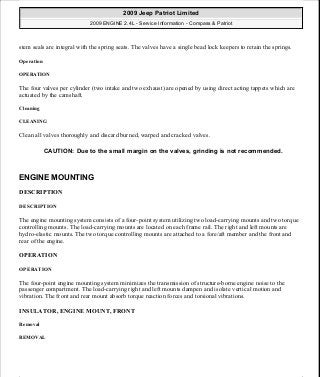

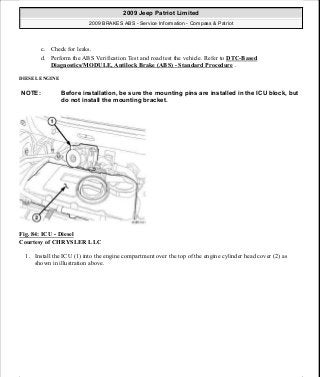

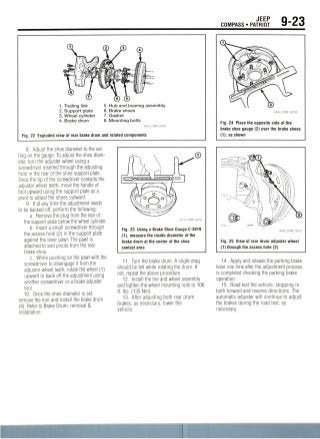

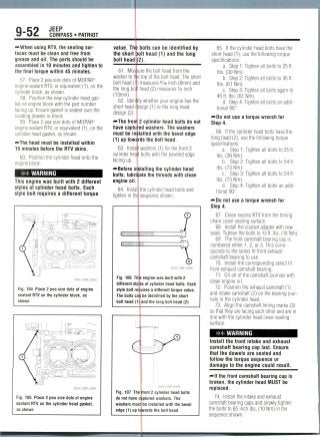

1. Upstream O2 sensor wire harness retainer

2. CKP sensor wife harness retainer

3. Heat shield

36543_COMP_G0095

Fig. 159 Disengage the upstream 02 sen-

sor wire harness retainer and the CKP

sensor wire harness retainer from the heat

shield

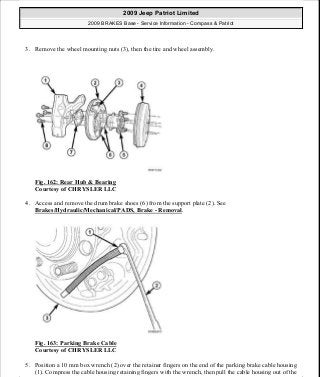

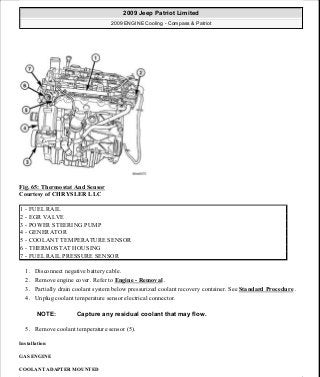

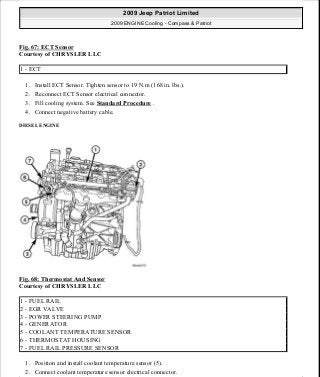

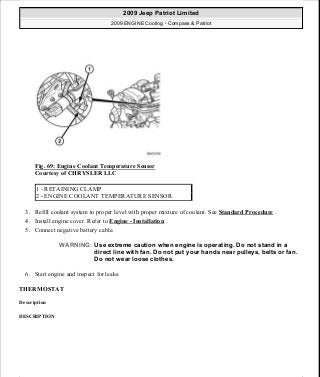

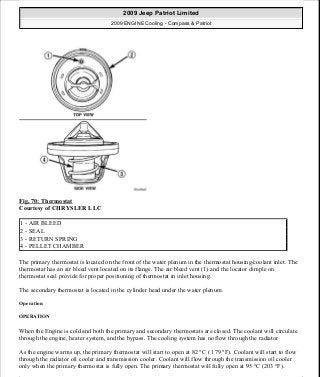

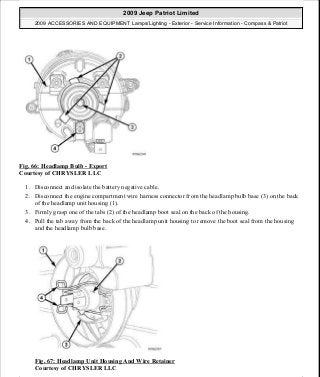

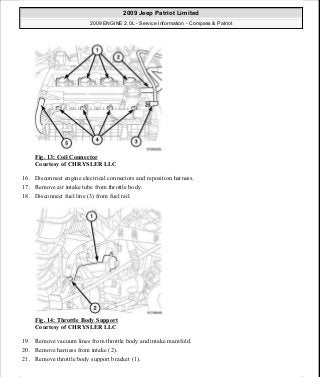

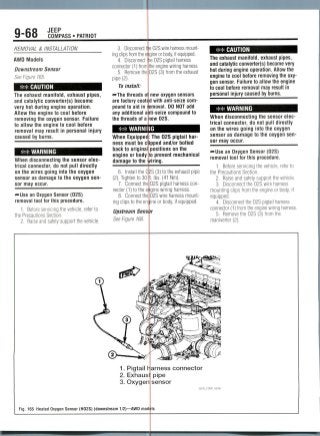

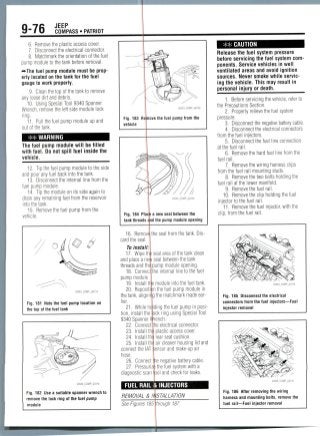

ENGINE COOLANT

TEMPERATURE (ECT) SENSOR

LOCATION

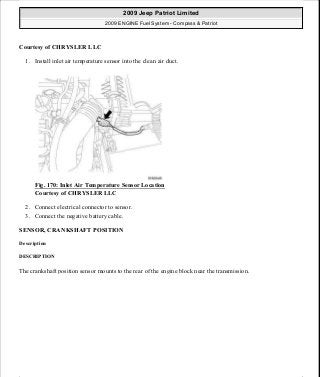

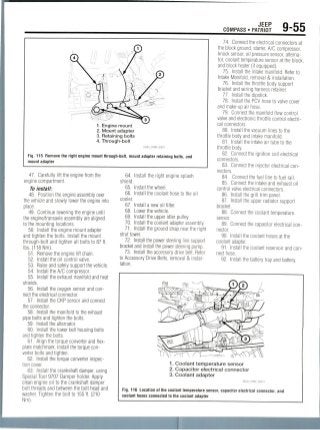

See Figures 160 and 161.

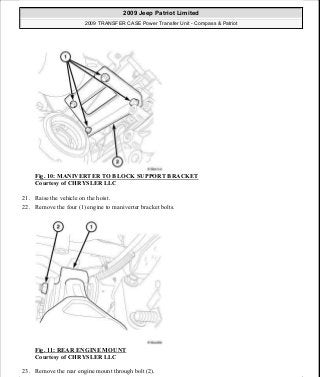

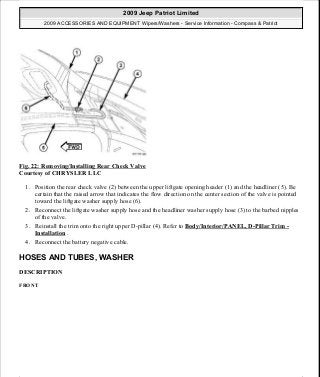

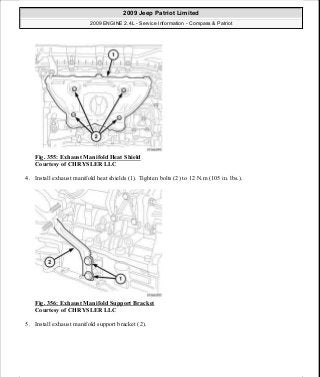

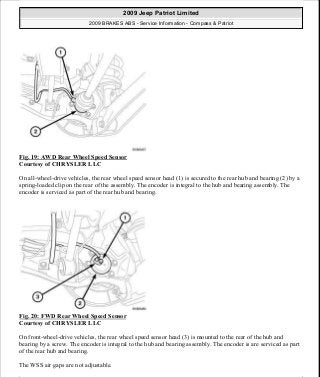

There are two coolant temperature sen-

sors. One is located in the coolant adapter

and one is located in the cylinder head.

1. Engine Coolant Temperature (ECT) sensor

2. Coolant adapter

22043_COMP_G0107

Fig. 160 Engine Coolant Temperature

(ECT) sensor location (coolant adaptor

mounted)—2.0L and 2.4L engines

Fig. 161 Engine Coolant Temperature

(ECT) sensor location (1) (engine block

mounted)—2.01 and 2.4L engines

REMOVAL & INSTALLATION

See Figures 160 and 161.

The following procedure can be used for

removal and installation of either ECTsensor.

1. Before servicing the vehicle, refer to

the Precautions Section.

2. Disconnect the negative battery cable.

3. Drain the cooling system.

4. Disconnect the Engine Coolant Tem-

perature (ECT) sensor electrical connector.

