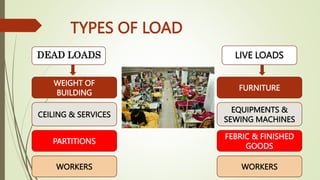

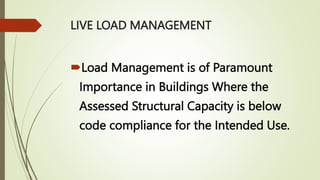

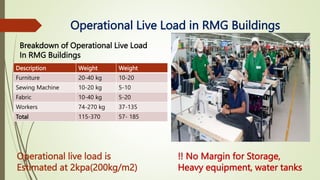

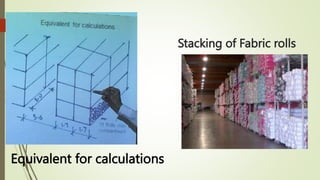

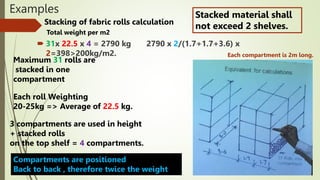

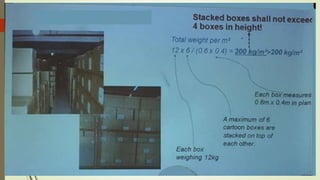

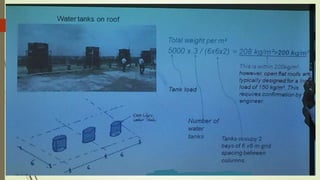

The document discusses live load management in buildings such as ready-made garment factories. It defines different types of live loads and provides examples of typical live loads from equipment, materials, and workers. It emphasizes that live load management is important when the structural capacity is below code compliance. Exceeding the structural capacity can cause damage or failure. It also provides guidance on monitoring live loads, relocating excess loads, and record keeping to help manage live loads.