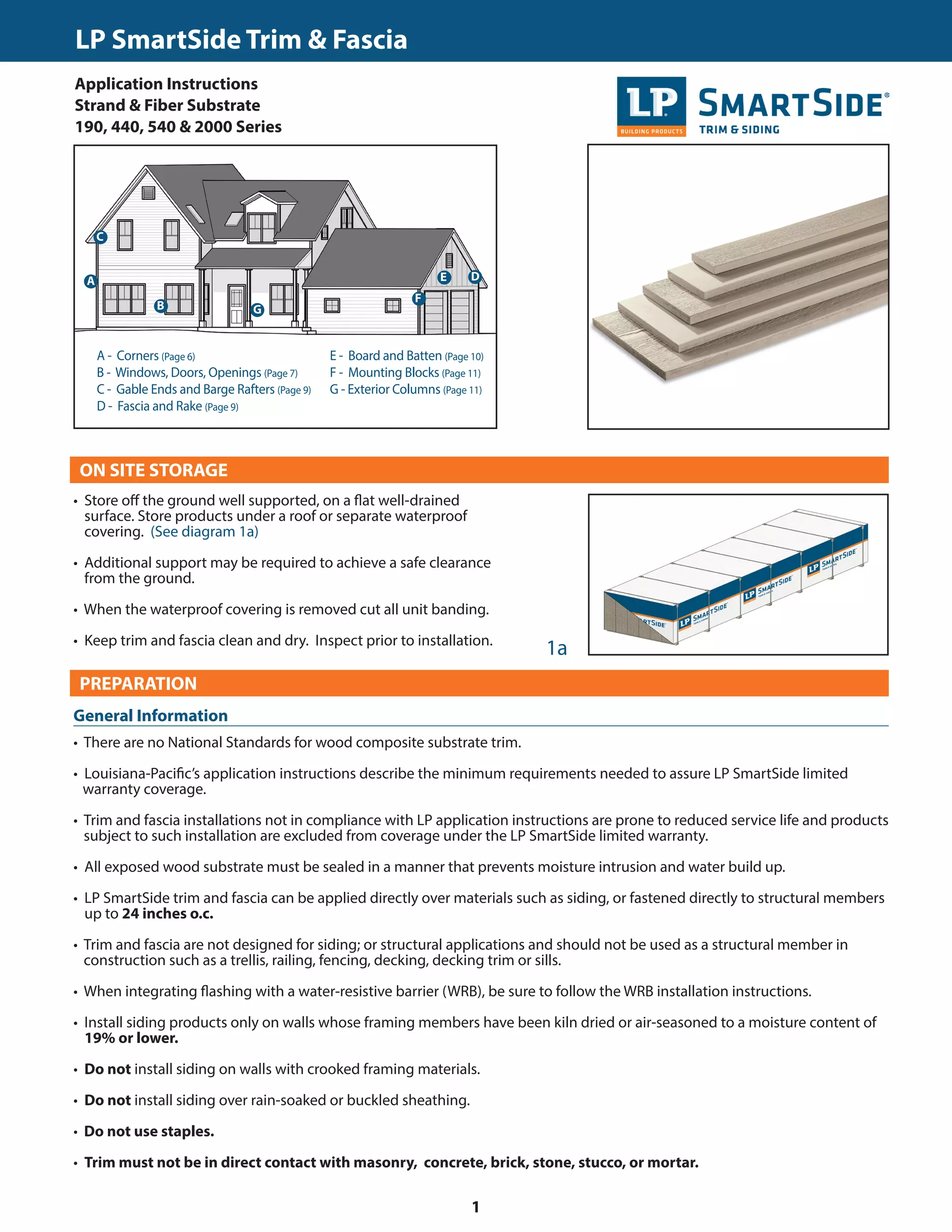

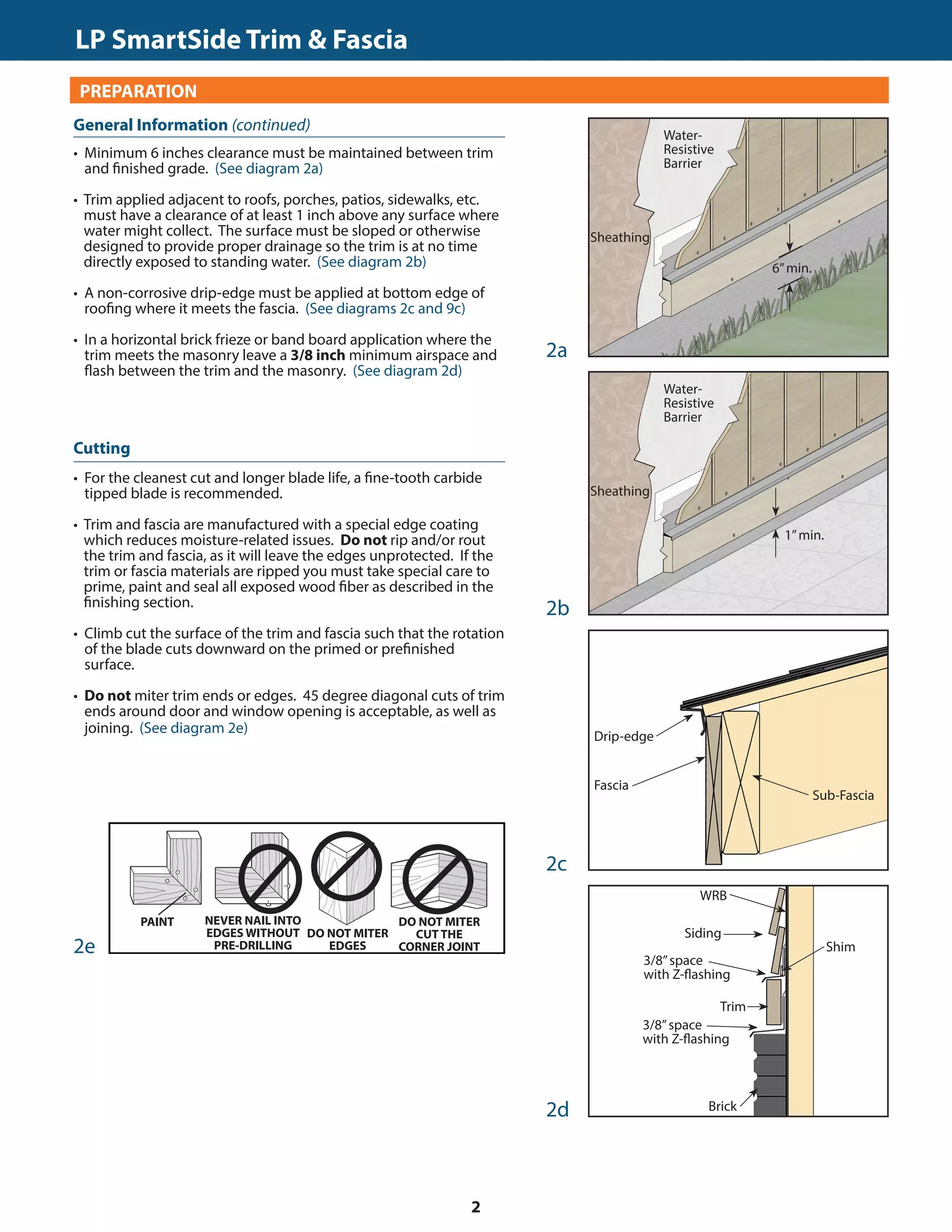

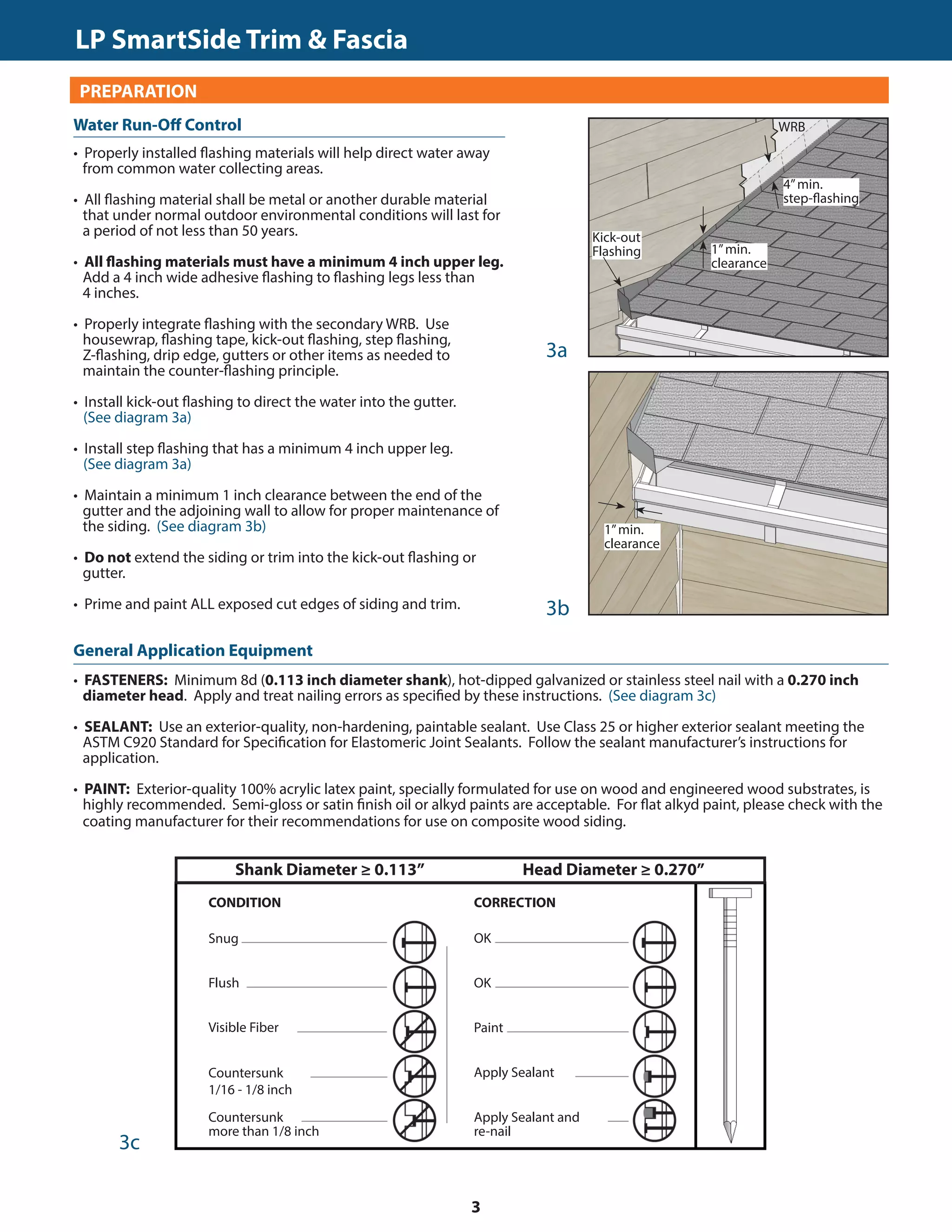

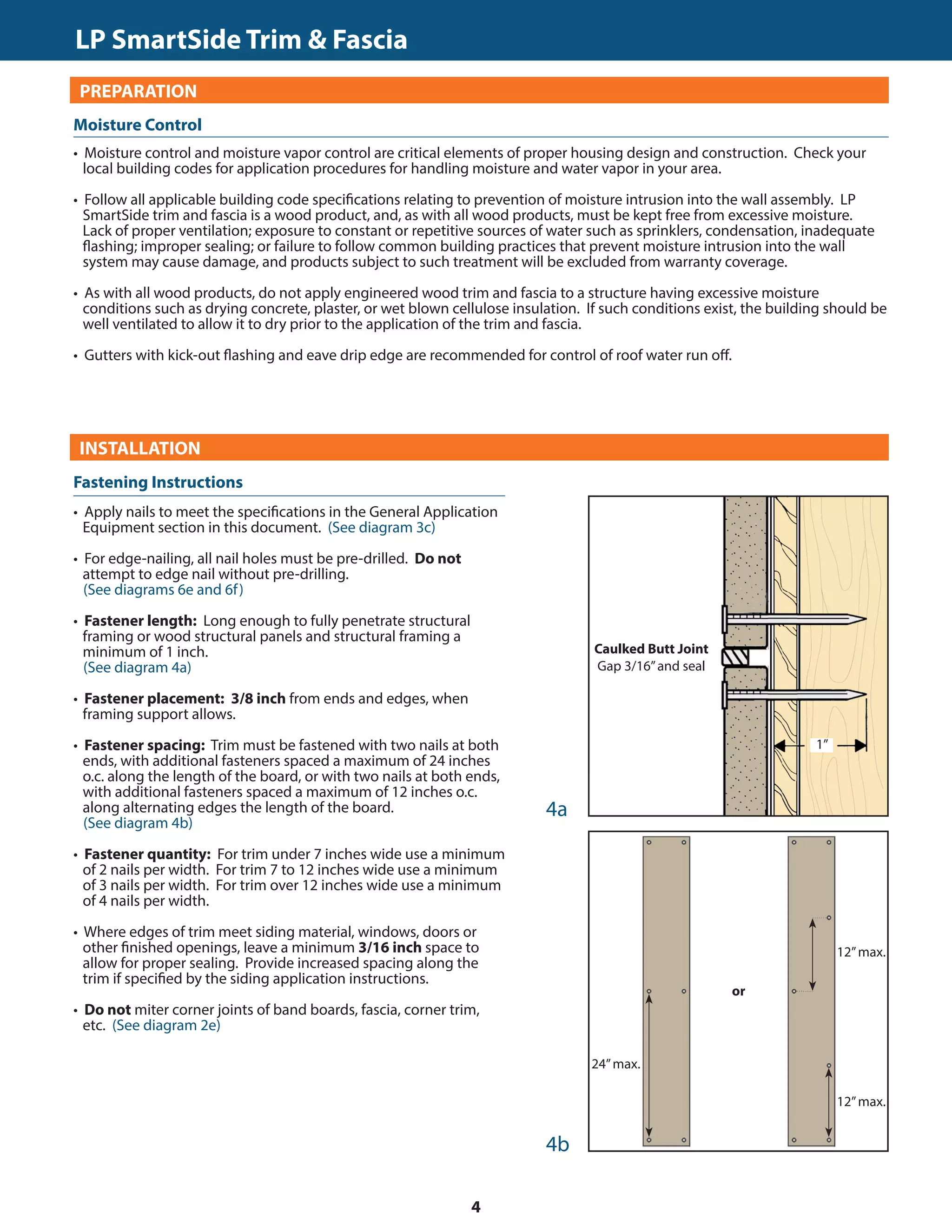

LP SmartSide Trim & Fascia application instructions provide guidelines for proper installation and finishing to ensure warranty coverage. Key points include: storing trim off the ground and under cover; maintaining clearances from grade and other surfaces; using flashing at intersections; fastening trim securely with the correct nails at proper spacing; leaving gaps at joints to seal; and following all instructions for cutting, fitting and finishing exposed edges. Proper installation is necessary to prevent moisture damage and ensure the trim performs as intended.