5. Remove the ECT sensor.

To install:

6. Install the ECT sensor as follows:

a. Coolant adapter mounted: Make

sure the ECT sensor is locked in place.](https://image.slidesharecdn.com/manualesreparacionesjeepcompass-patriotlimited2007-2009-150729164945-lva1-app6891/85/Manuales-de-reparaciones-jeep-compass-y-patriot-limited-2007-2009-855-320.jpg?cb=1438196953)

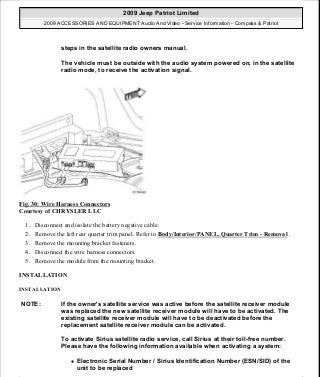

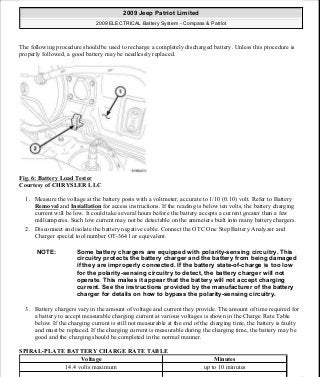

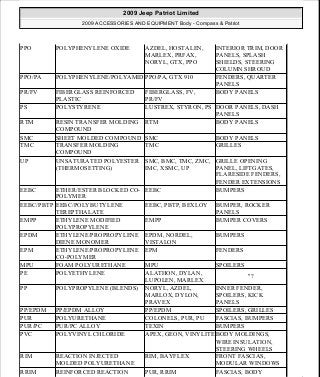

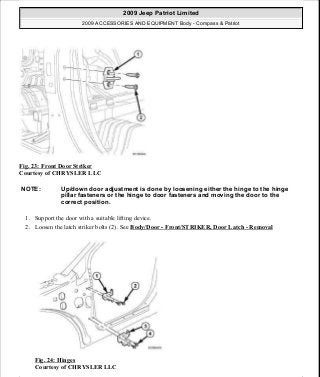

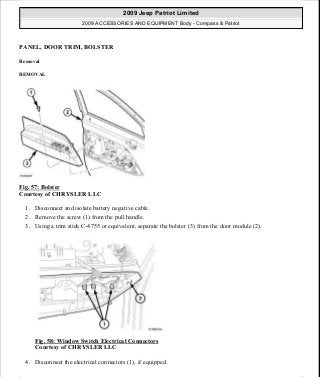

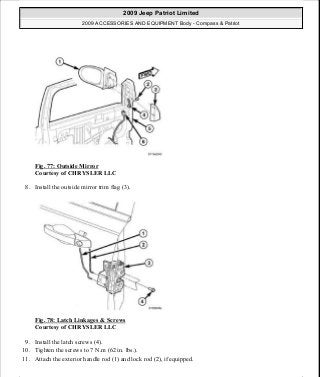

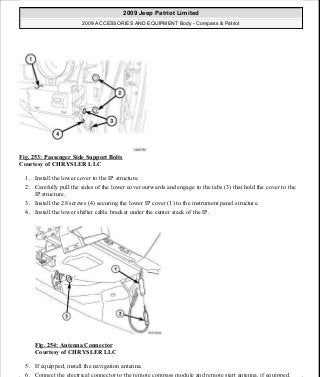

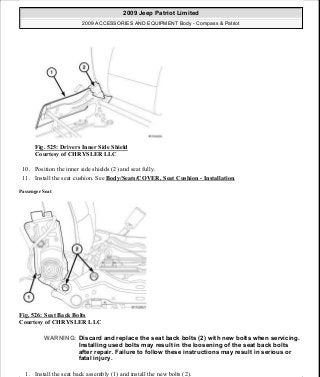

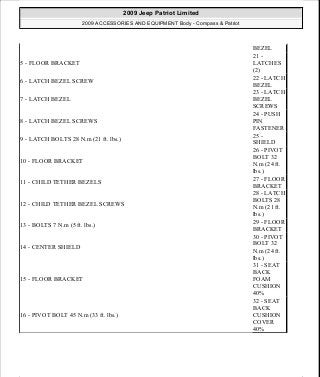

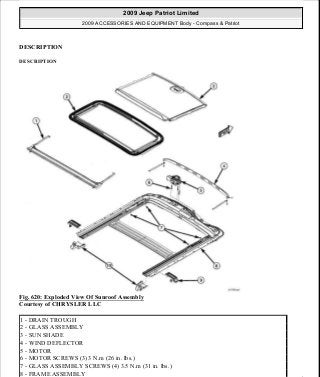

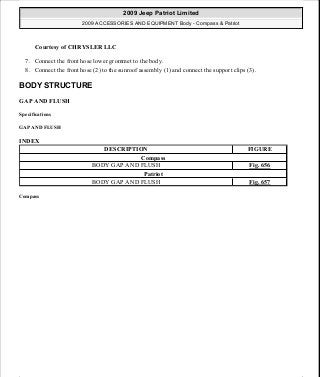

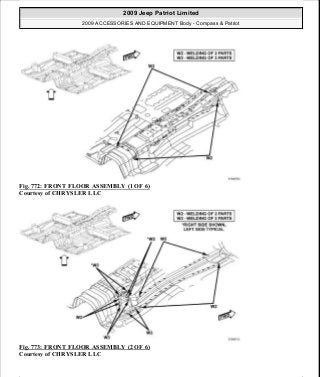

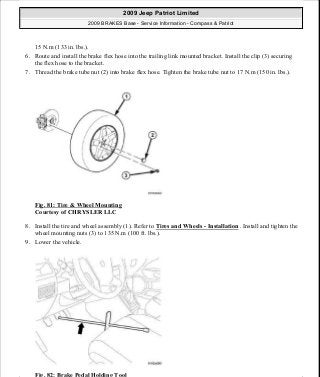

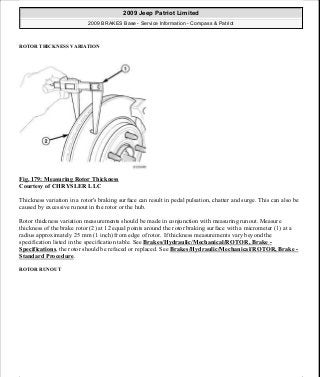

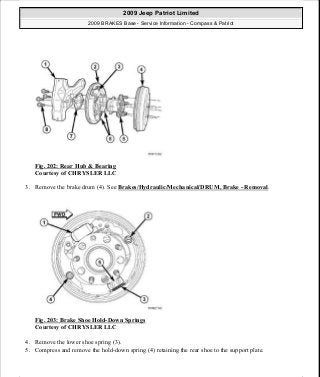

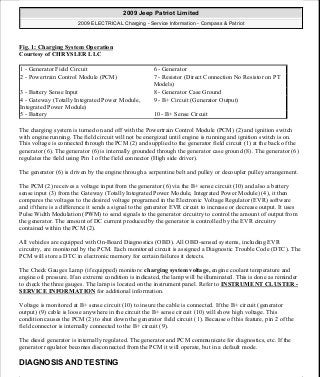

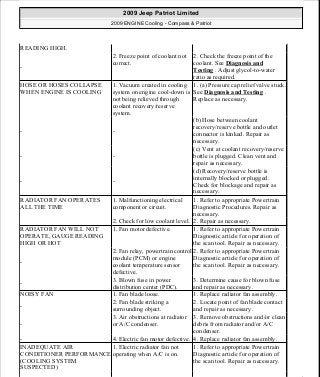

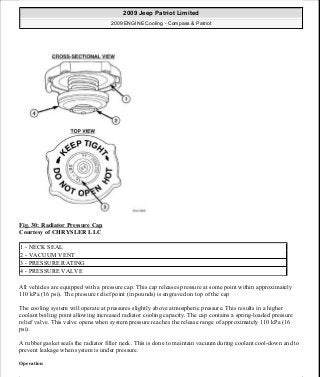

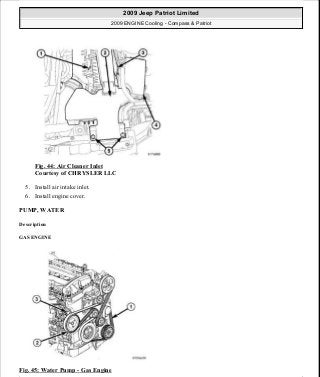

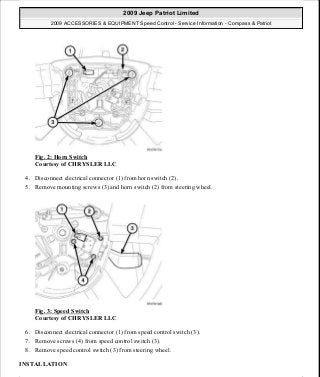

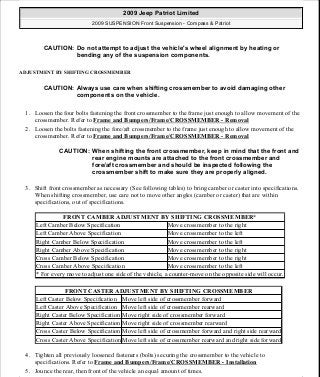

