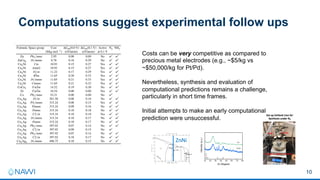

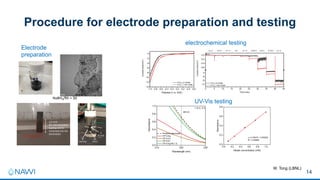

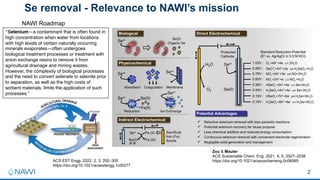

This document summarizes a presentation on developing an electrochemical system for selenium removal from water. The project aims to apply machine learning and automated synthesis techniques to accelerate materials development timelines. Initial calculations have reproduced experimental trends for nitrate reduction and screened candidate materials from databases. Procedures have also been established for electrode preparation, testing, and using robots to synthesize predicted candidates. While still early, progress has been made on computational screening, mitigating competing reactions, and testing baseline cathode materials for selenium removal performance and energy efficiency. The remainder of the first project year will focus on refining methods before demonstrating a commercially viable selenium removal system in years two and three.

![4

Project objectives

[1] DOI: 10.1021acscatal.9b02179

Autonomous

Precise

Resilient

Intensified

Modular

Electrified

Control voltage

Targets a single or a few solutes

Easily adjusted for variable water quality

No need for regeneration;

no brine to dispose

No high-pressure equipment;

no moving parts

Compatible with distributed DC power

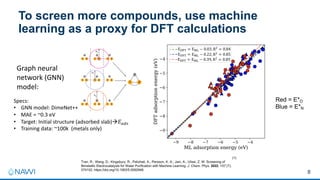

• Background: New

advancements in machine

learning, theory, and

automated labs can accelerate

materials development

timelines

Can we apply these

techniques to water treatment?

• Our 3-year outcome:

demonstrate commercially

viable system for Se removal

Singh & Goldsmith ACS Catal. 2020, 10.

Werth et al. ACS ES&T Engg. 2021, 1](https://image.slidesharecdn.com/nawipresentation-221128122839-f6c5eeb7/85/Machine-Learning-for-Catalyst-Design-4-320.jpg)

![6

Overview of computational approach

calculating the

adsorption and

activation energies

for monometallic systems

versus various

adsorbates

generating

linear scaling

relationships

estimating the

TOF and

selectivity from

microkinetic

modelling

plotting the TOF

volcano plot

from the

previous results

evaluating and

screening TOF

for calculated

bimetallic

materials

calculating

adsorption

energies for

bimetallic

materials

[1] DOI: 10.1021/acscatal.9b02179

[1]

[1] BM systems

metal oxides

more…](https://image.slidesharecdn.com/nawipresentation-221128122839-f6c5eeb7/85/Machine-Learning-for-Catalyst-Design-6-320.jpg)