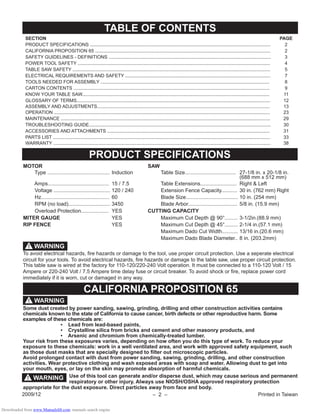

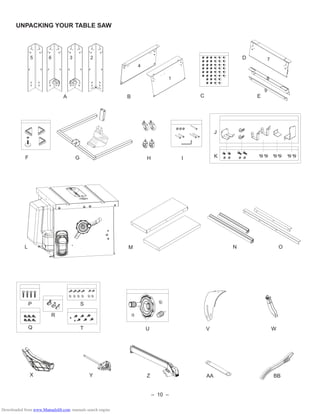

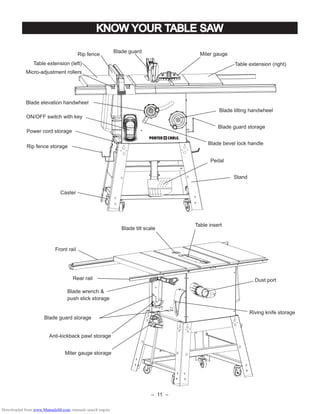

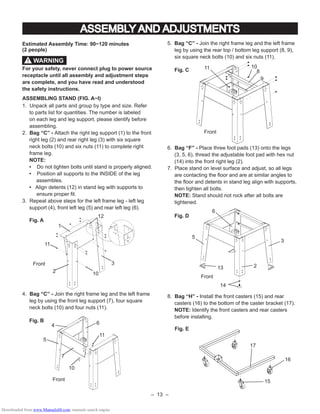

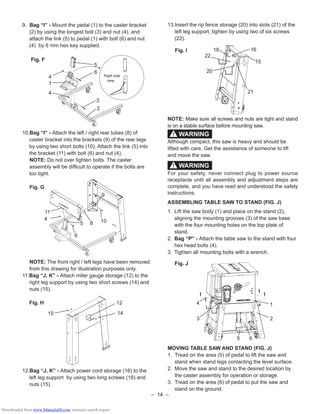

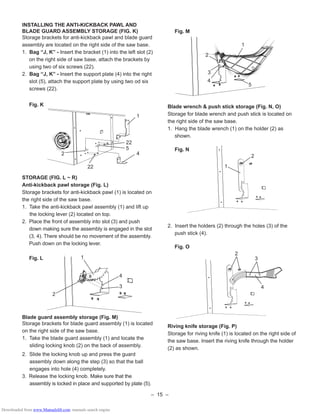

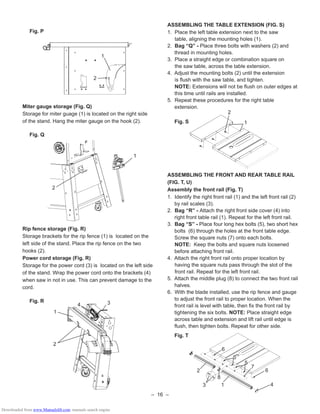

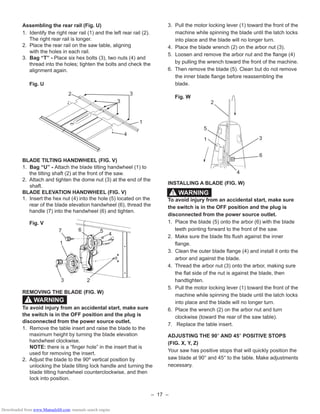

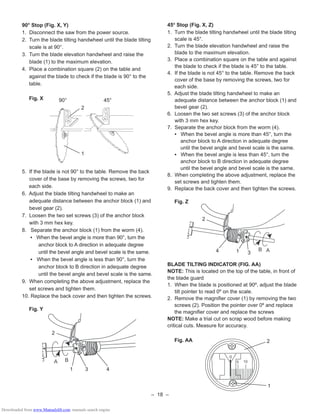

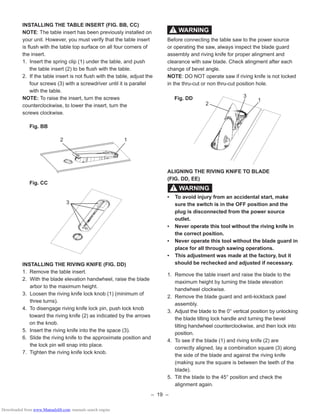

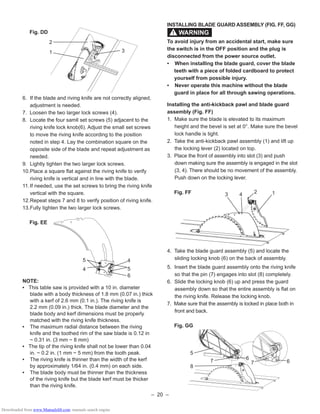

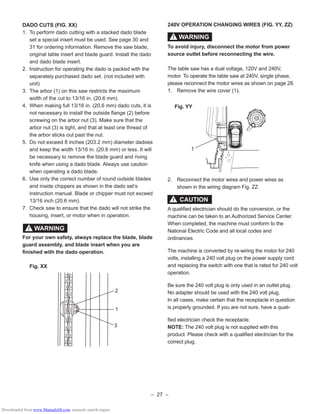

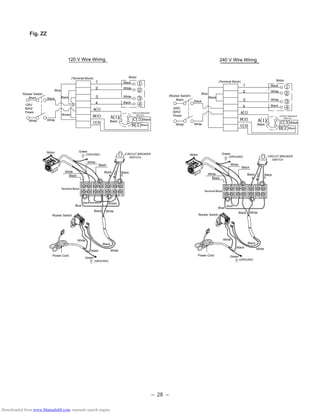

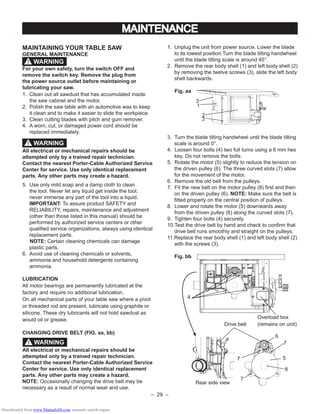

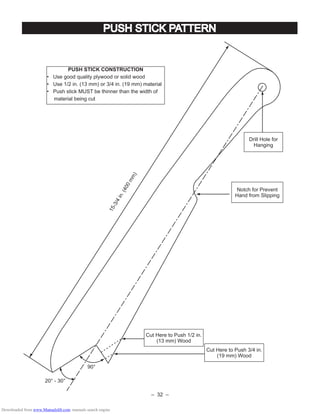