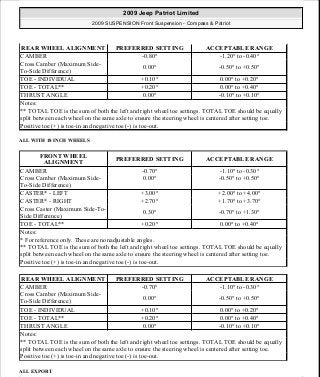

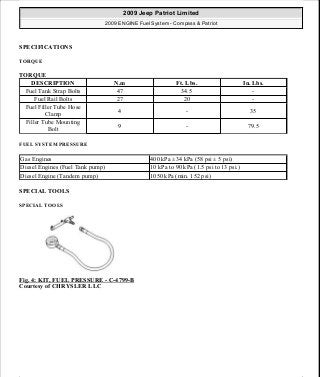

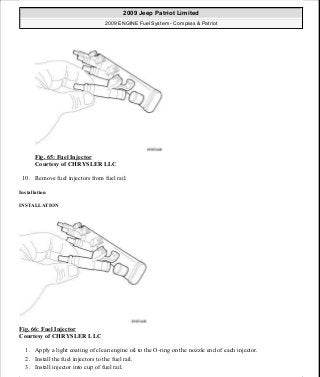

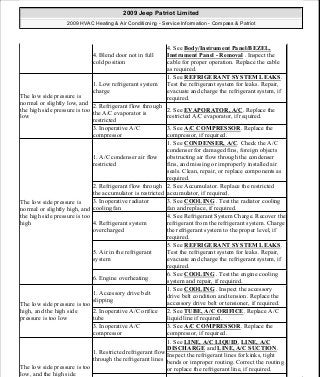

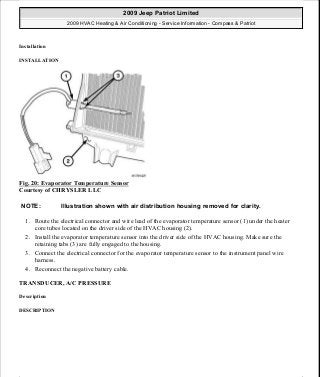

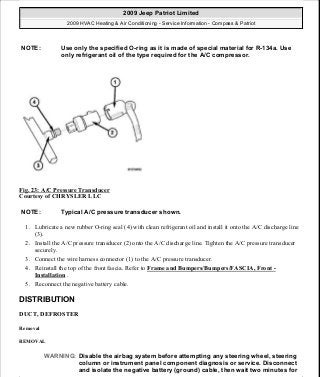

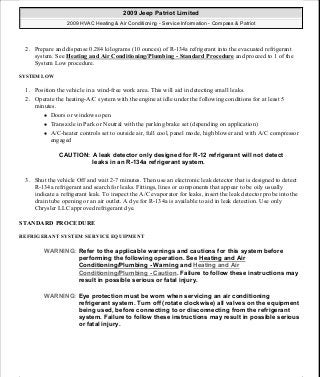

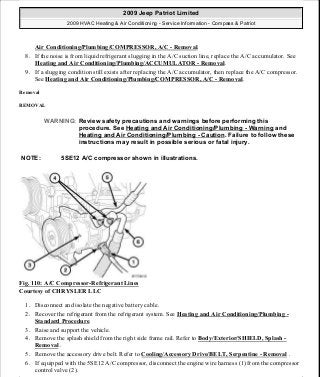

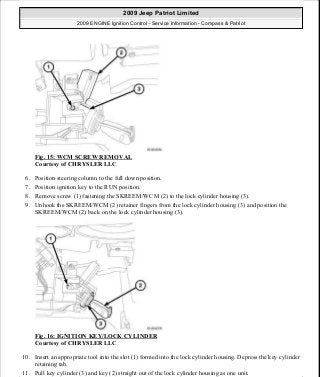

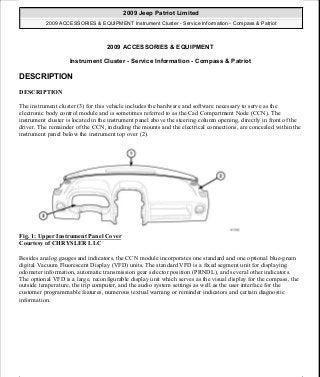

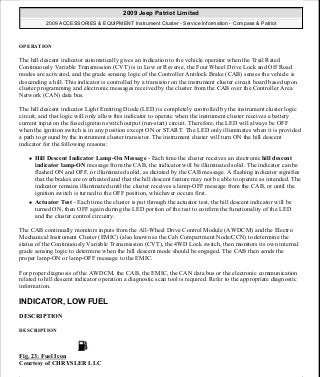

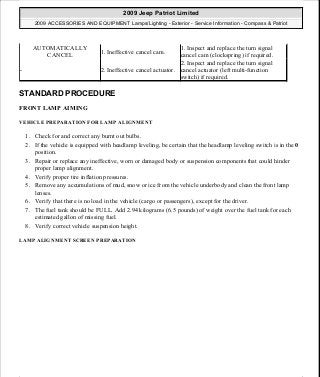

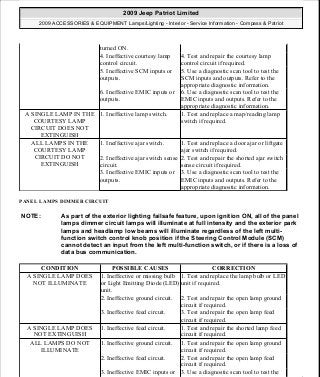

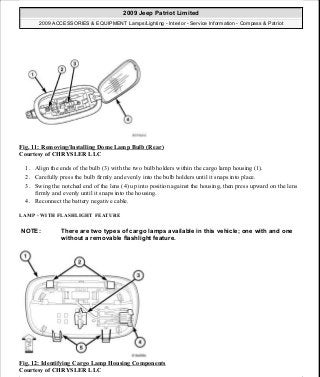

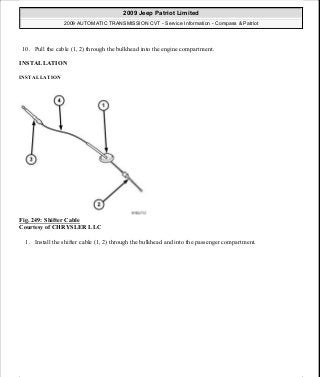

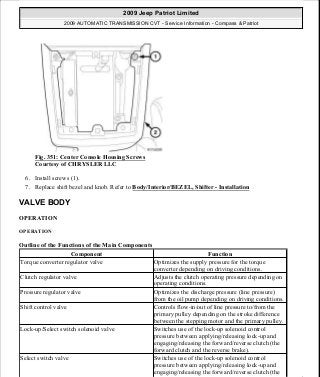

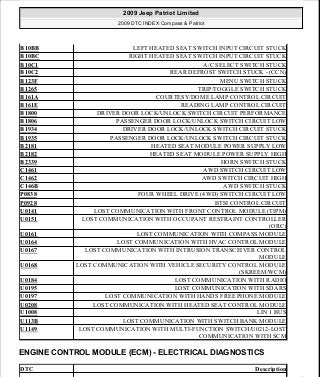

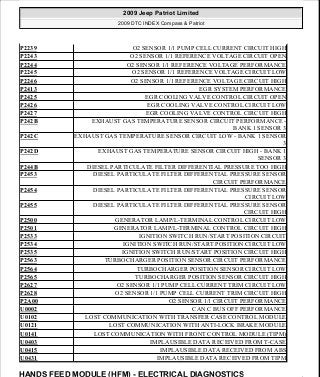

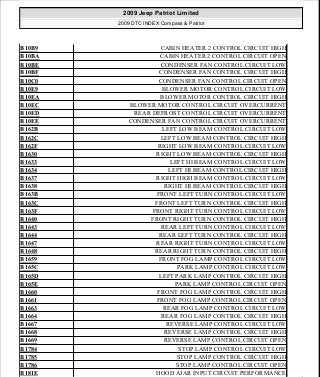

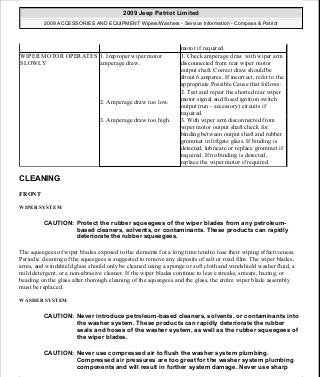

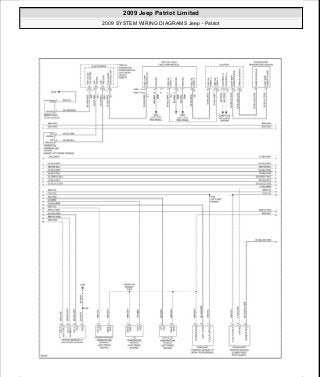

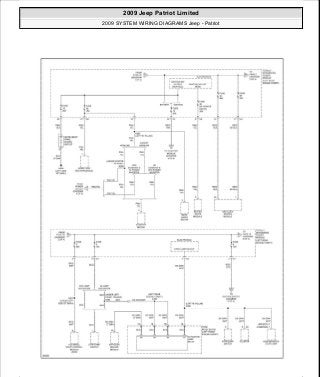

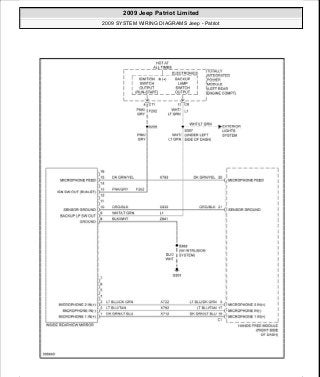

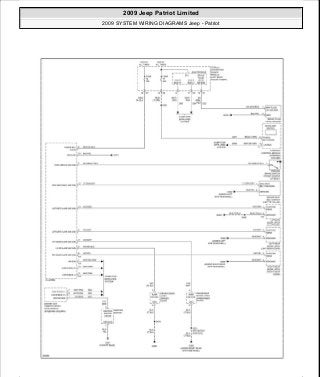

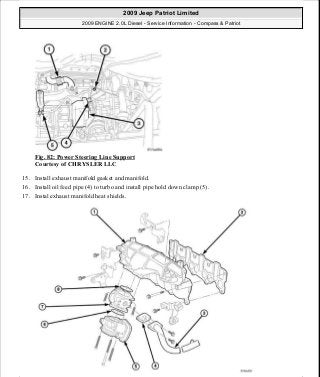

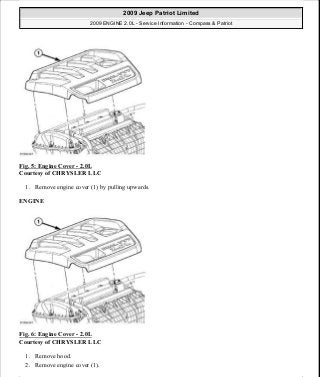

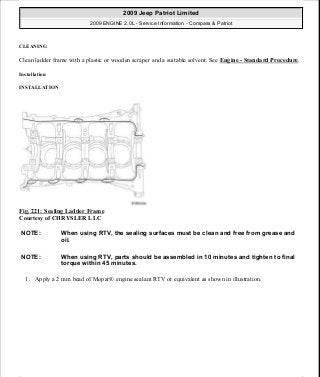

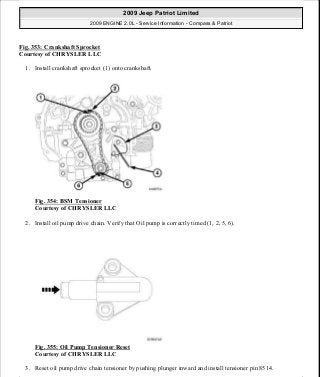

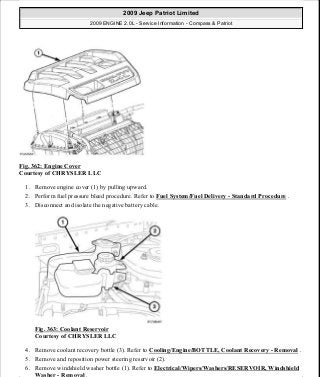

