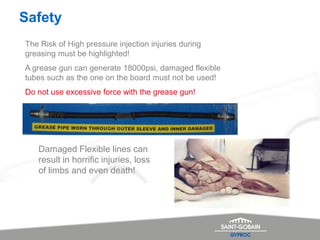

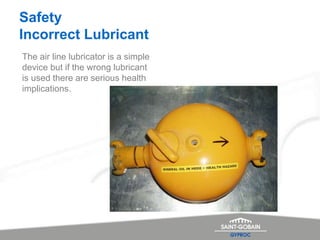

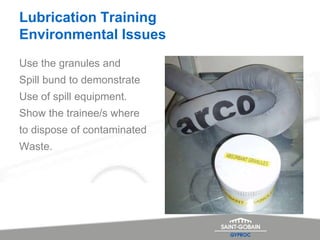

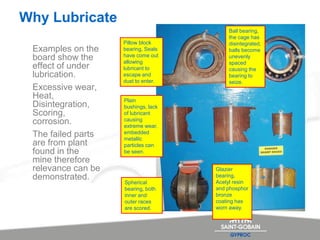

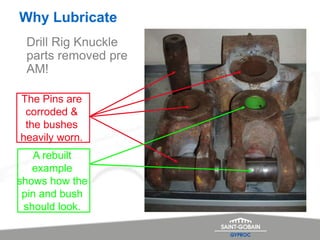

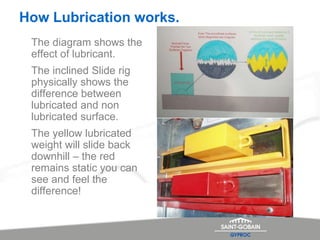

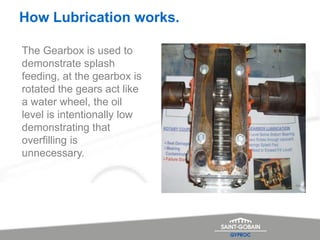

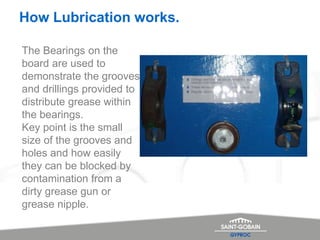

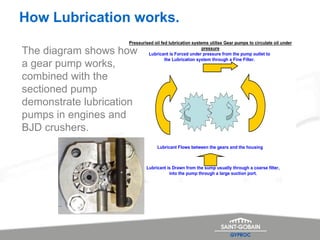

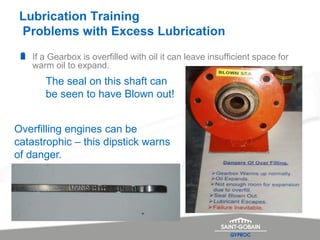

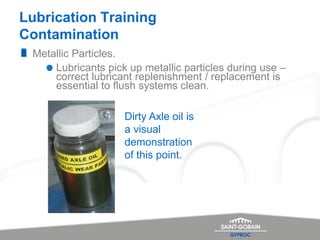

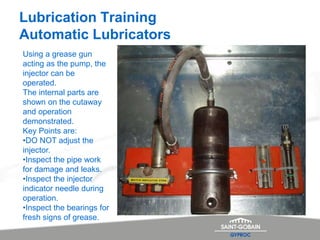

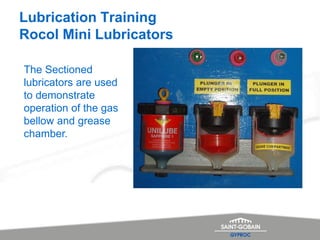

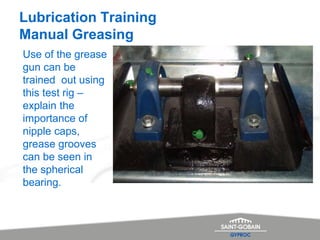

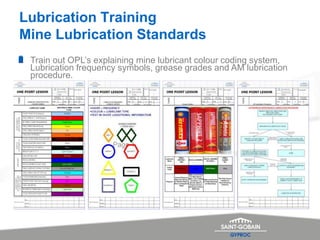

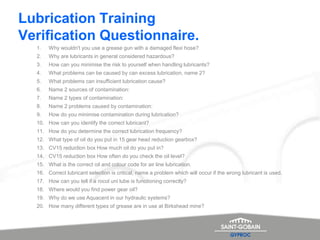

The document provides training information on lubrication safety, environmental considerations, why lubrication is important, how lubrication works, problems with incorrect or excess lubrication, automatic and manual greasing techniques, and mine lubrication standards. It discusses hazards like high pressure injection injuries, dermatitis, and fires from improper lubricant use. Trainees learn about proper personal protective equipment, lubricant disposal, and contamination issues. Visual aids are used to demonstrate lubrication principles and failures resulting from under-lubrication.