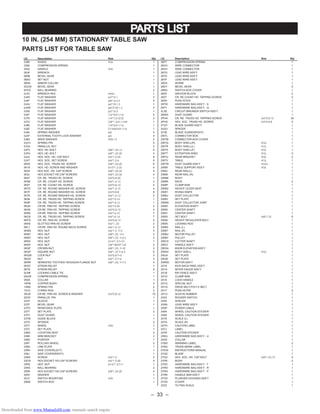

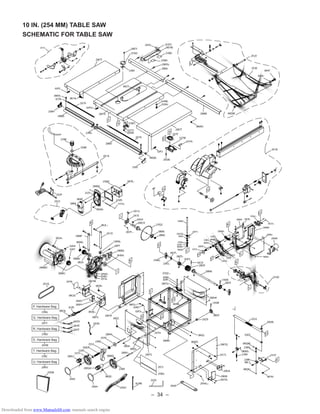

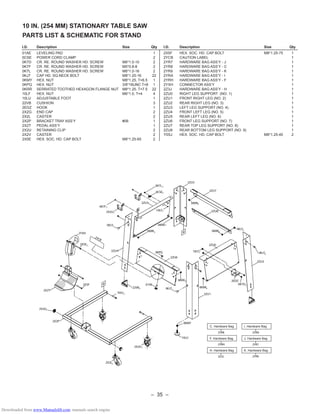

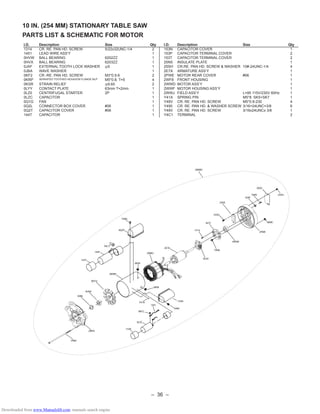

This document provides safety instructions and assembly instructions for a 10-inch stationary table saw. It begins with safety warnings and guidelines for power tool and table saw use. It then provides specifications for the saw such as its dimensions, voltage, blade size, and cutting capacities. The document continues with sections on assembly and adjustments, operation, maintenance, troubleshooting, accessories, parts lists, and warranty information for the saw.