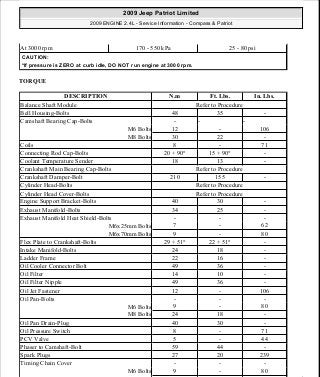

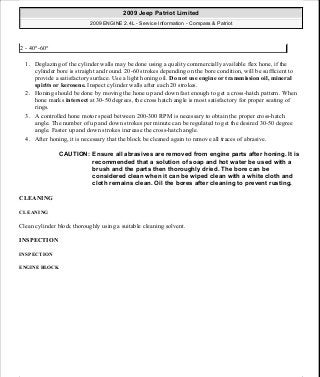

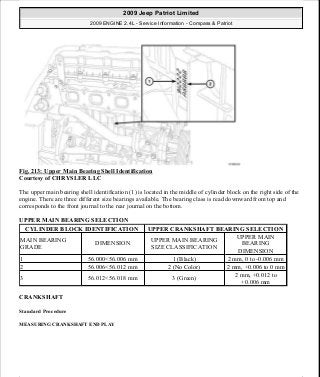

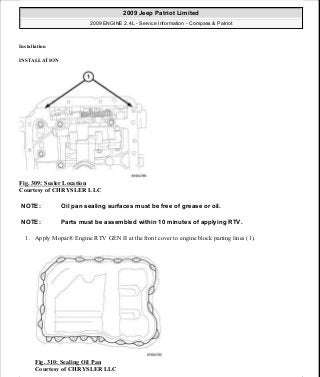

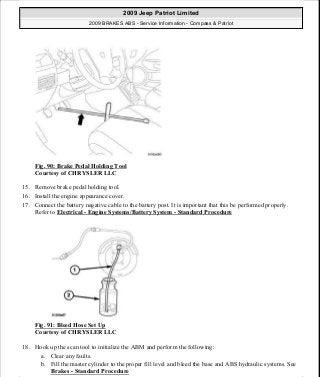

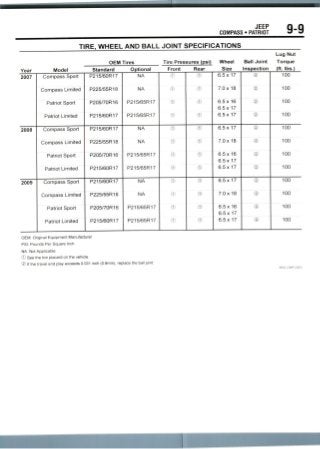

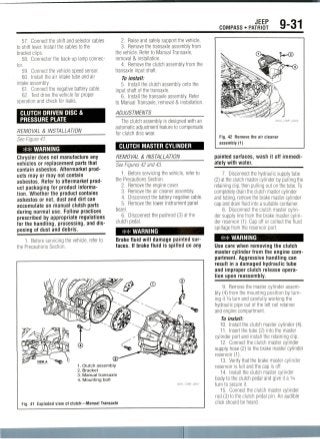

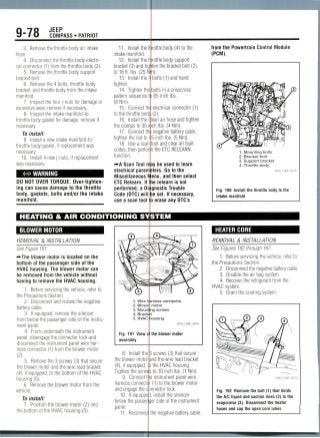

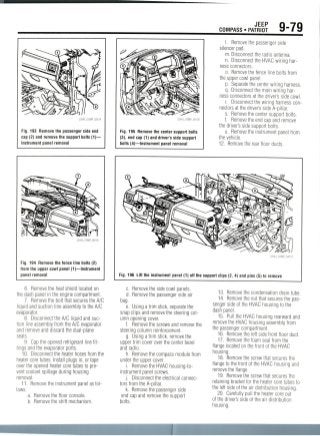

![9-80 JEEP

COMPASS • PATRIOT

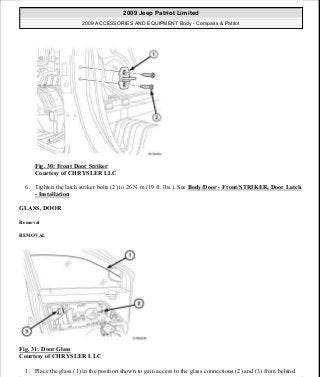

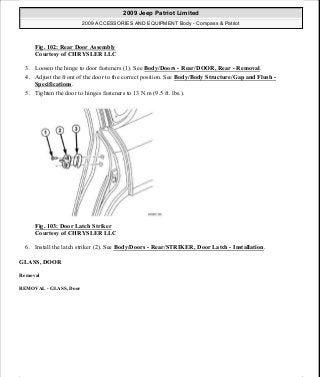

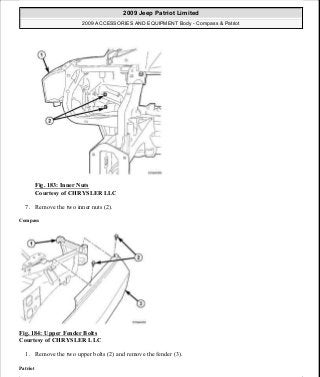

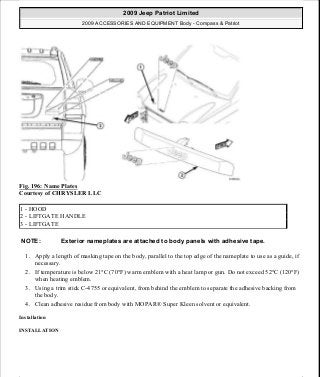

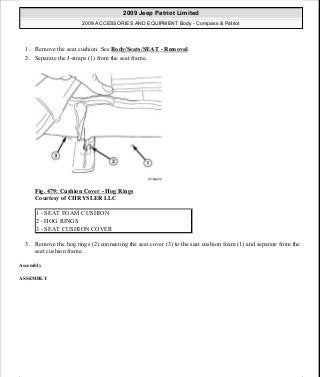

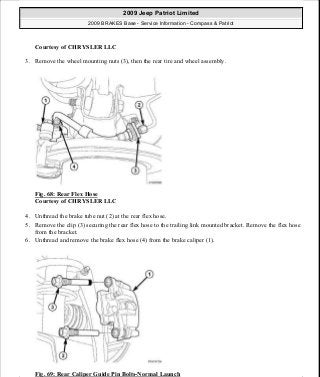

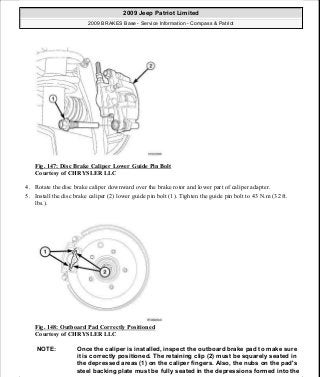

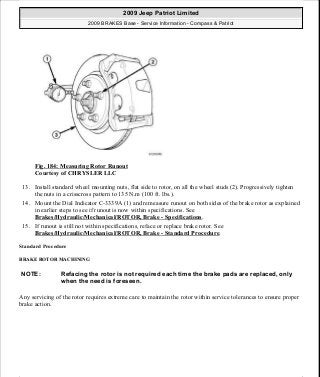

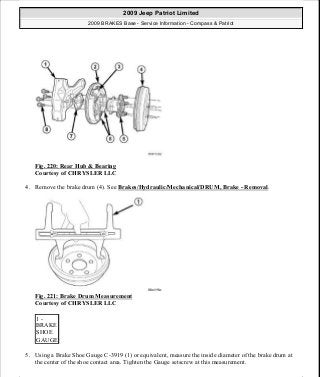

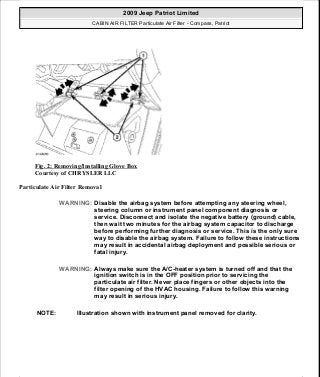

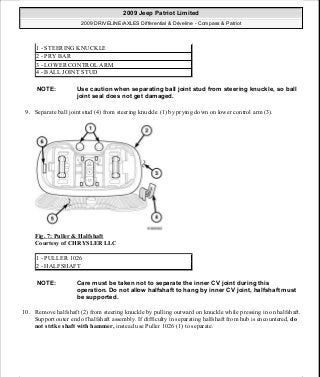

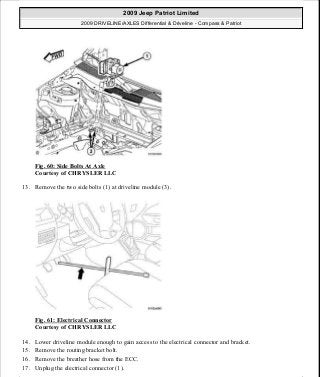

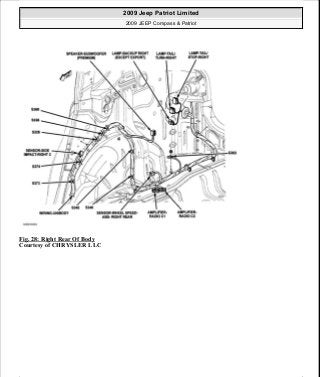

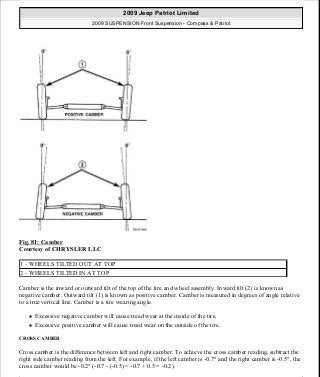

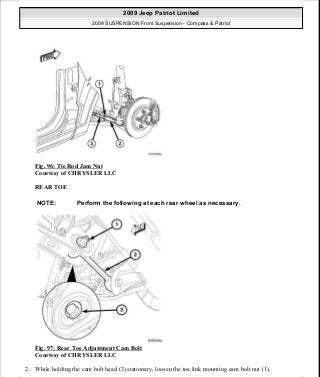

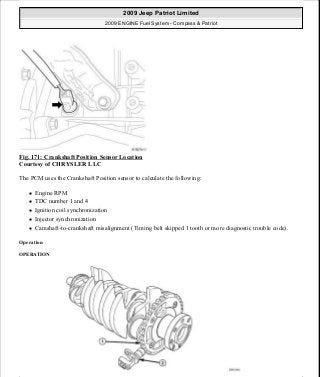

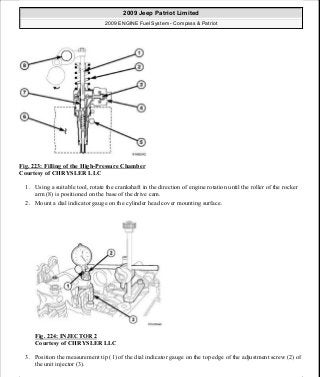

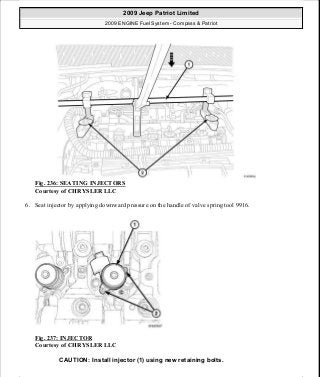

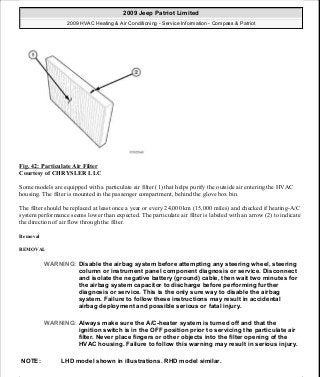

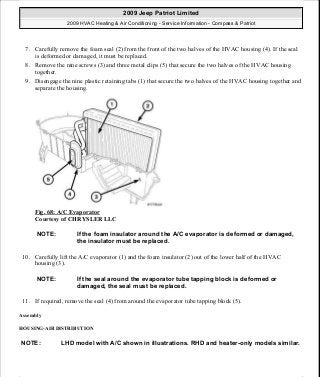

