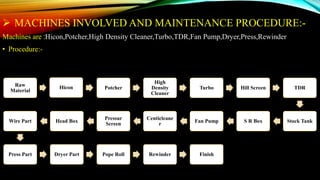

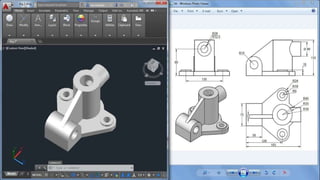

The document summarizes an industrial training completed at Chadha Papers Limited, which employs 1200 people and has an annual turnover of 2764778965 rupees. It produces kraft paper, writing paper, and newspaperboards. The trainee learned about the paper recycling process, which involves mixing used paper with water and chemicals to break it down into pulp. Key machines involved are the Hicon, Potcher, and dryer. Safety procedures included following approved methods, receiving training, maintaining cleanliness and attention to hazards. The trainee also completed software training in AutoCAD and SolidWorks, designing components like a piston and connecting rod. A safety valve was explained as a fail-safe valve that automatically releases pressure or temperature exceeds safe