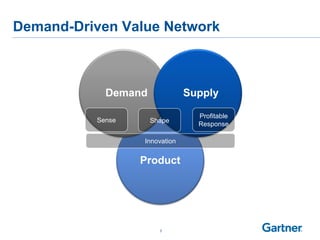

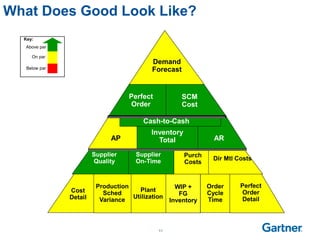

This presentation by Gartner discusses insights from their Supply Chain Top 25 research on leading supply chain organizations. It defines supply chain leadership and identifies distinguishing characteristics of leaders. Leaders focus on having demand-driven value networks with embedded innovation, extended supply chains, vision and execution excellence. They manage performance using a hierarchy of metrics to achieve predictable, flexible, and profitable supply chains that drive sustainable growth and customer satisfaction.