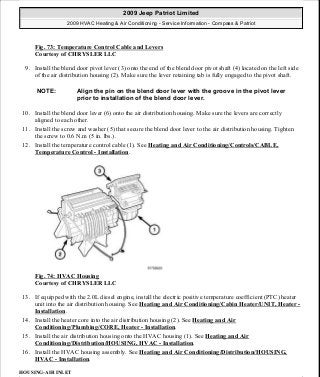

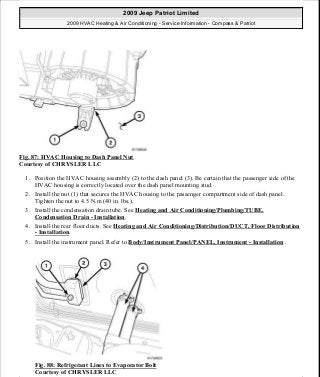

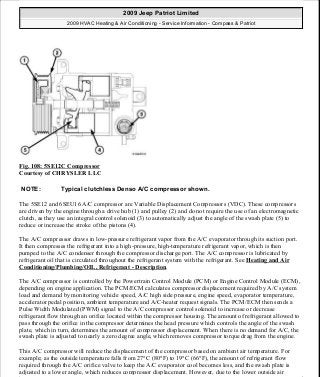

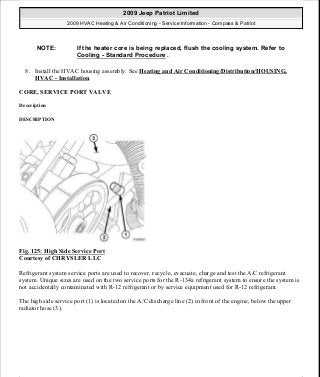

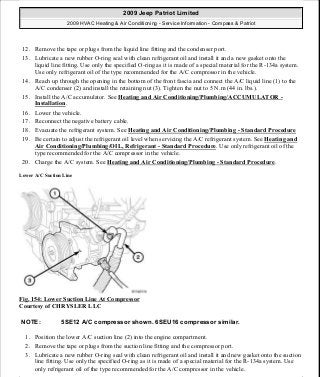

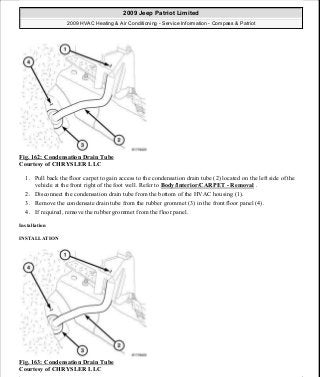

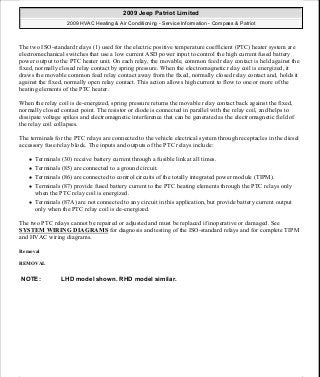

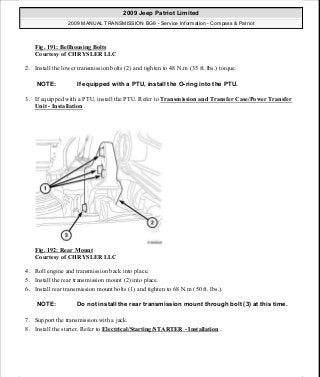

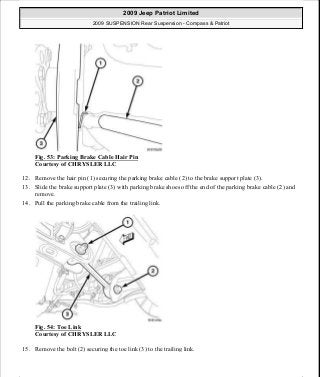

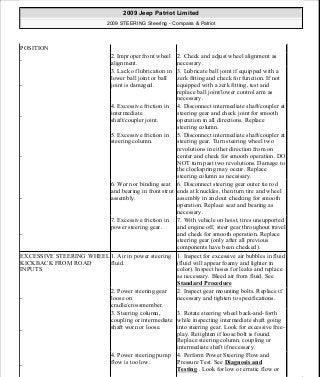

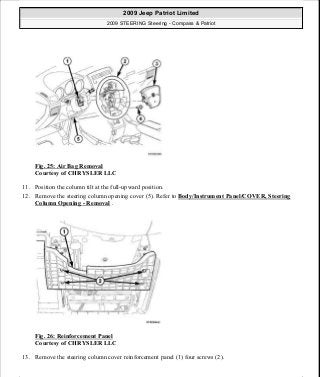

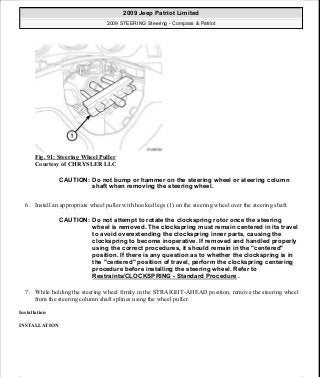

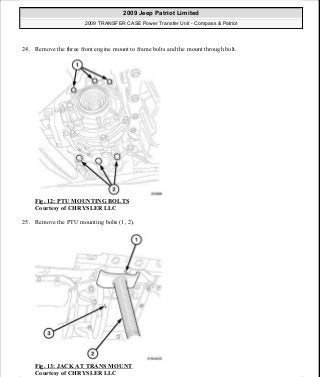

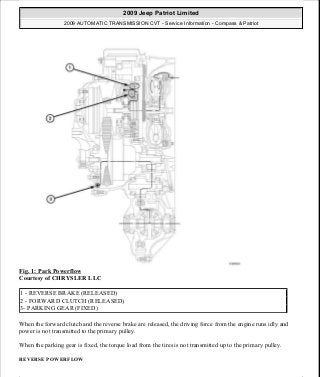

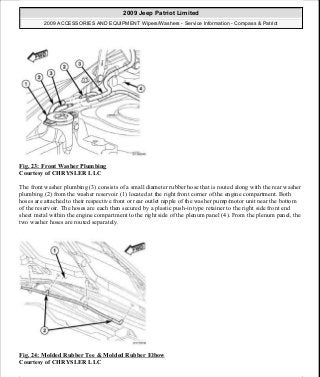

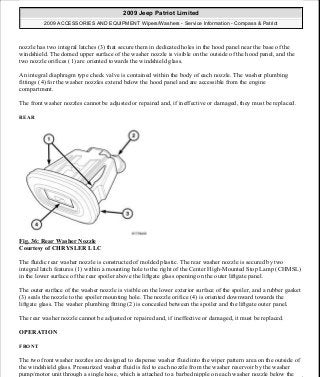

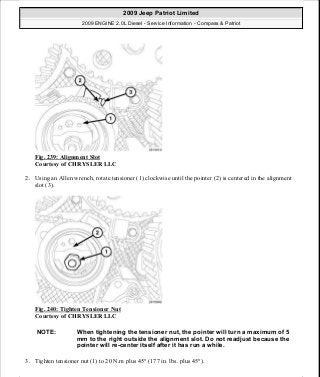

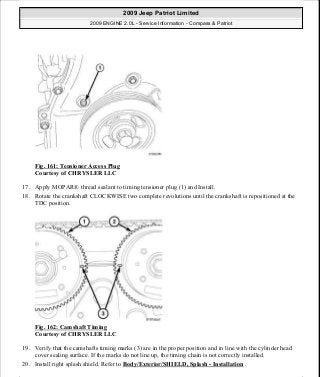

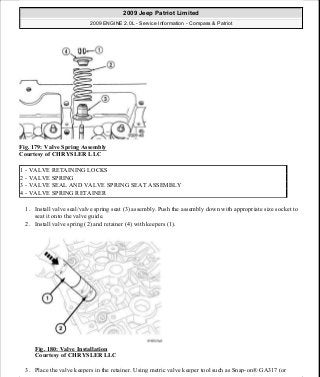

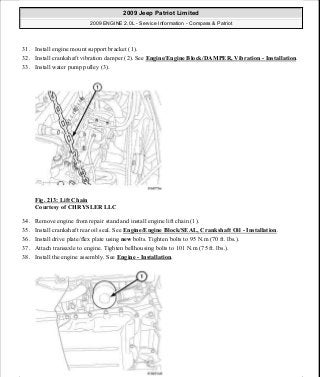

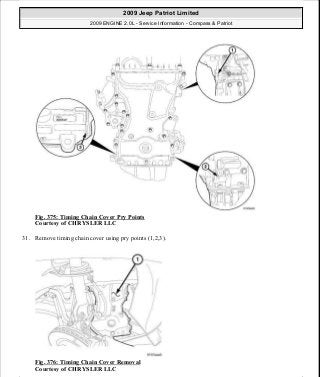

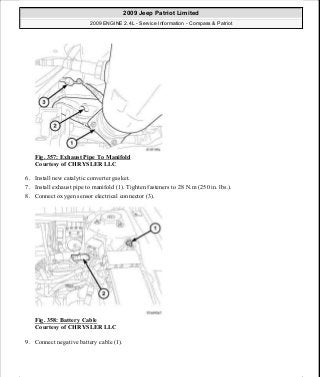

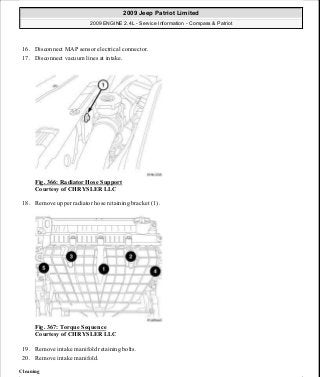

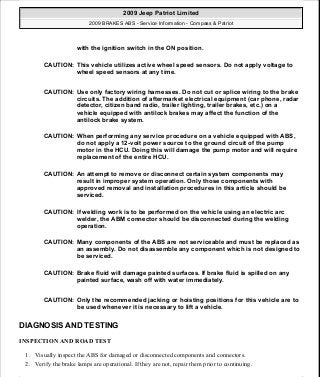

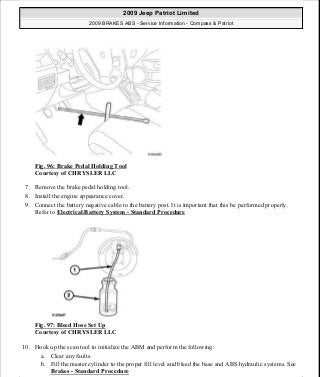

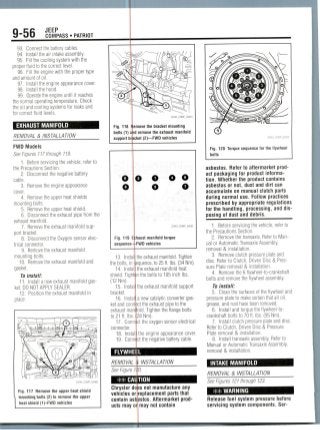

1. Foam seal

2. Flange

3. Screw

4. Retaining bracket

5. Air distribution housing 10. Screi

6. Heater core

7. Seal

8. Heated core tubes

