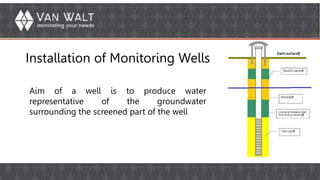

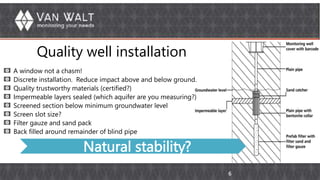

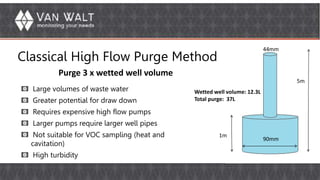

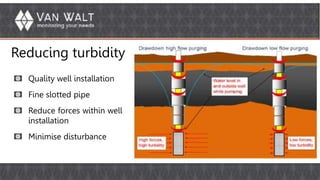

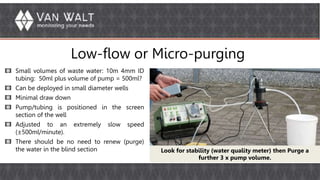

This document discusses groundwater sampling techniques. It begins by emphasizing the importance of obtaining a representative groundwater sample. It then discusses installing monitoring wells with discrete screens below the water table to access representative groundwater. The document reviews three purging methods - high flow, low flow, and no flow - and their advantages/disadvantages. Specifically, it notes low flow and no purge methods minimize waste water and drawdown while still obtaining representative samples, especially for volatile organic compounds. The overall goal is to develop more accurate, repeatable, and cost-effective sampling techniques.