9. HVAC housing

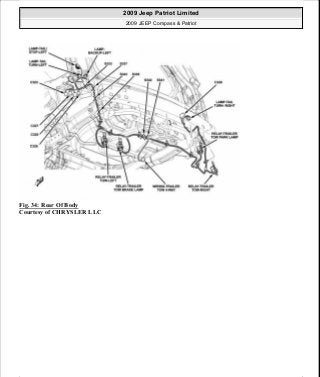

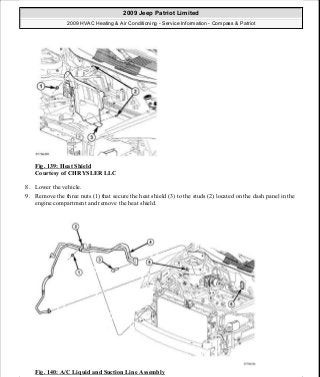

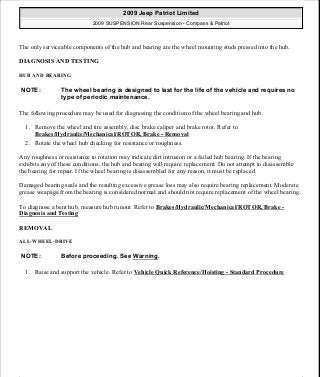

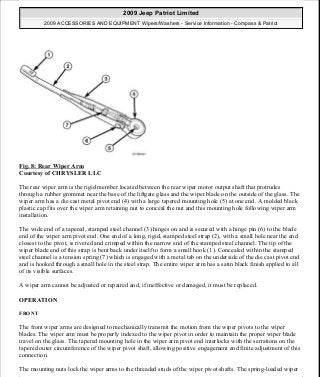

Fig. 197 Heater core components

22043_COMP_G0128

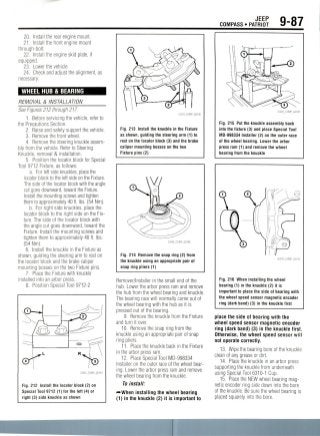

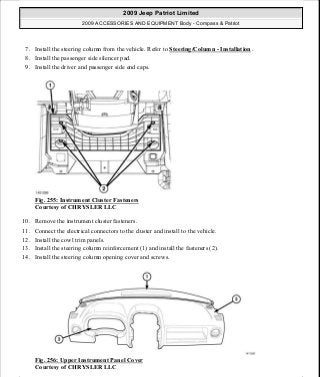

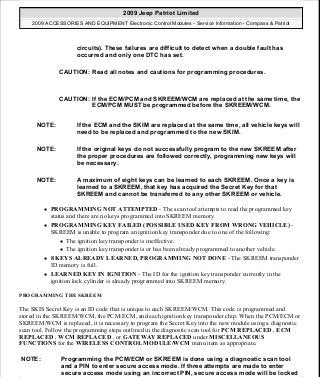

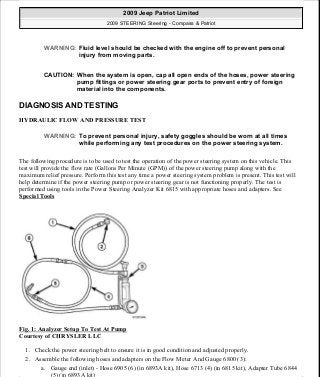

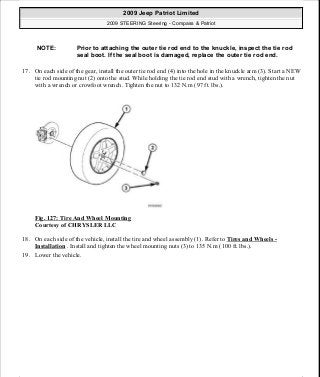

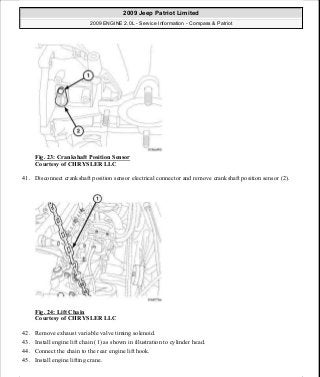

STEERING

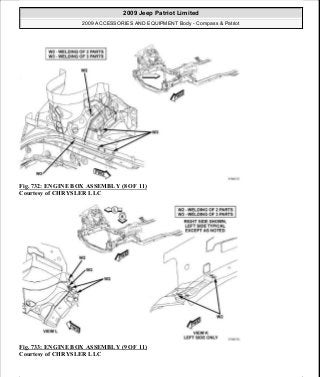

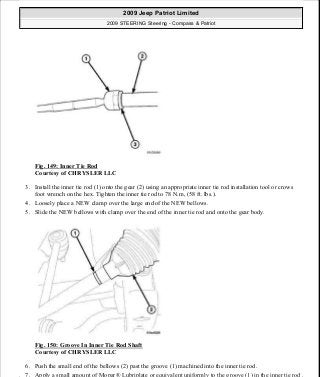

POWER RACK & PINION

STEERING GEAR

REMOVAL & INSTALLATION

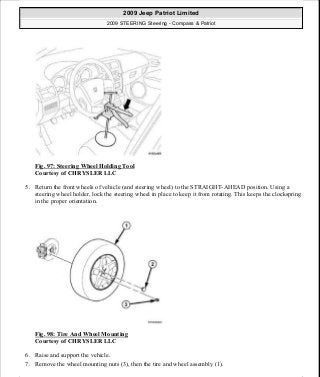

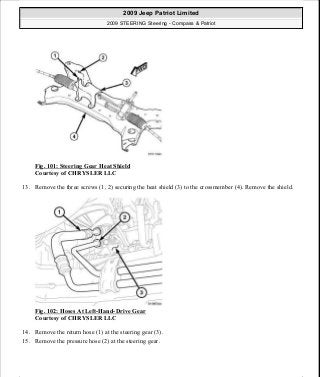

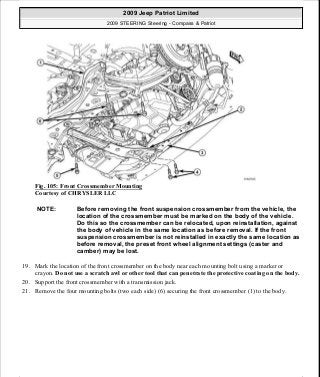

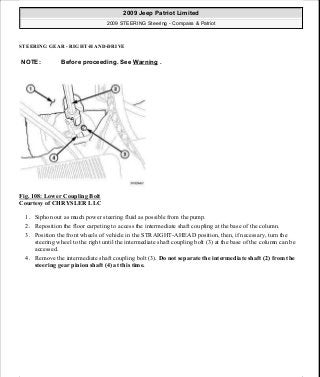

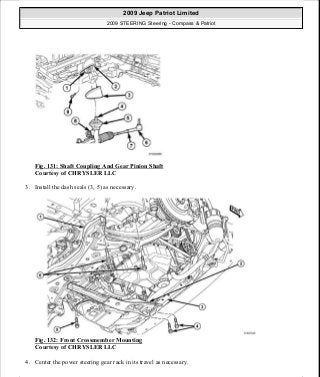

See Figures 198 through202.

1. Before servicing the vehicle, refer to

the Precautions Section.

2. Siphon as much power steering fluid

from the power steering pump as possible.

3. Reposition the floor carpeting to

access the intermediate shaft at the base of

the column.

4. Position the front wheels in the

straight-ahead position.

5. Turn

until the inti

the base of

accessed.

6. Rem

^Do nots

shaft from

shaft at thi

7. Retu

straight-ahe

8. Use

the wheel in

9. Raise

10. Rem

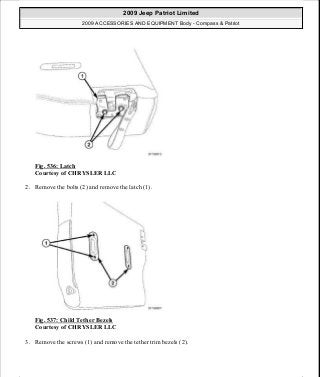

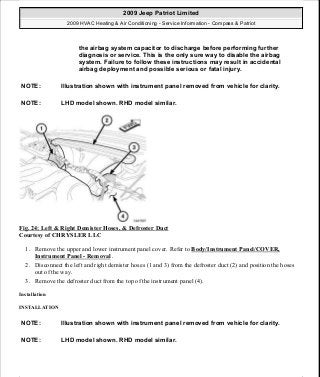

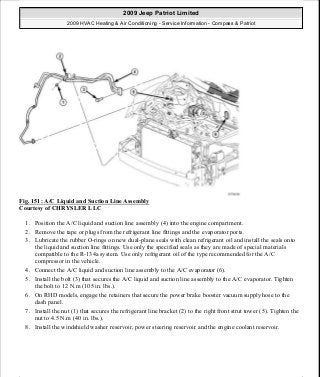

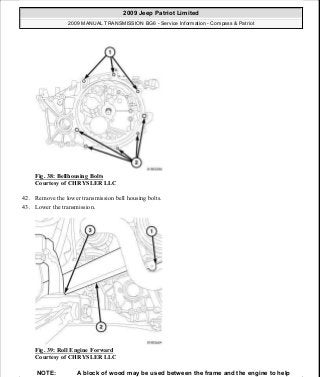

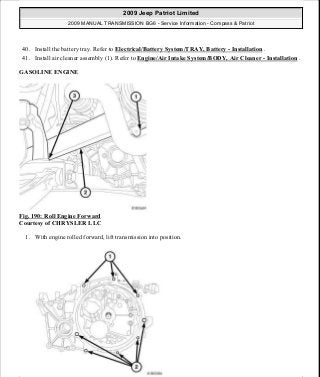

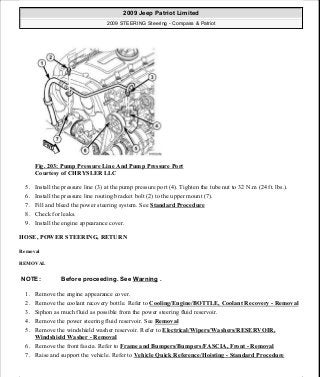

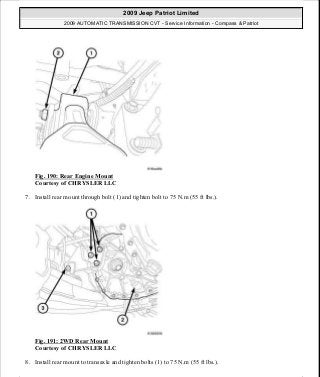

Fig. 198 Under the carpet (1), remove the

coupling bolt (3) that connects the inter-

mediate shaft (2) to the steering gear pin-

ion shaft (4)

Fig. 199 U

lock the wh

steering wheel to the right

mediate shaft coupling bolt at

steering column can be

the coupling bolt.

arate the intermediate

e steering gear pinion

ime.

the front wheels to the

position.

teering wheel holder to lock

place.

nd safely support the vehicle.

e the front wheels.

22043_COMP_G0130

a steering wheel holder to

j| into position

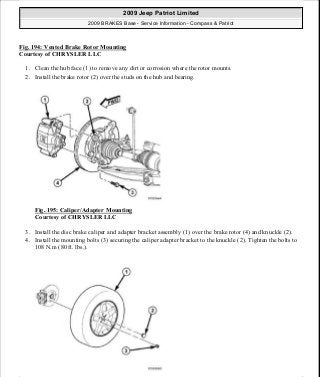

To install:

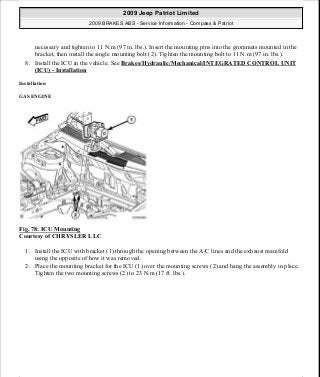

21. Carefully install the heater core

into the left side of the air distribution

housing.

22. Install the retaining bracket

that secures the heater core tubes.

Tighten the screw to 10 inch Ibs.

(1 Nm).

23. Install the flange that secures the

heater core tubes to the front of the HVAC

housing.

24. Tighten the screw that secures the

flange to the HVAC housing to 10 inchIbs.

(1 Nm).

25. Install the foam seal onto the

flange.

26. Installation is the reverse order of the

removal process.

27. If the heater core was replaced, the

cooling system must be flushed.

28. Charge the refrigerant system.

29. Refill the cooling system to the cor-

rect level.

30. Start the engine and check for

leaks.

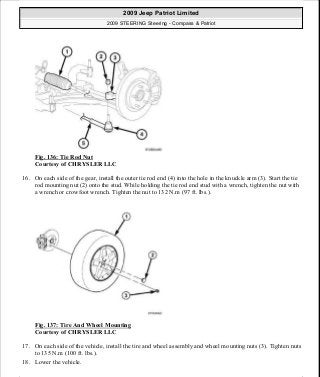

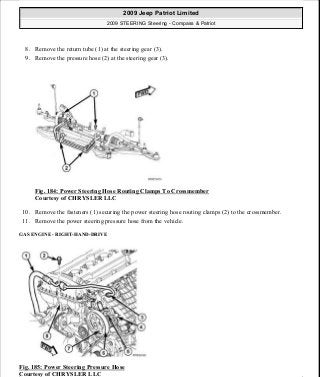

Fig. 200 Remove the bolts (1, 2) securing

the heat shield (3) to the crossmember

(4)—Steering gear removal

Fig. 201 Disconnect the pressure (2) and

return (1] hoses Uom Ihe steering gear

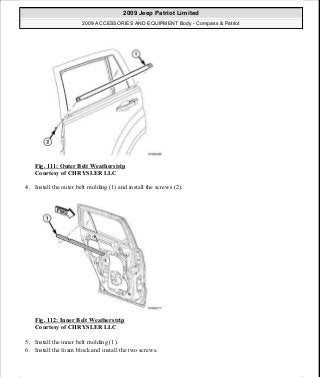

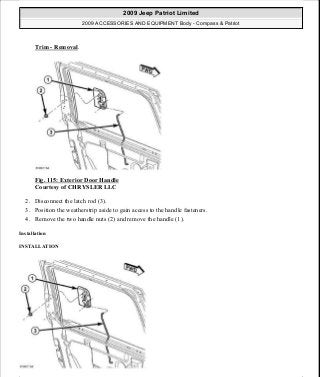

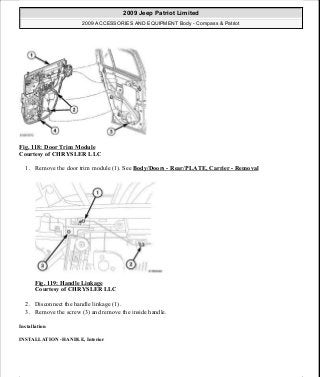

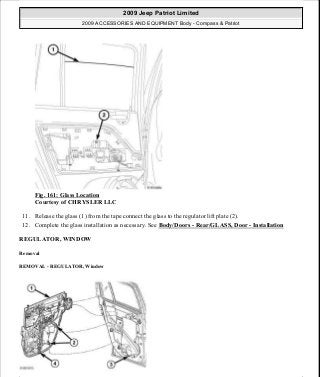

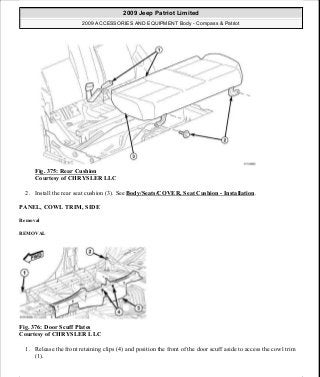

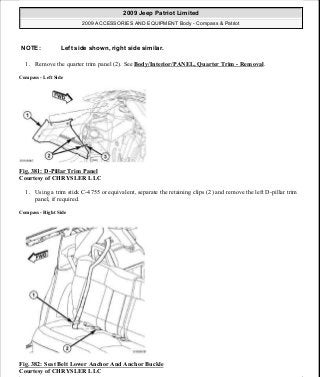

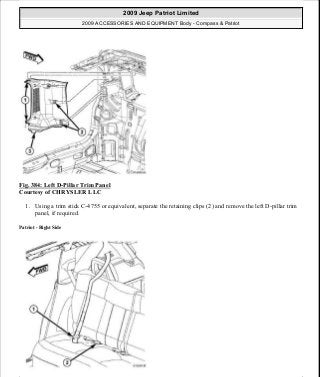

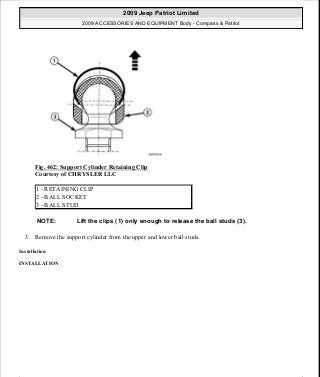

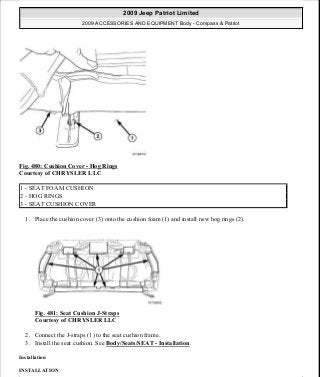

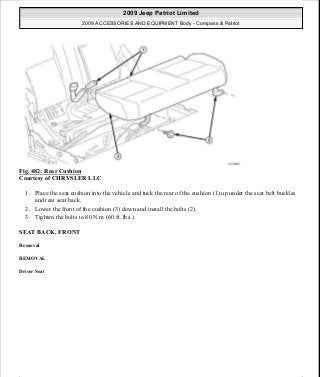

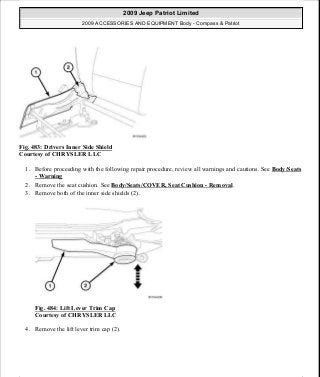

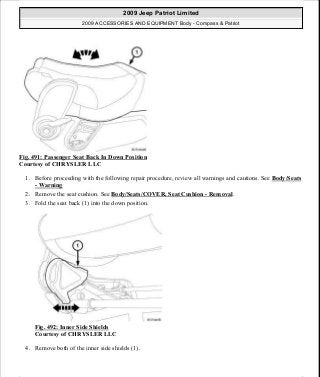

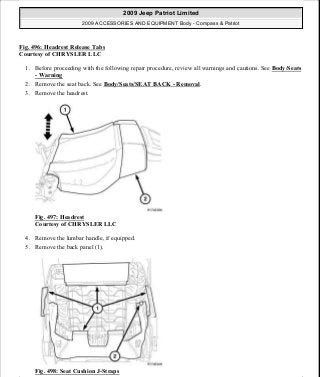

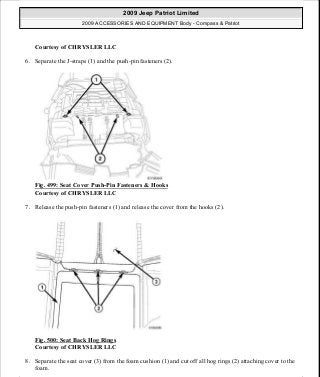

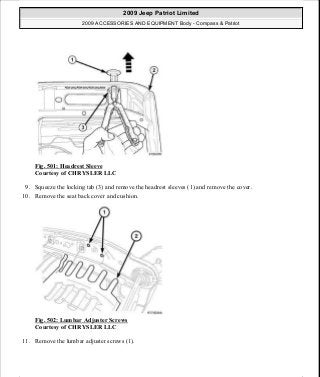

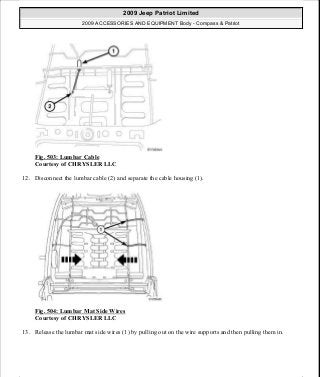

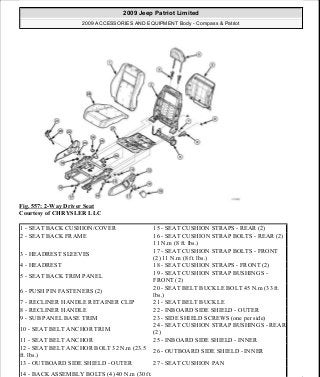

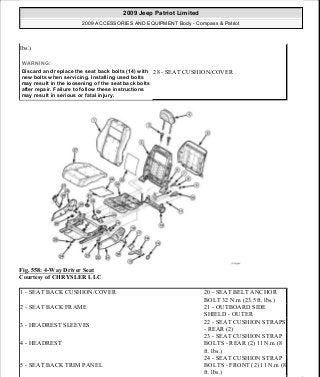

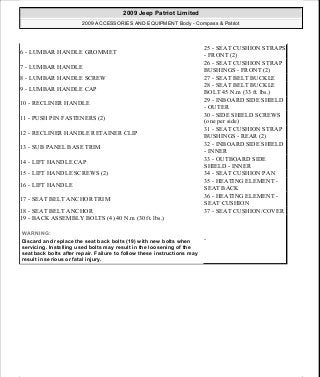

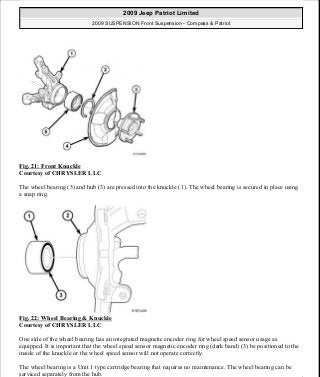

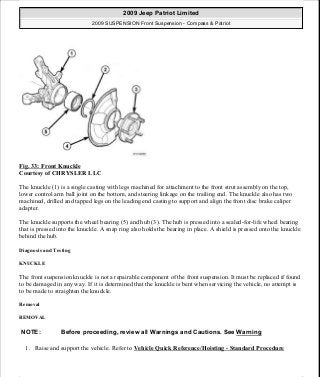

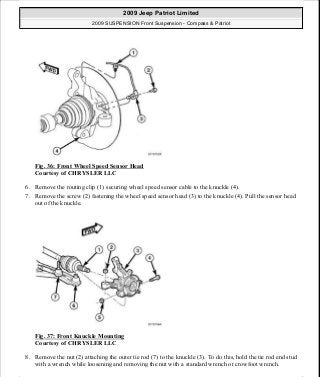

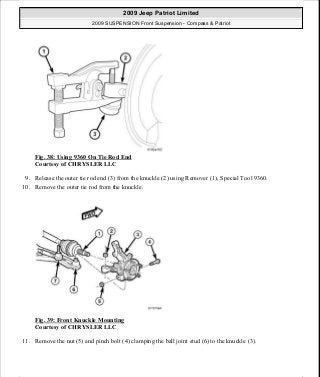

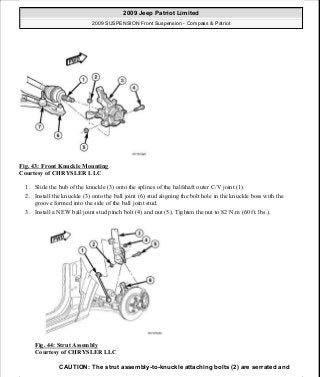

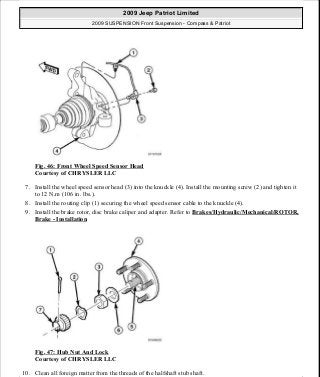

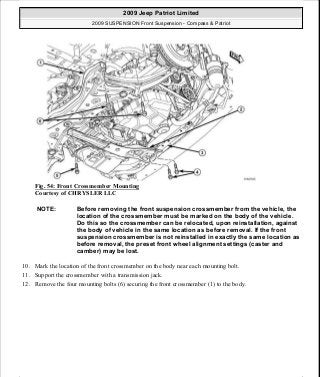

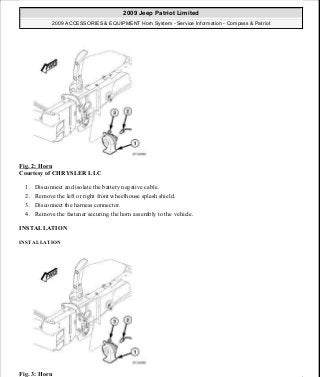

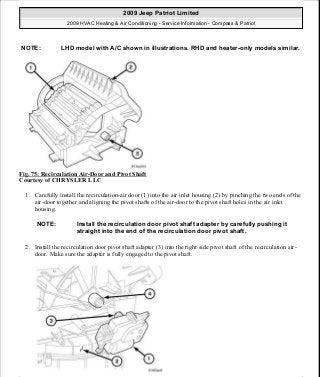

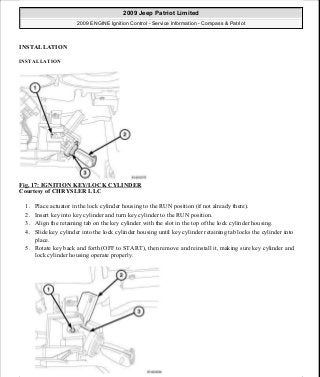

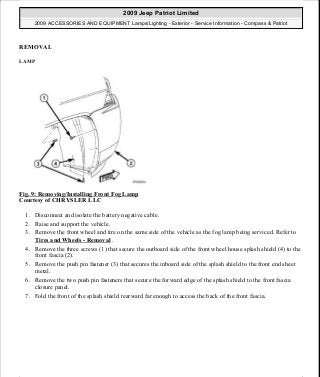

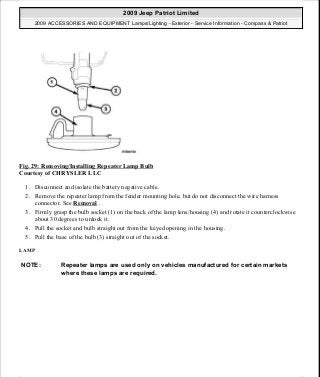

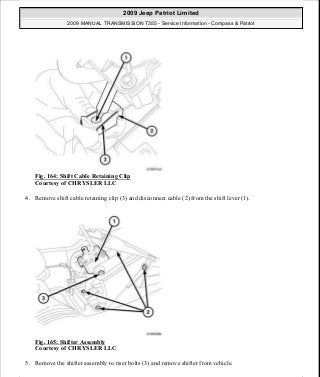

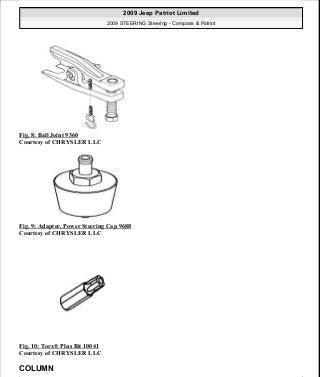

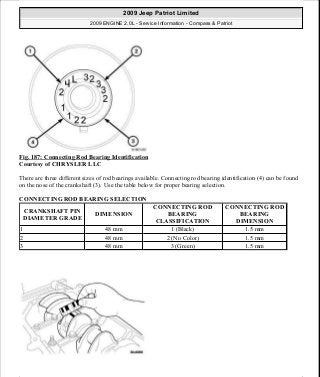

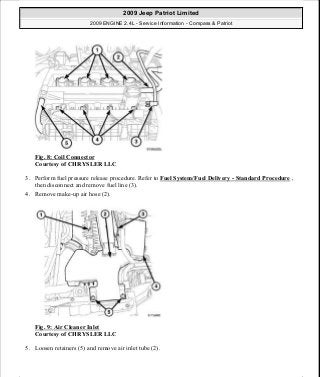

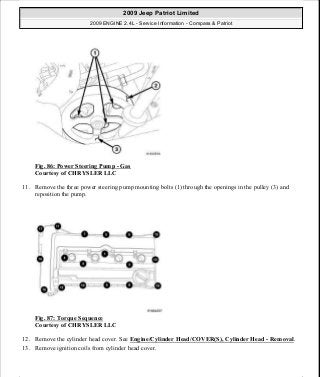

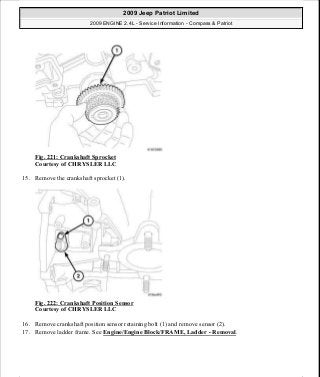

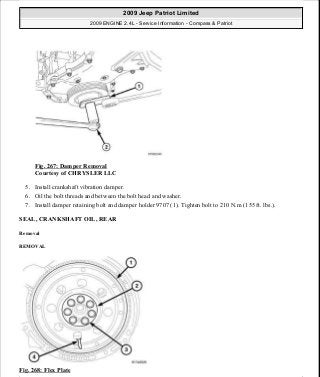

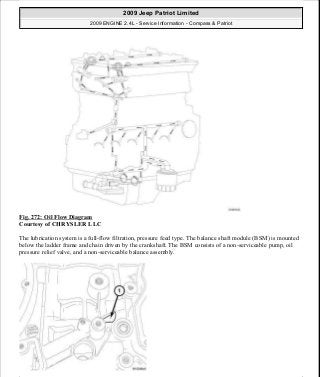

(3)—Steering gear removal](https://image.slidesharecdn.com/manualesreparacionesjeepcompass-patriotlimited2007-2009-150729164945-lva1-app6891/85/Manuales-de-reparaciones-jeep-compass-y-patriot-limited-2007-2009-869-320.jpg?cb=1438196953)